Professional Documents

Culture Documents

AWS D1.1 Visual Inspection Acceptance Criteria

AWS D1.1 Visual Inspection Acceptance Criteria

Uploaded by

briang-286%(7)86% found this document useful (7 votes)

9K views1 pageVisual Inspection Acceptance Criteria

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVisual Inspection Acceptance Criteria

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

86%(7)86% found this document useful (7 votes)

9K views1 pageAWS D1.1 Visual Inspection Acceptance Criteria

AWS D1.1 Visual Inspection Acceptance Criteria

Uploaded by

briang-2Visual Inspection Acceptance Criteria

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 1

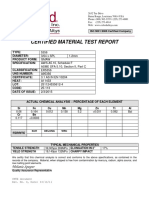

CLAUSE 6. INSPECTION

AWS D111D1-M2015

Table 6.1

Visual Inspection Acceptance Criteria (see 6.9)

Discontinaity Category and Inspection Criteria,

‘Staically Loaded

Nontubalar

Connections

(Cyelicaliy Loaded

Nonubalar

Connections

iO Crack Prohibition

Ay crack shal be unaccepable, regardless of size or location,

x

x

(@) WelaBase Metal Fusion

‘Complete fusion shall exit between adjacent layers of weld metal and becweon weld metal

sand base metal

x

x

(8) Crater Cross Section

‘All raters sll be fillod to provide the specified wel size, excupt forthe ends of

‘normitne lle welds outside of their elective langth.

@ Weld Profiles

‘Weld profiles shall be in conformance with 5.23.

© Time of Inspection

‘Visual inspetion of welds in all sees may begin immediately after the completed welds

have cooled to ambient temperate, Acceptance erteria for ASTM A514, ASIT. and

‘A709 Grade HPS 100W [HPS 6900 stels shall be based on visual inspection performed|

not less than 48 hours after completion ofthe wel.

(6) Undersized Welds

‘The size oil weld in any connuows weld ay be ls than the specified nominal

sire (L) tht comection the fling smaens()

L v

specified nominal weld sie rm] allowabe decrease om Lin

3/16 (5) $116 (2)

V4 (6) $9782 [2.5]

25/16 (8) $18 )3)

Inall exes the undesizeporion ofthe weld hal ot exceed 102% cf the wader

On web-to-ange wel on irs, underran shal be prohibited athe en oar

cqpalo ce te wih of he ange.

] Underewe

(A) For material les than 1 in [25 eum] thick, undercut shall not exceed 1/32 in [1 mn,

‘wit the following excepson: ndereat shall not exceed 1/16 in [2 em] for any accumu-

lated length up to 2 in [50mm] in any 12 in 200 mm]. For material equal oor greater than

im [25 mm] thick, undercut shall nat exceed 1/18 in [2 mm) for any length of weld

{B In primary members, undorout shall bene more than 0.01 in [0.25 mm) deep when

‘the wel is transverse to tensile stress under any design loading condition. Undereut shall

‘be no more than 1/32 in [1 mal deep forall other cases.

@ Porosigy

(A) CIP groove welds in bu Jott wansverse tothe diesion of computed tens sress

Shall ive no visible piping pros. For al ake raove welds ad for let wel the

Sum of the vse piping porosity 121 ma or gestern diameter shall ot exceed

[YS in (10 mm] in any linear ine f weld an shal ot excnd 3/4 in (20 malin any

12 in (300m length of wel

1) The frequency of piping porosity i ile welds shall not exceed one in each in

[100 mm| of weld length and the maximum dizmeter shall not excoed 3/32 in [2.5 mm,

Exception: for fillet welds connecting stiTeners co web, the sur of th diameters of

piping porosity shall not exceed 38 in [10 mm] in ay lnoar inch of weld and shall not

exceed 3/4 in [20 mm] in any 12 in [300 am length of weld

(© GP groove weds in but joins transverse to the direction of computed tensile stress

shall have no piping poeosty. Fr al other groove wold, the froquency of piping porosity

Shall not exceed one in 4 in [100 mm] of leg and the maxcmar diameter sall not

exceed 3/32 in 2.5 mm.

‘Not: Aa "lds epplienliy forthe connocion yp 8 shaded ara idan nar pb.

208

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Inspection and Test Plan (Itp) For Staircase Handrail 1 & 2Document3 pagesInspection and Test Plan (Itp) For Staircase Handrail 1 & 2Environ Support100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- NBA - Next Best ActionDocument37 pagesNBA - Next Best ActionLucia IordacheNo ratings yet

- Prequalified WPS Requirement ASTM D1.1Document1 pagePrequalified WPS Requirement ASTM D1.1briang-2No ratings yet

- AWS D1.1 2015 Table 4.1 PDFDocument1 pageAWS D1.1 2015 Table 4.1 PDFbriang-2No ratings yet

- ENiCrFe 2Document1 pageENiCrFe 2briang-2No ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- Certified Material Test Report: Melanie SpeyrerDocument1 pageCertified Material Test Report: Melanie Speyrerbriang-2No ratings yet

- American Welding Society 8669 NW 36 Street, #130 Miami, FL 33166-6672Document1 pageAmerican Welding Society 8669 NW 36 Street, #130 Miami, FL 33166-6672briang-2No ratings yet

- Ebook Riversand PIMDocument16 pagesEbook Riversand PIMpsn tempNo ratings yet

- Laudon & Laudon MIS, 7th Edition. Pg. 2.1: Learning ObjectivesDocument6 pagesLaudon & Laudon MIS, 7th Edition. Pg. 2.1: Learning ObjectivesJose MartinsNo ratings yet

- Economics 452 International Trade Theory and Policy Fall 2014Document14 pagesEconomics 452 International Trade Theory and Policy Fall 2014Muhammad Fakhri ArsyiNo ratings yet

- Batch Determination PPDocument13 pagesBatch Determination PPrvk386No ratings yet

- Tool 2 Value Chains Mapping GuidelinesDocument6 pagesTool 2 Value Chains Mapping GuidelinesMohammed JafarNo ratings yet

- Oracle Sales Cloud Brochure 20140923 v05Document4 pagesOracle Sales Cloud Brochure 20140923 v05Johan LouwersNo ratings yet

- Life Cycle Perspective in EMSDocument3 pagesLife Cycle Perspective in EMSSyd AglNo ratings yet

- Documaker ExamDocument3 pagesDocumaker ExamRahul RagavanNo ratings yet

- European Steel and Alloy Grades: About Us EN 10248-1Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10248-1farshid KarpasandNo ratings yet

- Language in AdvertisementDocument17 pagesLanguage in AdvertisementNguyen Ngoc LanNo ratings yet

- Project Report SiddharthDocument70 pagesProject Report SiddharthSiddharth PatidarNo ratings yet

- Internal Audit Checklist of Garments Manufacturing Industry - Garments AcademyDocument6 pagesInternal Audit Checklist of Garments Manufacturing Industry - Garments AcademyAriful HasanNo ratings yet

- SAEP-1150 Inspection Coverage On ProjectsDocument55 pagesSAEP-1150 Inspection Coverage On ProjectsAbdul Rahim Shaikh100% (5)

- Zara Case PPT 1Document28 pagesZara Case PPT 1estuputriwirasNo ratings yet

- CV - Lê Hoàng Tú UyênDocument1 pageCV - Lê Hoàng Tú Uyênuyenftu955No ratings yet

- Lecture Note 10. Chapter 16Document51 pagesLecture Note 10. Chapter 16nhatnguyen230602No ratings yet

- Paf Kiet (Karachi Institute of Economics & Technology) / AssignmentDocument7 pagesPaf Kiet (Karachi Institute of Economics & Technology) / AssignmentZaroon KhanNo ratings yet

- Annor Michael NarkoteyDocument100 pagesAnnor Michael Narkoteymoges tesfayeNo ratings yet

- The Dry Port Concept Theory and PracticeDocument13 pagesThe Dry Port Concept Theory and PracticeMostafa ShaheenNo ratings yet

- Logistics Operations and Supply Chain Management - XIIDocument120 pagesLogistics Operations and Supply Chain Management - XIISEBI P RAJA BABUNo ratings yet

- Shared Services ImplementationDocument30 pagesShared Services ImplementationDinav ConsultoresNo ratings yet

- Steel Castings, Carbon, For General ApplicationDocument4 pagesSteel Castings, Carbon, For General ApplicationHussein BeqaiNo ratings yet

- Business Model Canvas - NNEDocument2 pagesBusiness Model Canvas - NNEsubhasis7689No ratings yet

- Fundamentals of Limits, Fits & TolerancesDocument24 pagesFundamentals of Limits, Fits & TolerancesrajeshNo ratings yet

- Communicating ValueDocument45 pagesCommunicating Valuegoravjain1No ratings yet

- Chapter Five Institutionalizing StrategyDocument75 pagesChapter Five Institutionalizing Strategybutwalservice100% (4)

- SM MCQ's-converted-mergedDocument63 pagesSM MCQ's-converted-mergedIshandeep SinghNo ratings yet

- Proses Manufaktur (Proses Tempa)Document34 pagesProses Manufaktur (Proses Tempa)PRADITYO PUTRA PURNOMO ,No ratings yet