Professional Documents

Culture Documents

B1372 en 0516

B1372 en 0516

Uploaded by

yraju88Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B1372 en 0516

B1372 en 0516

Uploaded by

yraju88Copyright:

Available Formats

Issue 5-16 E

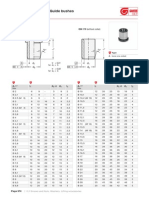

B 1.372

Low-Block Clamping Cylinder

single acting with spring return, max. operating pressure 500 bar

k Stroke

4

D

c

f

e

z2

r m z1 Socket head Leg spring

Sealing ring

cap screw

a n

Description

o

b

i

p

The preferred application of low-block clam-

ping cylinders are clamping situations w here

workholding from above is not possible or

Clamping possibilities

necessary. The low-clamping effect is caused g h

by the downward motion of the clamping

point. The average horizontal force compo-

nent is 94% and the vertical force component Piston D [mm] 16 25 36

is a

pprox. 34% of the nominal clamping force. Stroke [mm] 8 10 10

The high vertical force guarantees that the 100 bar [kN] 1.7 4 8

Clamping force at

workpieces are safely held down. The clam- 500 bar [kN] 8.5 20 40

ping lever is continuously hardened so that the Oil volume per 10 mm stroke [cm3] 2 4.9 10.2

shape of the clamping point can be adapted to a [mm] 68 90 96

the workpiece by regrinding. b [mm] 50 60 80

c [mm] 32 40 50

d max. [mm] 6 6 6

Material

e [mm] 19 23 27

Cylinder body material: Steel, black oxide f [mm] 31 39 49

Clamping lever: 58 Cr V4, Hrc 54-58 g [mm] 27 38 38

h [mm] 32 42 46

Important notes i [mm] 32 40 56

Cylinders have to be protected against direct k [mm] 13.5 15 18

influences of aggressive cutting lubricants and l [mm] 8.5 9 11

coolants. m [mm] 8.5 9 11

Operating conditions, tolerances and other n [mm] 2 2

data see data sheet A 0.100. o G 1/4 G 1/4 G 1/4

p [mm] 14

r [mm] 13 14 16

Application example z1 [mm] 5.5 6 8

z2 [mm] 6 9 11

Weight [kg] 0.9 1.15 2.1

Part no. 1371-010 1373-010 1374-010

Accessories

Screw plug G 1/4 3610-264 3610-264 3610-264

O-Ring 10 x 2 3000-347 3000-347 3000-347

Spare seal ring 3000-536 3000-536 3000-546

Clamping lever, one piece 3542-080 3542-081 3542-082

Leg spring, spare part 3715-104 3715-104 3716-109

Screw plug

Ra = 0,8

d max.

O-ring

The hydraulic oil can optionally by supplied through tubes or drilled channels in the fixture body;

4 fixing screws are required.

Rmheld GmbH Postfach 1253 35317 Laubach, Germany Tel.: +49(0)6405/89-0 Fax: +49(0)6405/89-211 Actual issue see www.roemheld.com

Subject to modifications

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 02 Sh210-6 Monitor DisplayDocument39 pages02 Sh210-6 Monitor DisplaySumitomo Laos Sumitomo Laos92% (13)

- MAKINO PRO3 ProgManual PDFDocument224 pagesMAKINO PRO3 ProgManual PDFyraju88100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- What Is The Best Cell Plate ConfigurationDocument19 pagesWhat Is The Best Cell Plate Configurationjctorres100% (1)

- Poojas MuttarukkalDocument1 pagePoojas Muttarukkalyraju88No ratings yet

- MAKINO - Machine A51 61nxDocument6 pagesMAKINO - Machine A51 61nxyraju88No ratings yet

- DocumentDocument11 pagesDocumentthanhhai31100% (1)

- Glosario MantenimientoDocument140 pagesGlosario MantenimientoJesus Alfaro AngelesNo ratings yet

- Surface FinishDocument26 pagesSurface Finishyraju88No ratings yet

- Datasheet Roughness Tester Hommel Etamic w5Document2 pagesDatasheet Roughness Tester Hommel Etamic w5yraju88No ratings yet

- First: United States PatentDocument7 pagesFirst: United States Patentyraju88No ratings yet

- Nitriding SteelDocument2 pagesNitriding Steelyraju88No ratings yet

- Zeiss Gear Pro 2016 Release Infomation enDocument56 pagesZeiss Gear Pro 2016 Release Infomation enyraju88100% (1)

- 1.4404 enDocument5 pages1.4404 enyraju88No ratings yet

- 2015 Osnastka Seco Tools Katalog en Page66Document1 page2015 Osnastka Seco Tools Katalog en Page66yraju88No ratings yet

- Area Code AO Type Range Code AO No.: Signature of The DeclarantDocument2 pagesArea Code AO Type Range Code AO No.: Signature of The Declarantyraju88No ratings yet

- Lha R00 2017KW GBDocument62 pagesLha R00 2017KW GByraju88No ratings yet

- Axip 0240Document38 pagesAxip 0240yraju88No ratings yet

- Down-Thrust Clamps: Size 25 EH 23310Document2 pagesDown-Thrust Clamps: Size 25 EH 23310yraju88No ratings yet

- BFW AiravatDocument4 pagesBFW Airavatyraju88No ratings yet

- DIN 172 DIN 179: Guide BushesDocument2 pagesDIN 172 DIN 179: Guide Bushesyraju88No ratings yet

- Aa0621104 EoiDocument8 pagesAa0621104 Eoiyraju88No ratings yet

- Fits and Internal ClearancesDocument7 pagesFits and Internal Clearancesyraju88No ratings yet

- ProductDocument28 pagesProductyraju88No ratings yet

- Spring-Loaded Work Locators: (Standard) (Accurate)Document4 pagesSpring-Loaded Work Locators: (Standard) (Accurate)yraju88No ratings yet

- Boneham and Turner LTD: The Precision EngineersDocument24 pagesBoneham and Turner LTD: The Precision Engineersyraju88No ratings yet

- TripDog TripRailDocument9 pagesTripDog TripRailyraju88No ratings yet

- Pipe Lengths SR No Size Description FromDocument2 pagesPipe Lengths SR No Size Description FromAnoopNo ratings yet

- European Patent Specification: For The Production of Acetic AcidDocument9 pagesEuropean Patent Specification: For The Production of Acetic AcidWisnu Rochman HidayatullahNo ratings yet

- 2 - Material Balance - Oil ReservoirDocument26 pages2 - Material Balance - Oil ReservoirWisnu EkoNo ratings yet

- 2.1.1 Start System (Pneumatic)Document11 pages2.1.1 Start System (Pneumatic)jamurbrotowaliNo ratings yet

- Fired Heaters - IntroductionDocument108 pagesFired Heaters - Introductions_m_kumar100% (4)

- Process Design Training: Line SizingDocument44 pagesProcess Design Training: Line SizingAnonymous fwKgPAW50% (2)

- PETSOC-09-07-18 Gas Condensate Reservoir Performance PDFDocument7 pagesPETSOC-09-07-18 Gas Condensate Reservoir Performance PDFEduardo UstarezNo ratings yet

- DBOOK wdg4Document13 pagesDBOOK wdg4RUDHRESH KUMAR SNo ratings yet

- Craftsman Air Compressor Manual - 919.165190Document27 pagesCraftsman Air Compressor Manual - 919.165190Dan CarsonNo ratings yet

- FOX - Maintenance HandbookDocument126 pagesFOX - Maintenance HandbookDan Și Maria Mierluț100% (6)

- Treatment of Oil-Based Mud Cuttings Via Bio RemediationDocument1 pageTreatment of Oil-Based Mud Cuttings Via Bio RemediationMuhammad Rizwan ShahidNo ratings yet

- Hunter Business GroupDocument2 pagesHunter Business GroupPratyushGarewalNo ratings yet

- Bureau Veritas Rules Ships 3Document4 pagesBureau Veritas Rules Ships 3ArturoNo ratings yet

- Bitumen and Mixture Characteristics of Lawele Buton Rock Asphalt - Madi HermadiDocument6 pagesBitumen and Mixture Characteristics of Lawele Buton Rock Asphalt - Madi HermadiMadi HermadiNo ratings yet

- SRD-vehicle Traction Applications PDFDocument20 pagesSRD-vehicle Traction Applications PDFEduardo BittencourtNo ratings yet

- Lecture 2Document32 pagesLecture 2api-292785878No ratings yet

- GulfSea PE Cooloil Series PDFDocument2 pagesGulfSea PE Cooloil Series PDFObydur RahmanNo ratings yet

- Ertalyte TXDataDocument5 pagesErtalyte TXDatavizcensoNo ratings yet

- 65631102162011KCB 2cy YcbDocument10 pages65631102162011KCB 2cy YcbGBHJRNo ratings yet

- Sprezarka Embraco Aspera NJ9238GK Karta-Produktu PDFDocument3 pagesSprezarka Embraco Aspera NJ9238GK Karta-Produktu PDFsergirojasNo ratings yet

- Actuador Woodward 37511Document4 pagesActuador Woodward 37511Luis Panti Ek100% (1)

- Releasing Value Heavy Oil and BitumenDocument16 pagesReleasing Value Heavy Oil and Bitumenram_river808No ratings yet

- Orbit Steam Turbine Seal Rub - OrbitDocument14 pagesOrbit Steam Turbine Seal Rub - OrbitHatem Ali100% (4)

- Calsep Nova Brochure OnlineDocument4 pagesCalsep Nova Brochure OnlineedgarelerNo ratings yet

- PKW A Aktiveanfahrsysteme 2017Document7 pagesPKW A Aktiveanfahrsysteme 2017Евгений КривулькоNo ratings yet

- Internal Combustion Engine MCQDocument39 pagesInternal Combustion Engine MCQHumphrey James B. BillonesNo ratings yet