Professional Documents

Culture Documents

Davit Calculation

Davit Calculation

Uploaded by

piziyu0 ratings0% found this document useful (0 votes)

13 views2 pagesThis document calculates the stresses on various components of a davit system to check if it will safely support the given loads. It performs calculations of (1) bending stress on the davit, (2) shear stress on welds connecting the davit to the stop, (3) bending and shear stresses on welds of an ear flange, and (4) bending and shear stresses on welds of a cover ear. The calculations show the stresses are below the allowable limits, indicating the davit system design is safe to use.

Original Description:

Original Title

DAVIT CALCULATION.xls

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document calculates the stresses on various components of a davit system to check if it will safely support the given loads. It performs calculations of (1) bending stress on the davit, (2) shear stress on welds connecting the davit to the stop, (3) bending and shear stresses on welds of an ear flange, and (4) bending and shear stresses on welds of a cover ear. The calculations show the stresses are below the allowable limits, indicating the davit system design is safe to use.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

13 views2 pagesDavit Calculation

Davit Calculation

Uploaded by

piziyuThis document calculates the stresses on various components of a davit system to check if it will safely support the given loads. It performs calculations of (1) bending stress on the davit, (2) shear stress on welds connecting the davit to the stop, (3) bending and shear stresses on welds of an ear flange, and (4) bending and shear stresses on welds of a cover ear. The calculations show the stresses are below the allowable limits, indicating the davit system design is safe to use.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 2

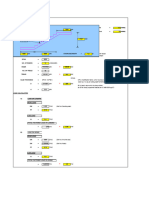

DAVIT CALCULATION

NOZZLE NO. J1-J5

DAVIT MATERIAL SA-105

EAR MATERIAL SA-516 70

DAVIT ALLOWABLE STRESS []d = 138 MPa

EAR ALLOWABLE STRESS []e = 138 MPa

DAVIT DIAMETER d = 30 mm

FLANGE EAR THICKNESS t1 = 25 mm

BLIND FLANGE WEIGHT m1 = 65 kg

DAVIT WEIGHT m2 = 7 kg

DISTANCE FROM DAVIT TO NOZZLE CENTER L1 = 250 mm

DISTANCE FROM DAVIT TO FLANGE OUT SURFACE L2 = 40 mm

SIZE OF WELDING LEG ON STOP H1 = 10 mm

OUT RADIUS OF EAR R1 = 30 mm

INNER RADIUS OF EAR R2 = 16 mm

LENGTH OF WELDING ON EAR L3 = 90 mm

SIZE OF WELDING LEG ON EAR H2 = 10 mm

COVER EAR THICKNESS t2 = 25 mm

1 DAVIT CHECK

BENDING MOMENT M1 = m1*g*L1

= 159250 N*mm

DAVIT MODULUS W1 = d3*/32

= 2649.375 mm3

BENDING STRESS IN DAVIT 1 = M1/W1

= 60.1085161595 MPa

< []d

BENDING STRESS SATISFIED! IT IS SAFE!

2 WELDINGS ON STOP CHECK

AREA OF WELDING A2 = d**H1

= 942 mm2

SHEAR ON THE WELDING 2 = (m1+m2)*g/A2

= 0.749044586 MPa

< 0.6*[]e

SHEAR STRESS SATISFIED! IT IS SAFE!

3 FLANGE EAR CHECK

FLANGE EAR MODULUS W3 = 2*(R1-R2)*t12/6

= 2916.6666666667 mm3

BENDING MOMENT M3 = (m1+m2)*g*L2

= 28224 N*mm

BENDING STRESS IN EAR b3 = M3/W3

= 9.6768 MPa

AREA OF WELDING A3 = L3*H2*2

= 1800 mm2

SHEAR ON THE WELDING 3 = (m1+m2)*g/A3

= 0.392 MPa

3

EQUIVALENT STRESS =

2 +3 2

b3 3

= 9.7005902006 MPa

< 0.6*[]e MPa

EQUIVALENT STRESS SATISFIED! IT IS SAFE!

4 COVER EAR CHECK

COVER EAR MODULUS W4 = 2*(R1-R2)*t22/6

= 2916.6666666667 mm3

BENDING MOMENT M4 = (m1+m2)*g*L1

= 176400 N*mm

BENDING STRESS IN EAR b4 = M4/W4

= 60.48 MPa

AREA OF WELDING A4 = L3*H2*2

= 1800 mm2

SHEAR ON THE WELDING 4 = (m1+m2)*g/A4

= 0.392 MPa

4

EQUIVALENT STRESS =

2 +3 2

b4 4

= 60.483810991 MPa

< 0.6*[]e MPa

EQUIVALENT STRESS SATISFIED! IT IS SAFE!

You might also like

- Crack Width As Per ACI 318 - SpreadsheetDocument2 pagesCrack Width As Per ACI 318 - Spreadsheetmassive8590% (10)

- Compensation To Opening Sums NptelDocument9 pagesCompensation To Opening Sums NptelRADHE GRAPHICSNo ratings yet

- Manicure and PedicureDocument38 pagesManicure and PedicureDesiree Clarisse B. DelaCruz100% (4)

- Design of Hume PipeDocument4 pagesDesign of Hume PipeYatendra TyagiNo ratings yet

- Aluminium Cladding DesignDocument2 pagesAluminium Cladding DesigntkofaiNo ratings yet

- Heat Exchanger Strength Calculation: Shell Side Design Data Tube Side Design DataDocument2 pagesHeat Exchanger Strength Calculation: Shell Side Design Data Tube Side Design DataSteve MoonNo ratings yet

- Rubber Burn Test SpecsDocument1 pageRubber Burn Test SpecsTushar BagdeNo ratings yet

- Timber Column Design: Mark Diameter 200mmDocument4 pagesTimber Column Design: Mark Diameter 200mmFarly VergelNo ratings yet

- Kpeter PDFDocument3 pagesKpeter PDFlive4sankarNo ratings yet

- Desingn of U.G TANK WALLDocument5 pagesDesingn of U.G TANK WALLnileshNo ratings yet

- End Cond... : Design of Stair CaseDocument6 pagesEnd Cond... : Design of Stair Caseazam1uNo ratings yet

- Base Plate DesignDocument8 pagesBase Plate DesignANANDA D SNo ratings yet

- Comparing Analysis of A Specified Pressure Vessel's Design MethodsDocument6 pagesComparing Analysis of A Specified Pressure Vessel's Design MethodsEstuardo Javier Gan RodríguezNo ratings yet

- SLAB-1: Effective Span Clear+Effective Depth (OR) Which Ever Is Less C/Cof SupportsDocument2 pagesSLAB-1: Effective Span Clear+Effective Depth (OR) Which Ever Is Less C/Cof SupportsvidudalaraviNo ratings yet

- Calculation For Pipe SplicingDocument2 pagesCalculation For Pipe SplicingAnonymous ZMLlQvBopNo ratings yet

- EJ CalculationDocument16 pagesEJ CalculationAmit NayakNo ratings yet

- Bundle Extractor ClipDocument1 pageBundle Extractor ClipSu Kil SungNo ratings yet

- Cric Bun AkDocument26 pagesCric Bun AkGabriel AkNo ratings yet

- SlabDocument4 pagesSlabAbdo SalahNo ratings yet

- Lifting/Tailing Lug Calculation: Design DataDocument3 pagesLifting/Tailing Lug Calculation: Design DataMr IncognitoNo ratings yet

- 148841505-Verificare-StalpDocument50 pages148841505-Verificare-StalpkrmeenNo ratings yet

- Dax SlabDocument3 pagesDax SlabLinoNo ratings yet

- Cold Stretch Cal For 80KL-17bar On 28.05.2013Document9 pagesCold Stretch Cal For 80KL-17bar On 28.05.2013Venkatesan ManikandanNo ratings yet

- Formwork 1Document6 pagesFormwork 1Enggar RianaNo ratings yet

- 1.) Reakcije U Osloncima Za Horizontalnu (X-Z) Osu: B Ax 1x 1z 4x 4z Ax 1x 1z 4x 4zDocument6 pages1.) Reakcije U Osloncima Za Horizontalnu (X-Z) Osu: B Ax 1x 1z 4x 4z Ax 1x 1z 4x 4zelma spahicNo ratings yet

- Data Input:: Z, D Max Z, D Min Xy, D X, DDocument2 pagesData Input:: Z, D Max Z, D Min Xy, D X, DMotaz SalahNo ratings yet

- Aluminium Cladding DesignDocument3 pagesAluminium Cladding Designjatin100% (1)

- Deign of PartsDocument11 pagesDeign of PartsMohamad Ahmed Hussein Abd elaalNo ratings yet

- TM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)Document13 pagesTM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)jhunkujha11No ratings yet

- One Way Slab Design 3Document3 pagesOne Way Slab Design 3Kenneth Peña JavierNo ratings yet

- Vessel Design CalculationDocument22 pagesVessel Design CalculationAh Leng LauNo ratings yet

- Tubesheet Calculation: Step 1Document2 pagesTubesheet Calculation: Step 1Bintang LazuardiNo ratings yet

- Torque CalculationDocument1 pageTorque CalculationKarun KumarNo ratings yet

- Placa Base EmpotradaDocument3 pagesPlaca Base EmpotradaRicardo ANo ratings yet

- Crack Check: Ec N Es / Ec FR 4700 FC'Document3 pagesCrack Check: Ec N Es / Ec FR 4700 FC'kamakshi100% (2)

- Quality of Materials:: Large Moment Base Plate Design AISC LRFD - MethodeDocument7 pagesQuality of Materials:: Large Moment Base Plate Design AISC LRFD - MethodejunarkoNo ratings yet

- Sample ConnectionDocument10 pagesSample ConnectionMarielle Bias MercadoNo ratings yet

- Designing of Slabs One Way FinalDocument2 pagesDesigning of Slabs One Way FinalZyril BestoNo ratings yet

- Staircase DesignDocument2 pagesStaircase DesignnileshNo ratings yet

- FFB2Document8 pagesFFB2prajjwal patidarNo ratings yet

- Base Plate Design Gangway ColumnDocument2 pagesBase Plate Design Gangway ColumnsandeepNo ratings yet

- Basement WallDocument3 pagesBasement WallSijan AdhikariNo ratings yet

- 2000 MM 1900 MM: Check For Crack Width As Per Is 456-2000Document1 page2000 MM 1900 MM: Check For Crack Width As Per Is 456-2000karthikmr85No ratings yet

- Base Design (Blocks) - Commented On 26.09.2017Document4 pagesBase Design (Blocks) - Commented On 26.09.2017tsinghal_19No ratings yet

- RaftDocument5 pagesRaftvidyaNo ratings yet

- Design of Beams at 419.10m LVL: General DataDocument3 pagesDesign of Beams at 419.10m LVL: General Dataankkeshmundra1No ratings yet

- 09 P Example Shear (Lecturenotes)Document5 pages09 P Example Shear (Lecturenotes)Matteo SoruNo ratings yet

- # Verification On Transom Profile: References CalculationsDocument1 page# Verification On Transom Profile: References CalculationsAzahar Bin HashimNo ratings yet

- Pressure Filter-2 (ASME, A516-70) ) 130930Document3 pagesPressure Filter-2 (ASME, A516-70) ) 130930strike999911No ratings yet

- Intze Tank 1 Moin 25-1-23Document17 pagesIntze Tank 1 Moin 25-1-23MOIN UDDINNo ratings yet

- Cylinderical ShellDocument1 pageCylinderical ShellJoosung HanNo ratings yet

- GROUP6 - GC42 - Design of Column Beam and SlabDocument8 pagesGROUP6 - GC42 - Design of Column Beam and SlabAlexander P. BelkaNo ratings yet

- 2 PileDocument2 pages2 PilemanishaNo ratings yet

- Slab S2 @RD AnalysisDocument1 pageSlab S2 @RD AnalysisMark Christian Esguerra100% (1)

- BOLT TORQUE CALCULATION pcc1Document4 pagesBOLT TORQUE CALCULATION pcc1Abhay UpadhyayNo ratings yet

- 6 Inch NB Nozzle Calculation Appendex 1-7Document11 pages6 Inch NB Nozzle Calculation Appendex 1-7SACHIN PATELNo ratings yet

- Achmad Fatchurrozi Zanuar - Perhitungan PlatDocument10 pagesAchmad Fatchurrozi Zanuar - Perhitungan PlatRo ZiNo ratings yet

- Pipes. Maxi 6Document1 pagePipes. Maxi 6Nasrul AdliNo ratings yet

- Design of Stairs and Landing: Page NoDocument6 pagesDesign of Stairs and Landing: Page NoJun Dela PeñaNo ratings yet

- Ceb804 Assign 1 PDFDocument22 pagesCeb804 Assign 1 PDFRandhir ChandNo ratings yet

- 2012 Training Materials PDFDocument32 pages2012 Training Materials PDFWisam Ankah100% (1)

- Quantitative Interpretation of The Response of Surface Plasmon Resonance Sensors To Adsorbed FilmsDocument13 pagesQuantitative Interpretation of The Response of Surface Plasmon Resonance Sensors To Adsorbed FilmsKaren Régules MedelNo ratings yet

- Adriafil SummerDocument5 pagesAdriafil SummerTatu AradiNo ratings yet

- An0002 Efm32 Hardware Design ConsiderationsDocument16 pagesAn0002 Efm32 Hardware Design ConsiderationsRam SakthiNo ratings yet

- Apple Serial Number Info - Decode Your Mac's Serial Number!Document1 pageApple Serial Number Info - Decode Your Mac's Serial Number!edp8 malsbyNo ratings yet

- Igcse Past PaperDocument36 pagesIgcse Past PaperfaiyazNo ratings yet

- BIOL207 Open GeneticsDocument182 pagesBIOL207 Open GeneticsBi Anh100% (1)

- PPM Schedule Anmol Feeds PVT LTD - PanchlaDocument1 pagePPM Schedule Anmol Feeds PVT LTD - PanchlaSatyajit DasNo ratings yet

- PSC Unit 3Document18 pagesPSC Unit 3Santosh ReddyNo ratings yet

- PPP-Eclipse-E05 Module 05 IDUsDocument11 pagesPPP-Eclipse-E05 Module 05 IDUsJervy SegarraNo ratings yet

- 320 Lecture 27Document8 pages320 Lecture 27Gathy BrayohNo ratings yet

- Product Requirements Specification Process in ProdDocument12 pagesProduct Requirements Specification Process in ProdemmyNo ratings yet

- 5th Fancy BreadDocument7 pages5th Fancy BreadMera Funportal0% (1)

- Assignment 3: Task #1 Has (10 Parts) That Corresponds To CLO # 2 For A Total of 30 PointsDocument2 pagesAssignment 3: Task #1 Has (10 Parts) That Corresponds To CLO # 2 For A Total of 30 PointsWaqas AliNo ratings yet

- Final Thesis of Tesfaye Asnake-Checked and CorrectedDocument93 pagesFinal Thesis of Tesfaye Asnake-Checked and CorrectedEsan DemissieNo ratings yet

- 561566642977unit-3 - TextilesDocument11 pages561566642977unit-3 - TextilesGaganpreet Kaur Fashion DesigningNo ratings yet

- Cryolite JM File 2011Document5 pagesCryolite JM File 2011mutemuNo ratings yet

- Staedtler Digitalpen 2.0 enDocument132 pagesStaedtler Digitalpen 2.0 enceciardittoNo ratings yet

- Music Therapy When Death Is Imminent - A Phenomenological InquiryDocument32 pagesMusic Therapy When Death Is Imminent - A Phenomenological InquiryJuan Luis Köstner MartinoNo ratings yet

- DIAGRAMA - 2007 - NEW YarisDocument1 pageDIAGRAMA - 2007 - NEW YarisLuis M. Valenzuela Arias50% (2)

- Semi Soft Coking Coal and PCI CoalDocument2 pagesSemi Soft Coking Coal and PCI CoalYusuff QuadrilateralNo ratings yet

- Drop Tower MQP Final ReportDocument70 pagesDrop Tower MQP Final ReportFABIAN FIENGONo ratings yet

- Smoke Alarm User's Guide: For Model: PI2010Document16 pagesSmoke Alarm User's Guide: For Model: PI2010goawayNo ratings yet

- Fire Water Curtain DesignDocument2 pagesFire Water Curtain Designkb_pramod89% (9)

- Power Plant Engg Lab Manual BeDocument32 pagesPower Plant Engg Lab Manual Besinan2yilmazNo ratings yet

- Outsmart Your Anxious Brain - Worksheet Diagnosis Guide ExercisesDocument6 pagesOutsmart Your Anxious Brain - Worksheet Diagnosis Guide Exercisesdoppler_100% (1)

- Filter BrochureDocument2 pagesFilter BrochureCanadaPool100% (1)

- LIST OF REGISTERED DRUGS As of Deceember 2012: DR No Generic Brand Strength Form CompanyDocument68 pagesLIST OF REGISTERED DRUGS As of Deceember 2012: DR No Generic Brand Strength Form CompanyBenjamin Tantiansu100% (1)