Professional Documents

Culture Documents

Comparison: Lift N Weld Conventional Method Plain Vanilla Jacking

Comparison: Lift N Weld Conventional Method Plain Vanilla Jacking

Uploaded by

kamlesh0106Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparison: Lift N Weld Conventional Method Plain Vanilla Jacking

Comparison: Lift N Weld Conventional Method Plain Vanilla Jacking

Uploaded by

kamlesh0106Copyright:

Available Formats

Comparison

Conventional Method Plain Vanilla Jacking Lift n Weld

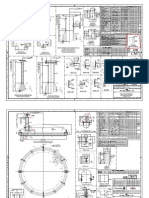

Comparision Between Conventional Method, Plain Vanilla Jacking Method and Bygging Lift n Weld (Jacking + Automatic Welding) both external & internal

Conventional Method Conventional Method Plain Vanilla Jacking Method Jacking Method With External

Parameter Lift N Weld

With Manual Welding With Automatic Welding With Manual Welding Welds Using Automatic Machine

Method of erection Bottom To Top Top down method and using automatic

Top down method

girth welding machine for external and

(or top to bottom)

Crainage cost (cost of crane 30 to 40 ton capacity with 30 mtr boom: us $24,500 per month internal horizontal welds

rental including fuel) 70 ton capacity with 40 mtr boom: us $50,000 per month A small 10 ton capacity crane with 8 mtrs boom length

Scaffolding Required for providing access to manpower for alignment of plates, required for handling of shell plates: us $2,000 per month

Welding, painting of underside of roof not required above 4 mtr level

Safety of workmen High risk of accidents from workmen falling from heights

Fixed roof construction Roof to be erected at height zero risk of workmen falling from heights

Safety of tank shell Since the tank is without a wind girder until top-most shell is erected, roof erected at ground level, leading to saving in erection time of roof by 30%

during erection Tank shell is subject to stresses due to high winds during erection phase Top most shell ring and wind girder are erected at first, and therefore tank shell is

Evacuation of personnel In case of an emergency during construction, evacuation of workmen working Stable against high winds during erection

in case of emergency At heights is time consuming and difficult Evacuation is quick and easy since workmen are working at a maximum of 3 mtr height

Incidence of weld repair High Low

Wastage of electrode butts High Nil High Medium Low

Cost of welding & grinding consumable High Low High Medium Nil

High Medium Low

Analysis of manpower and time required to erect tank shells of various sizes under different erection methods

Jacking+External Welds LIFT n WELD % Reduction in man

Conventional Conventional+Manual Conventional+Automatic Plain Vanilla Jacking+ % Reduction Compared

Welding Method Jacking Method of Erection by Auto Welding+ (Jacking+Auto Welding for both days compared to

Erection Method Welding Welding Manual Welding to manual Welding

Internal Welds manually External and Internal Welds) conventional method

No. of Auto Days For No. Of Days For No. Of

Welding No. Of

Welding Total Days Placing And Fitters / Placing And Fitters /

Tank Shell Speed Welders And

No. Of Working Required For Erecting Shell Riggers Erecting Shell Riggers

Diameter Thickness Per Machine / Machines Helpers A B C D E (C-E) (B-E)

Weld / No. Of Hrs Horizontal Plates, Aligning And Other Plates, Aligning And Other

(meters) (mm) Per Welder Required

Passes Manual Per Days Welding And Helpers And Helpers

(mtrs/ Min) For Welding

Welders Vertical Welding Required Vertical Welding Required

Mechanised External 4 1 1.26 2 16 4 24 Total days for 1 (one) shell course 8.07 6.20 6.07 5.00 4.20

0.333 4

Welding Internal 3 1 0.94 Total manpower required 34.00 28.00 26.00 21.00 20.00 23.08 28.57 Lesser workmen required

20 10 Manual External 4 4 10 2.33 Total days to erect 6 shell course 48.44 37.21 36.44 30.02 25.21 30.81 32.25 Lesser time for shell erection

0.045 10

Welding Internal 3 4 1.75 Total man days for shell 1,646.88 1,041.87 947.38 630.46 504.19 46.78 51.61

Mechanised External 5 2 1.18 2 21 4 28 Total days for 1 (one) shell course 9.59 5.89 7.59 5.27 3.89

0.333 4

Welding Internal 3 2 0.71 Total manpower required 40.00 32.00 33.00 27.00 25.00 24.24 21.88 Lesser workmen required

30 16 Manual External 5 5 10 3.49 Total days to erect 6 shell course 57.51 35.32 45.51 31.64 23.32 48.76 33.97 Lesser time for shell erection

0.045 12

Welding Internal 3 5 2.09 Total man days for shell 2,300.59 1,130.32 1,501.98 854.40 583.06 61.18 48.42

Mechanised External 5 3 1.31 5 28 8 37 Total days for 1 (one) shell course 16.73 10.36 13.73 10.19 7.36

0.333 6

Welding Internal 4 3 1.05 Total manpower required 52.00 43.00 43.00 35.50 34.00 20.93 20.93 Lesser workmen required

50 20 Manual External 5 6 10 4.85 Total days to erect 6 shell course 100.37 62.15 82.37 61.14 44.15 46.39 28.96 Lesser time for shell erection

0.045 15

Welding Internal 4 6 3.88 Total man days for shell 5,219.07 2,672.59 3,541.77 2,170.36 1,501.21 57.61 43.83

Mechanised External 7 5 1.76 8 40 11 54 Total days for 1 (one) shell course 20.31 14.02 17.31 13.64 11.02

0.333 12

Welding Internal 5 5 1.26 Total manpower required 81.00 66.00 67.00 53.50 52.00 22.39 21.21 Lesser workmen required

80 24 Manual External 7 12 10 5.43 Total days to erect 6 shell course 121.86 84.12 103.86 81.84 66.12 36.34 21.40 Lesser time for shell erection

0.045 27

Welding Internal 5 12 3.88 Total man days for shell 9,870.48 5,551.66 6,958.47 4,378.53 3,438.03 50.59 38.07

Notes: (A) Actual working days considered without holidays (B) Data on number of workmen and required working days are acquired from actual job sites and may vary from one job site to another

You might also like

- Rhourde El Baguel LPG Extraction Plant Feed Planning Rev 0 PDFDocument3 pagesRhourde El Baguel LPG Extraction Plant Feed Planning Rev 0 PDFZakari LOUNISNo ratings yet

- Turnip28 V16a Core RulesDocument73 pagesTurnip28 V16a Core RulesСлавік БачинськийNo ratings yet

- Jib Cranes: Fax To 262-790-4202Document8 pagesJib Cranes: Fax To 262-790-4202Theodoros AtheridisNo ratings yet

- IRAC Formulas PDFDocument7 pagesIRAC Formulas PDFroy rebosuraNo ratings yet

- A-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- Product Sheet ASME Porocedure PDFDocument2 pagesProduct Sheet ASME Porocedure PDFHoang Diep PhanNo ratings yet

- L1 34258 en T Union S 2 - UV 418 TT en MDPK 5aDocument2 pagesL1 34258 en T Union S 2 - UV 418 TT en MDPK 5aKrishna VachaNo ratings yet

- T 2171 - Diesel Storage TankDocument2 pagesT 2171 - Diesel Storage TankHuynh Thanh TamNo ratings yet

- Tectyl 506 PDFDocument4 pagesTectyl 506 PDFjaskaran singhNo ratings yet

- Clean Agent Releasing Devices - 011614Document3 pagesClean Agent Releasing Devices - 011614Vitra NurulNo ratings yet

- Esab, OK Autrod 12.22 (1222252800)Document1 pageEsab, OK Autrod 12.22 (1222252800)RodrigoNo ratings yet

- 01-Data Sheet Fire Alarm SystemDocument3 pages01-Data Sheet Fire Alarm Systemnaser hasan fauziNo ratings yet

- Compliance Sheet For Technical Spec For Fire Fighting SystemDocument9 pagesCompliance Sheet For Technical Spec For Fire Fighting SystemAnonymous G9t3IVfL4JNo ratings yet

- Weekly Progress ReportDocument2 pagesWeekly Progress ReportMade GileeNo ratings yet

- S-3000-1360-011 - F-Specification For Identification of Piping MaterialsDocument20 pagesS-3000-1360-011 - F-Specification For Identification of Piping MaterialsMessaoud Goutas0% (1)

- Ansaldo List of Cleaning AgentDocument2 pagesAnsaldo List of Cleaning AgentEDB100% (1)

- Bioethanol Manufacturing From Lignocellulosic BiomassDocument7 pagesBioethanol Manufacturing From Lignocellulosic BiomassRifqiNo ratings yet

- REB Process Flow DiagramDocument1 pageREB Process Flow DiagramhaceneNo ratings yet

- 2.30 S-000-1310-002 - Wind CriteriaDocument39 pages2.30 S-000-1310-002 - Wind CriteriaPravinNo ratings yet

- Electrocution Risks When Working Near Overhead Power Lines: Case No. 1 (One Person Serious Injured)Document1 pageElectrocution Risks When Working Near Overhead Power Lines: Case No. 1 (One Person Serious Injured)ken azuraNo ratings yet

- Sewerage SystemDocument9 pagesSewerage Systemhajjiyare2016No ratings yet

- Instrument Transformers Catalogue PDFDocument12 pagesInstrument Transformers Catalogue PDFErdyNo ratings yet

- EPDM Geomembrane Installation Guide - 4Document15 pagesEPDM Geomembrane Installation Guide - 4Mukti AwanNo ratings yet

- Desalination Plant ConstructionDocument104 pagesDesalination Plant Constructionadalcayde2514No ratings yet

- Brochure1711 PDFDocument48 pagesBrochure1711 PDFmirza tuzzamanNo ratings yet

- Basic 2D Engineering Drawing Checklist: 1. A Name For The Component And/or ProjectDocument5 pagesBasic 2D Engineering Drawing Checklist: 1. A Name For The Component And/or ProjectShacheendra SharmaNo ratings yet

- POSCO Brochure (플랜트소개용)Document27 pagesPOSCO Brochure (플랜트소개용)German Jaramillo VillarNo ratings yet

- FDR Gamma Ray SourceDocument1 pageFDR Gamma Ray Sourceu2006262918No ratings yet

- ASME CertificationDocument3 pagesASME Certificationtamim2014No ratings yet

- C MEC DWG 730 40558 B - Code 1Document4 pagesC MEC DWG 730 40558 B - Code 1Ramzi ZoghlamiNo ratings yet

- Difference-Between FRP and GRP PDFDocument3 pagesDifference-Between FRP and GRP PDFparesh_patsNo ratings yet

- Piping and Vessels Preparation For Commissioning - Part 2Document12 pagesPiping and Vessels Preparation For Commissioning - Part 2MohamedNo ratings yet

- Handling, Storage, Packaging, Preservation, and Delivery: ISO ProcedureDocument8 pagesHandling, Storage, Packaging, Preservation, and Delivery: ISO ProcedurecomyahoothanhNo ratings yet

- Cahier de Soudage G 11950 - Ver B - WPS 14Document1 pageCahier de Soudage G 11950 - Ver B - WPS 14YassineElabdNo ratings yet

- Types of Heat Tracing Systems - PIPING GUIDEDocument9 pagesTypes of Heat Tracing Systems - PIPING GUIDERaakze MoviNo ratings yet

- Release Notes - Instrument Inspector 2 - 0 - 2 - 0Document8 pagesRelease Notes - Instrument Inspector 2 - 0 - 2 - 0Adrian ReyesNo ratings yet

- Essar Constructions Ltd. Hazira.: List of FormatsDocument68 pagesEssar Constructions Ltd. Hazira.: List of Formatsravi00098No ratings yet

- WPSGMAW90 102011ExamplePDFDocument1 pageWPSGMAW90 102011ExamplePDFBhavani PrasadNo ratings yet

- Pressure Vessel Hydrotest Procedure - Google SearchDocument3 pagesPressure Vessel Hydrotest Procedure - Google SearchAsad KhanNo ratings yet

- Attach-10 Work Procedure For Process Piping Prefabrication and InstallationDocument17 pagesAttach-10 Work Procedure For Process Piping Prefabrication and InstallationSukalyan BasuNo ratings yet

- SgateDocument436 pagesSgateAyyanrajNo ratings yet

- Iso 12953 5 2020 PDF FreeDocument36 pagesIso 12953 5 2020 PDF FreebojanNo ratings yet

- Development of SA-738 Gr. B High Strength Steel Plate With Excellent Toughness For Power Generating PlantsDocument6 pagesDevelopment of SA-738 Gr. B High Strength Steel Plate With Excellent Toughness For Power Generating PlantsKK SinghNo ratings yet

- Polyken Utility Tape 900 910 908 911 920Document2 pagesPolyken Utility Tape 900 910 908 911 920Tracy EvansNo ratings yet

- NIBCO Copper Fittings PDFDocument56 pagesNIBCO Copper Fittings PDFAymeeenNo ratings yet

- Guide For Test Pack Eng ResponsibiliesDocument1 pageGuide For Test Pack Eng ResponsibiliesDinesh RadhakrishnanNo ratings yet

- Pressure Vessel PlateDocument4 pagesPressure Vessel PlateYetkin ErdoğanNo ratings yet

- Geo InstallationDocument33 pagesGeo Installationmauricio PEREZNo ratings yet

- RHOURDE EL BAGUEL LPG EXTRACTION PLANT FEED PLANNING REV 0 Level 2 PDFDocument2 pagesRHOURDE EL BAGUEL LPG EXTRACTION PLANT FEED PLANNING REV 0 Level 2 PDFZakari LOUNISNo ratings yet

- Cahier de Soudage G 11950 - Ver B - WPS 14 PDFDocument1 pageCahier de Soudage G 11950 - Ver B - WPS 14 PDFYassineElabdNo ratings yet

- Scope of Supply T60Document25 pagesScope of Supply T60cmaduroheNo ratings yet

- Wps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationDocument5 pagesWps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationAmit ChapagainNo ratings yet

- EpdmDocument2 pagesEpdmhappale2002No ratings yet

- Videsh Coal Services PVT LTD: Shipping AnalysisDocument24 pagesVidesh Coal Services PVT LTD: Shipping AnalysisGirish KumarNo ratings yet

- Documents Covering Welding Inspection and QualificationDocument28 pagesDocuments Covering Welding Inspection and QualificationMohamed El SayadNo ratings yet

- Tank Building Methodology: Sourcing Energy To Our LivesDocument43 pagesTank Building Methodology: Sourcing Energy To Our LiveskopnangNo ratings yet

- Company ProfileDocument18 pagesCompany ProfileAjay Singh LucknowNo ratings yet

- 800D SeriesDocument3 pages800D Seriesvkeie0206No ratings yet

- Method of Statement For ROO ProjectDocument12 pagesMethod of Statement For ROO ProjectAmmar Alkindy100% (1)

- Data Teknis BrilliantDocument13 pagesData Teknis Brilliantuiii projectNo ratings yet

- Process Flow Chart of Weaving - Textile LearnerDocument1 pageProcess Flow Chart of Weaving - Textile LearnerGOWTHAM CHANDRUNo ratings yet

- Hubantriebe FU ENGDocument15 pagesHubantriebe FU ENGpabloNo ratings yet

- 1.3.3 Underwater Stockpile - Intermediate Transfer Pit (ITP)Document1 page1.3.3 Underwater Stockpile - Intermediate Transfer Pit (ITP)kamlesh0106No ratings yet

- Terminal Area - Construction: 1.3.8 Disposal of Dredged FinesDocument1 pageTerminal Area - Construction: 1.3.8 Disposal of Dredged Fineskamlesh0106No ratings yet

- AECOM Schedule Basis 21Document1 pageAECOM Schedule Basis 21kamlesh0106No ratings yet

- Pre-Construction Planning Activities: Table 4.28: Tracking and Control Planning ChecklistDocument1 pagePre-Construction Planning Activities: Table 4.28: Tracking and Control Planning Checklistkamlesh0106No ratings yet

- Electrical Pre-Construction Planning Implementation Manual: Schedule Development Best Practices and Rules-Of-ThumbDocument1 pageElectrical Pre-Construction Planning Implementation Manual: Schedule Development Best Practices and Rules-Of-Thumbkamlesh0106No ratings yet

- N, ML, UlDocument1 pageN, ML, Ulkamlesh0106No ratings yet

- Available Valuesets That Should Appear in This Datagraph. Click OkDocument1 pageAvailable Valuesets That Should Appear in This Datagraph. Click Okkamlesh0106No ratings yet

- WBS Schedule ProDocument1 pageWBS Schedule Prokamlesh0106No ratings yet

- Tools - Reports - Earned Value - Estimate at Completion, CPI Report, CPIDocument1 pageTools - Reports - Earned Value - Estimate at Completion, CPI Report, CPIkamlesh0106No ratings yet

- Table 1. Conventional WBS of An Apartment Building: Proposed MethodDocument1 pageTable 1. Conventional WBS of An Apartment Building: Proposed Methodkamlesh0106No ratings yet

- Excel Management of Daily Progress in A Construction Project of Multiple Apartment BuildingsDocument1 pageExcel Management of Daily Progress in A Construction Project of Multiple Apartment Buildingskamlesh0106No ratings yet

- Fig. 2. Progress Plan Chart in MS-EXCEL: Problems and LessonsDocument1 pageFig. 2. Progress Plan Chart in MS-EXCEL: Problems and Lessonskamlesh0106No ratings yet

- Set A Horizontal Bar's DefaultsDocument1 pageSet A Horizontal Bar's Defaultskamlesh0106No ratings yet

- Index SSPC: SpecificationsDocument1 pageIndex SSPC: SpecificationsjosNo ratings yet

- Cortana Tutorial: Raphael Mudge, Strategic Cyber LLCDocument61 pagesCortana Tutorial: Raphael Mudge, Strategic Cyber LLCcastillo_leoNo ratings yet

- Tower Crane AccidentDocument37 pagesTower Crane Accidentparawansa muisNo ratings yet

- Electronic Immobilizers For The Automotive Industry: U2270B Application NoteDocument19 pagesElectronic Immobilizers For The Automotive Industry: U2270B Application NoteRuslan ValiakhmetovNo ratings yet

- Travels Booking SystemDocument88 pagesTravels Booking SystemindrajeetNo ratings yet

- CSO Advance Class Training V2Document6 pagesCSO Advance Class Training V2Wan AbadiNo ratings yet

- CATIA - Human Builder & SimulationDocument2 pagesCATIA - Human Builder & Simulationguen_betonamuNo ratings yet

- Inhibition of Methicillin-Resistant StaphylococcusDocument7 pagesInhibition of Methicillin-Resistant Staphylococcusdaniel_siitompulNo ratings yet

- Materi & Tugas Bing Kelas 2 - Bab 5Document3 pagesMateri & Tugas Bing Kelas 2 - Bab 5Ronald WeleNo ratings yet

- Solvent Extraction of Aluminium in The Presence of Cobalt, Nickel and Magnesium From Sulphate Solutions by Cyanex 272Document8 pagesSolvent Extraction of Aluminium in The Presence of Cobalt, Nickel and Magnesium From Sulphate Solutions by Cyanex 272Leda HidalgoNo ratings yet

- Tl-Sg108pe Tl-Sg105pe Tl-Sg1210mpe IgDocument2 pagesTl-Sg108pe Tl-Sg105pe Tl-Sg1210mpe IgMaxNo ratings yet

- Manual de Partes Tus-A300a PDFDocument206 pagesManual de Partes Tus-A300a PDFHugo Coaquira Arizaca0% (1)

- Quiz PASDocument3 pagesQuiz PASZoey Alvin EstarejaNo ratings yet

- 3 Object Oriented Modeling and DesignDocument9 pages3 Object Oriented Modeling and DesignMaya M SNo ratings yet

- Datron PRC-BC4 Multiple Battery Charger - Operator and Technical ManualDocument28 pagesDatron PRC-BC4 Multiple Battery Charger - Operator and Technical ManualAlexander J RokowetzNo ratings yet

- Case Study - 5Q Group 2Document5 pagesCase Study - 5Q Group 2ZulkifliyJamil100% (3)

- Chapter 14 - Just in Time SystemsDocument4 pagesChapter 14 - Just in Time Systemshello_khayNo ratings yet

- TalentTrees v1 PDFDocument22 pagesTalentTrees v1 PDFpaulopt21100% (1)

- JavelinDocument63 pagesJavelincaranmiroslavNo ratings yet

- Company Profile: A Proposed Computerized Advanced Warehousing System For Skin Sciences Laboratory, IncDocument11 pagesCompany Profile: A Proposed Computerized Advanced Warehousing System For Skin Sciences Laboratory, IncRafael LunarNo ratings yet

- Market Visit ReportDocument10 pagesMarket Visit Reportokwadha simionNo ratings yet

- MAON Google SlidesDocument74 pagesMAON Google SlidesavinteumfilmsNo ratings yet

- 3 Experiment ChemistryDocument30 pages3 Experiment ChemistryThangavel SarujanNo ratings yet

- As I Follow Christ by Dwain N. EsmondDocument138 pagesAs I Follow Christ by Dwain N. EsmondGabor KovacsNo ratings yet

- Edcd797 001 Spring 2015 Eating Disorders SyllabusDocument9 pagesEdcd797 001 Spring 2015 Eating Disorders Syllabusapi-329795302No ratings yet

- Project Based Learning And: Authentic AssessmentDocument52 pagesProject Based Learning And: Authentic Assessmentnancie8No ratings yet

- How To Become A Super Learner by Jim Kwik Workbook NSPDocument11 pagesHow To Become A Super Learner by Jim Kwik Workbook NSPmark50% (6)

- Ucs617 5Document2 pagesUcs617 5Suprit BeheraNo ratings yet