Professional Documents

Culture Documents

Fine Grout Mix Proportion Per 1 Bag of Portland Cement

Fine Grout Mix Proportion Per 1 Bag of Portland Cement

Uploaded by

Anwar Mohiuddin0 ratings0% found this document useful (0 votes)

27 views4 pagesFine Grout Mix Proportion

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFine Grout Mix Proportion

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

27 views4 pagesFine Grout Mix Proportion Per 1 Bag of Portland Cement

Fine Grout Mix Proportion Per 1 Bag of Portland Cement

Uploaded by

Anwar MohiuddinFine Grout Mix Proportion

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

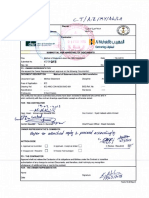

Tomer

28s 01100- im apa

iar penton contre wats

Prof. No.

[Contractor

NGA) Muhaidib Wma

rc

Contracting GUglénL)

‘SUBMITTAL FOR APPROVAL OF DOCUMENTS:

rite FINE GROUT MIX PROPORTION PER 1 BAG OF PORTLAND CEMENT

Date 22-01-2018

[Submittal No. Icc-Ds- 21 &

Rew. No ° No of

[To : OWNER REPRESENTATIVE

We request the Owner Representatve's approval onthe following Documents)

[DOCUMENT DESCRIPTION

Document Type Mic Design Decpine emt

Jcea of Appication For Masonry Block Works

brawing Ret. Al Block Wal Drawings 800 Ret. No

spectation ‘astm 42000 Standards asTc.a76

enciosues 1 sft copy & 3 Hard Copy

ve cory tat ta above submited documonte have Doon Tevawed W Seal and ae Sovea one

Jock conformity withthe contact drawings specication except as otherwise sited

ror : THE ConrRACTOR

BEN DOlS

HM MIA

bept Head: Mohammed Mowafak Ak Doc Control: Syed Habeeb uddin Armed

Jon/ac Manager es Project Director Majd Hamdalla

Final approswal will be after svomttriak Micof Fine great ani

JAcTTION cone

JA Approved as Submited — [7] 'B Approved - Except as Noted CRevise-Resubmit [—]

> osererved-Resutmt C] Receipt acknomedged Oo

[To : THE CONTRACTOR

JApproval shal not relieve the Contractor of its obligations and lites under the Contractor constitue

Jauthorization of any change to contract Documents, and therefore, shall not imply any recognition

[whatsoever of addtional ime or cost tothe contract

FOR: THE OWNER REPRESENTATIVE

ame =

Form 159 Ret

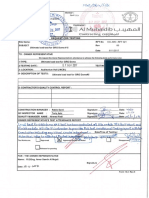

dara handasah INTERNATIONAL CONVENTION CENTER

Peers CONTRACT NO. $12085 - 01000

DESIGN SUBMITTAL

FINE GROUT MIX PROPORTION PER 1 BAG OF PORTLAND CEMENT

Cement Sand Ratio 1:3

Compressive Strength: 14 N/MM? Project Specification: 042000

Slump: 203 -279 mm (W/C=0.70) (astm c-476)

‘Absolute

Specific

ls.no. | TEM Material /Type | Compliance / Standard Dosage ey | Volume

0.125m?

oz | Cement orc ASTM C-150 ae 3.as | 0.0159

(50 kgs.)

Natural /

8 sand ena ASTM C-404 150 kegs. 2ss | 0.0581

o4 | Water Potable Water ASTM C-1506 35 Ltrs, 1.00 | 0.035

04 Lime Hydrated

05 | Admixtures | Plasticieer

06 | AirVoids % 13.00

‘Note : 1) Sand is in Saturated Surface Dry Condition (SSD) 2) Water dosage will be

adjusted according to the moisture content of sand and as per workability site requirement.

3) Mix proportion for cement and sand can be adjusted based on the allowable

proportion mentioned on ASTM C-476 as prescribed on Project Specs. No. 042000.

4) Lime and admixtures will be used as per site requirement and approval by Engineer

as per Project Specs.

TRIAL MIX TO CONDUCT FOR VERIFICATION OF WORKABILITY AND COMPRESSIVE STRENGTH

INTERNATIONAL CONVENTION CENTER ~ AL MADINAH

For masonry below grade or in contact with earth, use Type S,

For reinforced masonry, use Type S.

For exterior, above-grade, load-bearing and non-load-bearing walls and parapet walls; for

imerior load-bearing walls; for interior non-load-bearing partitions; and for other

applications where another type is not indicated, use Type N.

4. For interior non-load-bearing partitions, Type O may be used instead of Type N.

5. Compressive strength to be not less than $ +1 N/ mm2

D. Grout for Unit Masonry: Comply with ASTM C476,

21

|. Use grout of type indicated or, if not otherwise indicated, of type (fine or coarse) that will

comply with Table 1.15.1 in ACI530.1/ASCE 6/TMS 602 for dimensions of grout spaces

and pour height.

a ton grout in accordance with ASTM C 476, Table 1 or paragraph 4.2.2 for specified

compressive strength indicated, but not less than 14 MPa.

3. Provide lump of "203 to 279 mm as measured according to

_ASTMC 14

SOURCE QUALITY CONTROL,

Engage a qualified independent testing agency to perform source quality-control testing indicated

Clay Masonry Unit Test: For cach type of unit furnished, per ASTM C 67,

Concrete Masonry Unit Test: For each type of unit furnished, per ASTM C 140.

PART 3- EXECUTION

3 EXAMINATION

‘A. Examine conditions, with Installer present, for compliance with requirements for installation

tolerances and other conditions affecting performance of the Work.

1. For the record, prepare written report, endorsed by Installer, listing conditions detrimental

to performance of work.

2. Verify that foundations are within tolerances specified.

3. Verify that reinforcing dowels are properly placed.

B. Before installation, examine rough-in and built-in construetion for piping systems to verify actual

locations of piping connections.

C. Proceed with installation only after unsatisfactory conditions have been corrected.

32 INSTALLATION, GENERAL

|A, Thickness: Build cavity and composite walls and other masonry construction to full thickness

shown. Build single-wythe walls to actual widths of masonry units, using units of widths

indicated.

B. Build chases and recesses to accommodate items specified in this and other Sections.

CC. —_Leave openings for equipment to be installed before completing masonry. After instal

‘equipment, complete masonry to match the construction immediately adjacent to opening,

UNIT MASONRY. (042000 Page 9 of 14

S12085.0100D-TD-SPC-ISA-AROL-REV 0

{© Copyright Protected

ib caze

TABLE 2 Grout Proportions by Volume

Parts by Vol Pate

ume of Por ats

ae momen: Yolume Aggregate, Measured in « Damp, Loose Condition

ne ra ese Fine Coarse

Blast-Furnace

Bint Furnace ime Paty

“Pine grout et 010 Me Ag pee ee

Coarse grout ' 010 Me 2 t0 31 1 to 2 times the sum of

of the volumes of the volumes of the

the cementitious ma- ‘cementitious mate-

terials rials

TABLE 3. Physical Requirements of Mortar

Compressive Strength

“Average of three 2in,(50.8-mm)

ceubes, min, psi (MPa)

7 days 4600 (11.03)

28 days 2500 (17.24)

Water Retention:

Flow after suction, min, percent of 0

original flow

Ait Content:

‘Volume, max, percent iB

"IF the mortar fails to mest the 7-day comprestive

strength requirement, but meots the 28-day compressive

strength requirement, it shall be acceptable.

‘By publication of this standard no position ts taken with respect to the validity of any patent rights in connection there

with, and the American Society Jor Testing and Material does not undertake to Insure anyone utilizing the standard

against labiliy for infringement of any Letiers Patent nor assume any such liability.

272

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Inspection Test Plan (ITP) Tiling Works Floor & WallDocument2 pagesInspection Test Plan (ITP) Tiling Works Floor & WallAnwar Mohiuddin50% (6)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Risk AssesmentDocument6 pagesRisk AssesmentAnwar Mohiuddin0% (1)

- Inspection Test Plan (ITP) Painting WorksDocument3 pagesInspection Test Plan (ITP) Painting WorksAnwar Mohiuddin33% (3)

- Method Statement For Cmu Block WorkDocument8 pagesMethod Statement For Cmu Block WorkAnwar MohiuddinNo ratings yet

- Method Statement For Antibacterial PaintDocument7 pagesMethod Statement For Antibacterial PaintAnwar MohiuddinNo ratings yet

- Eye TestDocument1 pageEye TestAnwar MohiuddinNo ratings yet

- STAIRCASEDocument10 pagesSTAIRCASEAnwar MohiuddinNo ratings yet

- Static Pressure Cal. (KG-MECH)Document3 pagesStatic Pressure Cal. (KG-MECH)Anwar MohiuddinNo ratings yet

- Investment Contract of AgreementDocument1 pageInvestment Contract of AgreementAnwar MohiuddinNo ratings yet

- Cswip Application 10 YearsDocument9 pagesCswip Application 10 YearsAnwar MohiuddinNo ratings yet

- Method Statement For Bolting SystemDocument6 pagesMethod Statement For Bolting SystemAnwar Mohiuddin100% (1)

- Under Ground Utilities HazardsDocument1 pageUnder Ground Utilities HazardsAnwar MohiuddinNo ratings yet

- Welding & Cutting HazardsDocument1 pageWelding & Cutting HazardsAnwar MohiuddinNo ratings yet

- Hos-Pmt-Pro-001-01 Document and Communication Codification ProcedureDocument7 pagesHos-Pmt-Pro-001-01 Document and Communication Codification ProcedureAnwar MohiuddinNo ratings yet

- Hos-Sqm-Mos-009-01 Method Statement For Earthwork - CRSDocument1 pageHos-Sqm-Mos-009-01 Method Statement For Earthwork - CRSAnwar MohiuddinNo ratings yet

- Method of Statement About The BMU InstallationDocument12 pagesMethod of Statement About The BMU InstallationAnwar Mohiuddin50% (2)

- Non-Conformance Report (NCR) : 100 Bed Isolation Hospital For COVID-19Document1 pageNon-Conformance Report (NCR) : 100 Bed Isolation Hospital For COVID-19Anwar MohiuddinNo ratings yet

- Ultimate Load Test For GRG DomeDocument11 pagesUltimate Load Test For GRG DomeAnwar MohiuddinNo ratings yet

- Air Handling 02Document20 pagesAir Handling 02Anwar MohiuddinNo ratings yet

- Inspection Test Plan (ITP) Stone FlooringDocument2 pagesInspection Test Plan (ITP) Stone FlooringAnwar MohiuddinNo ratings yet

- Inspection Test Plan (ITP) - Waterproofing For Wet Areas Including Roof DeckDocument2 pagesInspection Test Plan (ITP) - Waterproofing For Wet Areas Including Roof DeckAnwar Mohiuddin0% (1)

- Elevators, Escalators & Travelators Installation, Method of StatementDocument30 pagesElevators, Escalators & Travelators Installation, Method of StatementAnwar MohiuddinNo ratings yet