Professional Documents

Culture Documents

2.1 JKR 28 Vacuum Brick Production Line

2.1 JKR 28 Vacuum Brick Production Line

Uploaded by

chrisofomaCopyright:

Available Formats

You might also like

- Patty Brennan Homeopathic GuideDocument54 pagesPatty Brennan Homeopathic Guidepawajee50% (2)

- CementProject PlanDocument54 pagesCementProject PlanDilnesa EjiguNo ratings yet

- Bill of Quantity For Construction of Containerized Housing UnitsDocument7 pagesBill of Quantity For Construction of Containerized Housing UnitsMashareq SaadiNo ratings yet

- Title: 250tph Gold Processing Plant: Tel: +27 11 748 8800 - Fax: +27 11 748 8898 P.O. Box 750, Benoni, 1500, South AfricaDocument17 pagesTitle: 250tph Gold Processing Plant: Tel: +27 11 748 8800 - Fax: +27 11 748 8898 P.O. Box 750, Benoni, 1500, South AfricaChrispen MachipisaNo ratings yet

- Kuresoi Stakeholders Peace Meeting ReportDocument21 pagesKuresoi Stakeholders Peace Meeting ReportkubasulnNo ratings yet

- Price List For Building MaterialsDocument16 pagesPrice List For Building MaterialsAYOBAMI BOOK100% (1)

- Wiring Diagram Elevator: 123/INDSBY-ELC/1014Document22 pagesWiring Diagram Elevator: 123/INDSBY-ELC/1014Gogik Anto85% (13)

- Afar 2 - Summative Test (Consolidated) Theories: Realized in The Second Year From Upstream Sales Made in Both YearsDocument23 pagesAfar 2 - Summative Test (Consolidated) Theories: Realized in The Second Year From Upstream Sales Made in Both YearsVon Andrei Medina100% (1)

- Generalized Problematic Internet Use Scale 2 (Gpius 2) Scale Items & InstructionsDocument2 pagesGeneralized Problematic Internet Use Scale 2 (Gpius 2) Scale Items & InstructionsShariqa100% (1)

- Residential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationDocument7 pagesResidential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationPedro JonesNo ratings yet

- HR4-10 Automatic Hydraulic Interlocking Lego Brick MachineDocument11 pagesHR4-10 Automatic Hydraulic Interlocking Lego Brick MachineSamuel Luis100% (2)

- Valvula Reductora de Presion Bermad Area 675 720-ULDocument4 pagesValvula Reductora de Presion Bermad Area 675 720-ULChristian FherNo ratings yet

- Block Making Machine Price ListDocument4 pagesBlock Making Machine Price ListgloryofmajapahitNo ratings yet

- Cbs CatalogueDocument195 pagesCbs Cataloguemadaboutalfa8168No ratings yet

- Cement Block Making Machine For SaleDocument4 pagesCement Block Making Machine For Saleanand_shrivastavNo ratings yet

- Boiler Water TDSDocument5 pagesBoiler Water TDSDurjoy ChakrabortyNo ratings yet

- ZCJK Brick Machine Price List - LilyDocument4 pagesZCJK Brick Machine Price List - LilyTimothy Ndeleva100% (1)

- Brick Market Demand Estimation in Bhubaneswar and Adjoining AreasDocument14 pagesBrick Market Demand Estimation in Bhubaneswar and Adjoining AreasSujitNo ratings yet

- Fully Automatic Colour Paver MachinesDocument3 pagesFully Automatic Colour Paver MachinesNipan DekaNo ratings yet

- Double Layer Tile PressDocument6 pagesDouble Layer Tile PressHaile Kebede100% (1)

- New QTJ4-35 Production Line PDFDocument4 pagesNew QTJ4-35 Production Line PDFTwokir A. TomalNo ratings yet

- Kb12 TechnicalDocument17 pagesKb12 TechnicalSohail KhanNo ratings yet

- Indian Backhoe Loaders - March 2008Document33 pagesIndian Backhoe Loaders - March 2008Huseyin TASKINNo ratings yet

- Technical Manual Metsec Mezzanine FloorsDocument23 pagesTechnical Manual Metsec Mezzanine FloorsMusheer BashaNo ratings yet

- Quotation For Fly Ash Brick MachinesDocument9 pagesQuotation For Fly Ash Brick MachinesVetri Odayakulam100% (2)

- 3QGB Screw PumpDocument7 pages3QGB Screw PumpWily WayerNo ratings yet

- Screw-Conveyor-Components-Amp-Design Chapter 1Document30 pagesScrew-Conveyor-Components-Amp-Design Chapter 1Trần Viết QuốcNo ratings yet

- 40 Cubic Meter Concrete Batching PlantDocument11 pages40 Cubic Meter Concrete Batching PlantRanndolf JavierNo ratings yet

- FMC Bucket ElevatorsDocument17 pagesFMC Bucket ElevatorsErizal HamdiNo ratings yet

- Westinghouse Electric Wall Oven WVE665S User ManualDocument48 pagesWestinghouse Electric Wall Oven WVE665S User ManualalexNo ratings yet

- Leather Footwear MachineryDocument10 pagesLeather Footwear MachineryaychiluhimhailuNo ratings yet

- Project Report For Fly Ash Bricks and It'S Allied Products: Plant & MachineryDocument3 pagesProject Report For Fly Ash Bricks and It'S Allied Products: Plant & Machinerydeepam1987No ratings yet

- Elecon Single Roll Crusher CatalogueDocument4 pagesElecon Single Roll Crusher Cataloguegunawansigi36No ratings yet

- CPM All EquipmentDocument161 pagesCPM All EquipmentShree ShreeNo ratings yet

- Internal GearsDocument4 pagesInternal GearsBranislav DjordjevicNo ratings yet

- MDDocument15 pagesMDRakesh Kumar Singh (Phase 1B)No ratings yet

- FactoriesDocument2 pagesFactoriesdanielNo ratings yet

- Concrete Batching Plant CatalogueDocument17 pagesConcrete Batching Plant CatalogueSelf ConceptNo ratings yet

- PowerPack+brochure+ (V1 0)Document2 pagesPowerPack+brochure+ (V1 0)Khánh VũNo ratings yet

- Fenner GearsDocument28 pagesFenner Gearsmanoj983@gmail.comNo ratings yet

- Fly Ash Brick Manufacturing PlantDocument5 pagesFly Ash Brick Manufacturing Plantkarthikraja21No ratings yet

- Oil Expeller Shaft Analysis JournalDocument11 pagesOil Expeller Shaft Analysis JournalRemartin MaglantayNo ratings yet

- 240 2011-08-18 549729 PDFDocument95 pages240 2011-08-18 549729 PDFasitdeyNo ratings yet

- BMG-BEL23042009 Idlers and RollersDocument16 pagesBMG-BEL23042009 Idlers and Rollersstevens75788No ratings yet

- 1 Comparison of SANY and SINO HOWO 10m3 Transit MixerDocument1 page1 Comparison of SANY and SINO HOWO 10m3 Transit MixerAdeelNo ratings yet

- Milling Separator SFI1000A T SFI1500A TDocument32 pagesMilling Separator SFI1000A T SFI1500A TAkhmad Zaenudin100% (1)

- HM150 Roller BrochureDocument8 pagesHM150 Roller BrochurePriyanshu GuptaNo ratings yet

- MTC Flexible Conduit (Anaconda)Document1 pageMTC Flexible Conduit (Anaconda)Aufa Jaya Perkasa LegalityNo ratings yet

- Cross Section of Metal BuildingDocument1 pageCross Section of Metal BuildingtechnopreneurvizagNo ratings yet

- Machinery Used in Const.Document18 pagesMachinery Used in Const.Tanuja Naryal100% (1)

- Plywood SpecificationsDocument2 pagesPlywood Specificationsanuchn007100% (1)

- Price List 2012Document66 pagesPrice List 2012Azhar HassanNo ratings yet

- Sample BOQDocument89 pagesSample BOQkanishkaNo ratings yet

- Bokaro Steel PlantDocument3 pagesBokaro Steel PlantSayan ChatterjeeNo ratings yet

- KTC BricksDocument55 pagesKTC BricksKiran KumarNo ratings yet

- Clay BrickDocument26 pagesClay BrickWerku Koshe Hareru0% (1)

- Material CostDocument8 pagesMaterial CostRebiyu KemalNo ratings yet

- Scaffold Towers Catalog: Rolling & StationaryDocument22 pagesScaffold Towers Catalog: Rolling & StationaryrhoewiebNo ratings yet

- Roller DesignDocument34 pagesRoller DesignAnonymous z4Fe39j100% (1)

- 2.2 JKR 28 Vacuum Brick Production LineDocument5 pages2.2 JKR 28 Vacuum Brick Production LinechrisofomaNo ratings yet

- Packing List UPDATEDocument1 pagePacking List UPDATEgerenciaNo ratings yet

- 2.1.JZK 30 Full Vacuum Brick Production LineDocument2 pages2.1.JZK 30 Full Vacuum Brick Production LineMONATY29No ratings yet

- Machine Spec 2 - Interlocking BrickDocument5 pagesMachine Spec 2 - Interlocking BrickZafry TahirNo ratings yet

- qt4 24 1Document6 pagesqt4 24 1Robin SuNo ratings yet

- Climate Finance Inflows To South Africa (Mitigation Versus Adaptation)Document60 pagesClimate Finance Inflows To South Africa (Mitigation Versus Adaptation)chrisofoma100% (1)

- Injection Molding MachineDocument3 pagesInjection Molding MachinechrisofomaNo ratings yet

- GPDC and Other Charts For Packed ColumnsDocument12 pagesGPDC and Other Charts For Packed ColumnschrisofomaNo ratings yet

- Hazard Identification Report FormDocument1 pageHazard Identification Report FormchrisofomaNo ratings yet

- Distillation Tower Flooding More Complex Than You Think PDFDocument8 pagesDistillation Tower Flooding More Complex Than You Think PDFchrisofomaNo ratings yet

- Comparative Studies of Gasoline Samples Used in Nigeria U.Z. Faruq, M. Runde, B.G. Danshehu, H.N. Yahaya, A.A. Zuru and A.B. MuhammadDocument6 pagesComparative Studies of Gasoline Samples Used in Nigeria U.Z. Faruq, M. Runde, B.G. Danshehu, H.N. Yahaya, A.A. Zuru and A.B. MuhammadchrisofomaNo ratings yet

- Haskel Gas Booster Booklet 4-30-16Document35 pagesHaskel Gas Booster Booklet 4-30-16chrisofoma100% (1)

- MEOH Flow ChartDocument1 pageMEOH Flow ChartchrisofomaNo ratings yet

- 2.2 JKR 28 Vacuum Brick Production LineDocument5 pages2.2 JKR 28 Vacuum Brick Production LinechrisofomaNo ratings yet

- Abstract - Marathon Oil Company - Unloading Horizontal Gas WellsDocument1 pageAbstract - Marathon Oil Company - Unloading Horizontal Gas WellschrisofomaNo ratings yet

- Euromktscan PlattsDocument16 pagesEuromktscan PlattschrisofomaNo ratings yet

- T22 User ManualDocument67 pagesT22 User ManualchrisofomaNo ratings yet

- Android CodesDocument2 pagesAndroid CodeschrisofomaNo ratings yet

- Fee Payment Form - Application For Permanent ResidenceDocument1 pageFee Payment Form - Application For Permanent ResidenceSlowfingerNo ratings yet

- RE StudioDocument41 pagesRE StudiochrisofomaNo ratings yet

- Hell by D.L. MoodyDocument7 pagesHell by D.L. MoodyLisaNo ratings yet

- Iridium Satellite System (Iss) : Wireless CommunicationDocument11 pagesIridium Satellite System (Iss) : Wireless CommunicationSmrithi K MNo ratings yet

- The Radiology Assistant - Fleischner 2017 GuidelineDocument11 pagesThe Radiology Assistant - Fleischner 2017 GuidelineHenry J. Hernández L.No ratings yet

- Sony Kdl-40xbr9 Kdl-46xbr9 Kdl-52xbr9 Ex2m ChassisDocument118 pagesSony Kdl-40xbr9 Kdl-46xbr9 Kdl-52xbr9 Ex2m ChassisAndy WilsonNo ratings yet

- Whittington 22e Solutions Manual Ch14Document14 pagesWhittington 22e Solutions Manual Ch14潘妍伶No ratings yet

- Academic Journal Guide 2021-MethodologyDocument22 pagesAcademic Journal Guide 2021-MethodologySyedNo ratings yet

- Understanding Organizational Behavior: de Castro, Donna Amor Decretales, Thea Marie Estimo, Adrian Maca-Alin, SaharaDocument41 pagesUnderstanding Organizational Behavior: de Castro, Donna Amor Decretales, Thea Marie Estimo, Adrian Maca-Alin, SaharaAnna Marie RevisadoNo ratings yet

- Safety Data Sheet Carbon Cathode SolutionDocument11 pagesSafety Data Sheet Carbon Cathode SolutionJeff BanasekNo ratings yet

- Board of Technical Education (Student Marksheet)Document2 pagesBoard of Technical Education (Student Marksheet)Manoj SainiNo ratings yet

- Mathematics Past Paper QuestionsDocument174 pagesMathematics Past Paper Questionsnodicoh572100% (2)

- Chinese Vocabulary BodyDocument3 pagesChinese Vocabulary BodyWei LeeNo ratings yet

- Part UhxDocument51 pagesPart UhxSaif Eddine MJNo ratings yet

- Course CurriculumDocument3 pagesCourse CurriculumPRASENJIT MUKHERJEENo ratings yet

- Informe Sobre El Manejo de CostasDocument88 pagesInforme Sobre El Manejo de CostasMetro Puerto RicoNo ratings yet

- Ai-Ai ResumeDocument3 pagesAi-Ai ResumeNeon True BeldiaNo ratings yet

- Manual Tecnico Jblgo PDFDocument2 pagesManual Tecnico Jblgo PDFMarcosDanielSoaresNo ratings yet

- STEWART Briony Kumiko and The Dragon FINAL2010Document8 pagesSTEWART Briony Kumiko and The Dragon FINAL2010Tahnee HallNo ratings yet

- Glass Configurator Datasheet 2023 03 27Document1 pageGlass Configurator Datasheet 2023 03 27Satrio PrakosoNo ratings yet

- Physical Pendulum - Angular SHM - Solved ProblemsDocument7 pagesPhysical Pendulum - Angular SHM - Solved ProblemsHomayoon GeramifarNo ratings yet

- Software Engineering. Specification, Implementation, VerificationDocument186 pagesSoftware Engineering. Specification, Implementation, Verificationazariel.rodrigo100% (1)

- Azosprilum 2Document24 pagesAzosprilum 2Dipti PriyaNo ratings yet

- 3700 S 24 Rev 0 ENDocument3 pages3700 S 24 Rev 0 ENJoão CorrêaNo ratings yet

- Arlon 38NDocument4 pagesArlon 38NRavindrakumar ParvathiniNo ratings yet

- 0547 s06 TN 3Document20 pages0547 s06 TN 3mstudy123456No ratings yet

- BDM SF 3 6LPA 2ndlisDocument20 pagesBDM SF 3 6LPA 2ndlisAvi VatsaNo ratings yet

- Rear Drive Halfshafts: 2016.0 RANGE ROVER (LG), 205-05Document46 pagesRear Drive Halfshafts: 2016.0 RANGE ROVER (LG), 205-05SergeyNo ratings yet

2.1 JKR 28 Vacuum Brick Production Line

2.1 JKR 28 Vacuum Brick Production Line

Uploaded by

chrisofomaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.1 JKR 28 Vacuum Brick Production Line

2.1 JKR 28 Vacuum Brick Production Line

Uploaded by

chrisofomaCopyright:

Available Formats

ZHENGZHOU YINGFENG MACHINERY CO.

,LTD

ADD: Block 5,South Longhai Road and East Tongbai Road,Zhongyuan District,Zhengzhou City,Henan Province,China

TEL: +86-371- 85962719 FAX: +86-371-55699146 WEB: www.yfbrickmachine.com

To: Country:

Email: Mobile

Brick size : Capacity:

JKR 28 vacuum brick production line

Power

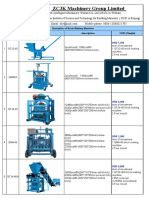

No. Item Picture SPEC Capacity

(KW)

Size(m) Qty. Unit Unit (USD) Total (USD) Note

1 Box feeder GD502m 10-20 m/h 3 2.5x0.73x0.85 1 set 2118 2118 Soil feeding

Double Roller Crushing soil

2 SGP50X40 15-20 m/h 7.52 2.5x0.73x0.85 1 set 2511 2511

crusher into powder

Double shaft Soil powder

3 SJ200X60 15~20 m/h 11 2.32x1.0x0.7 1 set 2511 2511

mixer mixs with water

Double stage

Vacuum extruder JKR28/28- 3000- to extrud mud

4 37 2.32x1.1x0.95 1 set 5550 5550

manual 1.5 4000(pcs/h) column

clutch

1.10x0.42x0.6 to absorb

5 Vacuum pump SK-3 3m/min 5.5 1 set 600 600

3 moisture

To cut long

Vertical

column

6 Automatic brick V01 1-1.3m/s 1.1 2.2X1.09X1.06 1 set 550 550

into short

strip cutter

column

to cut short

7 SS01 26 times/min 4 2.15X1.53X1.5 1 set 1200 1200 column

Brick cutter

into mud pieces

8 Belt conveyor DS408m 0.8m/s 3 8x0.4 1 set 928 928 To convey soil

Raw material

9 Belt conveyor DS406m 0.8m/s 3 6x0.4 1 set 744 744

conveying

start -over

10 Electric cabinet ED280 100 KW 1 set 700 700

Power control

Secondary start -over

11 SED 2 set 80 160

Control cabinet Power control

check motor Taken with working with

12 Motors 1 set 0

list machine machine

Taken with working with

13 V belt 1 set 0

machine pully

to produce

different shape

14 Alloy brick Mould 1 set for free 0

of

brick

15 Sub-Total Ex-work price 17572

16 Total FOB QINGDAO price (1X20'') 18672

Optional Equipment : Stone and plant root Removing system

No. Item Picture SPEC Capacity Power(KW) Size(m) Qty. Unit Unit (USD) Total (USD) Note

Remove stones

and

1 Vibration sieve YFV25 10-20 m/h 3 2.2x1.2x0.4 1 set 800 800

grass root from

soil

Crushing soil

Aolly Double into powder

2 SG50X40 15-20 m/h 7.52 2.5x0.73x0.85 1 set 3106 3106

Roller crusher less3 mm

HRC48~55

Crushing soil

Hammer roller lump ,remove

3 GS100X150 15-30m3/h 5.5 2.5*1.2*1.8 1 set 2754 2754

sieve stones and grass

root

removing iron

4 De-iroing D50 0 1 set 500 500

from soil

Machine installation flow chart

(1) Spare parts list will be sent separately. The above production line is standard layout ,the material is limited to soft clay,mud,soil.

If your material is shale,fly ash,coal Gangue,or clay which contains big stones,lumps,grass roots,etc, the above production line will

be adjusted after we get your feedback regarding your material condition.

(2) The above production capacity is based on Chinese standard brick size : 240X115X53 mm.

For more brick sizes production capacity,please refer to the following form

(3) If you want to know how our clay brick machine works you can watch the video as below:

JZ300 Nonv-vacuum clay brick prouction line http://youtu.be/sjg7GsfcYfk

JZK30 Vacuum clay brick prouction line with brick separator : http://youtu.be/TBgEnsWOGyM

JKRL35 Vacuum brick prouction line with unloader and brick loading cars : http://youtu.be/IQtzh_pjcxA

JKR40 Vacuum Clay block making machine: http://youtu.be/jZmoW49xtF8 http://youtu.be/qOCe79N43ns

JKRL45 Vacuum Clay brick prouction line with auto brick loading cars: http://youtu.be/3DCR2rR_wYA

JZK50 Vacuum Clay brick prouction line with dryer and hoffman kiln: http://youtu.be/h -m4Vnq8v3c

JKY60 Auto brick production line with tunnel kiln and dryer: http://youtu.be/8R_XzKkDySU

Production Capacity of JKR28 Brick Machine (According to Users' feedback)

Brick Size

Brick Size

No. Photo Pcs/hour Pcs/8 hours No. (L*W*H) Photo Pcs/hour Pcs/8hours

(L*W*H) MM

MM

1 250X120X60 3720 29760 7 200x50x300 1600 12800

2 250X120X65 3480 27840 8 200x70x300 1200 9600

3 230x105x72 3120 24960 9 200X100X300 800 6400

4 230x105x76 3000 24000 10 200X150X300 600 4800

5 230x102x63 3480 27840 11 200X200X300 400 3200

6 240X120X90 2436 19488 12 200X200X400 300 2400

Spare parts for Box feeder

No. Item Number Unit No. Item Number Unit

1 Pulling knife 4 Piece 3 conveyer belt 5 meter

2 Supporting roller 4 Piece

Spare parts for Double shaft mixer

Numbe

No. Item Number Unit No. Item Unit

r

1 Mixing blade 20 piece

Spare parts for DZK28 Vacuum extruder

No. Item Number Unit No. Item Number Unit

1 Auger 1 set 4 Clutch claw 3 Piece

Manual clutch

2 Mud press plate 4 Piece 5 2 Piece

sheet

Brick mould

3 Barrel liner 1 set 6 1 set

spare sheet

Spare parts for Brick strip cutter and brick cutter

No. Item Number Unit No. Item Number Unit

Fixed wire

1 endless-belt 1 Piece 4 4 Piece

ring

2 travel switch 1 set 5 tension spring 4 Piece

3 press handle 4 Piece 6 Steel wire 4 Kg

Spare parts for Belt conveyor

No. Item Number Unit No. Item Number Unit

1 supporting roller 2 Piece 3 Vertical roll 2 Piece

2 Pressure roller 2 Piece 4 buckle 1 set

Factory tool box list

No. Item Number Unit No. Item Number Unit

1 Ten openings 1 set 9 saw 1 set

5M tape

2 Ten Plum 2 set 10 1 set

measure

pipe vice

3 Sharp pliers 1 Piece 11 2 Piece

(300) (450)

4 jaw vice 1 Piece 12 12#screwplate 1 Piece

screwdriver

electric

5 (large,middle 3 Piece 13

screwdrivers

1 Piece

,small)

Adjustable wrench wire-stripping

6 2 Piece 14 1 Piece

(8 # ,12# ) pliers

bolt

7 Claw hammer 1 Piece 15 4 Piece

clipper(450)

hammer Fuel injection

8 2 Piece 16 1 Piece

(2 p) (10p) kettle

Note:

1. Validity: Valid before 30th Dec. 2017.

2. Payment terms:Usually,40%down payment,60% balance paid before delivery.

3. Delivery: 15 to 20 working days upon receipt of down payment.

4. Installation: We have a professional team of engineers to to install the machinery, build all kinds of Hoffman kilns and tunnel kilns and train workers for

you.

5. Machinery installation: 60 USD for one engineer per day. visa+ travel air tickets & food, accommodation cost.

6. After sales service: One years after sales service free of charge.

7. V-belt, Motors, one brick mould are supplied free of charge.(All Motors adopt 3-phase Motors with 380V,50Hz.)Price shall be adjusted if for different

volt .)

Machine Quality details

Adobe and red brick cars in Brick production

Contact us for more information for our Clay brick machine

0086 15039963315 0086 18638712391

kai@zzyfmc.com fanchen588 fanchen588@hotmail.com

http://www.yfbrickmachine.com

Our mission is to support you to build one successful modern brick factory which can produce large value for you

You might also like

- Patty Brennan Homeopathic GuideDocument54 pagesPatty Brennan Homeopathic Guidepawajee50% (2)

- CementProject PlanDocument54 pagesCementProject PlanDilnesa EjiguNo ratings yet

- Bill of Quantity For Construction of Containerized Housing UnitsDocument7 pagesBill of Quantity For Construction of Containerized Housing UnitsMashareq SaadiNo ratings yet

- Title: 250tph Gold Processing Plant: Tel: +27 11 748 8800 - Fax: +27 11 748 8898 P.O. Box 750, Benoni, 1500, South AfricaDocument17 pagesTitle: 250tph Gold Processing Plant: Tel: +27 11 748 8800 - Fax: +27 11 748 8898 P.O. Box 750, Benoni, 1500, South AfricaChrispen MachipisaNo ratings yet

- Kuresoi Stakeholders Peace Meeting ReportDocument21 pagesKuresoi Stakeholders Peace Meeting ReportkubasulnNo ratings yet

- Price List For Building MaterialsDocument16 pagesPrice List For Building MaterialsAYOBAMI BOOK100% (1)

- Wiring Diagram Elevator: 123/INDSBY-ELC/1014Document22 pagesWiring Diagram Elevator: 123/INDSBY-ELC/1014Gogik Anto85% (13)

- Afar 2 - Summative Test (Consolidated) Theories: Realized in The Second Year From Upstream Sales Made in Both YearsDocument23 pagesAfar 2 - Summative Test (Consolidated) Theories: Realized in The Second Year From Upstream Sales Made in Both YearsVon Andrei Medina100% (1)

- Generalized Problematic Internet Use Scale 2 (Gpius 2) Scale Items & InstructionsDocument2 pagesGeneralized Problematic Internet Use Scale 2 (Gpius 2) Scale Items & InstructionsShariqa100% (1)

- Residential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationDocument7 pagesResidential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationPedro JonesNo ratings yet

- HR4-10 Automatic Hydraulic Interlocking Lego Brick MachineDocument11 pagesHR4-10 Automatic Hydraulic Interlocking Lego Brick MachineSamuel Luis100% (2)

- Valvula Reductora de Presion Bermad Area 675 720-ULDocument4 pagesValvula Reductora de Presion Bermad Area 675 720-ULChristian FherNo ratings yet

- Block Making Machine Price ListDocument4 pagesBlock Making Machine Price ListgloryofmajapahitNo ratings yet

- Cbs CatalogueDocument195 pagesCbs Cataloguemadaboutalfa8168No ratings yet

- Cement Block Making Machine For SaleDocument4 pagesCement Block Making Machine For Saleanand_shrivastavNo ratings yet

- Boiler Water TDSDocument5 pagesBoiler Water TDSDurjoy ChakrabortyNo ratings yet

- ZCJK Brick Machine Price List - LilyDocument4 pagesZCJK Brick Machine Price List - LilyTimothy Ndeleva100% (1)

- Brick Market Demand Estimation in Bhubaneswar and Adjoining AreasDocument14 pagesBrick Market Demand Estimation in Bhubaneswar and Adjoining AreasSujitNo ratings yet

- Fully Automatic Colour Paver MachinesDocument3 pagesFully Automatic Colour Paver MachinesNipan DekaNo ratings yet

- Double Layer Tile PressDocument6 pagesDouble Layer Tile PressHaile Kebede100% (1)

- New QTJ4-35 Production Line PDFDocument4 pagesNew QTJ4-35 Production Line PDFTwokir A. TomalNo ratings yet

- Kb12 TechnicalDocument17 pagesKb12 TechnicalSohail KhanNo ratings yet

- Indian Backhoe Loaders - March 2008Document33 pagesIndian Backhoe Loaders - March 2008Huseyin TASKINNo ratings yet

- Technical Manual Metsec Mezzanine FloorsDocument23 pagesTechnical Manual Metsec Mezzanine FloorsMusheer BashaNo ratings yet

- Quotation For Fly Ash Brick MachinesDocument9 pagesQuotation For Fly Ash Brick MachinesVetri Odayakulam100% (2)

- 3QGB Screw PumpDocument7 pages3QGB Screw PumpWily WayerNo ratings yet

- Screw-Conveyor-Components-Amp-Design Chapter 1Document30 pagesScrew-Conveyor-Components-Amp-Design Chapter 1Trần Viết QuốcNo ratings yet

- 40 Cubic Meter Concrete Batching PlantDocument11 pages40 Cubic Meter Concrete Batching PlantRanndolf JavierNo ratings yet

- FMC Bucket ElevatorsDocument17 pagesFMC Bucket ElevatorsErizal HamdiNo ratings yet

- Westinghouse Electric Wall Oven WVE665S User ManualDocument48 pagesWestinghouse Electric Wall Oven WVE665S User ManualalexNo ratings yet

- Leather Footwear MachineryDocument10 pagesLeather Footwear MachineryaychiluhimhailuNo ratings yet

- Project Report For Fly Ash Bricks and It'S Allied Products: Plant & MachineryDocument3 pagesProject Report For Fly Ash Bricks and It'S Allied Products: Plant & Machinerydeepam1987No ratings yet

- Elecon Single Roll Crusher CatalogueDocument4 pagesElecon Single Roll Crusher Cataloguegunawansigi36No ratings yet

- CPM All EquipmentDocument161 pagesCPM All EquipmentShree ShreeNo ratings yet

- Internal GearsDocument4 pagesInternal GearsBranislav DjordjevicNo ratings yet

- MDDocument15 pagesMDRakesh Kumar Singh (Phase 1B)No ratings yet

- FactoriesDocument2 pagesFactoriesdanielNo ratings yet

- Concrete Batching Plant CatalogueDocument17 pagesConcrete Batching Plant CatalogueSelf ConceptNo ratings yet

- PowerPack+brochure+ (V1 0)Document2 pagesPowerPack+brochure+ (V1 0)Khánh VũNo ratings yet

- Fenner GearsDocument28 pagesFenner Gearsmanoj983@gmail.comNo ratings yet

- Fly Ash Brick Manufacturing PlantDocument5 pagesFly Ash Brick Manufacturing Plantkarthikraja21No ratings yet

- Oil Expeller Shaft Analysis JournalDocument11 pagesOil Expeller Shaft Analysis JournalRemartin MaglantayNo ratings yet

- 240 2011-08-18 549729 PDFDocument95 pages240 2011-08-18 549729 PDFasitdeyNo ratings yet

- BMG-BEL23042009 Idlers and RollersDocument16 pagesBMG-BEL23042009 Idlers and Rollersstevens75788No ratings yet

- 1 Comparison of SANY and SINO HOWO 10m3 Transit MixerDocument1 page1 Comparison of SANY and SINO HOWO 10m3 Transit MixerAdeelNo ratings yet

- Milling Separator SFI1000A T SFI1500A TDocument32 pagesMilling Separator SFI1000A T SFI1500A TAkhmad Zaenudin100% (1)

- HM150 Roller BrochureDocument8 pagesHM150 Roller BrochurePriyanshu GuptaNo ratings yet

- MTC Flexible Conduit (Anaconda)Document1 pageMTC Flexible Conduit (Anaconda)Aufa Jaya Perkasa LegalityNo ratings yet

- Cross Section of Metal BuildingDocument1 pageCross Section of Metal BuildingtechnopreneurvizagNo ratings yet

- Machinery Used in Const.Document18 pagesMachinery Used in Const.Tanuja Naryal100% (1)

- Plywood SpecificationsDocument2 pagesPlywood Specificationsanuchn007100% (1)

- Price List 2012Document66 pagesPrice List 2012Azhar HassanNo ratings yet

- Sample BOQDocument89 pagesSample BOQkanishkaNo ratings yet

- Bokaro Steel PlantDocument3 pagesBokaro Steel PlantSayan ChatterjeeNo ratings yet

- KTC BricksDocument55 pagesKTC BricksKiran KumarNo ratings yet

- Clay BrickDocument26 pagesClay BrickWerku Koshe Hareru0% (1)

- Material CostDocument8 pagesMaterial CostRebiyu KemalNo ratings yet

- Scaffold Towers Catalog: Rolling & StationaryDocument22 pagesScaffold Towers Catalog: Rolling & StationaryrhoewiebNo ratings yet

- Roller DesignDocument34 pagesRoller DesignAnonymous z4Fe39j100% (1)

- 2.2 JKR 28 Vacuum Brick Production LineDocument5 pages2.2 JKR 28 Vacuum Brick Production LinechrisofomaNo ratings yet

- Packing List UPDATEDocument1 pagePacking List UPDATEgerenciaNo ratings yet

- 2.1.JZK 30 Full Vacuum Brick Production LineDocument2 pages2.1.JZK 30 Full Vacuum Brick Production LineMONATY29No ratings yet

- Machine Spec 2 - Interlocking BrickDocument5 pagesMachine Spec 2 - Interlocking BrickZafry TahirNo ratings yet

- qt4 24 1Document6 pagesqt4 24 1Robin SuNo ratings yet

- Climate Finance Inflows To South Africa (Mitigation Versus Adaptation)Document60 pagesClimate Finance Inflows To South Africa (Mitigation Versus Adaptation)chrisofoma100% (1)

- Injection Molding MachineDocument3 pagesInjection Molding MachinechrisofomaNo ratings yet

- GPDC and Other Charts For Packed ColumnsDocument12 pagesGPDC and Other Charts For Packed ColumnschrisofomaNo ratings yet

- Hazard Identification Report FormDocument1 pageHazard Identification Report FormchrisofomaNo ratings yet

- Distillation Tower Flooding More Complex Than You Think PDFDocument8 pagesDistillation Tower Flooding More Complex Than You Think PDFchrisofomaNo ratings yet

- Comparative Studies of Gasoline Samples Used in Nigeria U.Z. Faruq, M. Runde, B.G. Danshehu, H.N. Yahaya, A.A. Zuru and A.B. MuhammadDocument6 pagesComparative Studies of Gasoline Samples Used in Nigeria U.Z. Faruq, M. Runde, B.G. Danshehu, H.N. Yahaya, A.A. Zuru and A.B. MuhammadchrisofomaNo ratings yet

- Haskel Gas Booster Booklet 4-30-16Document35 pagesHaskel Gas Booster Booklet 4-30-16chrisofoma100% (1)

- MEOH Flow ChartDocument1 pageMEOH Flow ChartchrisofomaNo ratings yet

- 2.2 JKR 28 Vacuum Brick Production LineDocument5 pages2.2 JKR 28 Vacuum Brick Production LinechrisofomaNo ratings yet

- Abstract - Marathon Oil Company - Unloading Horizontal Gas WellsDocument1 pageAbstract - Marathon Oil Company - Unloading Horizontal Gas WellschrisofomaNo ratings yet

- Euromktscan PlattsDocument16 pagesEuromktscan PlattschrisofomaNo ratings yet

- T22 User ManualDocument67 pagesT22 User ManualchrisofomaNo ratings yet

- Android CodesDocument2 pagesAndroid CodeschrisofomaNo ratings yet

- Fee Payment Form - Application For Permanent ResidenceDocument1 pageFee Payment Form - Application For Permanent ResidenceSlowfingerNo ratings yet

- RE StudioDocument41 pagesRE StudiochrisofomaNo ratings yet

- Hell by D.L. MoodyDocument7 pagesHell by D.L. MoodyLisaNo ratings yet

- Iridium Satellite System (Iss) : Wireless CommunicationDocument11 pagesIridium Satellite System (Iss) : Wireless CommunicationSmrithi K MNo ratings yet

- The Radiology Assistant - Fleischner 2017 GuidelineDocument11 pagesThe Radiology Assistant - Fleischner 2017 GuidelineHenry J. Hernández L.No ratings yet

- Sony Kdl-40xbr9 Kdl-46xbr9 Kdl-52xbr9 Ex2m ChassisDocument118 pagesSony Kdl-40xbr9 Kdl-46xbr9 Kdl-52xbr9 Ex2m ChassisAndy WilsonNo ratings yet

- Whittington 22e Solutions Manual Ch14Document14 pagesWhittington 22e Solutions Manual Ch14潘妍伶No ratings yet

- Academic Journal Guide 2021-MethodologyDocument22 pagesAcademic Journal Guide 2021-MethodologySyedNo ratings yet

- Understanding Organizational Behavior: de Castro, Donna Amor Decretales, Thea Marie Estimo, Adrian Maca-Alin, SaharaDocument41 pagesUnderstanding Organizational Behavior: de Castro, Donna Amor Decretales, Thea Marie Estimo, Adrian Maca-Alin, SaharaAnna Marie RevisadoNo ratings yet

- Safety Data Sheet Carbon Cathode SolutionDocument11 pagesSafety Data Sheet Carbon Cathode SolutionJeff BanasekNo ratings yet

- Board of Technical Education (Student Marksheet)Document2 pagesBoard of Technical Education (Student Marksheet)Manoj SainiNo ratings yet

- Mathematics Past Paper QuestionsDocument174 pagesMathematics Past Paper Questionsnodicoh572100% (2)

- Chinese Vocabulary BodyDocument3 pagesChinese Vocabulary BodyWei LeeNo ratings yet

- Part UhxDocument51 pagesPart UhxSaif Eddine MJNo ratings yet

- Course CurriculumDocument3 pagesCourse CurriculumPRASENJIT MUKHERJEENo ratings yet

- Informe Sobre El Manejo de CostasDocument88 pagesInforme Sobre El Manejo de CostasMetro Puerto RicoNo ratings yet

- Ai-Ai ResumeDocument3 pagesAi-Ai ResumeNeon True BeldiaNo ratings yet

- Manual Tecnico Jblgo PDFDocument2 pagesManual Tecnico Jblgo PDFMarcosDanielSoaresNo ratings yet

- STEWART Briony Kumiko and The Dragon FINAL2010Document8 pagesSTEWART Briony Kumiko and The Dragon FINAL2010Tahnee HallNo ratings yet

- Glass Configurator Datasheet 2023 03 27Document1 pageGlass Configurator Datasheet 2023 03 27Satrio PrakosoNo ratings yet

- Physical Pendulum - Angular SHM - Solved ProblemsDocument7 pagesPhysical Pendulum - Angular SHM - Solved ProblemsHomayoon GeramifarNo ratings yet

- Software Engineering. Specification, Implementation, VerificationDocument186 pagesSoftware Engineering. Specification, Implementation, Verificationazariel.rodrigo100% (1)

- Azosprilum 2Document24 pagesAzosprilum 2Dipti PriyaNo ratings yet

- 3700 S 24 Rev 0 ENDocument3 pages3700 S 24 Rev 0 ENJoão CorrêaNo ratings yet

- Arlon 38NDocument4 pagesArlon 38NRavindrakumar ParvathiniNo ratings yet

- 0547 s06 TN 3Document20 pages0547 s06 TN 3mstudy123456No ratings yet

- BDM SF 3 6LPA 2ndlisDocument20 pagesBDM SF 3 6LPA 2ndlisAvi VatsaNo ratings yet

- Rear Drive Halfshafts: 2016.0 RANGE ROVER (LG), 205-05Document46 pagesRear Drive Halfshafts: 2016.0 RANGE ROVER (LG), 205-05SergeyNo ratings yet