Professional Documents

Culture Documents

Ico3s Iom Manual

Ico3s Iom Manual

Uploaded by

Aditya B. RyantoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ico3s Iom Manual

Ico3s Iom Manual

Uploaded by

Aditya B. RyantoCopyright:

Available Formats

Maxseal ICO3S Marking Indicator

MARKING (TYPICAL) DESCRIPTION

Description

Installation, Operation and WARNING: DO NOT OPEN WHEN AN

EXPLOSIVE ATMOSPHERE IS PRESENT

COVER FORMS PART OF FLAMEPROOF ENCLOSURE AND SHOULD NOT BE

REMOVED WHEN AN EXPLOSIVE ATMOSPHERE IS PRESENT

The ICO3S is an Ex certified solenoid valve used to control a

pressurised media (liquid or gas). The standard variant

Maintenance Instructions (MI0294 Rev.9) WARNING:MAXIMUM INTERNAL RISE 30K,

USE SUITABLY RATED CABLE

THIS INDICATES THE MAX INTERNAL TEMPERATURE RISE,

THIS CAN BE USED TO EVALUATE CABLE TEMPERATURE RATING.

(3/2 0-12 bar automatic) has the following characteristics.

Ex II 2 G D ATEX MARKING EQUIPMENT SUITABLE FOR EXPLOSIVE GAS AND DUST

ENVIRONMENTS. EQUIPMENT GROUP 2 EQUIPMENT CATEGORY 2.

The following instructions apply to equipment certificate numbers: - Equipment weighs 2.0 kg () 2.5kg (1/2) Typical.

Ex tD A21 IEC MARKING - DUST ENVIRONMENTS

- Valves typical speed <70ms pull in, <50ms drop out.

Exd Certificate No. SIRA IECEx 05.0029 IP66 INGRESS PROTECTION RATING FOR BOTH ATEX AND IEC

66 = STRONG WATER JETS

Exd Certificate No. SIRA ATEX 1156

Exd Certificate No CSA 1805901 (LR51486) Exmbe IIC EQUIPMENT RELIES ON Exmbe PROTECTION

SUITABLE FOR USE IN Ex GAS GROUP IIC

Exmbe Certificate No. SIRA IECEx SIR05.0056 Exd IIC EQUIPMENT RELIES ON Exd PROTECTION

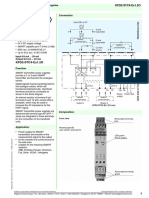

SUITABLE FOR USE IN Ex GAS GROUP IIC Standard IC03 Construction and Installation Dimensions

Exmbe Certificate No. SIRA ATEX 5284 T4 Ta (-60 to 80C) T-CLASSIFIED EQUIPMENT SHOULD NOT BE EXPOSED TO TEMP OUTSIDE

THE SPECIFIED TEMPERATURE RANGES (Ta). TYPICAL MARKING SHOWN.

FUNCTIONAL SAFETY Certificate SIRA FSP 04001/01

Y013AA1H1BS WORKING CONDITIONS SHOULD NOT EXEED THE CAPABILITIES OF

COMPONENTS /MATERIALS DETAILED IN THE CONSTRUCTION

THE ICO3 SHALL ONLY BE USED IN ACCORDANCE WITH WP 0-12BAR THE RANGE AND MAXIMUM MEDIA WORKING PRESSURE RATING

INLET, OUTLET, VENT PIPEWORK SHOULD BE CONNECTED SUCH THAT IT FUNCTIONS AS PORT

REQUIREMENTS OF THIS DOCUMENT. READ ALL THE MARKINGS

INSTRUCTIONS CAREFULLY BEFORE USING THIS PRODUCT. 24V DC 3W (1/4) 8W (1/2) THE ELECTRICAL SUPPLY LIMITS ARE NOMINAL VOLTAGE +/-10%

Serial No. FOR YEAR OF MANUFACTURE REFER TO CERTIFICATE OF CONFORMITY

The IC03S is designed and certified to meet the requirements of:

IEC61508-1:1998 & IEC61508-2:2000 as being suitable for use in Expected duty

safety-related applications up to and including SIL3 & SIL4 where The ICO3 should not be used in excess of the expected duty limits

safety operation of the valve is by de-energisation of the solenoid. as shown below. In special applications that exceed these duty

This manual covers all installation, maintenance and operation limits, contact Maxseal sales before installing / operating an ICO3.

requirements for these applications.

CONDITIONS LIMITS

Installation by a suitably-trained personnel in accordance with the FUNCTION The working temperature and pressure shall not exceed the marked label

applicable code of practice e.g. EN 60079-14:1997. rating. The valve should not be operated at a speed >6 cycles/min.

ENVIRONMENT All external conditions shall not exceed IP66. External conditions shall

Inspection and maintenance of equipment by trained personnel in not degrade the Exd enclosure or pressure boundary.

accordance with the applicable code of practice e.g. EN 60079-17. MAINTENANCE 10 years or 100,000 cycles. 12 month Max Proof Test Interval.

PERIOD For best practice exercise the valve once per month.

Repair of this equipment by suitably trained personnel in LIFE 20 years or 1million cycles.

accordance with the applicable code of practice e.g. EN 60079-19. MEDIA Media: Instrument air or non-corrosive hydraulic fluids - clean and free

from particulate pollution. A suitable inlet filter should be fitted (eg. 20 m)

Components to be incorporated into or used as replacement parts

for the equipment shall be fitted by suitably trained personnel in Part Number Details

accordance with this documentation.

The certification of this equipment relies upon 316 stainless steel

materials used in its construction.

Maxseal sales

If the equipment is likely to come into contact with aggressive

substances, then it is the responsibility of the user to take suitable

precautions that prevent it from being adversely affected, thus

TEL.: +44(0) 1202 647331

ensuring that the type of protection provided by the equipment is FAX: +44(0) 1202 647302

not compromised. E-MAIL: maxseal@thompson-valves.com

Aggressive substances: e.g. acidic liquids or gases that may

WEB: www.thompson-valves.com

attack metals, or solvents that may affect polymeric materials.

Maxseal products are manufactured by:

Suitable precautions: e.g. regular checks as part of

routine inspections or establishing from the materials data sheets

Thompson Valves

that it is resistant to specific chemicals. 17 Balena Close, Creekmoor,

Poole, Dorset, England. BH17 7EF

DO NOT MODIFY, RECLAIM OR CHANGE ANY COMPONENTS.

Storage and Handling For best practice, the valve should ideally be exercised at Maintenance

least once a month.

The ICO3 should not be stored in a corrosive environment. All

It is recommended that all products be returned to Thompson

ports should remain sealed and the valve markings made visible.

Removing an existing valve Valves for refurbishment.

Recommended storage temperature 5 to 25 C, relative humidity

<75%. Storage areas shall not contain ozone producing

Tools Spares

equipment (eg. welding equipment, mercury vapour lamps). Due

3mm Electrical Screw Driver Only Maxseal spares kits should be used. Maxseal supply

attention should be paid to personal protection during handling.

Allen Keys: 2.5mm, 3mm, 4mm and 5mm. seals specially designed for the duty. Incorrect seals will affect

5mm A/F spanner. 5mm Tommy Bar. valve performance.

Operation Main valve kit includes: seals and operating spring.

1. Obtain work permit and check area for hazards.

All ICO3 solenoid valves consist of an Exd or Exmbe enclosure. 2. Isolate valve from all pipeline and electrical supplies. Lubrication

In order for the enclosure to provide flameproof protection: 3. Loosen M5 locking screw and unscrew cover. -60C to 90C: Molycote 55 medium grease

- None of the flameproof joints shall be damaged. 4. Disconnect supply cable and remove.

- All flameproof joints with threads shall be fully engaged. 5. Remove pipe connections from valve assembly. Part A. Disassembling a standard valve

6. Unscrew mounting bolts and remove the valve. 1. Remove the Cap Head Bolts at the base of the valve body

and remove valve body and armature assembly.

Installing a valve 2. Remove C/Sunk screws holding valve to flange and remove

valve body.

General requirements 3. Secure armature with a Tommy bar and using a spanner

- Pipe work and media must be clean. remove the spool assembly.

- Suitable Inlet filters are recommended (e.g. <20 microns). 4. Separate all valve assembly components, noting orientation,

- Prevent pipe sealant from entering the system. sequence and position of parts.

- Use only correct tools (i.e. as listed above).

- Do not use valve as a lever. Part B. Examining a valves components

- Earth equipment to prevent the build up of electrostatic charge. Examine and replace all worn or damaged parts.

- Ensure all interfacing equipment is rated to the expected duty The flameproof joints will retain their original certified clearances

conditions and will not degrade the integrity of the ICO3. provided they are not damaged.

Replace all seals, seats and operating spring with Maxseal spare

Mounting parts kit. All seals should be lubricated and have no deformation.

An ICO3 will function satisfactorily when mounted inclined from the All seating and sealing faces should be free from contamination,

vertical. However for maximum life and efficiency mount vertically - marks, scratches, etc.

Do not invert. The ICO3 is not designed for use in vibration DO NOT MODIFY OR RECLAIM FLAMEPROOF JOINTS.

applications. Do not mechanically stress the equipment.

Part C. Assembling a standard valve

High temperature applications Smear all seals with recommended grease. Build assemblies in

In applications where the media is > 80C, an IC03 with a high reverse order shown in part A.

The pressurised media is retained within the valve assembly Torque: Valve M5 bolts to 5Nm. Valve spool to 4Nm.

temperature spacer shall be used. The high temperature spacer

(pressure boundary) by the mechanical strength of all its metal

provides a thermal barrier between the media and the enclosure.

parts, seats and seals. Degradation of any of these components Part D. Adjusting & testing a standard valve

To ensure that the spacer performs its intended function:

will cause the valve to leak. 1. Loosen M5 locking screw and remove solenoid cover.

- The user shall provide ventilation around the valve assembly,

enclosure and spacer. 2. Make connections to valve ports as per markings.

The flow path of the media is altered by moving the spool 3. Apply air to valve body and energise coil.

- The valve assembly and Exd enclosure shall not be lagged.

assembly and engaging / disengaging the seats. 4. Using 5mm AF Allen Key screw down core to the point

Additionally, ensure all associated parts, including cable glands

The spool assembly can be moved by either: just before ports leak.

and cabling are fit for rated duty.

5. Screw core back a further 1/10 of a turn.

Energising the coil to produce an electromotive force. Low temperature applications 6. Ensure valve operates correctly at Nom Voltage 12%

Applying a pressure to a piston. Contact Maxseal Sales for special operating conditions.

Applying a mechanical force to a linkage. Part E. Problems

Compressing a mechanical spring. Procedure If the IC03 does not function as intended, do not install valve.

1. Make connections to the valve ports as required. DO NOT Repeat the maintenance procedures Parts A to D. If the problem

Restricting the spool movement or allowing the seats to degrade, OVERTIGHTEN. persists contact Maxseal Sales.

will not allow the flow to be re-directed. 2. Loosen M5 locking screw and remove solenoid cover.

3. Install cable using an appropriate certified gland fit for duty. If you are not sure about any application, maintenance or

The ICO3 has an IP66 rating. Degradation of the IP66 seals / 4. Make terminal connections as labelled. All terminals must be technical issue, contact Maxseal Sales for advice.

gaskets / sealing faces or failure to tighten all sealing joints, will tightened before commissioning.

allow water to leak inside the enclosure. 5. Replace solenoid cover and lock M5 locking screw.

You might also like

- ISO 7597 - 2013 - Hook With LatchDocument18 pagesISO 7597 - 2013 - Hook With LatchRoby MastreNo ratings yet

- IEC 60079-2-2014 Cor1-2015Document8 pagesIEC 60079-2-2014 Cor1-2015grauNo ratings yet

- 03 - A1 - CCU (Cargo Carrying Unit) Rev.2 (MIGAS) PDFDocument77 pages03 - A1 - CCU (Cargo Carrying Unit) Rev.2 (MIGAS) PDFelvin100% (2)

- Iso 10619 2 2021Document10 pagesIso 10619 2 2021ThejaswiniNo ratings yet

- International Standard: Cryogenic Vessels - Valves For Cryogenic ServiceDocument6 pagesInternational Standard: Cryogenic Vessels - Valves For Cryogenic ServiceRamazan YaşarNo ratings yet

- CI Checklist Pile InstallationDocument6 pagesCI Checklist Pile InstallationDilhara WickramaarachchiNo ratings yet

- Model Selection 1: Process ValvesDocument15 pagesModel Selection 1: Process ValvesBagus SetyaNo ratings yet

- ISA Submits New Control Valve StandardsDocument1 pageISA Submits New Control Valve Standards윤병택No ratings yet

- Air Torque Pneumatic Actuator ManualDocument1 pageAir Torque Pneumatic Actuator ManualAmit AGRAWALNo ratings yet

- Liquid SizingDocument38 pagesLiquid SizingChetan Churi100% (1)

- IMF IMF IMF IMF: Solutions For Pressure RegulationDocument8 pagesIMF IMF IMF IMF: Solutions For Pressure RegulationMohamed MahmoudNo ratings yet

- Surface Vehicle StandardDocument9 pagesSurface Vehicle Standardanupthatta0% (1)

- Reciprocating Compressors For Industrial Refrigeration Grasso VDocument50 pagesReciprocating Compressors For Industrial Refrigeration Grasso VCUIDAITONo ratings yet

- Amazon Web Services TrainingDocument5 pagesAmazon Web Services TrainingvisualpathNo ratings yet

- DBB CatalogueDocument28 pagesDBB CatalogueHeri SetyantoNo ratings yet

- Robert Cort Brochure Oct12Document8 pagesRobert Cort Brochure Oct12vishnuNo ratings yet

- NR 26 Safety SignallingDocument6 pagesNR 26 Safety SignallingMarcia Rezende AntonioNo ratings yet

- NF 16101 Explained PDFDocument8 pagesNF 16101 Explained PDFhammouche_soufianeNo ratings yet

- RB 4700 BrochureDocument6 pagesRB 4700 Brochuretuan pham minhNo ratings yet

- Sa 193&sa 193M PDFDocument18 pagesSa 193&sa 193M PDFGabriel RodríguezNo ratings yet

- AIR1707B - Patterns of O-Ring FailuresDocument20 pagesAIR1707B - Patterns of O-Ring FailuresEmiliya Emiliya100% (1)

- ISO 4126-5 2004 Controlled Safety Pressure Relief SystemDocument34 pagesISO 4126-5 2004 Controlled Safety Pressure Relief SystemPushkar GopalNo ratings yet

- API 622 Valve Packing For Fugitive EmissionsDocument2 pagesAPI 622 Valve Packing For Fugitive EmissionsHungphamphiNo ratings yet

- Thermalrock S Product Data Sheet inDocument4 pagesThermalrock S Product Data Sheet inIvyrod Umalsa- EnterprisesNo ratings yet

- Mako Compressors Breathing Air Catalog 2021Document30 pagesMako Compressors Breathing Air Catalog 2021jose chirinoNo ratings yet

- Lcie Bureau Veritas Atex Poster PDFDocument1 pageLcie Bureau Veritas Atex Poster PDFAncaOniscuNo ratings yet

- Specifications, Applications, Service Instructions & PartsDocument20 pagesSpecifications, Applications, Service Instructions & Partsfranmolina1212No ratings yet

- JIS ChannelsDocument5 pagesJIS ChannelsRuri IswadiNo ratings yet

- Mesc Spe 76 121 2016Document6 pagesMesc Spe 76 121 2016Salahuddin FarooquiNo ratings yet

- As 1349-1986 Bourdon Tube Pressure and Vacuum GaugesDocument7 pagesAs 1349-1986 Bourdon Tube Pressure and Vacuum GaugesSAI Global - APACNo ratings yet

- Fas 13Document6 pagesFas 13LPG Equipment Consulting and ServicesNo ratings yet

- 3 - Rite Manual de Instalacion y MantenimientoDocument18 pages3 - Rite Manual de Instalacion y MantenimientoRoman Arango Herrera0% (1)

- Sferova API6 Ball Valve CatalogueDocument27 pagesSferova API6 Ball Valve CatalogueWong JowoNo ratings yet

- Ball Valves - R43/R44 Trunnion MountedDocument10 pagesBall Valves - R43/R44 Trunnion MountedThomasFrenchNo ratings yet

- IMIOrton MV SeriesDocument4 pagesIMIOrton MV SeriesFelipe Gamboa GálvezNo ratings yet

- Gear Box No Load Run Test ReportDocument1 pageGear Box No Load Run Test ReportPRABHUDAYAL SHARMANo ratings yet

- Astm F 541-04Document6 pagesAstm F 541-04Jorge ToribioNo ratings yet

- 3300 XL 8mm Proximity Transducer System: Bently Nevada Asset Condition MonitoringDocument32 pages3300 XL 8mm Proximity Transducer System: Bently Nevada Asset Condition MonitoringFamilia Mena GodoyNo ratings yet

- Tosaca Catalogue PDFDocument16 pagesTosaca Catalogue PDFgabNo ratings yet

- ASTM F1545 Plastic Lined Pipe 0803Document6 pagesASTM F1545 Plastic Lined Pipe 0803JabranYounasNo ratings yet

- N176 Iso CD 5149 4 2006 PDFDocument25 pagesN176 Iso CD 5149 4 2006 PDFniceday9_4100% (1)

- Understanding Ped For Asme VesselsDocument33 pagesUnderstanding Ped For Asme VesselsRamakrishnan SrinivasanNo ratings yet

- Machinery Directive 98 37 ECDocument1 pageMachinery Directive 98 37 ECAnonymous zPeOAQUYjNo ratings yet

- Is 8451Document30 pagesIs 8451Ramakrishnan AmbiSubbiahNo ratings yet

- BS 5146-1 Petroleum Valves InspectionDocument11 pagesBS 5146-1 Petroleum Valves InspectionPradhipta86No ratings yet

- Orbit Parts List and Ordering InstructionsDocument24 pagesOrbit Parts List and Ordering Instructionskeertiraj09No ratings yet

- Catalogue KLELINE GBDocument28 pagesCatalogue KLELINE GBA_ValsamisNo ratings yet

- Is 210Document16 pagesIs 210Debopriyo GhoshNo ratings yet

- Type: Cocon 13: Operators-ManualDocument33 pagesType: Cocon 13: Operators-ManualAbraham Tellez FloresNo ratings yet

- Metal Hose With Braiding Catalogue ArsenflexDocument16 pagesMetal Hose With Braiding Catalogue ArsenflexcecotheoneNo ratings yet

- NRV - IntervalveDocument2 pagesNRV - IntervalveRajkishorNo ratings yet

- Hydrant ValvesDocument4 pagesHydrant ValvesoscarninanNo ratings yet

- Sailor VHFDocument5 pagesSailor VHFsudipta_kolNo ratings yet

- 618ti PDFDocument8 pages618ti PDFpeach5No ratings yet

- BS EN 837-1:1998 Pressure Gauges. Bourdon Tube Pressure Gauge - Part 1: Dimensions Metrology Requirements and TestingDocument3 pagesBS EN 837-1:1998 Pressure Gauges. Bourdon Tube Pressure Gauge - Part 1: Dimensions Metrology Requirements and TestingСергей ПарахинNo ratings yet

- Vk-202A Transducer: SpecificationsDocument2 pagesVk-202A Transducer: SpecificationsAditya PandeyNo ratings yet

- RevA MP Series ManualDocument34 pagesRevA MP Series ManualD. Thanh NguyễnNo ratings yet

- Im 1XSW-04Document23 pagesIm 1XSW-04belenNo ratings yet

- E1fwm MetricDocument1 pageE1fwm MetricHazzim Abu HanipahNo ratings yet

- MURS320: Vishay General SemiconductorDocument5 pagesMURS320: Vishay General SemiconductorAgustin DiocaNo ratings yet

- TD 210-1-ENG ShedDocument2 pagesTD 210-1-ENG ShedzaidNo ratings yet

- I Om IndustrialDocument6 pagesI Om Industrialmajin buuNo ratings yet

- ICM518 LIS450 Sell SheetDocument1 pageICM518 LIS450 Sell SheetdevaughnNo ratings yet

- 816Document4 pages816Nic ParrottNo ratings yet

- 425ºC AHT: Ower EATDocument2 pages425ºC AHT: Ower EATSivagurunathan SpNo ratings yet

- General Service Solenoid Valves: ConstructionDocument3 pagesGeneral Service Solenoid Valves: ConstructionAditya B. RyantoNo ratings yet

- DatasheetDocument3 pagesDatasheetAditya B. RyantoNo ratings yet

- Manual Topworx D Series Discrete Valve Controller Hart Protocol Topworx en 82604Document20 pagesManual Topworx D Series Discrete Valve Controller Hart Protocol Topworx en 82604Aditya B. RyantoNo ratings yet

- Belman Wafer Check Lug VelanDocument2 pagesBelman Wafer Check Lug VelanAditya B. Ryanto100% (1)

- Gate Valve CataogueDocument4 pagesGate Valve CataogueAditya B. RyantoNo ratings yet

- Material EquivalentsDocument25 pagesMaterial EquivalentsAditya B. Ryanto100% (7)

- Kwik Clamp SizesDocument1 pageKwik Clamp SizesAditya B. RyantoNo ratings yet

- Examples Use of VisuDocument4 pagesExamples Use of VisumiguelpomaNo ratings yet

- Pad8 W57acDocument2 pagesPad8 W57acpandavision76No ratings yet

- Voltage Drop Calc: 1Ph 2wire 1Ph 2wire Tap 1Ph 2wire LengthDocument13 pagesVoltage Drop Calc: 1Ph 2wire 1Ph 2wire Tap 1Ph 2wire LengthWilson PavãoNo ratings yet

- Mettler DL36 Operating InstructionsDocument44 pagesMettler DL36 Operating InstructionsLadycorinth137No ratings yet

- PPPLF Transaction Specific Disclosures 04-12-21Document1,044 pagesPPPLF Transaction Specific Disclosures 04-12-21Dez Drii MarieNo ratings yet

- 01 Introduction On Data DictionaryDocument22 pages01 Introduction On Data Dictionary19hwang59No ratings yet

- A Gauge BlockDocument3 pagesA Gauge Blockmy nameNo ratings yet

- MFMEA Workshop Class Overhead 04Document43 pagesMFMEA Workshop Class Overhead 04Carlos Lourenço100% (2)

- Introduction To Broadband: - Networking Basics - Overview of NIB - Broadband Network - Installations OverviewDocument64 pagesIntroduction To Broadband: - Networking Basics - Overview of NIB - Broadband Network - Installations OverviewsrshelkeNo ratings yet

- Informatics Practices: Class XI (As Per CBSE Board)Document23 pagesInformatics Practices: Class XI (As Per CBSE Board)AtanuBhandaryNo ratings yet

- Cathodic Protection Clarifier Specification-Jun 2010Document7 pagesCathodic Protection Clarifier Specification-Jun 2010656665665No ratings yet

- Design Guide 205 TJ PDFDocument18 pagesDesign Guide 205 TJ PDFmick2560100% (1)

- Steel Quiz PDFDocument2 pagesSteel Quiz PDFEmad A.AhmadNo ratings yet

- Events Manager CV Template PDFDocument2 pagesEvents Manager CV Template PDFHamed GrechNo ratings yet

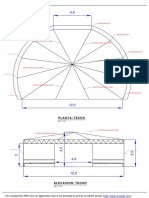

- Planos de Cobertura ModelDocument1 pagePlanos de Cobertura Modelmss_mavelNo ratings yet

- Farlinx Mini x.25 Gateway DatasheetDocument6 pagesFarlinx Mini x.25 Gateway Datasheetbeto0206No ratings yet

- Especificaciones Exxal 8Document2 pagesEspecificaciones Exxal 8Gonzalo Ale Olave A.No ratings yet

- PTP 400 Series User Guide: Motorola Point-To-Point Wireless SolutionsDocument212 pagesPTP 400 Series User Guide: Motorola Point-To-Point Wireless SolutionsAlseny M'mah SoumahNo ratings yet

- Defects and Discontinuities: Boiler and Mechanical PowerDocument78 pagesDefects and Discontinuities: Boiler and Mechanical PowerthejusNo ratings yet

- All Operators Freq's & BCCH'sDocument17 pagesAll Operators Freq's & BCCH'smailsianNo ratings yet

- ELECTRICALDocument34 pagesELECTRICALPeetNo ratings yet

- DB2 QuestionnaireDocument4 pagesDB2 Questionnairelokeshscribd186No ratings yet

- Schneider Lc1e3210n5 1no 415v Ac Power Contactor Specification SheetDocument3 pagesSchneider Lc1e3210n5 1no 415v Ac Power Contactor Specification Sheetrajeshgat2008No ratings yet

- Juniper Netscreen NS 5GT Series & GreenBow IPSec VPN Client Software ConfigurationDocument14 pagesJuniper Netscreen NS 5GT Series & GreenBow IPSec VPN Client Software ConfigurationgreenbowNo ratings yet

- Computer Networks (CS425) : Network Layer (Continued... )Document3 pagesComputer Networks (CS425) : Network Layer (Continued... )akyadav123No ratings yet