Professional Documents

Culture Documents

E211502 Eng Aug00

E211502 Eng Aug00

Uploaded by

Mohammed sabatinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E211502 Eng Aug00

E211502 Eng Aug00

Uploaded by

Mohammed sabatinCopyright:

Available Formats

PRESSURE REDUCING AND SUSTAINING VALVE

E2115-02

OPERATING & MAINTENANCE

MANUAL

Via L.Galvani 6 tel. 0039 0461 248311 ISI SRL

38105 Lavis TN fax 0039 0461 247024

Italy

OPERATION CONTROL of the main valve is returned to the

pressure reducing pilot (4).

The pressure reducing/sustaining valve E2115-02

(SCH002) is controlled by a normally open

diaphragm actuated, two way, spring loaded, MOUNTING

adjustable pressure reducing control pilot (4), set

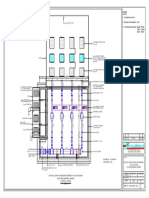

to maintain a constant outlet pressure from the The mounting principle of a regulating valve is

main valve and by normally closed diaphragm shown in the SCH 450 (at the end of this

actuated, two way, spring loaded adjustable procedure); the choice of the proper "by-pass"

pressure discharging control pilot (5), set to alternative must be taking into consideration the

maintain a minimum pressure at valve inlet, which following points:

is open when upstream pressure is above the

setting point. a) Can the main transport/feeding line be put

As long as the inlet pressure is higher than the out of service during some hours (corresponding

value of the prescribed minimum value, the main to the requested time for maintening the MAIN

valve (1) is controlled by the pressure reducing VALVE), without generating problem for the

pilot (4); the set point of the downstream reduced exploitation of the system? In particular, it must be

pressure, which is sensed under the pilot noted that an empty system may required several

diaphragm, is adjustable within the indicated days to be vented properly.

spring range of the pilot.

b) Has the downstream zone of the system to be

As downstream pressure increases, the protected against any risk of pressure surge

diaphragm pushes against the spring, allowing the (quick closing of heavy demands, closing time of

pilot poppet loaded by an auxiliary spring to be pressure reducing valve)?

pulled towards its closed position, restricting the In order to get the best accuracy from the

flow through the pilot (4) and modulating the main pressure reducing/sustaining valve operation, the

valve towards a closed position. preset values for the reduced downstream

pressure and the minimum upstream pressure

The closing speed can be adjusted by the should be included in the indicated range of the

independent flow regulator "CLOSING SPEED" pilot valves. If it is very near of the extreme limits

located in the lockable central control "TUP-93". of the range, it would then be advisable to replace

the spring by the correct one.

As downstream pressure decreases, the control

pilot 4) throttles towards open, modulating the Available 263 APN 263 SS PV20C

main valve towards open. ranges (brassNi) (SS-316) (BZ/biNi)

press.red. press.red. Press.sustain.

The opening speed can be adjusted by the 0,1 - 2,0 X X X

independent flow regulator "OPENING SPEED" 1,4 - 12,0 X X X

located in the lockable central control "TUP-93". 7,0 - 21,0 - X X

Valve inlet pressure can drop as upstream or

Should installation require the main valve stem to

downstream demands increase. When there is a

be horizontal (cover pointed sideways),

decrease of upstream pressure to the sustaining

manufacturer should be consulted concerning

set-point of pilot (5), this one throttles towards

valves of DN 200 mm and larger.

closed, modulating the main valve towards closed

NOTE:

an appropriate amount to maintain the desired All sizes on request are available with a

upstream pressure, regardless the drop of additional venting cover device ( venting cock

pressure at the outlet of the valve (eventually may installed at the top of the cover ) to permit a

become null). simple escaping of air during the first

The set-point of the pressure sustaining pilot (5), commissioning.

which is sensed under the pilot diaphragm through

a sensing line connected to the inlet of the

INSTALLATION-START UP see.sch002

lockable central control "TUP-93" (unfiltered

intake), is adjustable within the indicated spring

range of the pilot. - Before the installation of the regulating valve

As upstream pressure rises above the sustaining (and respective strainer), it is recommended to

set-point, the control pilot (5) throttles open: flush the upstream line, in order to clear it of slags

and other debris.

E2115-02AUG00 PRESSURE REDUCING AND SUSTAINING VALVE 2

FM 0800

Rel 1.2 ISI PROPERTY INFORMATION

Note: An efficient flushing should be made with a gradually increase the pressure, up to the

fluid velocity of at leat 1,5 m/s during several prescribed one.

hours!

STEP 3

- Install the valve so that the FLOW ARROW Adjust the central control "TUP-93" as prescribed

marked on the valve body matches flow through above.

the line.

STEP 4

Open upstream isolation valve SLOWLY of

UPSTREAM DOWNSTREAM

one/two turns, in order to allow a controlled

filling of the regulating

valve, which is going to close (2C closed). Vent air

- Close upstream and downstream isolation of cover through the safety venting cock mounted

valves on the valve position indicator E50 (8).

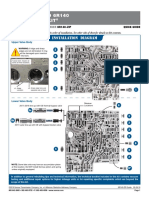

- Preset the central control "TUP-93": STEP 5

A) reaction speed (RS) (normally preset in Open completely upstream isolating valve. Check

factory), should be located on: 2,5 downstream pressure gauge. If during the step 4

B) opening speed (OS) = 2 the main chambre with air wasn't able to close

C) closing speed (CS) = 6 very fast, the downstream pressure could be the

same that inlet. Take out the downstream

- Open isolating cocks 2 A-B and maintain pressure ( throught the manometer gauge holder

closed the 2C, of control circuit- ball valve 9 downstream side) until to rich the 0

If not included in the order, install two pressure value .

gauges (one for each side) by utilizing the gauge Open the 2C and wait few second in terms to

holder ball valves (9). check the downstream pressure to 0 value.

The isolating valves ( before the Y strainer

Turn the reducing control adjusting screw

and after the pressure reducer) are in closed

CLOCKWISE (IN) to increase the pressure at the

position.

prescribed value. Slowly 180 degree for time and

wait the pressure stabilized on the new value step

START UP OF AN AUTOMATIC CONTROL by step.

VALVE REQUIRES THAT PROPER

PROCEDURES BE FOLLOWED. TIME MUST STEP 7

BE ALLOWED FOR THE VALVE TO REACT When the desired pressure is reached, gradually

TO ADJUSTMENTS AND THE SYSTEM TO open the downstream isolating valve.

STABILIZE. THE OBJECTIVE OF THE It is recommended to fill the downstream system

FOLLOWING PROCEDURE IS TO BRING THE with a low flow, in order to avoid any surge due to

VALVE INTO SERVICE IN A CONTROLLED the presence of air in the system, which should be

MANNER. vented through the venting device installed at the

outlet of the regulating valve, as well as through

A) SETTING THE PRESSURE REDUCING the one(s) installed in the system itself.

CONTROL

STEP 8

STEP 1 Allow the system to stabilize. OPEN then

On pressure sustaining pilot (5), loose lock nut completely the downstream isolation valve.

and turn the setting screw counterclockwise

(OUT), until the screw is practically unloaded,

which will allow the pilot (5) to stay OPEN during

the pressure reducing set-up procedure. STEP 9

Fine-tune the pressure reducing pilot valve to the

STEP 2 set point:

On pressure reducing pilot (4), loose lock nut and

turn the setting screw counterclockwise (OUT), SCREW CLOCKWISE (IN) ----> increases the

until the screw is practically unloaded. This is outlet pressure

simulating the lowest setting value of the range,

from which the commissioner will have to SCREW COUNTERCLOCKWISE (OUT) ---->

decreases the outlet pressure

E2115-02AUG00 PRESSURE REDUCING AND SUSTAINING VALVE 3

FM 0800

Rel 1.2 ISI PROPERTY INFORMATION

Then lock the setting screw by its locking nut!

SCREW CLOCKWISE(IN) ----> increases the

STEP 10: "(TUP 93)" inlet pressure

The opening speed adjustment restricts the

control flow out of the main valve control chamber. SCREW COUNTERCLOCKWISE (OUT) ---->

If recovery of pressure is too slow pre-setting of decreases the inlet pressure

the

flow regulator at value (2) upon increased Then lock the setting screw by its locking nut!

downstream demand, increase the adjustment of

the regulator progressively up to (3) or even higher STEP 6

setting, if requested, which will increase the rate of Open upstream isolation valve to return to normal

opening. operation.

If recovery of downstream pressure is too quick,

as indicated by a rapid increase in pressure,

possibly higher than the desired set-point, TROUBLE SHOOTING

decrease the adjustment of the regulator

progressively up to (0,5) at the maximum. Do not

close the regulator completely on (0), since the Downstream pressure value equalizes upstream

opening speed would then become too long! value.

STEP 11: "(TUP-93)" First of all verify if this problem arises from

leakage inside the main valve (1), seal problem of

The closing speed adjustment restricts the control

quad-ring on inox sealing seat (SCH016 pos. 4

flow into the main valve control chamber,

and 15), or failure of diaphragm (SCH016 pos.

controlling the valve closing speed. 17), or it is caused by a small leakage from the

Its maximum pre-setting (6) is insuring the highest pilot (4) (SCH002).

closing speed possible, in order to avoid any To identify the part subject to intervention, act as

downstream pressure increase, when the demand follows:

is decreasing. If however the too quick closing is 1. Close downstream isolating valve. It is not

generating surge in the upstream system, then possible to verify shortly possible causes

decrease the adjustment of the regulator without this isolation. Flow rate must be at 0 l/s

progressively down to (5) or any lower value. Do value. Follow drawing SCH002 and close ball

not decrease more than value (1), in order to still valve (2C). Upstream and downstream gauges

insure a proper closing of the valve. will show the same value of static pressure.

2. Discharge the part of the line on main valve

SETTING THE SUSTAINING CONTROL upstream up to reach an upstream pressure

value of 0 bars. This operation may be carried

out by the gauge holder ball valve with drain

STEP 1 hole or through the device installed on

This procedure requires the lowering of the valve upstream between main valve (1) and isolating

inlet pressure! valve.

3. After releasing close the ball valve or the other

STEP 2 device. Wait a little time verifying that the

Leave downstream isolation valve full open and gauge does not reach again any pressure

close the upstream isolation valve until the inlet value over 0 bar. Shut off control circuit by the

pressure drops to or below the desired setting. ball valve (2C) forcing main valve (1) to close.

Downstream gauge will show a 0 pressure

STEP 3 value thanks to main valve (1) bubble

Turn the sustaining pilot screw clockwise (IN) until tightness. In the opposite case, if downstream

the inlet pressure begins to increase, or pressure value comes to the upstream one,

counterclockwise (OUT) to decrease, stopping at disassemble main valve (1) and replace or the

the desired pressure. quad-ring or the diaphragm. It is advisable to

have always at your disposal a main valve (1)

STEP 4 spare gaskets set so to put in service the valve

Allow pressure to stabilize. autonomously and with no waste of time.

During reassembling of cover and main body,

fasten softly (without forcing) the nuts of stud

STEP 5

bolts and centering pins between body and

Fine-tune the pressure sustaining pilot valve to the cover. The connections of control circuit on the

set point: cover will indicate the right position.

E2115-02AUG00 PRESSURE REDUCING AND SUSTAINING VALVE 4

FM 0800

Rel 1.2 ISI PROPERTY INFORMATION

In absence of losses and with a downstream Verify perfect closing of position indicator drain

gauge showing a 0 value, act as follows: cock. In the opposite case the valve does not

1. Loosen the protection of pilot (4) adjusting work. In control chamber pressure value is 0.

screw; Make sure also ball valves (2 A-B-C) are in open

2. Loosen completely pilot (4) adjusting screw position.

and turn it counterclockwise up to release

completely the inner spring; Pilot dripping (4) (5)

3. Open again ball valve (2C). Downstream

pressure value can remain at 0 or it can rise up The diaphragm of pressure control pilot is

to the minimum allowed by pilot control range damaged. Lets start replacing it.

(standard pilot: 1,4 bar).

When downstream demand rises, downstream

If the pressure on downstream gauge comes to pressure decreases to unacceptable values

higher values, the breakdown is caused by the Verify that Reaction Speed (RS) value is exactly

pilot. In this case act as follows: 2,5. In case of regulations at lower or different

values repeat adjusting as previously explained

1. Close ball valves (2 A-B-C), see drawing (see INSTALLATION). If after regulations the inlet

SCH014-A; pressure can come to a value near the one of

2. Remove bottom plug (pos. 14) avoiding to lose outlet pressure (for example P1=4, P2=3.5) lead

the spring (pos. 16) between bottom plug and reaction speed at value 3. Then adjust again the

shutter. This spring is essential for pilot pilot (4). Due to this fact the valve regulates up to

working; reach the pressure loss value of the valve.

3. Extract, by using tweezers, the shutter (pos.

18) e check seal zone characterized by a 45 Recommended spare parts:

rubber cone. Eliminate possible foreign matters Full set of gaskets for E2001;

that can create leakage even at 0 value. It is Full set of gaskets for 263 (specify the model:

advisable to have always at your disposal for 263AP in nickel plated brass or 263 SS in

such services a pilot (4) full set of gaskets; stainless steel).

4. Reassemble the pilot (4) by slipping the shutter Full set of gasket for PV20C.

stem into the proper guide, the spring and the

pertinent plug ;

5. Open ball valves (2 A-B-C); MAINTENANCE

6. Release downstream pressure by the proper

device or through the gauge holder ball valves; If the valve has been installed as per enclosed

7. After releasing close the ball valves or the drawing, the quality of constructive materials

other device. Wait a little time verifying that the should produce no wear of the internal

downstream pressure reported by the gauge components. However we are recommending:

remains at 0 or at the most comes to the

minimum pressure adjustable according to the

type of pilot.

AFTER 6 MONTHS OF SERVICE:

If downstream pressure value equalizes the Control and clean the filter on TUP-93 (see

upstream one we suggest to contact our SCH017). The results of this inspection will permit

Customer Service. to fix the frequency of such control.

NOTE: A plugged screen will prevent any flow of

Hunting control fluid into the pilot circuit, which will put the

main valve progressively out of control.

Verify the position of speed regulators on control

unit TUP-93 (pos. 3). Hunting may be reduced by

regulating the two speeds with completely different AFTER 12/18 MONTHS OF SERVICE:

values.

For example: - Control and clean the TUP-93 (3) screen.

In case of standard regulations (OS=2, CS=6) - Take the main valve (1) apart, by removing first

there is no hunting; the complete pilot circuit.

OS=3, CS=3, the possibility of hunting is higher - Then unscrew the stud nuts and remove the

for a valve under particular working conditions cover and internal diaphragm assembly.

with low flow. - Check for any eventual damage of the QUAD-

RING and the diaphragm.

Lack of regulation

E2115-02AUG00 PRESSURE REDUCING AND SUSTAINING VALVE 5

FM 0800

Rel 1.2 ISI PROPERTY INFORMATION

- Clean thoroughly the internal part of the valve,

grease slightly the stem at both guided locations

(water grease, non toxic !!).

- Assemble main valve (1) and pilot circuit.

- Put the valve back into service.

This control should then allow to determine the

cycle of the requested maintenance, since it is

taking into consideration the true service

conditions of the valve.

STORAGE

The valves from ND 40 to ND 200 are packed in

special cardboard boxes. Outside the carton are

clearly pointed out:

- The arrow indicating the position of the valve;

- The name of the customer;

- The code of the valve;

- The number of order confirmation.

The valve is protected by two hardening foam

cushions, carefully coated by a thermal plate. This

kind of packing if properly stored avoids all the

damages originated from transport, unloading,

and handling before installation. Avoid to store it

under the rain for more than 24 hours!

Open the upper side of the carton and remove the

upper cushion. Do not lift the valve by utilizing the

pilot, the pilot circuit, or the position indicator. For

any kind of handling we recommend to utilize

proper eyebolts.

For any further information contact our

Customer Service, indicating all data as per

inox plate on main valve body. Give full

detailed informations about working

conditions, the type of problem, and report the

adjusting values (OS-CS-RS).

E2115-02AUG00 PRESSURE REDUCING AND SUSTAINING VALVE 6

FM 0800

Rel 1.2 ISI PROPERTY INFORMATION

You might also like

- Detroit Diesel - Series 60 Ddec V Troubleshooting Guide Ch11Document32 pagesDetroit Diesel - Series 60 Ddec V Troubleshooting Guide Ch11JOHN Wright67% (3)

- G1888-90009 Headspace SamplerDocument74 pagesG1888-90009 Headspace Samplerpoeta_oscuroNo ratings yet

- Pressure Regulators Selection Guidelines & CriteriaDocument17 pagesPressure Regulators Selection Guidelines & CriteriaTala RamezaniNo ratings yet

- PRM FRDocument7 pagesPRM FRGelber Norberto Gutierrez PalaciosNo ratings yet

- 90 20 1Document4 pages90 20 1Kumar sssssNo ratings yet

- Gas Pressure Regulator RB 1700 RB 1800 RB 1800FDocument16 pagesGas Pressure Regulator RB 1700 RB 1800 RB 1800FMORELLI silvioNo ratings yet

- Adaptomode Inlet Pressure Regulators: ® Types: A4AS, A4AB, A4AD, A4AZDocument16 pagesAdaptomode Inlet Pressure Regulators: ® Types: A4AS, A4AB, A4AD, A4AZpedroNo ratings yet

- Regulador AxialDocument12 pagesRegulador Axialluis_d_mNo ratings yet

- Wet Pilot TypeDocument15 pagesWet Pilot TypeDipanjan ChakrabartiNo ratings yet

- Model 6115-74JM Installation InstructionsDocument2 pagesModel 6115-74JM Installation InstructionsWattsNo ratings yet

- Operating Instructions Pressure Controller Type ROBOTER": 1. Function 1.1Document2 pagesOperating Instructions Pressure Controller Type ROBOTER": 1. Function 1.1shob1984No ratings yet

- Classic Series F114-2 (Globe), F1114-2 (Angle) Installation InstructionsDocument1 pageClassic Series F114-2 (Globe), F1114-2 (Angle) Installation InstructionsWattsNo ratings yet

- 12 Series-24Document1 page12 Series-24RE musicNo ratings yet

- 290 08 PDFDocument4 pages290 08 PDFmlevNo ratings yet

- Tm-90-21-Ul (R-03/30/22)Document20 pagesTm-90-21-Ul (R-03/30/22)Mohamed Abou El hassanNo ratings yet

- Mechanical RegulatorDocument12 pagesMechanical Regulatorshashi chauguleNo ratings yet

- PTP 18.0 HandoutDocument12 pagesPTP 18.0 HandoutJayNo ratings yet

- Stainless Series S115-43 or S6115-43 (Globe), S1115-43 or S61115-43 (Angle) Installation InstructionsDocument2 pagesStainless Series S115-43 or S6115-43 (Globe), S1115-43 or S61115-43 (Angle) Installation InstructionsWattsNo ratings yet

- Installation: Pressure Reducing Valves EuropressDocument2 pagesInstallation: Pressure Reducing Valves EuropressTahir SaeedNo ratings yet

- Axial Flow Valves 9710 7 032713ADocument12 pagesAxial Flow Valves 9710 7 032713Adilor19No ratings yet

- 90G-21/90A-21 UL: UL Listed Pilot-Operated Pressure ControlDocument2 pages90G-21/90A-21 UL: UL Listed Pilot-Operated Pressure ControllesterNo ratings yet

- JbdlimDocument4 pagesJbdlimNoemi ZeballosNo ratings yet

- Stainless Series S115-2 or S6115-2 (Globe), S1115-2 or S61115-2 (Angle) Installation InstructionsDocument1 pageStainless Series S115-2 or S6115-2 (Globe), S1115-2 or S61115-2 (Angle) Installation InstructionsWattsNo ratings yet

- Singer ValveDocument2 pagesSinger ValverongdhanuonlineNo ratings yet

- Singer Valve 106 206 F Type 4 IOM Operation GuideDocument4 pagesSinger Valve 106 206 F Type 4 IOM Operation GuideSijo JoyNo ratings yet

- Spence - 6 - Safety Relief Valve Sizing - 2nd Edition PDFDocument24 pagesSpence - 6 - Safety Relief Valve Sizing - 2nd Edition PDFJorge DuranNo ratings yet

- Pressure Control ValveDocument34 pagesPressure Control ValveHASHEMNo ratings yet

- 1171-2171 IomDocument10 pages1171-2171 IomBladimir MontecinosNo ratings yet

- TM 90 21Document21 pagesTM 90 21enrique RiosNo ratings yet

- Mustang Series M114-2 or M6114-2 (Globe), M1114-2 or M61114-2 (Angle) Installation InstructionsDocument2 pagesMustang Series M114-2 or M6114-2 (Globe), M1114-2 or M61114-2 (Angle) Installation InstructionsWattsNo ratings yet

- Chapter 9 Refrigeration RegulatorsDocument48 pagesChapter 9 Refrigeration RegulatorsRutaremwa VicentNo ratings yet

- Pressure Reducing Valve PDFDocument3 pagesPressure Reducing Valve PDFneversigNo ratings yet

- 12 Series-30Document1 page12 Series-30RE musicNo ratings yet

- Full Bore Emerg Unloading Valve O&m - 02-24-2011Document9 pagesFull Bore Emerg Unloading Valve O&m - 02-24-2011Enrique AssmannNo ratings yet

- Singer PRV ManualDocument3 pagesSinger PRV ManualAdityaNo ratings yet

- I & M Mark 57: Ideal InstallationDocument4 pagesI & M Mark 57: Ideal Installationbenzerga karimNo ratings yet

- HD 101 Deluge Valve Model ADocument15 pagesHD 101 Deluge Valve Model APiyush JainNo ratings yet

- Capacity Correction Factors: Back PressureDocument2 pagesCapacity Correction Factors: Back PressureSusheel WankhedeNo ratings yet

- Control ValveDocument102 pagesControl ValveAnil Bag100% (3)

- Pressure Safety Relief Valves Pressure Safety Relief Valves: Technical Bulletin 3 Technical Bulletin 3Document16 pagesPressure Safety Relief Valves Pressure Safety Relief Valves: Technical Bulletin 3 Technical Bulletin 3PravinNo ratings yet

- Series 400 Piston Pilot POPRV Maintenance InstructionsDocument26 pagesSeries 400 Piston Pilot POPRV Maintenance InstructionsCristiam BejaranoNo ratings yet

- Diaphragm Operated Pressure Flow Control Valve OmDocument7 pagesDiaphragm Operated Pressure Flow Control Valve OmAnupmaNo ratings yet

- Mustang Series M116-31 or M6116-31 (Globe), M1116-31 or M61116-31 (Angle) Installation InstructionsDocument1 pageMustang Series M116-31 or M6116-31 (Globe), M1116-31 or M61116-31 (Angle) Installation InstructionsWattsNo ratings yet

- SINGER MODEL 106/206-RPS: Pressure Relief or Sustaining ValveDocument2 pagesSINGER MODEL 106/206-RPS: Pressure Relief or Sustaining ValvezaidNo ratings yet

- Wa-4 Alivio Ul-Fm 1116fmDocument4 pagesWa-4 Alivio Ul-Fm 1116fmeselcosac100% (1)

- Model ZW209FP: Installation Start-Up Maintenance InstructionsDocument5 pagesModel ZW209FP: Installation Start-Up Maintenance InstructionsRanses RomanNo ratings yet

- LIT1307 Pilot Operated Relief Valves 2020 WebDocument28 pagesLIT1307 Pilot Operated Relief Valves 2020 WebLance Noel SirayNo ratings yet

- N1 Reducing ValveDocument8 pagesN1 Reducing ValveAlexander Mugabe100% (1)

- 08 - Column Pressure ReliefDocument10 pages08 - Column Pressure ReliefjeedanNo ratings yet

- Pressure Reducing Valve: ModelDocument2 pagesPressure Reducing Valve: Modeljuliancardona77No ratings yet

- Bendix E-7 Dual Brake Valve: DescriptionDocument8 pagesBendix E-7 Dual Brake Valve: DescriptionmnvijaybabuNo ratings yet

- R431002626 AventicsH 3Controlair®ValveswithRollerDocument2 pagesR431002626 AventicsH 3Controlair®ValveswithRollerHamza ChenakerNo ratings yet

- Classic Series F116-5 (Globe), F1116-5 (Angle) Installation InstructionsDocument2 pagesClassic Series F116-5 (Globe), F1116-5 (Angle) Installation InstructionsWattsNo ratings yet

- SPM Full Bore Emergency Unloading Valve Manual PDFDocument9 pagesSPM Full Bore Emergency Unloading Valve Manual PDFPablo SotoNo ratings yet

- Staflux 187: Pressure RegulatorDocument23 pagesStaflux 187: Pressure RegulatorRadhakrishnan PaulNo ratings yet

- Basics of Pressure RegulationDocument18 pagesBasics of Pressure Regulationar174_569868987No ratings yet

- Fundamentals of Pressure Regulation: John M. Kruse Invensys Metering SystemsDocument4 pagesFundamentals of Pressure Regulation: John M. Kruse Invensys Metering SystemsrockieballNo ratings yet

- Manual Series 400 Piston Pilot Poprv Installation Maintenance Instructions Anderson Greenwood en en 546Document26 pagesManual Series 400 Piston Pilot Poprv Installation Maintenance Instructions Anderson Greenwood en en 546ungkaphutasoitNo ratings yet

- Inlet Pressure Regulators: Type A4A-DN, A4AK-DN, A4AE-DN, A4Ar-DnDocument8 pagesInlet Pressure Regulators: Type A4A-DN, A4AK-DN, A4AE-DN, A4Ar-Dn13667514No ratings yet

- FMS Power PackDocument3 pagesFMS Power PackJAVIER GONZALEZ CUESTANo ratings yet

- Solenoid Control Valve: Installation / Operation / MaintenanceDocument2 pagesSolenoid Control Valve: Installation / Operation / Maintenanceahmsa.morsyNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- 63mm PE100 SDR11 PN16 ML 20.01.2020 DN - 33504274Document1 page63mm PE100 SDR11 PN16 ML 20.01.2020 DN - 33504274Mohammed sabatinNo ratings yet

- WeldingDocument80 pagesWeldingMohammed sabatinNo ratings yet

- PVC Schedule 80 Catalogue NEWDocument32 pagesPVC Schedule 80 Catalogue NEWMohammed sabatinNo ratings yet

- Multiple Meter Cabinet DetailsDocument1 pageMultiple Meter Cabinet DetailsMohammed sabatinNo ratings yet

- Large Capacity Oil InterceptorDocument1 pageLarge Capacity Oil InterceptorMohammed sabatinNo ratings yet

- Terracotta Price List TE101 March 1st 2019 Rev1Document22 pagesTerracotta Price List TE101 March 1st 2019 Rev1Mohammed sabatinNo ratings yet

- MCHW Vol 1 Series 500 Web PDFDocument41 pagesMCHW Vol 1 Series 500 Web PDFMohammed sabatinNo ratings yet

- Iso 13480 (1997) PDFDocument11 pagesIso 13480 (1997) PDFMohammed sabatinNo ratings yet

- Data Sheet 1.60 Issue C: OS&Y Flanged Gate Valve F4 Series Fig. 116FFDocument2 pagesData Sheet 1.60 Issue C: OS&Y Flanged Gate Valve F4 Series Fig. 116FFMohammed sabatinNo ratings yet

- GF ELGEF Plus Modularni Sistem ENGDocument20 pagesGF ELGEF Plus Modularni Sistem ENGMohammed sabatinNo ratings yet

- 6469 4 Sun-Protection DigitalDocument2 pages6469 4 Sun-Protection DigitalMohammed sabatinNo ratings yet

- Below Ground & Civils Systems: Trade Price ListDocument67 pagesBelow Ground & Civils Systems: Trade Price ListMohammed sabatinNo ratings yet

- Ashghal Training Provider Pre-Qualification FormDocument12 pagesAshghal Training Provider Pre-Qualification FormMohammed sabatinNo ratings yet

- Fusion Technology PDFDocument58 pagesFusion Technology PDFMohammed sabatinNo ratings yet

- Electrofusion Elbow 45° For Gas - SDR11 (ISO S5)Document1 pageElectrofusion Elbow 45° For Gas - SDR11 (ISO S5)Mohammed sabatinNo ratings yet

- Gfps System Specification PVC C Metric en PDFDocument24 pagesGfps System Specification PVC C Metric en PDFMohammed sabatinNo ratings yet

- 547 PDFDocument389 pages547 PDFMohammed sabatinNo ratings yet

- BS en 1555-3 (2008) PDFDocument29 pagesBS en 1555-3 (2008) PDFMohammed sabatinNo ratings yet

- Gfps 9200 Brochure CNC Automated Butt Fusion Machine Line enDocument8 pagesGfps 9200 Brochure CNC Automated Butt Fusion Machine Line enMohammed sabatinNo ratings yet

- FINALE GFDO 6202 4b Allgemein iJOINTDocument6 pagesFINALE GFDO 6202 4b Allgemein iJOINTMohammed sabatinNo ratings yet

- Clay Specification BrochureDocument8 pagesClay Specification BrochureMohammed sabatinNo ratings yet

- Dual Modular Safety Shutoff Valves DMV-D/11 Series DMV-DLE/11 SeriesDocument6 pagesDual Modular Safety Shutoff Valves DMV-D/11 Series DMV-DLE/11 SeriesJose Leandro Del ZarNo ratings yet

- Operation & Maintenance Manual Integra-Mate: Water Purification SystemsDocument22 pagesOperation & Maintenance Manual Integra-Mate: Water Purification Systemsanandhra2010No ratings yet

- Caja 727Document8 pagesCaja 727Esteban Del AngelNo ratings yet

- EvaporadortoyotaDocument108 pagesEvaporadortoyotaPaco LozadaNo ratings yet

- 7013 Pressure Regulator DataDocument4 pages7013 Pressure Regulator DataNasredine AlainNo ratings yet

- TLESMAW9 Q1 Mod1 Prepare-Weld-Materials v3Document71 pagesTLESMAW9 Q1 Mod1 Prepare-Weld-Materials v3Zergie ZapantaNo ratings yet

- Session 3 Gas Distribution NetworkDocument31 pagesSession 3 Gas Distribution NetworkHugo Ruiz100% (2)

- HOB-AM15T SPM PDFDocument83 pagesHOB-AM15T SPM PDFHamid IkkuNo ratings yet

- Basic Blueprint Reading 110Document110 pagesBasic Blueprint Reading 110Vidjeane Mourthy100% (2)

- What Is Fuel Pump - Types of Fuel Pump - Its Working PrincipleDocument14 pagesWhat Is Fuel Pump - Types of Fuel Pump - Its Working PrincipleMark MubiruNo ratings yet

- Grill Master 720-0697Document27 pagesGrill Master 720-0697Jocelyn Weber BartaNo ratings yet

- 6R140 Zip inDocument10 pages6R140 Zip inUlloaElias100% (2)

- MR98 Series Backpressure Regulators, Relief and Differential Relief ValvesDocument40 pagesMR98 Series Backpressure Regulators, Relief and Differential Relief ValvesnomurapreNo ratings yet

- Crankcase Pressure RegulatorsDocument11 pagesCrankcase Pressure Regulatorsdoni.ekosaputroNo ratings yet

- B42 Series Regulator: Residential and Light Commercial RegulatorDocument42 pagesB42 Series Regulator: Residential and Light Commercial RegulatorLpg Power SupplyNo ratings yet

- AirSep Centrox PSA Concentrator - Technical ManualDocument106 pagesAirSep Centrox PSA Concentrator - Technical Manuallegasu100% (1)

- AirValves 2013Document268 pagesAirValves 2013Peter Toralva YauriNo ratings yet

- Installation and Operating Manual: From Tech Development IncDocument6 pagesInstallation and Operating Manual: From Tech Development IncMauricio Ariel H. OrellanaNo ratings yet

- Atlas Copco Stationary Air Compressors LE LTDocument53 pagesAtlas Copco Stationary Air Compressors LE LTjohn smithNo ratings yet

- RR112 enDocument8 pagesRR112 enqian heNo ratings yet

- 580 590 Series 3 Variable Volume Pilot Controls PDFDocument62 pages580 590 Series 3 Variable Volume Pilot Controls PDFG & C Maquinaria100% (1)

- Design and Layout of Pipes For Water Supply To A Building PDFDocument5 pagesDesign and Layout of Pipes For Water Supply To A Building PDFVishal InamadarNo ratings yet

- Pulsation DampenerDocument12 pagesPulsation DampenerAnibal Jose Cruz Larez100% (2)

- Sampling Conditioning SystemDocument24 pagesSampling Conditioning System王祚No ratings yet

- En Cylinder Regulators DatasheetDocument18 pagesEn Cylinder Regulators DatasheetMalikZohaibNazarNo ratings yet

- Montacargas Toyota 4 Tons Service Manual 91507B MI04 4.3L GM EPA Fuel SysDocument98 pagesMontacargas Toyota 4 Tons Service Manual 91507B MI04 4.3L GM EPA Fuel SysOrlando Flores100% (3)

- 6R140-VacTestGuide Interactive PDFDocument4 pages6R140-VacTestGuide Interactive PDFbelchior100% (1)