Professional Documents

Culture Documents

Input: KN.M 59.00 ### KN KN MM 500 MM 200 MM 24 MM 16 MM 24 MM 100 MM 100

Input: KN.M 59.00 ### KN KN MM 500 MM 200 MM 24 MM 16 MM 24 MM 100 MM 100

Uploaded by

maheshbandhamCopyright:

Available Formats

You might also like

- Crane Wheel Load CalculationDocument12 pagesCrane Wheel Load Calculationmaheshbandham100% (2)

- Socketed Steel H and Bored Pile CalculationDocument13 pagesSocketed Steel H and Bored Pile CalculationYUK LAM WONG100% (2)

- Crane Bracket - AvestaDocument55 pagesCrane Bracket - AvestamaheshbandhamNo ratings yet

- AISC2005 Anchor Bolt Version22042015 FixDocument8 pagesAISC2005 Anchor Bolt Version22042015 FixThuyTranNo ratings yet

- Aisc Chevron BraceDocument42 pagesAisc Chevron Bracegvlanusha100% (1)

- Deck SheetDocument2 pagesDeck SheetmaheshbandhamNo ratings yet

- Excel Anchor Bolt Calculator-1Document2 pagesExcel Anchor Bolt Calculator-1teesk200350% (2)

- Key & Solutions: Stress F KX Modulus StressDocument5 pagesKey & Solutions: Stress F KX Modulus StressSyed Owais GillaniNo ratings yet

- Base Plate - LSDDocument14 pagesBase Plate - LSDrelu59No ratings yet

- Kirby - Typ Base PlateDocument19 pagesKirby - Typ Base PlateNitesh Singh100% (1)

- 2 ConnectionDocument18 pages2 Connectionssikha100% (1)

- Calculation Sheet: Design PhilosophyDocument18 pagesCalculation Sheet: Design PhilosophyrammohanNo ratings yet

- Typ-Base PlateDocument11 pagesTyp-Base PlateManoj Jaiswal100% (2)

- Bolted Connection Angle Brace TensionDocument2 pagesBolted Connection Angle Brace TensionRajib MaharjanNo ratings yet

- Design of Base PlateDocument14 pagesDesign of Base PlateSunidhi ItagiNo ratings yet

- Ub 254 Fin Plate To Column Web - LRFDDocument10 pagesUb 254 Fin Plate To Column Web - LRFDihpeterNo ratings yet

- R.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateDocument10 pagesR.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateMarkNo ratings yet

- Hollow Section Bracing Connetion - LRFDDocument5 pagesHollow Section Bracing Connetion - LRFDkalpanaadhiNo ratings yet

- Bracing Connection RefDocument5 pagesBracing Connection Refsukarma acharyaNo ratings yet

- Pinned Base Anchor Bolt DesignDocument2 pagesPinned Base Anchor Bolt Designkhan84mind100% (1)

- Design of Builtup SectionDocument4 pagesDesign of Builtup SectiondsanandaNo ratings yet

- Moment Connection Portal FrameDocument18 pagesMoment Connection Portal Frametmssorin100% (1)

- Pile Cap of CrystalDocument19 pagesPile Cap of CrystalPriyank MotivarasNo ratings yet

- 6-Bracing Connection - TDocument2 pages6-Bracing Connection - TMUTHUKKUMARAMNo ratings yet

- Design of Column Using Channel (Front)Document8 pagesDesign of Column Using Channel (Front)Nitesh SinghNo ratings yet

- Steel Connection - IS CodeDocument4 pagesSteel Connection - IS CodeAmit Ghosh75% (4)

- Cleat Angle ConnectionDocument3 pagesCleat Angle ConnectionSrishti Project ConsultantsNo ratings yet

- Design of Moment ConnectionDocument2 pagesDesign of Moment ConnectionDushyantha Jayawardena100% (2)

- AISC360-05 LRFD Shear Bolted Connection CheckDocument12 pagesAISC360-05 LRFD Shear Bolted Connection CheckMario FeghaliNo ratings yet

- Pinned Base (I-Section) : Design CapacitiesDocument8 pagesPinned Base (I-Section) : Design CapacitiesAwais HameedNo ratings yet

- Shear Steel ConnectionDocument3 pagesShear Steel ConnectionНемања Караклајић100% (1)

- Calculation/ Sketch: Site: Dmm:Tower 10/4/2019 Job No.: ### Beam: SB1 TEH Sheet NoDocument23 pagesCalculation/ Sketch: Site: Dmm:Tower 10/4/2019 Job No.: ### Beam: SB1 TEH Sheet NoPlacido O. Fabillo, JR. [aldev]No ratings yet

- Embeddedplate With StudsDocument78 pagesEmbeddedplate With StudsAkhil VNNo ratings yet

- Simple Shear Connection DesignDocument2 pagesSimple Shear Connection DesignElvin SandajanNo ratings yet

- LRFD Steel BeamDocument30 pagesLRFD Steel Beam정영철100% (1)

- Column Splice 356 x368x129 Column - WeldDocument4 pagesColumn Splice 356 x368x129 Column - WeldNiraj Shinde100% (1)

- Base Plate Design (From RCC ColDocument9 pagesBase Plate Design (From RCC ColJanya AssociatesNo ratings yet

- Bolted ConnectionDocument79 pagesBolted ConnectionMEPNo ratings yet

- Base Plate Design (Fixed Base)Document3 pagesBase Plate Design (Fixed Base)Saravana NNo ratings yet

- Steel Connections v1.3Document83 pagesSteel Connections v1.3Mateus GehlenNo ratings yet

- PLATE Beam To BeamDocument73 pagesPLATE Beam To BeamKutty Mansoor100% (1)

- Design of Base PlateDocument258 pagesDesign of Base PlateDushyantha Jayawardena100% (2)

- Beam Column Connection-Design2Document16 pagesBeam Column Connection-Design2abdul kareeNo ratings yet

- Moment ConnectionDocument15 pagesMoment Connectionnitin400No ratings yet

- Shear Connection - Is 800-ModifiedDocument159 pagesShear Connection - Is 800-ModifiedDarshan Panchal100% (1)

- Flust-Extended End Plate ConnectionDocument8 pagesFlust-Extended End Plate ConnectionamachmouchiNo ratings yet

- PDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDocument29 pagesPDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDEVANG VIJAY SHINDENo ratings yet

- Base Plate DesignDocument38 pagesBase Plate DesignRitwick MishraNo ratings yet

- Connection Design SheetDocument47 pagesConnection Design SheetStephen James100% (1)

- Fin Plate Connection DesignDocument10 pagesFin Plate Connection DesigncklconNo ratings yet

- Shear Connections (Steel-Steel)Document14 pagesShear Connections (Steel-Steel)Izzan SabelloNo ratings yet

- Advance Connection Design - 1Document298 pagesAdvance Connection Design - 1amitkumar8946No ratings yet

- Calculation For Moment Connection - Type ADocument15 pagesCalculation For Moment Connection - Type ANitesh Singh100% (1)

- Anchor Bolt Design IS Code LSDDocument56 pagesAnchor Bolt Design IS Code LSDajNo ratings yet

- Cleat Connection For PlatformsDocument29 pagesCleat Connection For PlatformsRajveer Singh100% (1)

- Design of Moment Connection (Welded Type) : Beam Properties: ISB 113.5x113.5x4.5 Column Properties: ISMC 200Document10 pagesDesign of Moment Connection (Welded Type) : Beam Properties: ISB 113.5x113.5x4.5 Column Properties: ISMC 200Rajib MaharjanNo ratings yet

- Beam To Column End Plate ConnectionDocument10 pagesBeam To Column End Plate ConnectionParchuri PraveenNo ratings yet

- Base Plate Dan Anchor Bolt Calculation: Connection DesignDocument21 pagesBase Plate Dan Anchor Bolt Calculation: Connection DesignSurya FahmiNo ratings yet

- Loads:: Donnees de Calcul ChargesDocument6 pagesLoads:: Donnees de Calcul ChargesAdekimi EmmanuelNo ratings yet

- 4 stiffened-WH500X400X12X25-WH500X400X12X25Document7 pages4 stiffened-WH500X400X12X25-WH500X400X12X25phanikrishnabNo ratings yet

- Welded Splice Connection-R2Document33 pagesWelded Splice Connection-R2Anonymous cG5MyHM100% (1)

- Eccentric Shear Connection Analysis of Bolt GroupDocument4 pagesEccentric Shear Connection Analysis of Bolt GroupjaffnaNo ratings yet

- Steel-Angle Bracing Design-1Document12 pagesSteel-Angle Bracing Design-1rohitbhagat005No ratings yet

- Moment Connection DETAIL 2Document5 pagesMoment Connection DETAIL 2way2vaseemNo ratings yet

- Frame ConnectionsDocument14 pagesFrame ConnectionsShawkat Ali KhanNo ratings yet

- Typ Base PlateDocument19 pagesTyp Base PlateumeshNo ratings yet

- HIGH BAY RoofNav-RatingsCalculatorDocument2 pagesHIGH BAY RoofNav-RatingsCalculatormaheshbandhamNo ratings yet

- BOLTED END PLATE ReportDocument19 pagesBOLTED END PLATE Reportmaheshbandham100% (1)

- SHEAR TAB LARGE PLATE ReportDocument14 pagesSHEAR TAB LARGE PLATE ReportmaheshbandhamNo ratings yet

- Design of Base PlateDocument161 pagesDesign of Base PlatemaheshbandhamNo ratings yet

- BOLT PLATE ReportDocument17 pagesBOLT PLATE ReportmaheshbandhamNo ratings yet

- Base PlateDocument15 pagesBase PlatemaheshbandhamNo ratings yet

- A. Material Properties: SC1 Base Plate Analysis and Design Project (Based On AISC LRFD - 2005) BuildingDocument8 pagesA. Material Properties: SC1 Base Plate Analysis and Design Project (Based On AISC LRFD - 2005) BuildingmaheshbandhamNo ratings yet

- Project Calculation Sheets Eng. Check.: Sec. 1 Shear TorsionDocument2 pagesProject Calculation Sheets Eng. Check.: Sec. 1 Shear TorsionmaheshbandhamNo ratings yet

- 1 Input Data: Hilti PROFIS Engineering 3.0.64Document10 pages1 Input Data: Hilti PROFIS Engineering 3.0.64maheshbandhamNo ratings yet

- Structural Steel Standards and Specification PDFDocument1 pageStructural Steel Standards and Specification PDFmaheshbandhamNo ratings yet

- 10 MT Crane RWB FORDocument5 pages10 MT Crane RWB FORmaheshbandhamNo ratings yet

- Purlin - ConnectionDocument8 pagesPurlin - ConnectionmaheshbandhamNo ratings yet

- Base Plate For Tension1Document7 pagesBase Plate For Tension1maheshbandhamNo ratings yet

- Brace Load CalculationDocument14 pagesBrace Load CalculationmaheshbandhamNo ratings yet

- Concrete (Non-Cracked) Static/ Quasi-StaticDocument8 pagesConcrete (Non-Cracked) Static/ Quasi-StaticmaheshbandhamNo ratings yet

- LM&& LM&& LM&& LM&&Document17 pagesLM&& LM&& LM&& LM&&maheshbandhamNo ratings yet

- List of Agencies by StateDocument84 pagesList of Agencies by Statemaheshbandham100% (1)

- Anchor Bolt and Base Plate Design CheckDocument48 pagesAnchor Bolt and Base Plate Design Checkmaheshbandham100% (1)

- Base Plate Design PDFDocument1 pageBase Plate Design PDFmaheshbandhamNo ratings yet

- Result Summary - Overall: Pass Pass Pass PassDocument17 pagesResult Summary - Overall: Pass Pass Pass PassmaheshbandhamNo ratings yet

- Angle Brace ConnectionDocument20 pagesAngle Brace Connectionmaheshbandham100% (1)

- Cusack PHD ThesisDocument142 pagesCusack PHD ThesisJitendra KumarNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- G11 - LP Fluid MechanicsDocument14 pagesG11 - LP Fluid MechanicsJerry Lloyd BocadoNo ratings yet

- Light and Sound 2 MSDocument10 pagesLight and Sound 2 MSSumira ZamanNo ratings yet

- Impact of JetDocument8 pagesImpact of JetOmar Faruqi100% (1)

- Base Isolation For Multistoried Buildings With Lead Rubber BearingDocument5 pagesBase Isolation For Multistoried Buildings With Lead Rubber BearingFelipeNo ratings yet

- Difusión MethodsDocument5 pagesDifusión MethodsKeily VilcarromeroNo ratings yet

- Guia Caida LibreDocument14 pagesGuia Caida LibreMåiirå SDj K. ZYtNo ratings yet

- Band Theory?: J. Phys. Chem. SolidsDocument5 pagesBand Theory?: J. Phys. Chem. Solidsgarguz94No ratings yet

- Latest Lifting LugDocument8 pagesLatest Lifting Lugjagannadha varmaNo ratings yet

- FM 204Document2 pagesFM 204Muzaffar AlamNo ratings yet

- 20 Zienkiewicz, O. C., Watson, M., and King, I. P., A Numerical Method of Visco-Elastic PDFDocument21 pages20 Zienkiewicz, O. C., Watson, M., and King, I. P., A Numerical Method of Visco-Elastic PDFTariq MahmoodNo ratings yet

- High Voltage EngineeringDocument36 pagesHigh Voltage EngineeringsukandeNo ratings yet

- Engineering Materials and Testing IIDocument37 pagesEngineering Materials and Testing IILorie Mae BelloNo ratings yet

- Multi Degrees of Freedom SystemDocument23 pagesMulti Degrees of Freedom SystemHani BanatNo ratings yet

- Interaction Module in AbaqusDocument16 pagesInteraction Module in Abaquseureka.nitishNo ratings yet

- Ch1 Lecture 1Document32 pagesCh1 Lecture 1Wolf MoonNo ratings yet

- Sii Smith International Inc. (713) 443 - 3370: DrilcoDocument27 pagesSii Smith International Inc. (713) 443 - 3370: DrilcoIvan Dario Benavides BonillaNo ratings yet

- (1.0 Credit) : Structural Analysis and Design Sessional-IDocument34 pages(1.0 Credit) : Structural Analysis and Design Sessional-IAnonymous aE0YYlCOKNo ratings yet

- RC Phase Shift OscillatorDocument25 pagesRC Phase Shift Oscillatorahmed omarNo ratings yet

- ES 13 ProbSet 1Document2 pagesES 13 ProbSet 1Sammy Marquez50% (2)

- Regarding The Formalism of Quantum MechanicsDocument2 pagesRegarding The Formalism of Quantum MechanicsΚουταντου ΕφηNo ratings yet

- SPE Paper ReferencesDocument4 pagesSPE Paper ReferencesjamartiNo ratings yet

- Geotubes Proceeding CSt2011 FINAL PDFDocument13 pagesGeotubes Proceeding CSt2011 FINAL PDFathanasius_adiNo ratings yet

- HC Verma Gauss Law SolutionsDocument31 pagesHC Verma Gauss Law SolutionsSakshamNo ratings yet

- II.3 Classical Laminate TheoryDocument31 pagesII.3 Classical Laminate TheoryMAURICIO NICARAGUA MENDEZNo ratings yet

- Physical Sciences P1 Grade 10 Nov 2018 EngDocument20 pagesPhysical Sciences P1 Grade 10 Nov 2018 EngNompumelelo IkkoNo ratings yet

Input: KN.M 59.00 ### KN KN MM 500 MM 200 MM 24 MM 16 MM 24 MM 100 MM 100

Input: KN.M 59.00 ### KN KN MM 500 MM 200 MM 24 MM 16 MM 24 MM 100 MM 100

Uploaded by

maheshbandhamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Input: KN.M 59.00 ### KN KN MM 500 MM 200 MM 24 MM 16 MM 24 MM 100 MM 100

Input: KN.M 59.00 ### KN KN MM 500 MM 200 MM 24 MM 16 MM 24 MM 100 MM 100

Uploaded by

maheshbandhamCopyright:

Available Formats

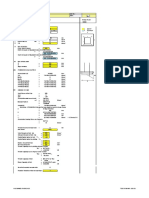

DESIGN SHEET 1 of 11

JOB No. J-1229 Rev. No. 2

Building-A

DQ.No. 104-316 Date 1-Jun-05

CLIENT MULTICOLOR STEEL LTDDesigned By KP

DESCRIPTION BASE CONNECTION A Checked By MDP

DESIGN OF FIXED BASE CONNECTION

INPUT DL+LL+ELDL+WL

Bending Moment Kn.m 59.00 ###

Shear Force (Fx) Kn 13.70 58.50

Axial Force (Fy) Kn 53.70 29.33

Web Depth mm 500

Flange Depth mm 200

Bolts Dia mm 24

Embed length (Le mm 735

No. Of Bolts (n) 16

Plate Thickness (t mm 24

Pitch (p) mm 100

guage (g) mm 100

WEB DEPTH : 500 mm

PLATE LENGTH : 710 mm

PLATE WIDTH : 400 mm

Effective Lever arm : 516 mm

Total Tension in each extreme Bolts ( T : Maximum moment / Eff. Lever arm

[DL+LL] : 114

(DL+WL) : 393

CHECK FOR BOLT SIZE [DL+LL+EL] (DL+WL)

FORCES IN THE BOLTS Actual Actual Allowable

(Kn) (Kn) (Kn)

Max. Tension in each Bolt ( T/ 14.29 49.18

Tension due to Axial Force ( Fy 3.36 1.83

Total Tension ( P= T/10+Fy/n) 17.65 51.01 47.20 HENCE SAFE

Shear in each Bolt ( Fx/n) 0.86 3.66 31.80 HENCE SAFE

CHECK FOR THICKNESS OF PLATE

Maximum bending moment in the plate(Ma) 2P x g/ 8

( About criticle section X-X) : 17.65 x 100/8

: 1.28 Kn-M

Thickness of plate required ( t ) : 6 x Ma / f x p

: 18.33 < 24 MM HENCE SAFE

CHECK FOR COMBINED TENSION AND SHEAR

Actual Tension + Actual Shear < 1. 4

Allowable Tension Allowable Shear

(51.01 / 47.2)+(3.66 / 31.8) 1.20 < 1.4 HENCE SAFE

DESIGN SHEET 2 of 11

JOB No. J-1229 Rev. No. 2

Building-A

DQ.No. 104-316 Date 1-Jun-05

CLIENT MULTICOLOR STEEL LTDDesigned By KP

DESCRIPTION BASE CONNECTION A Checked By MDP

CHECK FOR BOLT LENGTH

Bond Stress For M25 grade Cocrete : 0.90 N/mm2

Length of bolt required : Tension in bolt/(p x bolt Dia.)x Bond stress

: 51.01 *1000/(p* 24)*0.9

: 752 mm TRY AGAIN

CHECK FOR BASE PLATE SIZE

Area of Base Plate (A) : 710x400 = 284000 mm2

Pressure over the concrete pedestal P/A +M/Z : 1.94 N/mm2

Allowable pressure below the base plate : 5.0 N/mm2

Allowable pressure > Actual pressure HENCE SAFE

888 HENCE PROVIDE : 24 mm Thick Plate/ 16 No.s 24 mm Dia Anchor Bolts.

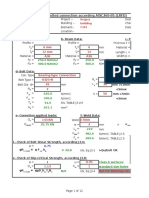

DESIGN SHEET 3 of 11

JOB No. J-1229 Rev. No. 2

Building-01

DQ.No. 104-316 Date 1-Jun-05

CLIENT MULTICOLOR STEEL LTDDesigned By KP

DESCRIPTION BASE CONNECTION B Checked By MDP

DESIGN OF PINNED BASE CONNECTION

INPUT DL+LL+EL

88 DL+WL

Shear Force (Fx) Kn 384.00 95.00

Axial Force (Fy) Kn 361.00 73.00

Web Depth mm 400

Flange Depth mm 375

Bolts Dia mm 24

Embed length (Le mm 685

No. Of Bolts (n) 4

Plate Thickness (t

mm 16

Pitch (p) mm 100

guage (g) mm 100

WEB DEPTH : 400 mm

PLATE LENGTH : 450 mm

PLATE WIDTH : 375 mm

CHECK FOR BOLT SIZE

FORCES IN THE BOLTS Actual Allowable

(Kn) (Kn)

Max. Tension in each Bolt (Fy/n ) : 18.25 47.20 HENCE SAFE

Shear in each Bolt ( Fx/n) : 23.75 31.80 HENCE SAFE

CHECK FOR THICKNESS OF PLATE

Maximum bending moment in the plate(Ma) P x g/ 4

( About criticle section X-X) : 18.25 x 100/4

: 0.46 Kn-M

Thickness of plate required ( t ) : 6 x Ma / f x p

: 10.96 < 16 MM HENCE SAFE

CHECK FOR COMBINED TENSION AND SHEAR

Actual Tension + Actual Shear

< 1. 4

Allowable Tension Allowable Shea

(18.25 / 47.2)+(23.75 / 31.8) 1.13 < 1.4 HENCE SAFE

CHECK FOR BOLT LENGTH

Bond Stress For M20 grade Cocrete : 1.00 N/mm2 (= 0.8 *1.25 )

Length of bolt required : Tension in bolt/(p x bolt Dia.)x Bond stress

: 18.25 *1000/(p* 24)*1

: 242 mm HENCE SAFE

CHECK FOR BASE PLATE SIZE

Area of Base Plate (A) : 450x375 = 168750 mm2

Pressure over the concrete pedestal (Fy(DL+LL)/A) : 2.14 N/mm2

Allowable pressure below the base plate : 5.0 N/mm2

Allowable pressure > Actual pressure HENCE SAFE

888 HENCE PROVIDE : 16 mm Thick Plate/ 4 No.s 24 mm Dia Anchor Bolts.

DESIGN SHEET 4 of 11

JOB No. J-1229 Rev. No. 2

Building-01

DQ.No. 104-316 Date 1-Jun-05

CLIENT MULTICOLOR STEEL LTDDesigned By KP

DESCRIPTION BASE CONNECTION C Checked By MDP

DESIGN OF PINNED BASE CONNECTION

INPUT DL+LL+EL

88 DL+WL

Shear Force (Fx) Kn 21.00 64.00

Axial Force (Fy) Kn 58.00 63.00

Web Depth mm 270

Flange Depth mm 150

Bolts Dia mm 20

Embed length (Le mm 535

No. Of Bolts (n) 4

Plate Thickness (t

mm 16

Pitch (p) mm 100

guage (g) mm 100

WEB DEPTH : 270 mm

PLATE LENGTH : 292 mm

PLATE WIDTH : 150 mm

CHECK FOR BOLT SIZE

FORCES IN THE BOLTS Actual Allowable

(Kn) (Kn)

Max. Tension in each Bolt (Fy/n ) : 15.75 32.70 HENCE SAFE

Shear in each Bolt ( Fx/n) : 16.00 21.30 HENCE SAFE

CHECK FOR THICKNESS OF PLATE

Maximum bending moment in the plate(Ma) P x g/ 4

( About criticle section X-X) : 15.75 x 100/4

: 0.39 Kn-M

Thickness of plate required ( t ) : 6 x Ma / f x p

: 10.19 < 16 MM HENCE SAFE

CHECK FOR COMBINED TENSION AND SHEAR

Actual Tension + Actual Shear

< 1. 4

Allowable Tension Allowable Shea

(15.75 / 32.7)+(16 / 21.3) = 1.23 < 1.4 HENCE SAFE

CHECK FOR BOLT LENGTH

Bond Stress For M20 grade Cocrete : 1.00 N/mm2 (= 0.8 *1.25 )

Length of bolt required : Tension in bolt/(p x bolt Dia.)x Bond stress

: 15.75 *1000/(p* 20)*1

: 251 mm HENCE SAFE

CHECK FOR BASE PLATE SIZE

Area of Base Plate (A) : 292x150 = 43800 mm2

Pressure over the concrete pedestal (Fy(DL+LL)/A) : 1.32 N/mm2

Allowable pressure below the base plate : 5.0 N/mm2

Allowable pressure > Actual pressure HENCE SAFE

888 HENCE PROVIDE : 16 mm Thick Plate/ 4 No.s 20 mm Dia Anchor Bolts.

DESIGN SHEET 5 of 11

JOB No. J-1229 Rev. No. 2

Building-01

DQ.No. 104-316 Date 1-Jun-05

CLIENT MULTICOLOR STEEL LTDDesigned By KP

DESCRIPTION BASE CONNECTION D Checked By MDP

DESIGN OF PINNED BASE CONNECTION

INPUT DL+LL

88 DL+WL

Shear Force (Fx) Kn 2.00 0.00

Axial Force (Fy) Kn 34.00 56.00

Web Depth mm 316

Flange Depth mm 150

Bolts Dia mm 32

Embed length (Le mm 975

No. Of Bolts (n) 4

Plate Thickness (t

mm 16

Pitch (p) mm 100

guage (g) mm 100

WEB DEPTH : 316 mm

PLATE LENGTH : 366 mm

PLATE WIDTH : 170 mm

CHECK FOR BOLT SIZE

FORCES IN THE BOLTS Actual Allowable

(Kn) (Kn)

Max. Tension in each Bolt (Fy/n ) : 14.00 65.00 HENCE SAFE

Shear in each Bolt ( Fx/n) : 0.00 56.50 HENCE SAFE

CHECK FOR THICKNESS OF PLATE

Maximum bending moment in the plate(Ma) P x g/ 4

( About criticle section X-X) : 14 x 100/4

: 0.35 Kn-M

Thickness of plate required ( t ) : 6 x Ma / f x p

: 9.60 < 16 MM HENCE SAFE

CHECK FOR COMBINED TENSION AND SHEAR

Actual Tension + Actual Shear

< 1. 4

Allowable Tension Allowable Shea

(14 / 65)+(0 / 56.5) = 0.22 < 1.4 HENCE SAFE

CHECK FOR BOLT LENGTH

Bond Stress For M20 grade Cocrete : 1.00 N/mm2 (= 0.8 *1.25 )

Length of bolt required : Tension in bolt/(p x bolt Dia.)x Bond stress

: 14 *1000/(p* 32)*1

: 139 mm HENCE SAFE

CHECK FOR BASE PLATE SIZE

Area of Base Plate (A) : 366x170 = 62220 mm2

Pressure over the concrete pedestal (Fy(DL+LL)/A) : 0.55 N/mm2

Allowable pressure below the base plate : 5.0 N/mm2

Allowable pressure > Actual pressure HENCE SAFE

888 HENCE PROVIDE : 16 mm Thick Plate/ 4 No.s 32 mm Dia Anchor Bolts.

DESIGN SHEET 6 of 11

JOB No. J-1229 Rev. No. 2

Building-A

DQ.No. 104-316 Date 1-Jun-05

CLIENT MULTICOLOR STEEL LTD Designed By KP

DESCRIPTION HAUNCH CONNECTION Checked By MDP

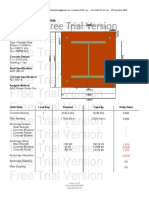

DESIGN OF HAUNCH CONNECTION

INPUT 6

Bending Moment Kn.m ###

Shear Force (Fx) Kn 417.00

pitch

Axial Force (Fy) Kn 305.00

Web Depth mm 1500

Flange Depth mm 400

Lengthof Plate

WebDepth

Bolts Dia mm 32

No. Of Bolts (n) 24

Plate Thickness (t mm 32

Pitch (p) mm 130

guage (g) mm 130

guage

Width of Plate

WEB DEPTH : 1500 mm

PLATE LENGTH : 1760 mm

PLATE WIDTH : 520 mm

Effective Lever arm : 1300 mm

Total Tension in each extreme Bolts ( T ) : Maximum moment / Eff. Lever arm

: 453/600

: 2112.31 Kn

CHECK FOR BOLT SIZE

FORCES IN THE BOLTS Actual llowable

(Kn) (Kn)

Max. Tension in each Bolt ( T/2 ) : 176.03

Tension due to Axial Force ( Fy/n ) : 12.71 yield sterss

Total Tension ( P= T/2+Fy/n) : 188.73 221.97 HENCE SAFE

Shear in each Bolt ( Fx/n) : 17.38 83.32 HENCE SAFE

CHECK FOR THICKNESS OF PLATE

Maximum bending moment in the plate(Ma) P x g/ 4

( About criticle section X-X) : 188.73 x 130/4

: 4.40 Kn-M

Thickness of plate required ( t ) : 6 x Ma / f x p

: 29.87 < 32 MM HENCE SAFE

CHECK FOR COMBINED TENSION AND SHEAR

Actual Tension + Actual Shear < 1. 4

Allowable Tension Allowable Shear

(188.73 / 221.97)+(17.38 / 83.1.06 < 1.4 HENCE SAFE

888 HENCE PROVIDE : 2 - 32 mm Thick Plates/ 24 No.s 32 mm Dia H.S.Bolts.

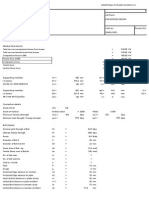

DESIGN SHEET 7 of 11

JOB No. J-1229 Rev. No. 2

Building-A

DQ.No. 104-316 Date 1-Jun-05

CLIENT MULTICOLOR STEEL LTD Designed By KP

DESCRIPTION SPLICE CONNECTION 1 Checked By MDP

Width of Plate

DESIGN OF SPLICE CONNECTION

guage 12-B0LTS

INPUT 6

Bending Moment Kn.m ###

Shear Force (Fx) Kn

itch

179.00

p

Axial Force (Fy) Kn 16.00

Web Depth mm 1400

Flange Depth mm 275

Bolts Dia mm 24

late

epth

gthofP

ebD

No. Of Bolts (n) 16

W

Len

Plate Thickness (t mm 32

Pitch (p) mm 100

guage (g) mm 100

WEB DEPTH (mm) : 1400

PLATE LENGTH (mm : 1600

PLATE WIDTH (mm : 275

Effective Lever arm : 1300 mm

Total Tension in each extreme Bolts ( T ) : Maximum moment / Eff. Lever arm

: 138/600

: 778.46 Kn

CHECK FOR BOLT SIZE

FORCES IN THE BOLTS Actual Allowable

(Kn) (Kn)

Max. Tension in each Bolt ( T/2 ) : 97.31

Tension due to Axial Force ( Fy/n ) : 1.00

Total Tension ( P= T/2+Fy/n) : 98.31 124.86 HENCE SAFE

Shear in each Bolt ( Fx/n) : 11.19 46.87 HENCE SAFE

CHECK FOR THICKNESS OF PLATE

Maximum bending moment in the plate(Ma) P x g/ 4

( About criticle section X-X) : 98.31 x 100/4

: 2.43 Kn-M

Thickness of plate required ( t ) : 6 x Ma / f x p

: 25.32 < 32 MM HENCE SAFE

CHECK FOR COMBINED TENSION AND SHEAR

Actual Tension + Actual Shear < 1. 4

Allowable Tension Allowable Shear

(98.31 / 124.86)+(11.19 / 46.91.03 < 1.4 HENCE SAFE

888 HENCE PROVIDE : 2 - 32 mm Thick Plates/ 16 No.s 24 mm Dia H.S.Bolts.

DESIGN SHEET 8 of 11

JOB No. J-1229 Rev. No. 2

Building-A

DQ.No. 104-316 Date 1-Jun-05

CLIENT MULTICOLOR STEEL LTD Designed By KP

DESCRIPTION SPLICE CONNECTION 2 Checked By MDP

Width of Plate

guage 12-B0LTS

DESIGN OF SPLICE CONNECTION

INPUT 6

Bending Moment Kn.m 168.00

itch

Shear Force (Fx) Kn 101.00

p

Axial Force (Fy) Kn 80.00

Web Depth mm 700

Flange Depth mm 200

Bolts Dia mm 24

th

late

ep

thofP

ebD

No. Of Bolts (n) 12

W

L g

en

Plate Thickness (t mm 20

Pitch (p) mm 100

guage (g) mm 100

WEB DEPTH (mm) : 700

PLATE LENGTH (mm : 900

PLATE WIDTH (mm : 200

Effective Lever arm : 600 mm

Total Tension in each extreme Bolts ( T ) : Maximum moment / Eff. Lever arm

: 168/600

: 280.00 Kn

CHECK FOR BOLT SIZE

FORCES IN THE BOLTS Actual Allowable

(Kn) (Kn)

Max. Tension in each Bolt ( T/2 ) : 46.67

Tension due to Axial Force ( Fy/n ) : 6.67

Total Tension ( P= T/2+Fy/n) : 53.33 124.86 HENCE SAFE

Shear in each Bolt ( Fx/n) : 8.42 46.87 HENCE SAFE

CHECK FOR THICKNESS OF PLATE

Maximum bending moment in the plate(Ma) P x g/ 4

( About criticle section X-X) : 53.33 x 100/4

: 1.17 Kn-M

Thickness of plate required ( t ) : 6 x Ma / f x p

: 17.53 < 20 MM HENCE SAFE

CHECK FOR COMBINED TENSION AND SHEAR

Actual Tension + Actual Shear < 1. 4

Allowable Tension Allowable Shear

(53.33 / 124.86)+(8.42 / 46.9) 0.61 < 1.4 HENCE SAFE

888 HENCE PROVIDE : 2 - 20 mm Thick Plates/ 12 No.s 24 mm Dia H.S.Bolts.

DESIGN SHEET 9 of 11

JOB No. J-1229 Rev. No. 2

Building-A

DQ.No. 104-316 Date 1-Jun-05

CLIENT MULTICOLOR STEEL LTD Designed By KP

DESCRIPTION HAUNCH CONNECTION BC(HORZ.) Checked By MDP

Width of Plate

DESIGN OF HAUNCH CONNECTION BC guage 8-B0LTS

INPUT 6

Bending Moment Kn.m 54.00

pitch

Shear Force (Fx) Kn 6.00

Axial Force (Fy) Kn 228.00

Web Depth mm 400

Flange Depth mm 300

Bolts Dia mm 24

No. Of Bolts (n) 8

Length of Plate

LEVER ARM

Plate Thickness (t mm 20

Web Depth

Pitch (p) mm 100

guage (g) mm 100

WEB DEPTH (mm) : 400

PLATE LENGTH (mm : 600

PLATE WIDTH (mm : 300

Effective Lever arm : 400 mm

Total Tension in each extreme Bolts ( T ) : Maximum moment / Eff. Lever arm

: 54/400

: 135.00 Kn

CHECK FOR BOLT SIZE

FORCES IN THE BOLTS Actual Allowable

(Kn) (Kn)

Max. Tension in each Bolt ( T/2 ) : 33.75

Tension due to Axial Force ( Fy/n ) : 28.50

Total Tension ( P= T/2+Fy/n) : 62.25 124.86 HENCE SAFE

Shear in each Bolt ( Fx/n) : 0.75 46.87 HENCE SAFE

CHECK FOR THICKNESS OF PLATE

Maximum bending moment in the plate(Ma) P x g/ 4

( About criticle section X-X) : 62.25 x 100/4

: 0.84 Kn-M

Thickness of plate required ( t ) : 6 x Ma / f x p

: 14.93 < 20 MM HENCE SAFE

CHECK FOR COMBINED TENSION AND SHEAR

Actual Tension + Actual Shear < 1. 4

Allowable Tension Allowable Shear

(62.25 / 124.86)+(0.75 / 46.9) 0.51 < 1.4 HENCE SAFE

888 HENCE PROVIDE : 2 - 20 mm Thick Plates/ 8 No.s 24 mm Dia H.S.Bolts.

DESIGN SHEET 10 of 11

JOB No. J-1229 Rev. No. 2

Building-A

DQ.No. 104-316 Date 1-Jun-05

CLIENT MULTICOLOR STEEL LTD Designed By KP

DESCRIPTION SPLICE CONNECTION 3 Checked By MDP

Width of Plate

DESIGN OF SPLICE CONNECTION

guage 12-B0LTS

INPUT 6

Bending Moment Kn.m 233.00

Shear Force (Fx) Kn 97.00

p h

itc

Axial Force (Fy) Kn 100.00

Web Depth mm 700

Flange Depth mm 180

Bolts Dia mm 24

No. Of Bolts (n) 12

th

te

ep

thofPla

WebD

Plate Thickness (t mm 24

L g

en

Pitch (p) mm 100

guage (g) mm 100

WEB DEPTH (mm) : 700

PLATE LENGTH (mm : 900

PLATE WIDTH (mm : 180

Effective Lever arm : 600 mm

Total Tension in each extreme Bolts ( T ) : Maximum moment / Eff. Lever arm

: 243/600

: 388.33 Kn

CHECK FOR BOLT SIZE

FORCES IN THE BOLTS Actual Allowable

(Kn) (Kn)

Max. Tension in each Bolt ( T/2 ) : 64.72

Tension due to Axial Force ( Fy/n ) : 8.33

Total Tension ( P= T/2+Fy/n) : 73.06 124.86 HENCE SAFE

Shear in each Bolt ( Fx/n) : 8.08 46.87 HENCE SAFE

CHECK FOR THICKNESS OF PLATE

Maximum bending moment in the plate(Ma) P x g/ 4

( About criticle section X-X) : 73.06 x 100/4

: 1.62 Kn-M

Thickness of plate required ( t ) : 6 x Ma / f x p

: 20.68 < 24 MM HENCE SAFE

CHECK FOR COMBINED TENSION AND SHEAR

Actual Tension + Actual Shear < 1. 4

Allowable Tension Allowable Shear

(73.06 / 124.86)+(8.08 / 46.9) 0.76 < 1.4 HENCE SAFE

888 HENCE PROVIDE : 2 - 24 mm Thick Plates/ 12 No.s 24 mm Dia H.S.Bolts.

DESIGN SHEET 11 of 11

JOB No. J-1229 Rev. No. 2

Building-A

DQ.No. 104-316 Date 1-Jun-05

CLIENT MULTICOLOR STEEL LTD Designed By KP

DESCRIPTION SPLICE CONNECTION 4 AT RIDGE Checked By MDP

Width of Plate

DESIGN OF RIDGE CONNECTION guage 8-B0LTS

INPUT 6

Bending Moment Kn.m 119.00

pitch

Shear Force (Fx) Kn 9.00

Axial Force (Fy) Kn 84.00

Web Depth mm 550

Flange Depth mm 180

Bolts Dia mm 24

No. Of Bolts (n) 8

Length of Plate

LEVER ARM

Plate Thickness (t mm 20

Web Depth

Pitch (p) mm 100

guage (g) mm 100

WEB DEPTH (mm) : 550

PLATE LENGTH (mm : 750

PLATE WIDTH (mm : 180

Effective Lever arm : 550 mm

Total Tension in each extreme Bolts ( T ) : Maximum moment / Eff. Lever arm

: 119/550

: 216.36 Kn

CHECK FOR BOLT SIZE

FORCES IN THE BOLTS Actual Allowable

(Kn) (Kn)

Max. Tension in each Bolt ( T/2 ) : 54.09

Tension due to Axial Force ( Fy/n ) : 10.50

Total Tension ( P= T/2+Fy/n) : 64.59 124.86 HENCE SAFE

Shear in each Bolt ( Fx/n) : 1.13 46.87 HENCE SAFE

CHECK FOR THICKNESS OF PLATE

Maximum bending moment in the plate(Ma) P x g/ 4

( About criticle section X-X) : 64.59 x 100/4

: 1.35 Kn-M

Thickness of plate required ( t ) : 6 x Ma / f x p

: 18.91 < 20 MM HENCE SAFE

CHECK FOR COMBINED TENSION AND SHEAR

Actual Tension + Actual Shear < 1. 4

Allowable Tension Allowable Shear

(64.59 / 124.86)+(1.13 / 46.9) 0.54 < 1.4 HENCE SAFE

888 HENCE PROVIDE : 2 - 20 mm Thick Plates/ 8 No.s 24 mm Dia H.S.Bolts.

You might also like

- Crane Wheel Load CalculationDocument12 pagesCrane Wheel Load Calculationmaheshbandham100% (2)

- Socketed Steel H and Bored Pile CalculationDocument13 pagesSocketed Steel H and Bored Pile CalculationYUK LAM WONG100% (2)

- Crane Bracket - AvestaDocument55 pagesCrane Bracket - AvestamaheshbandhamNo ratings yet

- AISC2005 Anchor Bolt Version22042015 FixDocument8 pagesAISC2005 Anchor Bolt Version22042015 FixThuyTranNo ratings yet

- Aisc Chevron BraceDocument42 pagesAisc Chevron Bracegvlanusha100% (1)

- Deck SheetDocument2 pagesDeck SheetmaheshbandhamNo ratings yet

- Excel Anchor Bolt Calculator-1Document2 pagesExcel Anchor Bolt Calculator-1teesk200350% (2)

- Key & Solutions: Stress F KX Modulus StressDocument5 pagesKey & Solutions: Stress F KX Modulus StressSyed Owais GillaniNo ratings yet

- Base Plate - LSDDocument14 pagesBase Plate - LSDrelu59No ratings yet

- Kirby - Typ Base PlateDocument19 pagesKirby - Typ Base PlateNitesh Singh100% (1)

- 2 ConnectionDocument18 pages2 Connectionssikha100% (1)

- Calculation Sheet: Design PhilosophyDocument18 pagesCalculation Sheet: Design PhilosophyrammohanNo ratings yet

- Typ-Base PlateDocument11 pagesTyp-Base PlateManoj Jaiswal100% (2)

- Bolted Connection Angle Brace TensionDocument2 pagesBolted Connection Angle Brace TensionRajib MaharjanNo ratings yet

- Design of Base PlateDocument14 pagesDesign of Base PlateSunidhi ItagiNo ratings yet

- Ub 254 Fin Plate To Column Web - LRFDDocument10 pagesUb 254 Fin Plate To Column Web - LRFDihpeterNo ratings yet

- R.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateDocument10 pagesR.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateMarkNo ratings yet

- Hollow Section Bracing Connetion - LRFDDocument5 pagesHollow Section Bracing Connetion - LRFDkalpanaadhiNo ratings yet

- Bracing Connection RefDocument5 pagesBracing Connection Refsukarma acharyaNo ratings yet

- Pinned Base Anchor Bolt DesignDocument2 pagesPinned Base Anchor Bolt Designkhan84mind100% (1)

- Design of Builtup SectionDocument4 pagesDesign of Builtup SectiondsanandaNo ratings yet

- Moment Connection Portal FrameDocument18 pagesMoment Connection Portal Frametmssorin100% (1)

- Pile Cap of CrystalDocument19 pagesPile Cap of CrystalPriyank MotivarasNo ratings yet

- 6-Bracing Connection - TDocument2 pages6-Bracing Connection - TMUTHUKKUMARAMNo ratings yet

- Design of Column Using Channel (Front)Document8 pagesDesign of Column Using Channel (Front)Nitesh SinghNo ratings yet

- Steel Connection - IS CodeDocument4 pagesSteel Connection - IS CodeAmit Ghosh75% (4)

- Cleat Angle ConnectionDocument3 pagesCleat Angle ConnectionSrishti Project ConsultantsNo ratings yet

- Design of Moment ConnectionDocument2 pagesDesign of Moment ConnectionDushyantha Jayawardena100% (2)

- AISC360-05 LRFD Shear Bolted Connection CheckDocument12 pagesAISC360-05 LRFD Shear Bolted Connection CheckMario FeghaliNo ratings yet

- Pinned Base (I-Section) : Design CapacitiesDocument8 pagesPinned Base (I-Section) : Design CapacitiesAwais HameedNo ratings yet

- Shear Steel ConnectionDocument3 pagesShear Steel ConnectionНемања Караклајић100% (1)

- Calculation/ Sketch: Site: Dmm:Tower 10/4/2019 Job No.: ### Beam: SB1 TEH Sheet NoDocument23 pagesCalculation/ Sketch: Site: Dmm:Tower 10/4/2019 Job No.: ### Beam: SB1 TEH Sheet NoPlacido O. Fabillo, JR. [aldev]No ratings yet

- Embeddedplate With StudsDocument78 pagesEmbeddedplate With StudsAkhil VNNo ratings yet

- Simple Shear Connection DesignDocument2 pagesSimple Shear Connection DesignElvin SandajanNo ratings yet

- LRFD Steel BeamDocument30 pagesLRFD Steel Beam정영철100% (1)

- Column Splice 356 x368x129 Column - WeldDocument4 pagesColumn Splice 356 x368x129 Column - WeldNiraj Shinde100% (1)

- Base Plate Design (From RCC ColDocument9 pagesBase Plate Design (From RCC ColJanya AssociatesNo ratings yet

- Bolted ConnectionDocument79 pagesBolted ConnectionMEPNo ratings yet

- Base Plate Design (Fixed Base)Document3 pagesBase Plate Design (Fixed Base)Saravana NNo ratings yet

- Steel Connections v1.3Document83 pagesSteel Connections v1.3Mateus GehlenNo ratings yet

- PLATE Beam To BeamDocument73 pagesPLATE Beam To BeamKutty Mansoor100% (1)

- Design of Base PlateDocument258 pagesDesign of Base PlateDushyantha Jayawardena100% (2)

- Beam Column Connection-Design2Document16 pagesBeam Column Connection-Design2abdul kareeNo ratings yet

- Moment ConnectionDocument15 pagesMoment Connectionnitin400No ratings yet

- Shear Connection - Is 800-ModifiedDocument159 pagesShear Connection - Is 800-ModifiedDarshan Panchal100% (1)

- Flust-Extended End Plate ConnectionDocument8 pagesFlust-Extended End Plate ConnectionamachmouchiNo ratings yet

- PDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDocument29 pagesPDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDEVANG VIJAY SHINDENo ratings yet

- Base Plate DesignDocument38 pagesBase Plate DesignRitwick MishraNo ratings yet

- Connection Design SheetDocument47 pagesConnection Design SheetStephen James100% (1)

- Fin Plate Connection DesignDocument10 pagesFin Plate Connection DesigncklconNo ratings yet

- Shear Connections (Steel-Steel)Document14 pagesShear Connections (Steel-Steel)Izzan SabelloNo ratings yet

- Advance Connection Design - 1Document298 pagesAdvance Connection Design - 1amitkumar8946No ratings yet

- Calculation For Moment Connection - Type ADocument15 pagesCalculation For Moment Connection - Type ANitesh Singh100% (1)

- Anchor Bolt Design IS Code LSDDocument56 pagesAnchor Bolt Design IS Code LSDajNo ratings yet

- Cleat Connection For PlatformsDocument29 pagesCleat Connection For PlatformsRajveer Singh100% (1)

- Design of Moment Connection (Welded Type) : Beam Properties: ISB 113.5x113.5x4.5 Column Properties: ISMC 200Document10 pagesDesign of Moment Connection (Welded Type) : Beam Properties: ISB 113.5x113.5x4.5 Column Properties: ISMC 200Rajib MaharjanNo ratings yet

- Beam To Column End Plate ConnectionDocument10 pagesBeam To Column End Plate ConnectionParchuri PraveenNo ratings yet

- Base Plate Dan Anchor Bolt Calculation: Connection DesignDocument21 pagesBase Plate Dan Anchor Bolt Calculation: Connection DesignSurya FahmiNo ratings yet

- Loads:: Donnees de Calcul ChargesDocument6 pagesLoads:: Donnees de Calcul ChargesAdekimi EmmanuelNo ratings yet

- 4 stiffened-WH500X400X12X25-WH500X400X12X25Document7 pages4 stiffened-WH500X400X12X25-WH500X400X12X25phanikrishnabNo ratings yet

- Welded Splice Connection-R2Document33 pagesWelded Splice Connection-R2Anonymous cG5MyHM100% (1)

- Eccentric Shear Connection Analysis of Bolt GroupDocument4 pagesEccentric Shear Connection Analysis of Bolt GroupjaffnaNo ratings yet

- Steel-Angle Bracing Design-1Document12 pagesSteel-Angle Bracing Design-1rohitbhagat005No ratings yet

- Moment Connection DETAIL 2Document5 pagesMoment Connection DETAIL 2way2vaseemNo ratings yet

- Frame ConnectionsDocument14 pagesFrame ConnectionsShawkat Ali KhanNo ratings yet

- Typ Base PlateDocument19 pagesTyp Base PlateumeshNo ratings yet

- HIGH BAY RoofNav-RatingsCalculatorDocument2 pagesHIGH BAY RoofNav-RatingsCalculatormaheshbandhamNo ratings yet

- BOLTED END PLATE ReportDocument19 pagesBOLTED END PLATE Reportmaheshbandham100% (1)

- SHEAR TAB LARGE PLATE ReportDocument14 pagesSHEAR TAB LARGE PLATE ReportmaheshbandhamNo ratings yet

- Design of Base PlateDocument161 pagesDesign of Base PlatemaheshbandhamNo ratings yet

- BOLT PLATE ReportDocument17 pagesBOLT PLATE ReportmaheshbandhamNo ratings yet

- Base PlateDocument15 pagesBase PlatemaheshbandhamNo ratings yet

- A. Material Properties: SC1 Base Plate Analysis and Design Project (Based On AISC LRFD - 2005) BuildingDocument8 pagesA. Material Properties: SC1 Base Plate Analysis and Design Project (Based On AISC LRFD - 2005) BuildingmaheshbandhamNo ratings yet

- Project Calculation Sheets Eng. Check.: Sec. 1 Shear TorsionDocument2 pagesProject Calculation Sheets Eng. Check.: Sec. 1 Shear TorsionmaheshbandhamNo ratings yet

- 1 Input Data: Hilti PROFIS Engineering 3.0.64Document10 pages1 Input Data: Hilti PROFIS Engineering 3.0.64maheshbandhamNo ratings yet

- Structural Steel Standards and Specification PDFDocument1 pageStructural Steel Standards and Specification PDFmaheshbandhamNo ratings yet

- 10 MT Crane RWB FORDocument5 pages10 MT Crane RWB FORmaheshbandhamNo ratings yet

- Purlin - ConnectionDocument8 pagesPurlin - ConnectionmaheshbandhamNo ratings yet

- Base Plate For Tension1Document7 pagesBase Plate For Tension1maheshbandhamNo ratings yet

- Brace Load CalculationDocument14 pagesBrace Load CalculationmaheshbandhamNo ratings yet

- Concrete (Non-Cracked) Static/ Quasi-StaticDocument8 pagesConcrete (Non-Cracked) Static/ Quasi-StaticmaheshbandhamNo ratings yet

- LM&& LM&& LM&& LM&&Document17 pagesLM&& LM&& LM&& LM&&maheshbandhamNo ratings yet

- List of Agencies by StateDocument84 pagesList of Agencies by Statemaheshbandham100% (1)

- Anchor Bolt and Base Plate Design CheckDocument48 pagesAnchor Bolt and Base Plate Design Checkmaheshbandham100% (1)

- Base Plate Design PDFDocument1 pageBase Plate Design PDFmaheshbandhamNo ratings yet

- Result Summary - Overall: Pass Pass Pass PassDocument17 pagesResult Summary - Overall: Pass Pass Pass PassmaheshbandhamNo ratings yet

- Angle Brace ConnectionDocument20 pagesAngle Brace Connectionmaheshbandham100% (1)

- Cusack PHD ThesisDocument142 pagesCusack PHD ThesisJitendra KumarNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- G11 - LP Fluid MechanicsDocument14 pagesG11 - LP Fluid MechanicsJerry Lloyd BocadoNo ratings yet

- Light and Sound 2 MSDocument10 pagesLight and Sound 2 MSSumira ZamanNo ratings yet

- Impact of JetDocument8 pagesImpact of JetOmar Faruqi100% (1)

- Base Isolation For Multistoried Buildings With Lead Rubber BearingDocument5 pagesBase Isolation For Multistoried Buildings With Lead Rubber BearingFelipeNo ratings yet

- Difusión MethodsDocument5 pagesDifusión MethodsKeily VilcarromeroNo ratings yet

- Guia Caida LibreDocument14 pagesGuia Caida LibreMåiirå SDj K. ZYtNo ratings yet

- Band Theory?: J. Phys. Chem. SolidsDocument5 pagesBand Theory?: J. Phys. Chem. Solidsgarguz94No ratings yet

- Latest Lifting LugDocument8 pagesLatest Lifting Lugjagannadha varmaNo ratings yet

- FM 204Document2 pagesFM 204Muzaffar AlamNo ratings yet

- 20 Zienkiewicz, O. C., Watson, M., and King, I. P., A Numerical Method of Visco-Elastic PDFDocument21 pages20 Zienkiewicz, O. C., Watson, M., and King, I. P., A Numerical Method of Visco-Elastic PDFTariq MahmoodNo ratings yet

- High Voltage EngineeringDocument36 pagesHigh Voltage EngineeringsukandeNo ratings yet

- Engineering Materials and Testing IIDocument37 pagesEngineering Materials and Testing IILorie Mae BelloNo ratings yet

- Multi Degrees of Freedom SystemDocument23 pagesMulti Degrees of Freedom SystemHani BanatNo ratings yet

- Interaction Module in AbaqusDocument16 pagesInteraction Module in Abaquseureka.nitishNo ratings yet

- Ch1 Lecture 1Document32 pagesCh1 Lecture 1Wolf MoonNo ratings yet

- Sii Smith International Inc. (713) 443 - 3370: DrilcoDocument27 pagesSii Smith International Inc. (713) 443 - 3370: DrilcoIvan Dario Benavides BonillaNo ratings yet

- (1.0 Credit) : Structural Analysis and Design Sessional-IDocument34 pages(1.0 Credit) : Structural Analysis and Design Sessional-IAnonymous aE0YYlCOKNo ratings yet

- RC Phase Shift OscillatorDocument25 pagesRC Phase Shift Oscillatorahmed omarNo ratings yet

- ES 13 ProbSet 1Document2 pagesES 13 ProbSet 1Sammy Marquez50% (2)

- Regarding The Formalism of Quantum MechanicsDocument2 pagesRegarding The Formalism of Quantum MechanicsΚουταντου ΕφηNo ratings yet

- SPE Paper ReferencesDocument4 pagesSPE Paper ReferencesjamartiNo ratings yet

- Geotubes Proceeding CSt2011 FINAL PDFDocument13 pagesGeotubes Proceeding CSt2011 FINAL PDFathanasius_adiNo ratings yet

- HC Verma Gauss Law SolutionsDocument31 pagesHC Verma Gauss Law SolutionsSakshamNo ratings yet

- II.3 Classical Laminate TheoryDocument31 pagesII.3 Classical Laminate TheoryMAURICIO NICARAGUA MENDEZNo ratings yet

- Physical Sciences P1 Grade 10 Nov 2018 EngDocument20 pagesPhysical Sciences P1 Grade 10 Nov 2018 EngNompumelelo IkkoNo ratings yet