Professional Documents

Culture Documents

Ghousia College of Engineering Ramanagaram: I Internal Assessment

Ghousia College of Engineering Ramanagaram: I Internal Assessment

Uploaded by

SyedZameerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ghousia College of Engineering Ramanagaram: I Internal Assessment

Ghousia College of Engineering Ramanagaram: I Internal Assessment

Uploaded by

SyedZameerCopyright:

Available Formats

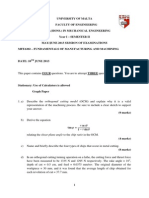

Ghousia College of Engineering Ramanagaram

DEPARTMENT OF MECHANICAL ENGINEERING

IV SEM B.E, B Sec

Sub code: 10ME45 MANUFACTURING PROESS-II Time: 1hr

Date: 16-03-2016 I Internal Assessment Max. Marks: 25

Note: Answer any TWO full Questions.

1.a. With suitable sketches. Explain the different types of chips formed during machining (6Marks)

b. Explain the fallowing with a neat sketch.

i) Back Rake Angle, ii) Side cutting edge angle, iii) End Relief Angle, iii) Nose radius (6Marks)

2. a Explain with sketch Merchants circle of force analysis (6Mark)

b. Explain the differences between Orthogonal and Oblique cutting giving one example

of each. (6Marks)

3. a The fallowing data was obtained during orthogonal cutting on a workpiece material

Chip thickness ratio=0.45mm,width of cut = 8.5mm,feed = 0.25mm/rev,cutting force

= 113kg, Thurst force= 29.5 kg, Cutting speed was 150m/min,Cutting speed was 150m/min

and the rake angle was+100 .Calculate the fallowing

i).Chip thickness ratio ii).Chip reduction coefficient iii).Shear angle iv).Velocity along chip/tool face

v).Frictional force along tool face vi).Shear stress vii).Power required for cutting (12Marks)

Sign of Staff in charge Sign of H.O.D

Ghousia College of Engineering Ramanagaram

DEPARTMENT OF MECHANICAL ENGINEERING

IV SEM B.E, B Sec

Sub code: 10ME45 MANUFACTURING PROESS-II Time: 1hr

Date: 16-03-2016 I Internal Assessment Max. Marks: 25

Note: Answer any TWO full Questions.

1.a. With suitable sketches. Explain the different types of chips formed during machining (6Marks)

b. Explain the fallowing with a neat sketch.

i) Back Rake Angle, ii) Side cutting edge angle, iii) End Relief Angle, iii) Nose radius (6 Marks)

2. a Explain with sketch Merchants circle of force analysis (6Mark)

b. Explain the differences between Orthogonal and Oblique cutting giving one example

of each. (6Marks)

3. a The fallowing data was obtained during orthogonal cutting on a workpiece material

Chip thickness ratio=0.45mm,width of cut = 8.5mm,feed = 0.25mm/rev,cutting force

= 113kg, Thurst force= 29.5 kg, Cutting speed was 150m/min,Cutting speed was 150m/min

and the rake angle was+100 .Calculate the fallowing

i).Chip thickness ratio ii).Chip reduction coefficient iii).Shear angle iv).Velocity along chip/tool face

v).Frictional force along tool face vi).Shear stress vii).Power required for cutting (12Marks)

Sign of Staff in charge Sign of H.O.D

You might also like

- Selection of Liquid & Vapour SeparatorDocument33 pagesSelection of Liquid & Vapour SeparatorVismit BansalNo ratings yet

- Force: 'A' TwoDocument11 pagesForce: 'A' TwoApaar PandeyNo ratings yet

- Final Examination SEMESTER I, SESSION2014/2015Document13 pagesFinal Examination SEMESTER I, SESSION2014/2015Mohamad Yusuf HelmiNo ratings yet

- 53112-MT - Theory of Metal Cutting & Tool DesignDocument2 pages53112-MT - Theory of Metal Cutting & Tool Designhari0118No ratings yet

- PUT Paper of Manufacturing Science II (2019-20)Document3 pagesPUT Paper of Manufacturing Science II (2019-20)Tulsi ChouhanNo ratings yet

- Theory of Metal CuttingDocument2 pagesTheory of Metal CuttingSohan RaoNo ratings yet

- Btech Mech Plastic 5 Sem Machining Science and Technology Pcme4304 2020Document2 pagesBtech Mech Plastic 5 Sem Machining Science and Technology Pcme4304 2020BAPUJI KUMAR SAHOONo ratings yet

- Question Bank For Machining and MetrologyDocument7 pagesQuestion Bank For Machining and MetrologyAbhisheak DineshNo ratings yet

- Suresh Gyan Vihar University: τ / P = r (1-µr) /1+rDocument3 pagesSuresh Gyan Vihar University: τ / P = r (1-µr) /1+rSonu ChhipaNo ratings yet

- EMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Document4 pagesEMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Charles OndiekiNo ratings yet

- SHEETSDocument13 pagesSHEETSXHaMzAXNo ratings yet

- EMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Document4 pagesEMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Charles OndiekiNo ratings yet

- 2021 22jun 2022IVRegularAR20MECH20ME403MetalCutting&MachineToolsDocument2 pages2021 22jun 2022IVRegularAR20MECH20ME403MetalCutting&MachineToolsJury.rahulNo ratings yet

- Question BankDocument48 pagesQuestion Banksanjai kumarNo ratings yet

- Slip TestDocument3 pagesSlip TestSaravanan MathiNo ratings yet

- Machine Tool Tech.Document7 pagesMachine Tool Tech.Shashi Bhushan PatelNo ratings yet

- Metal Cutting & Machine ToolsDocument4 pagesMetal Cutting & Machine Toolstumati venkata vinayNo ratings yet

- IPE 203 Fall 2020 Mist (Sec A)Document2 pagesIPE 203 Fall 2020 Mist (Sec A)Ayesha MalihaNo ratings yet

- 2017 Dec Intermediate 2 Exam ME IDocument2 pages2017 Dec Intermediate 2 Exam ME IshanthakumargcNo ratings yet

- P.E.S. College of Engineering, Mandya - 571 401Document2 pagesP.E.S. College of Engineering, Mandya - 571 401coolmagaNo ratings yet

- Mee 210-Ipe 210.Document2 pagesMee 210-Ipe 210.dreamivory29No ratings yet

- Tools Design Question Paper 2021 CVSRDocument2 pagesTools Design Question Paper 2021 CVSRRadha Krishna100% (1)

- 2013Document4 pages2013AmyRapaNo ratings yet

- Tutorial SheetDocument21 pagesTutorial Sheetankita awasthiNo ratings yet

- 5th Sem. / Mechanical Engg. (F.T.) Subject: Workshop Technology - III (F.T.)Document2 pages5th Sem. / Mechanical Engg. (F.T.) Subject: Workshop Technology - III (F.T.)Neat & Clean ReviewNo ratings yet

- (A) (C) (D) (E) (0 (G) (H) (, Fi) 2. (A) Formation. (B)Document2 pages(A) (C) (D) (E) (0 (G) (H) (, Fi) 2. (A) Formation. (B)api-279049687No ratings yet

- MT 2labDocument32 pagesMT 2labPRINCE MATHEWNo ratings yet

- Anna University Exam Paper Theory of Metal Cutting: Production EngineeringDocument3 pagesAnna University Exam Paper Theory of Metal Cutting: Production EngineeringAkash Kumar DevNo ratings yet

- CAT I - EMMU 7241 - Machine Tool Vibrations and Cutting DynamicsDocument2 pagesCAT I - EMMU 7241 - Machine Tool Vibrations and Cutting DynamicsCharles OndiekiNo ratings yet

- University Exam PaperDocument1 pageUniversity Exam PapermehuoyeyeNo ratings yet

- Assignment 1 ENG 173 METAL FORMING First 2023 2024Document2 pagesAssignment 1 ENG 173 METAL FORMING First 2023 2024toursena44No ratings yet

- Mantech Tie 6122 Assignment Bouquet Oct 2019 PDFDocument4 pagesMantech Tie 6122 Assignment Bouquet Oct 2019 PDFNativity MabasaNo ratings yet

- Unit Test I. 1920Document2 pagesUnit Test I. 1920Balakrushna ParkaleNo ratings yet

- Jntuworld: R09 Set No. 2Document6 pagesJntuworld: R09 Set No. 2Dr-Asit Kumar ParidaNo ratings yet

- Key 2Document22 pagesKey 2Jury.rahulNo ratings yet

- W 2019 A - Merged - WatermarkDocument18 pagesW 2019 A - Merged - WatermarkDivya ChandewarNo ratings yet

- A New Dynamic Model For Drilling and Reaming Processes Yang2002Document13 pagesA New Dynamic Model For Drilling and Reaming Processes Yang2002RihabChommakhNo ratings yet

- MEC 205 Ass1Document1 pageMEC 205 Ass1tushar2323No ratings yet

- Assignment-I-MC &MT PDFDocument2 pagesAssignment-I-MC &MT PDFChadaram JagadishNo ratings yet

- Theory of Metal Cutting: Course ContentsDocument177 pagesTheory of Metal Cutting: Course Contentshassan tagNo ratings yet

- Working Parameters Drilling Boring Shaper MillingDocument2 pagesWorking Parameters Drilling Boring Shaper MillingVishal Kumar SinghNo ratings yet

- RK University: InstructionsDocument3 pagesRK University: InstructionsShiraj SunasaraNo ratings yet

- EMG 1205 Manufactruing Processes II - Exam 2022-23Document3 pagesEMG 1205 Manufactruing Processes II - Exam 2022-23kiokocurtisNo ratings yet

- Assignment 1 ENG 173 METAL FORMINGDocument2 pagesAssignment 1 ENG 173 METAL FORMINGtoursena44No ratings yet

- 10.1007s40430 019 1708 9Document24 pages10.1007s40430 019 1708 9Turtle ArtNo ratings yet

- MC&TDDocument4 pagesMC&TDGopal Krishan0% (1)

- Manufacturing Technology - IIDocument2 pagesManufacturing Technology - IIMANOJ MNo ratings yet

- Compre 15-16 Sem1 With Soln (Charsichoco)Document4 pagesCompre 15-16 Sem1 With Soln (Charsichoco)Jasdeep SinghNo ratings yet

- Engi MatarialDocument8 pagesEngi MatarialAnirban BarmonNo ratings yet

- Machining E BookDocument37 pagesMachining E BookunitybeginsathomeNo ratings yet

- P.E.S. College of Engineering, Mandya - 571 401Document2 pagesP.E.S. College of Engineering, Mandya - 571 401coolmagaNo ratings yet

- 4 Hours / 100 Marks: InstructionsDocument36 pages4 Hours / 100 Marks: InstructionsPandit BarelaNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.Priyadharshan RNo ratings yet

- Homework Solution p3Document10 pagesHomework Solution p3Petro ManNo ratings yet

- NR-310305-Design of Machine ElementsDocument9 pagesNR-310305-Design of Machine ElementsSrinivasa Rao GNo ratings yet

- Describe The Various Programming Modes of A Robotic SystemDocument2 pagesDescribe The Various Programming Modes of A Robotic Systemgovind raoNo ratings yet

- Manufacturing Engineering-19Document1 pageManufacturing Engineering-19SameerChauhanNo ratings yet

- 3-1 MT (Nov 2009 Regular)Document5 pages3-1 MT (Nov 2009 Regular)micmechNo ratings yet

- Advanced Tool Design Question PaperDocument1 pageAdvanced Tool Design Question PaperMr. N. GnaneswaranNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

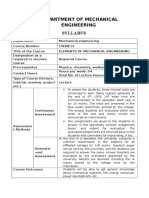

- Admission Intake in The Programme: 4. Students' PerformanceDocument3 pagesAdmission Intake in The Programme: 4. Students' PerformanceSyedZameerNo ratings yet

- Computer Aided Engineering DrawingDocument11 pagesComputer Aided Engineering DrawingSyedZameerNo ratings yet

- Review of Transducer and SensorDocument113 pagesReview of Transducer and SensorSyedZameerNo ratings yet

- Non-Traditional MachiningDocument48 pagesNon-Traditional MachiningSyedZameerNo ratings yet

- Programming Methods of RobotsDocument2 pagesProgramming Methods of RobotsSyedZameer100% (2)

- Analysis of Autaomated Flow LinesDocument1 pageAnalysis of Autaomated Flow LinesSyedZameerNo ratings yet

- Work Volume of RobotDocument4 pagesWork Volume of RobotSyedZameer100% (4)

- Objectives For Mechatronic & MicroprocessorDocument3 pagesObjectives For Mechatronic & MicroprocessorSyedZameerNo ratings yet

- SYLLABUSDocument6 pagesSYLLABUSSyedZameerNo ratings yet

- Date: 18-09-2015 To Whom Ever So It May ConcernDocument4 pagesDate: 18-09-2015 To Whom Ever So It May ConcernSyedZameerNo ratings yet

- Alumni Survey Form - Peos: Ghousia College of Engineering, Ramanagaram Department of Mechanical EngineeringDocument4 pagesAlumni Survey Form - Peos: Ghousia College of Engineering, Ramanagaram Department of Mechanical EngineeringSyedZameerNo ratings yet

- What Is Automation?: Automation Encompasses Many Vital Elements, Systems, and Job FunctionsDocument3 pagesWhat Is Automation?: Automation Encompasses Many Vital Elements, Systems, and Job FunctionsSyedZameerNo ratings yet

- New Doc 1Document1 pageNew Doc 1SyedZameerNo ratings yet

- Module 1: Overview of Smart MaterialsDocument23 pagesModule 1: Overview of Smart MaterialsSyedZameerNo ratings yet

- Bio CAD WSDocument18 pagesBio CAD WSSyedZameerNo ratings yet

- List of VTU JournalsDocument5 pagesList of VTU JournalsSyedZameerNo ratings yet

- Samiulla KaziDocument4 pagesSamiulla KaziTHE UNCHANGED ONENo ratings yet

- BSB61218 - Advanced Diploma of Project Management: This Study Resource WasDocument7 pagesBSB61218 - Advanced Diploma of Project Management: This Study Resource WasAroosa MirzaNo ratings yet

- Reading Lesson Plan PortfolioDocument3 pagesReading Lesson Plan Portfolioapi-543319841No ratings yet

- Chantal Udasco)Document70 pagesChantal Udasco)yantiNo ratings yet

- 4-Unit 2Document10 pages4-Unit 2sandraNo ratings yet

- Ministry of Defence KDF Recruitment Advertisement 2019 1Document6 pagesMinistry of Defence KDF Recruitment Advertisement 2019 1MasterNo ratings yet

- Sri Lanka Top ScientistsDocument147 pagesSri Lanka Top ScientistsKasun Ranga WijeweeraNo ratings yet

- C HFI: Securing ForensicDocument8 pagesC HFI: Securing Forensickauane lysienNo ratings yet

- Beautiful Letter Written by A Father To His Son ?Document2 pagesBeautiful Letter Written by A Father To His Son ?Musa Eve AikehNo ratings yet

- Should The Drinking Age Be LoweredDocument4 pagesShould The Drinking Age Be Loweredapi-547168074No ratings yet

- Sahipa ResumeDocument2 pagesSahipa ResumeVia SahipaNo ratings yet

- Assessment Activity (Reflection Paper)Document1 pageAssessment Activity (Reflection Paper)Jenny DonascoNo ratings yet

- Assessment Test Test (Physics, Chemistry & Mathematics) PhysicsDocument13 pagesAssessment Test Test (Physics, Chemistry & Mathematics) PhysicsPratham MaanNo ratings yet

- Overview of The Curriculum Development ProcessDocument13 pagesOverview of The Curriculum Development ProcessAnouMalieNo ratings yet

- CAT6A Reference GuideDocument56 pagesCAT6A Reference GuideMarcilio CarvalhoNo ratings yet

- CROSS TREE - Biznis Planovi Za Proizvodnju Sadnica Jabuke, Leske, Trešnje, Višnje, Vinove LozeDocument90 pagesCROSS TREE - Biznis Planovi Za Proizvodnju Sadnica Jabuke, Leske, Trešnje, Višnje, Vinove LozeNikola TesanovicNo ratings yet

- Kerangka Penilaian Guru Terhadap Pengajaran Kursus Tarannum KKQ Berdasarkan Konsep Penilaian CippDocument8 pagesKerangka Penilaian Guru Terhadap Pengajaran Kursus Tarannum KKQ Berdasarkan Konsep Penilaian CippzulkifliabdmubiNo ratings yet

- LearnEnglish Listening B1 A Team Meeting About DiversityDocument2 pagesLearnEnglish Listening B1 A Team Meeting About Diversitysyaza athirahNo ratings yet

- Resume - Mackenzie Cullen 1Document1 pageResume - Mackenzie Cullen 1api-502329402No ratings yet

- Albert Bandura: Free Powerpoint Templates Free Powerpoint TemplatesDocument17 pagesAlbert Bandura: Free Powerpoint Templates Free Powerpoint Templatesjana corpuzNo ratings yet

- Kawsar-Cv - Docx CVDocument2 pagesKawsar-Cv - Docx CVTic ONNo ratings yet

- Uganda Technical College Bushenyi Construction Materials NotesDocument36 pagesUganda Technical College Bushenyi Construction Materials Notesokwii DavidNo ratings yet

- Lesson 5 Unit PlanDocument8 pagesLesson 5 Unit Planapi-425144490No ratings yet

- Esl NewsletterDocument1 pageEsl Newsletterapi-237226873No ratings yet

- 2023-2024 MHPS School CalendarDocument1 page2023-2024 MHPS School CalendarKTLO NewsNo ratings yet

- LC - Little ChampsDocument28 pagesLC - Little ChampszumrotiNo ratings yet

- Math Gingerbread ActivityDocument3 pagesMath Gingerbread Activityapi-501803778No ratings yet

- School Grade Level Teacher Charish Mae O. Demegillo Learning Area Quarter Date: Time: SectionsDocument4 pagesSchool Grade Level Teacher Charish Mae O. Demegillo Learning Area Quarter Date: Time: SectionsRoss AnaNo ratings yet

- WebSphere DataPower SOA Appliances and XSLT Part 1Document23 pagesWebSphere DataPower SOA Appliances and XSLT Part 1Gema Alcolado AyusoNo ratings yet