Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

10 viewsSuper Critical Power - Part56

Super Critical Power - Part56

Uploaded by

Dhiraj SatyamThe document provides technical specifications for air preheaters used in a supercritical 660/800 MW thermal power plant unit. It states that regenerative tri-sector or bi-sector air preheaters should be used with steam coil heating capabilities. The air preheaters must be able to handle operating conditions including a 27 degree Celsius ambient temperature and 60% relative humidity.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Essentials of Steam Turbine Design and Analysis: Back To BasicsDocument9 pagesEssentials of Steam Turbine Design and Analysis: Back To BasicsJohn AnthoniNo ratings yet

- 2021-2022 GE Gas-Power-CatalogDocument105 pages2021-2022 GE Gas-Power-Catalogapartado69No ratings yet

- Class IV-Model Question paper-MEK (General)Document3 pagesClass IV-Model Question paper-MEK (General)ritheshNo ratings yet

- The Source of Hydraulic PowerDocument16 pagesThe Source of Hydraulic Powersekar507100% (1)

- 2.2.4 Air Pre Heaters and Steam Coil Air Pre Heaters 2.2.4.1 Air Pre Heaters (Aphs)Document22 pages2.2.4 Air Pre Heaters and Steam Coil Air Pre Heaters 2.2.4.1 Air Pre Heaters (Aphs)sabrila wandaNo ratings yet

- Super Critical Power - Part58Document1 pageSuper Critical Power - Part58Dhiraj SatyamNo ratings yet

- Super Critical Power - Part35Document1 pageSuper Critical Power - Part35Dhiraj SatyamNo ratings yet

- 17chap18 PDFDocument9 pages17chap18 PDFmick.pride81No ratings yet

- Heat Loss Calculation in Fluidised BedDocument3 pagesHeat Loss Calculation in Fluidised BedArun MuraliNo ratings yet

- Super Critical Power - Part31Document1 pageSuper Critical Power - Part31Dhiraj SatyamNo ratings yet

- Chap 14Document14 pagesChap 14Khurram AliNo ratings yet

- Angel LinoDocument9 pagesAngel LinoSAAD AL.SHAHRANINo ratings yet

- Parametric and Working Fluid Analysis of A Combined Organic Rankine-Vapor Compression Refrigeration System Activated by Low-Grade Thermal EnergyDocument10 pagesParametric and Working Fluid Analysis of A Combined Organic Rankine-Vapor Compression Refrigeration System Activated by Low-Grade Thermal EnergyCatalina DobreNo ratings yet

- Emch394 - Final Project ReportDocument7 pagesEmch394 - Final Project Reportapi-402108223No ratings yet

- Experimental Investigation of A Dual Stage Ignition Biomass DowndraftDocument10 pagesExperimental Investigation of A Dual Stage Ignition Biomass Downdraft吳浩宇No ratings yet

- Zero Export Steam Reforming Article - 1001307 PDFDocument8 pagesZero Export Steam Reforming Article - 1001307 PDFSakthi VelNo ratings yet

- Heat Balane Diagram & Interface Parameters of An 800 MW Unit.Document4 pagesHeat Balane Diagram & Interface Parameters of An 800 MW Unit.Ashwin NarayanNo ratings yet

- Turbocharger Test Stand With A Hot Gas Generator For High - Performance Supercharging SystemsDocument4 pagesTurbocharger Test Stand With A Hot Gas Generator For High - Performance Supercharging SystemsintelligentloveNo ratings yet

- Analysis of A 10 MW Recompression Supercritical Carbon Dioxide Cycle For Tropical Climatic Conditions Sathish Et AlDocument14 pagesAnalysis of A 10 MW Recompression Supercritical Carbon Dioxide Cycle For Tropical Climatic Conditions Sathish Et AlTanatswa MoyoNo ratings yet

- Tech Job 41768Document10 pagesTech Job 41768Sachin GangwarNo ratings yet

- Carbon Dioxide Condensation Cycles For Power Production: G. AngelinoDocument9 pagesCarbon Dioxide Condensation Cycles For Power Production: G. AngelinoDa DdeNo ratings yet

- Improvement in Efficiency of Air Preheater in Boiler Tps-1 ExpansionDocument7 pagesImprovement in Efficiency of Air Preheater in Boiler Tps-1 Expansionحمودي معزNo ratings yet

- ASHRAE 90.1 LEED RequirementsDocument2 pagesASHRAE 90.1 LEED RequirementsAbdul Malik Malinao DiamlaNo ratings yet

- S LB CombustifumeDocument20 pagesS LB CombustifumeThaiminh VoNo ratings yet

- Matlab Program Computes ThermalDocument9 pagesMatlab Program Computes ThermalBahar MeschiNo ratings yet

- Super Critical Power - Part38Document1 pageSuper Critical Power - Part38Dhiraj SatyamNo ratings yet

- ES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Document10 pagesES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Nikki RobertsNo ratings yet

- Aerospace Engineering: University Institute of EngineeringDocument2 pagesAerospace Engineering: University Institute of EngineeringAvishiNo ratings yet

- Genset Installation Recommendation: A LocationDocument27 pagesGenset Installation Recommendation: A LocationShiv Kumar VermaNo ratings yet

- Performance Enhancement of Unitary and Packaged Air Conditioners With Phase Change MaterialDocument6 pagesPerformance Enhancement of Unitary and Packaged Air Conditioners With Phase Change MaterialsergioNo ratings yet

- RS1075 - Modelling of The BP 6MW Burner Test Rig With FIHR V 2.0Document13 pagesRS1075 - Modelling of The BP 6MW Burner Test Rig With FIHR V 2.0Ian MannNo ratings yet

- Ventilation Recommendation C32 1500 KVA StandbyDocument2 pagesVentilation Recommendation C32 1500 KVA StandbyjibinNo ratings yet

- Gas Turbine Problem Statement 29Document2 pagesGas Turbine Problem Statement 29Daniel Andres Canro CalderónNo ratings yet

- Enclosed Combustion EquipmentDocument4 pagesEnclosed Combustion EquipmentSteve WanNo ratings yet

- Vitocrossal 200-cm2 SM gw6b TDMDocument16 pagesVitocrossal 200-cm2 SM gw6b TDMCiprian BalcanNo ratings yet

- Khadem I 2017Document12 pagesKhadem I 2017Michael KennedyNo ratings yet

- Chapter 8 - SolutionDocument43 pagesChapter 8 - SolutionIzaNo ratings yet

- CC GDocument8 pagesCC GHue Kin FeiNo ratings yet

- JSIR 63 (1) 68-73 - Edit PDFDocument6 pagesJSIR 63 (1) 68-73 - Edit PDFshadow friendNo ratings yet

- On Mixtures As Working Fluids For Air-Cooled ORC Bottoming Power Plants of Gas TurbinesDocument12 pagesOn Mixtures As Working Fluids For Air-Cooled ORC Bottoming Power Plants of Gas Turbinescarlo83No ratings yet

- Super Critical Power - Part40Document1 pageSuper Critical Power - Part40Dhiraj SatyamNo ratings yet

- Advanced Combustion Systems For Annealing and Pickling LinesDocument5 pagesAdvanced Combustion Systems For Annealing and Pickling LinesAlessandro LazzarettoNo ratings yet

- Technical Spec BoilerDocument13 pagesTechnical Spec Boilermochamad RasjidNo ratings yet

- Sistemas de PotenciaDocument6 pagesSistemas de PotenciaEduardo VCNo ratings yet

- Turbine Inlet Air CoolingDocument4 pagesTurbine Inlet Air Coolingkrazylion100% (2)

- Temperature: Heat Transfer and Air Flow Analysis Environmental Chambers and Air ServosDocument12 pagesTemperature: Heat Transfer and Air Flow Analysis Environmental Chambers and Air ServosKrishna ChaitanyaNo ratings yet

- WS-CA-PR-024 - Atmospheric & Low Preesure Tank VentingDocument4 pagesWS-CA-PR-024 - Atmospheric & Low Preesure Tank Ventinghhvg100% (1)

- GPRSDocument6 pagesGPRSRoberto CapchaNo ratings yet

- RAC (7th&8th) Dec2017Document2 pagesRAC (7th&8th) Dec2017MuDas IrNo ratings yet

- Compressed Air Energy StorageDocument5 pagesCompressed Air Energy StorageDr-Aditya ChauhanNo ratings yet

- 2 - Hvac Design Report 0801 (Civil Defense)Document6 pages2 - Hvac Design Report 0801 (Civil Defense)mohamednavaviNo ratings yet

- 151 361 1 PBDocument7 pages151 361 1 PBElafanNo ratings yet

- Chapter-10 Electrostatic Precipitator: 10.1 Design DataDocument1 pageChapter-10 Electrostatic Precipitator: 10.1 Design DataDhiraj SatyamNo ratings yet

- Me F214 1084 C 2013 2Document3 pagesMe F214 1084 C 2013 2siddharth deshmukhNo ratings yet

- Reviewing HVAC Designs For Compliance With ACCA Manual SDocument5 pagesReviewing HVAC Designs For Compliance With ACCA Manual SKanphong.smNo ratings yet

- Choudari Et Al. (2012) - Distillation Optimization Vapor RecompressionDocument5 pagesChoudari Et Al. (2012) - Distillation Optimization Vapor Recompressionvazzoleralex6884No ratings yet

- Huntorf CAES: More Than 20 Years of Successful OperationDocument7 pagesHuntorf CAES: More Than 20 Years of Successful OperationGokul VenugopalNo ratings yet

- Chiller Type From ASHRAE 90 1Document2 pagesChiller Type From ASHRAE 90 1Karuna KaranNo ratings yet

- SteamTurbineanalysisms KumanaIETC20173 27 17Document9 pagesSteamTurbineanalysisms KumanaIETC20173 27 17Vivek DomadiyaNo ratings yet

- The Essentials of Chilled Beams - Part 3: Skills WorkshopDocument3 pagesThe Essentials of Chilled Beams - Part 3: Skills WorkshoprkibNo ratings yet

- Design of Hvac KibaDocument8 pagesDesign of Hvac KibaAparna AwasthiNo ratings yet

- Moscow TPP-26 Combined-Cycle CHP Plant: Simplified Flow DiagramDocument1 pageMoscow TPP-26 Combined-Cycle CHP Plant: Simplified Flow DiagramAntonio ChoquevilcaNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Super Critical Power - Part91Document1 pageSuper Critical Power - Part91Dhiraj SatyamNo ratings yet

- Super Critical Power - Part92Document1 pageSuper Critical Power - Part92Dhiraj SatyamNo ratings yet

- Chapter-10 Electrostatic Precipitator: 10.1 Design DataDocument1 pageChapter-10 Electrostatic Precipitator: 10.1 Design DataDhiraj SatyamNo ratings yet

- Super Critical Power - Part88Document1 pageSuper Critical Power - Part88Dhiraj SatyamNo ratings yet

- Super Critical Power - Part81Document1 pageSuper Critical Power - Part81Dhiraj SatyamNo ratings yet

- Super Critical Power - Part86Document1 pageSuper Critical Power - Part86Dhiraj SatyamNo ratings yet

- Super Critical Power - Part85Document1 pageSuper Critical Power - Part85Dhiraj SatyamNo ratings yet

- Super Critical Power - Part76Document1 pageSuper Critical Power - Part76Dhiraj SatyamNo ratings yet

- Super Critical Power - Part83Document1 pageSuper Critical Power - Part83Dhiraj SatyamNo ratings yet

- Super Critical Power - Part80Document1 pageSuper Critical Power - Part80Dhiraj SatyamNo ratings yet

- Super Critical Power - Part77Document1 pageSuper Critical Power - Part77Dhiraj SatyamNo ratings yet

- Suitable For Remote Manual OperationDocument1 pageSuitable For Remote Manual OperationDhiraj SatyamNo ratings yet

- Super Critical Power - Part58Document1 pageSuper Critical Power - Part58Dhiraj SatyamNo ratings yet

- Super Critical Power - Part62Document1 pageSuper Critical Power - Part62Dhiraj SatyamNo ratings yet

- Super Critical Power - Part60Document1 pageSuper Critical Power - Part60Dhiraj SatyamNo ratings yet

- Super Critical Power - Part57Document1 pageSuper Critical Power - Part57Dhiraj SatyamNo ratings yet

- Super Critical Power - Part40Document1 pageSuper Critical Power - Part40Dhiraj SatyamNo ratings yet

- Super Critical Power - Part42Document1 pageSuper Critical Power - Part42Dhiraj SatyamNo ratings yet

- Super Critical Power - Part59Document1 pageSuper Critical Power - Part59Dhiraj SatyamNo ratings yet

- Super Critical Power - Part48Document1 pageSuper Critical Power - Part48Dhiraj SatyamNo ratings yet

- Super Critical Power - Part47Document1 pageSuper Critical Power - Part47Dhiraj SatyamNo ratings yet

- Super Critical Power - Part46Document1 pageSuper Critical Power - Part46Dhiraj SatyamNo ratings yet

- Super Critical Power - Part38Document1 pageSuper Critical Power - Part38Dhiraj SatyamNo ratings yet

- Super Critical Power - Part41Document1 pageSuper Critical Power - Part41Dhiraj SatyamNo ratings yet

- Super Critical Power - Part34Document1 pageSuper Critical Power - Part34Dhiraj SatyamNo ratings yet

- Super Critical Power - Part35Document1 pageSuper Critical Power - Part35Dhiraj SatyamNo ratings yet

- Super Critical Power - Part37Document1 pageSuper Critical Power - Part37Dhiraj SatyamNo ratings yet

- Actividad de Aprendizaje Número 1Document6 pagesActividad de Aprendizaje Número 1jesus manuel alvarez riveraNo ratings yet

- Introduction To Energy Transition Alex MolinaDocument176 pagesIntroduction To Energy Transition Alex MolinaSivLyNo ratings yet

- 06 - D155 - Hyd Fan CircuitDocument12 pages06 - D155 - Hyd Fan CircuitMichael Davenport100% (2)

- Chapter One Background of EEPDocument15 pagesChapter One Background of EEPBelayneh Tadesse100% (6)

- Ieee Pes T&D La 2018 - HVDC by Gabriel OlguinDocument51 pagesIeee Pes T&D La 2018 - HVDC by Gabriel OlguingmolguinpNo ratings yet

- The Gravitational Vortex Water Turbine Puts Small Hydro On The Map - EE PublishersDocument10 pagesThe Gravitational Vortex Water Turbine Puts Small Hydro On The Map - EE Publishersdishku100% (1)

- Product SummaryDocument2 pagesProduct SummaryHakki KorcumNo ratings yet

- SynopsisDocument3 pagesSynopsisPreeti RawatNo ratings yet

- 27th December MGSIPADocument111 pages27th December MGSIPAkhannamoneyNo ratings yet

- 06 FanDocument20 pages06 FanCecilia GilNo ratings yet

- pc0525304 PDFDocument12 pagespc0525304 PDFZander_luvNo ratings yet

- 10Document3 pages10Heet DoshiNo ratings yet

- Panasonic CS-W50BD2P CU-V50BBP8 CU-W50BBP8 Service Manual Repair GuideDocument97 pagesPanasonic CS-W50BD2P CU-V50BBP8 CU-W50BBP8 Service Manual Repair Guideevangalos100% (1)

- Ieee RTS 24 PDFDocument5 pagesIeee RTS 24 PDFJoshNo ratings yet

- Msi Ansi Asme StandardsDocument2 pagesMsi Ansi Asme StandardstuyencntnNo ratings yet

- TAD1343GEDocument8 pagesTAD1343GEGeorge BarsoumNo ratings yet

- DPDC Ques AnsDocument3 pagesDPDC Ques AnsRaihanNo ratings yet

- New Initiative For Development and Deployment of Improved Cookstoves: Recommended Action PlanDocument223 pagesNew Initiative For Development and Deployment of Improved Cookstoves: Recommended Action Planzakir551100% (2)

- Pdu ! Distribution System Planning and AutomationDocument17 pagesPdu ! Distribution System Planning and AutomationZeeshan AbdullahNo ratings yet

- Energy (22-28)Document6 pagesEnergy (22-28)Jane Andrea VillafuerteNo ratings yet

- Co-Firing Wood in Coal-Fired Industrial Stoker Boilers: Strategies For Increasing Co-Firing in New York and The NortheastDocument31 pagesCo-Firing Wood in Coal-Fired Industrial Stoker Boilers: Strategies For Increasing Co-Firing in New York and The Northeastdoni_indrionoNo ratings yet

- PGC 2016 Edition - 20160527-2Document176 pagesPGC 2016 Edition - 20160527-2Glenn TanNo ratings yet

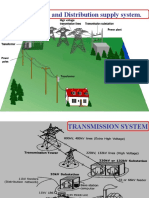

- Transmission and Distribution Supply SystemDocument108 pagesTransmission and Distribution Supply SystemAshok Kumar100% (1)

- Green EnergyDocument4 pagesGreen EnergyAlexandru AndreiNo ratings yet

- Rainwater Collection SystemDocument28 pagesRainwater Collection SystemHESuarezNo ratings yet

- SYNERGY - Profile (Electricals)Document9 pagesSYNERGY - Profile (Electricals)kuraimundNo ratings yet

- Calculationsolar Module PHOTOWATT PW1400502Document3 pagesCalculationsolar Module PHOTOWATT PW1400502Cer Fl100% (1)

Super Critical Power - Part56

Super Critical Power - Part56

Uploaded by

Dhiraj Satyam0 ratings0% found this document useful (0 votes)

10 views1 pageThe document provides technical specifications for air preheaters used in a supercritical 660/800 MW thermal power plant unit. It states that regenerative tri-sector or bi-sector air preheaters should be used with steam coil heating capabilities. The air preheaters must be able to handle operating conditions including a 27 degree Celsius ambient temperature and 60% relative humidity.

Original Description:

Super Critical Power_Part56

Original Title

Super Critical Power_Part56

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides technical specifications for air preheaters used in a supercritical 660/800 MW thermal power plant unit. It states that regenerative tri-sector or bi-sector air preheaters should be used with steam coil heating capabilities. The air preheaters must be able to handle operating conditions including a 27 degree Celsius ambient temperature and 60% relative humidity.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

10 views1 pageSuper Critical Power - Part56

Super Critical Power - Part56

Uploaded by

Dhiraj SatyamThe document provides technical specifications for air preheaters used in a supercritical 660/800 MW thermal power plant unit. It states that regenerative tri-sector or bi-sector air preheaters should be used with steam coil heating capabilities. The air preheaters must be able to handle operating conditions including a 27 degree Celsius ambient temperature and 60% relative humidity.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

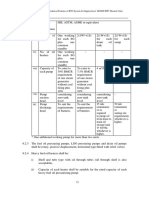

Standard Technical Features of BTG System for Supercritical 660/800 MW Thermal Units

iv) Space Provision

Space provision shall be kept on gas inlet side for installation of atleast

20% additional economizer surfaces, if required, in future. Structure/

hanger design shall be suitable for loads due to these additional surfaces

(filled with water) also.

6.5.8 Air pre-heaters

i) Design requirements of the air pre-heaters shall be as below:

a) Type Regenerative type tri-sector air pre

heaters with facility of steam coil

heating on secondary air side to guard

against low cold end temperature.

or

Regenerative type bi-sector air pre

heaters for primary air and secondary

air with facility of steam coil heating

both on primary air side and secondary

air side to guard against low cold end

temperature.

b) No. of air preheaters per Two tri-sector type APH

steam generator or

two bi-sector type APH each for

primary air and secondary air.

c) Design ambient air 27oC and 60% RH.

d) Boiler load to be 1. 60% BMCR with design/ best/ worst

coal and maximum moisture

whichever gives maximum flow

with one set of APH in service.

2. 100% BMCR with design/ best/

worst coal and maximum moisture

whichever gives maximum flow

with both sets of APH in service.

e) Air temperature rise across Adequate to achieve the required

air preheater coal/air mixture temperature at burner

inlet at all loads and for complete range

of specified coals.

0

f) Minimum average cold 76 C

end metal temperature at

100% BMCR (with

SCAPHs out of service)

0

g) Minimum AH flue gas exit 125 C

temperature (corrected) at

100% TMCR with range

of specified coal

45

You might also like

- Essentials of Steam Turbine Design and Analysis: Back To BasicsDocument9 pagesEssentials of Steam Turbine Design and Analysis: Back To BasicsJohn AnthoniNo ratings yet

- 2021-2022 GE Gas-Power-CatalogDocument105 pages2021-2022 GE Gas-Power-Catalogapartado69No ratings yet

- Class IV-Model Question paper-MEK (General)Document3 pagesClass IV-Model Question paper-MEK (General)ritheshNo ratings yet

- The Source of Hydraulic PowerDocument16 pagesThe Source of Hydraulic Powersekar507100% (1)

- 2.2.4 Air Pre Heaters and Steam Coil Air Pre Heaters 2.2.4.1 Air Pre Heaters (Aphs)Document22 pages2.2.4 Air Pre Heaters and Steam Coil Air Pre Heaters 2.2.4.1 Air Pre Heaters (Aphs)sabrila wandaNo ratings yet

- Super Critical Power - Part58Document1 pageSuper Critical Power - Part58Dhiraj SatyamNo ratings yet

- Super Critical Power - Part35Document1 pageSuper Critical Power - Part35Dhiraj SatyamNo ratings yet

- 17chap18 PDFDocument9 pages17chap18 PDFmick.pride81No ratings yet

- Heat Loss Calculation in Fluidised BedDocument3 pagesHeat Loss Calculation in Fluidised BedArun MuraliNo ratings yet

- Super Critical Power - Part31Document1 pageSuper Critical Power - Part31Dhiraj SatyamNo ratings yet

- Chap 14Document14 pagesChap 14Khurram AliNo ratings yet

- Angel LinoDocument9 pagesAngel LinoSAAD AL.SHAHRANINo ratings yet

- Parametric and Working Fluid Analysis of A Combined Organic Rankine-Vapor Compression Refrigeration System Activated by Low-Grade Thermal EnergyDocument10 pagesParametric and Working Fluid Analysis of A Combined Organic Rankine-Vapor Compression Refrigeration System Activated by Low-Grade Thermal EnergyCatalina DobreNo ratings yet

- Emch394 - Final Project ReportDocument7 pagesEmch394 - Final Project Reportapi-402108223No ratings yet

- Experimental Investigation of A Dual Stage Ignition Biomass DowndraftDocument10 pagesExperimental Investigation of A Dual Stage Ignition Biomass Downdraft吳浩宇No ratings yet

- Zero Export Steam Reforming Article - 1001307 PDFDocument8 pagesZero Export Steam Reforming Article - 1001307 PDFSakthi VelNo ratings yet

- Heat Balane Diagram & Interface Parameters of An 800 MW Unit.Document4 pagesHeat Balane Diagram & Interface Parameters of An 800 MW Unit.Ashwin NarayanNo ratings yet

- Turbocharger Test Stand With A Hot Gas Generator For High - Performance Supercharging SystemsDocument4 pagesTurbocharger Test Stand With A Hot Gas Generator For High - Performance Supercharging SystemsintelligentloveNo ratings yet

- Analysis of A 10 MW Recompression Supercritical Carbon Dioxide Cycle For Tropical Climatic Conditions Sathish Et AlDocument14 pagesAnalysis of A 10 MW Recompression Supercritical Carbon Dioxide Cycle For Tropical Climatic Conditions Sathish Et AlTanatswa MoyoNo ratings yet

- Tech Job 41768Document10 pagesTech Job 41768Sachin GangwarNo ratings yet

- Carbon Dioxide Condensation Cycles For Power Production: G. AngelinoDocument9 pagesCarbon Dioxide Condensation Cycles For Power Production: G. AngelinoDa DdeNo ratings yet

- Improvement in Efficiency of Air Preheater in Boiler Tps-1 ExpansionDocument7 pagesImprovement in Efficiency of Air Preheater in Boiler Tps-1 Expansionحمودي معزNo ratings yet

- ASHRAE 90.1 LEED RequirementsDocument2 pagesASHRAE 90.1 LEED RequirementsAbdul Malik Malinao DiamlaNo ratings yet

- S LB CombustifumeDocument20 pagesS LB CombustifumeThaiminh VoNo ratings yet

- Matlab Program Computes ThermalDocument9 pagesMatlab Program Computes ThermalBahar MeschiNo ratings yet

- Super Critical Power - Part38Document1 pageSuper Critical Power - Part38Dhiraj SatyamNo ratings yet

- ES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Document10 pagesES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Nikki RobertsNo ratings yet

- Aerospace Engineering: University Institute of EngineeringDocument2 pagesAerospace Engineering: University Institute of EngineeringAvishiNo ratings yet

- Genset Installation Recommendation: A LocationDocument27 pagesGenset Installation Recommendation: A LocationShiv Kumar VermaNo ratings yet

- Performance Enhancement of Unitary and Packaged Air Conditioners With Phase Change MaterialDocument6 pagesPerformance Enhancement of Unitary and Packaged Air Conditioners With Phase Change MaterialsergioNo ratings yet

- RS1075 - Modelling of The BP 6MW Burner Test Rig With FIHR V 2.0Document13 pagesRS1075 - Modelling of The BP 6MW Burner Test Rig With FIHR V 2.0Ian MannNo ratings yet

- Ventilation Recommendation C32 1500 KVA StandbyDocument2 pagesVentilation Recommendation C32 1500 KVA StandbyjibinNo ratings yet

- Gas Turbine Problem Statement 29Document2 pagesGas Turbine Problem Statement 29Daniel Andres Canro CalderónNo ratings yet

- Enclosed Combustion EquipmentDocument4 pagesEnclosed Combustion EquipmentSteve WanNo ratings yet

- Vitocrossal 200-cm2 SM gw6b TDMDocument16 pagesVitocrossal 200-cm2 SM gw6b TDMCiprian BalcanNo ratings yet

- Khadem I 2017Document12 pagesKhadem I 2017Michael KennedyNo ratings yet

- Chapter 8 - SolutionDocument43 pagesChapter 8 - SolutionIzaNo ratings yet

- CC GDocument8 pagesCC GHue Kin FeiNo ratings yet

- JSIR 63 (1) 68-73 - Edit PDFDocument6 pagesJSIR 63 (1) 68-73 - Edit PDFshadow friendNo ratings yet

- On Mixtures As Working Fluids For Air-Cooled ORC Bottoming Power Plants of Gas TurbinesDocument12 pagesOn Mixtures As Working Fluids For Air-Cooled ORC Bottoming Power Plants of Gas Turbinescarlo83No ratings yet

- Super Critical Power - Part40Document1 pageSuper Critical Power - Part40Dhiraj SatyamNo ratings yet

- Advanced Combustion Systems For Annealing and Pickling LinesDocument5 pagesAdvanced Combustion Systems For Annealing and Pickling LinesAlessandro LazzarettoNo ratings yet

- Technical Spec BoilerDocument13 pagesTechnical Spec Boilermochamad RasjidNo ratings yet

- Sistemas de PotenciaDocument6 pagesSistemas de PotenciaEduardo VCNo ratings yet

- Turbine Inlet Air CoolingDocument4 pagesTurbine Inlet Air Coolingkrazylion100% (2)

- Temperature: Heat Transfer and Air Flow Analysis Environmental Chambers and Air ServosDocument12 pagesTemperature: Heat Transfer and Air Flow Analysis Environmental Chambers and Air ServosKrishna ChaitanyaNo ratings yet

- WS-CA-PR-024 - Atmospheric & Low Preesure Tank VentingDocument4 pagesWS-CA-PR-024 - Atmospheric & Low Preesure Tank Ventinghhvg100% (1)

- GPRSDocument6 pagesGPRSRoberto CapchaNo ratings yet

- RAC (7th&8th) Dec2017Document2 pagesRAC (7th&8th) Dec2017MuDas IrNo ratings yet

- Compressed Air Energy StorageDocument5 pagesCompressed Air Energy StorageDr-Aditya ChauhanNo ratings yet

- 2 - Hvac Design Report 0801 (Civil Defense)Document6 pages2 - Hvac Design Report 0801 (Civil Defense)mohamednavaviNo ratings yet

- 151 361 1 PBDocument7 pages151 361 1 PBElafanNo ratings yet

- Chapter-10 Electrostatic Precipitator: 10.1 Design DataDocument1 pageChapter-10 Electrostatic Precipitator: 10.1 Design DataDhiraj SatyamNo ratings yet

- Me F214 1084 C 2013 2Document3 pagesMe F214 1084 C 2013 2siddharth deshmukhNo ratings yet

- Reviewing HVAC Designs For Compliance With ACCA Manual SDocument5 pagesReviewing HVAC Designs For Compliance With ACCA Manual SKanphong.smNo ratings yet

- Choudari Et Al. (2012) - Distillation Optimization Vapor RecompressionDocument5 pagesChoudari Et Al. (2012) - Distillation Optimization Vapor Recompressionvazzoleralex6884No ratings yet

- Huntorf CAES: More Than 20 Years of Successful OperationDocument7 pagesHuntorf CAES: More Than 20 Years of Successful OperationGokul VenugopalNo ratings yet

- Chiller Type From ASHRAE 90 1Document2 pagesChiller Type From ASHRAE 90 1Karuna KaranNo ratings yet

- SteamTurbineanalysisms KumanaIETC20173 27 17Document9 pagesSteamTurbineanalysisms KumanaIETC20173 27 17Vivek DomadiyaNo ratings yet

- The Essentials of Chilled Beams - Part 3: Skills WorkshopDocument3 pagesThe Essentials of Chilled Beams - Part 3: Skills WorkshoprkibNo ratings yet

- Design of Hvac KibaDocument8 pagesDesign of Hvac KibaAparna AwasthiNo ratings yet

- Moscow TPP-26 Combined-Cycle CHP Plant: Simplified Flow DiagramDocument1 pageMoscow TPP-26 Combined-Cycle CHP Plant: Simplified Flow DiagramAntonio ChoquevilcaNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Super Critical Power - Part91Document1 pageSuper Critical Power - Part91Dhiraj SatyamNo ratings yet

- Super Critical Power - Part92Document1 pageSuper Critical Power - Part92Dhiraj SatyamNo ratings yet

- Chapter-10 Electrostatic Precipitator: 10.1 Design DataDocument1 pageChapter-10 Electrostatic Precipitator: 10.1 Design DataDhiraj SatyamNo ratings yet

- Super Critical Power - Part88Document1 pageSuper Critical Power - Part88Dhiraj SatyamNo ratings yet

- Super Critical Power - Part81Document1 pageSuper Critical Power - Part81Dhiraj SatyamNo ratings yet

- Super Critical Power - Part86Document1 pageSuper Critical Power - Part86Dhiraj SatyamNo ratings yet

- Super Critical Power - Part85Document1 pageSuper Critical Power - Part85Dhiraj SatyamNo ratings yet

- Super Critical Power - Part76Document1 pageSuper Critical Power - Part76Dhiraj SatyamNo ratings yet

- Super Critical Power - Part83Document1 pageSuper Critical Power - Part83Dhiraj SatyamNo ratings yet

- Super Critical Power - Part80Document1 pageSuper Critical Power - Part80Dhiraj SatyamNo ratings yet

- Super Critical Power - Part77Document1 pageSuper Critical Power - Part77Dhiraj SatyamNo ratings yet

- Suitable For Remote Manual OperationDocument1 pageSuitable For Remote Manual OperationDhiraj SatyamNo ratings yet

- Super Critical Power - Part58Document1 pageSuper Critical Power - Part58Dhiraj SatyamNo ratings yet

- Super Critical Power - Part62Document1 pageSuper Critical Power - Part62Dhiraj SatyamNo ratings yet

- Super Critical Power - Part60Document1 pageSuper Critical Power - Part60Dhiraj SatyamNo ratings yet

- Super Critical Power - Part57Document1 pageSuper Critical Power - Part57Dhiraj SatyamNo ratings yet

- Super Critical Power - Part40Document1 pageSuper Critical Power - Part40Dhiraj SatyamNo ratings yet

- Super Critical Power - Part42Document1 pageSuper Critical Power - Part42Dhiraj SatyamNo ratings yet

- Super Critical Power - Part59Document1 pageSuper Critical Power - Part59Dhiraj SatyamNo ratings yet

- Super Critical Power - Part48Document1 pageSuper Critical Power - Part48Dhiraj SatyamNo ratings yet

- Super Critical Power - Part47Document1 pageSuper Critical Power - Part47Dhiraj SatyamNo ratings yet

- Super Critical Power - Part46Document1 pageSuper Critical Power - Part46Dhiraj SatyamNo ratings yet

- Super Critical Power - Part38Document1 pageSuper Critical Power - Part38Dhiraj SatyamNo ratings yet

- Super Critical Power - Part41Document1 pageSuper Critical Power - Part41Dhiraj SatyamNo ratings yet

- Super Critical Power - Part34Document1 pageSuper Critical Power - Part34Dhiraj SatyamNo ratings yet

- Super Critical Power - Part35Document1 pageSuper Critical Power - Part35Dhiraj SatyamNo ratings yet

- Super Critical Power - Part37Document1 pageSuper Critical Power - Part37Dhiraj SatyamNo ratings yet

- Actividad de Aprendizaje Número 1Document6 pagesActividad de Aprendizaje Número 1jesus manuel alvarez riveraNo ratings yet

- Introduction To Energy Transition Alex MolinaDocument176 pagesIntroduction To Energy Transition Alex MolinaSivLyNo ratings yet

- 06 - D155 - Hyd Fan CircuitDocument12 pages06 - D155 - Hyd Fan CircuitMichael Davenport100% (2)

- Chapter One Background of EEPDocument15 pagesChapter One Background of EEPBelayneh Tadesse100% (6)

- Ieee Pes T&D La 2018 - HVDC by Gabriel OlguinDocument51 pagesIeee Pes T&D La 2018 - HVDC by Gabriel OlguingmolguinpNo ratings yet

- The Gravitational Vortex Water Turbine Puts Small Hydro On The Map - EE PublishersDocument10 pagesThe Gravitational Vortex Water Turbine Puts Small Hydro On The Map - EE Publishersdishku100% (1)

- Product SummaryDocument2 pagesProduct SummaryHakki KorcumNo ratings yet

- SynopsisDocument3 pagesSynopsisPreeti RawatNo ratings yet

- 27th December MGSIPADocument111 pages27th December MGSIPAkhannamoneyNo ratings yet

- 06 FanDocument20 pages06 FanCecilia GilNo ratings yet

- pc0525304 PDFDocument12 pagespc0525304 PDFZander_luvNo ratings yet

- 10Document3 pages10Heet DoshiNo ratings yet

- Panasonic CS-W50BD2P CU-V50BBP8 CU-W50BBP8 Service Manual Repair GuideDocument97 pagesPanasonic CS-W50BD2P CU-V50BBP8 CU-W50BBP8 Service Manual Repair Guideevangalos100% (1)

- Ieee RTS 24 PDFDocument5 pagesIeee RTS 24 PDFJoshNo ratings yet

- Msi Ansi Asme StandardsDocument2 pagesMsi Ansi Asme StandardstuyencntnNo ratings yet

- TAD1343GEDocument8 pagesTAD1343GEGeorge BarsoumNo ratings yet

- DPDC Ques AnsDocument3 pagesDPDC Ques AnsRaihanNo ratings yet

- New Initiative For Development and Deployment of Improved Cookstoves: Recommended Action PlanDocument223 pagesNew Initiative For Development and Deployment of Improved Cookstoves: Recommended Action Planzakir551100% (2)

- Pdu ! Distribution System Planning and AutomationDocument17 pagesPdu ! Distribution System Planning and AutomationZeeshan AbdullahNo ratings yet

- Energy (22-28)Document6 pagesEnergy (22-28)Jane Andrea VillafuerteNo ratings yet

- Co-Firing Wood in Coal-Fired Industrial Stoker Boilers: Strategies For Increasing Co-Firing in New York and The NortheastDocument31 pagesCo-Firing Wood in Coal-Fired Industrial Stoker Boilers: Strategies For Increasing Co-Firing in New York and The Northeastdoni_indrionoNo ratings yet

- PGC 2016 Edition - 20160527-2Document176 pagesPGC 2016 Edition - 20160527-2Glenn TanNo ratings yet

- Transmission and Distribution Supply SystemDocument108 pagesTransmission and Distribution Supply SystemAshok Kumar100% (1)

- Green EnergyDocument4 pagesGreen EnergyAlexandru AndreiNo ratings yet

- Rainwater Collection SystemDocument28 pagesRainwater Collection SystemHESuarezNo ratings yet

- SYNERGY - Profile (Electricals)Document9 pagesSYNERGY - Profile (Electricals)kuraimundNo ratings yet

- Calculationsolar Module PHOTOWATT PW1400502Document3 pagesCalculationsolar Module PHOTOWATT PW1400502Cer Fl100% (1)