Professional Documents

Culture Documents

Marking Forms With Aspects Automobile Technology Draft

Marking Forms With Aspects Automobile Technology Draft

Uploaded by

Marvin Sarmiento TalimonganCopyright:

Available Formats

You might also like

- Events API DocumentationDocument5 pagesEvents API Documentationmario librerosNo ratings yet

- Bse8klna en v220413Document2 pagesBse8klna en v220413danilo Mendoza0% (1)

- MS1920 ENGIRO-MS1920 Official Electric Motor INFODocument7 pagesMS1920 ENGIRO-MS1920 Official Electric Motor INFOJoan Ferrao GenescàNo ratings yet

- FINAL Marking Scheme in CIS Format - v1.3Document52 pagesFINAL Marking Scheme in CIS Format - v1.3Marvin Sarmiento TalimonganNo ratings yet

- Winters PreviewDocument265 pagesWinters PreviewcqpresscustomNo ratings yet

- WSC2007 13 MSF Autobody RepairDocument2 pagesWSC2007 13 MSF Autobody Repairmy.hostNo ratings yet

- DP computerSMARTIII ENDocument2 pagesDP computerSMARTIII ENJovan NikolicNo ratings yet

- DC Locomotive System PDFDocument2 pagesDC Locomotive System PDFRizki Fajar NovantoNo ratings yet

- GA 250 VSD - 125 Psi - Water Cooled - 2015 Rev 0Document1 pageGA 250 VSD - 125 Psi - Water Cooled - 2015 Rev 0Vi Na Ridho ChabieNo ratings yet

- Smart Iii: ComputerDocument2 pagesSmart Iii: ComputerfaikNo ratings yet

- Engiro Datasheet 205a 04016 ABC v001Document6 pagesEngiro Datasheet 205a 04016 ABC v001Francisco Palacios López100% (1)

- Nissan Leaf Teardown (Part 1) - MarkLines Automotive Industry PortalDocument11 pagesNissan Leaf Teardown (Part 1) - MarkLines Automotive Industry PortalHtek Thu ThwinNo ratings yet

- Draft Power System Design and Setting Data SheetDocument87 pagesDraft Power System Design and Setting Data SheetMohamed HamdallahNo ratings yet

- Maxon A Max Catalog Data2 PDFDocument28 pagesMaxon A Max Catalog Data2 PDFM. Luthfi Alhadi ZNo ratings yet

- Cagi zr250 VSD 8.6 125psigDocument2 pagesCagi zr250 VSD 8.6 125psigHabib ur RehmanNo ratings yet

- Atlazo Technology Applied Ventures Oct 2021Document18 pagesAtlazo Technology Applied Ventures Oct 2021Kevin G. DavisNo ratings yet

- Atlas Copco: Xair-CooledDocument6 pagesAtlas Copco: Xair-Cooledthiyagarajan v100% (1)

- Sod MatrixDocument9 pagesSod Matrixrishi_rajarshiNo ratings yet

- Rotary Ups: Performances and Characteristics Standard FeaturesDocument1 pageRotary Ups: Performances and Characteristics Standard Featuresedson_spinaNo ratings yet

- 16 Rooms Workers DormitoryDocument50 pages16 Rooms Workers DormitoryRoselle Lyn EvangelistaNo ratings yet

- DCRL5 20231102Document4 pagesDCRL5 20231102Hernando RobledoNo ratings yet

- Qinsw Atk XXXX XX SC Ut 050001Document3 pagesQinsw Atk XXXX XX SC Ut 050001Nad EemNo ratings yet

- IntacDocument1 pageIntac2022301307No ratings yet

- Hamburg Wheel Tracking Device Update 0412Document2 pagesHamburg Wheel Tracking Device Update 0412Nguyễn Văn MinhNo ratings yet

- Compressor Data Sheet Federal Uniform Test Method For Certain Air Compressors Not ApplicableDocument1 pageCompressor Data Sheet Federal Uniform Test Method For Certain Air Compressors Not ApplicablehansNo ratings yet

- Engineering Estimate Cold Room RehabilitationDocument2 pagesEngineering Estimate Cold Room RehabilitationChristyanKerafNo ratings yet

- Presentation 2 - DeconinckDocument45 pagesPresentation 2 - Deconinckdeskaug1No ratings yet

- Fattura PA SpecificationDocument6 pagesFattura PA SpecificationlamyaelogNo ratings yet

- Ultima U75 Air Cooled 100 Psig CAGI Datasheet 6-01-21Document1 pageUltima U75 Air Cooled 100 Psig CAGI Datasheet 6-01-21Ehsan ZiyaeiNo ratings yet

- tvs74 A125Document1 pagetvs74 A125Ali kamail sadeghianNo ratings yet

- Kansas City Deaerator Product BrochureDocument2 pagesKansas City Deaerator Product BrochureProjects0% (1)

- Section 5: Motor ListDocument7 pagesSection 5: Motor ListazamNo ratings yet

- CAGI Data Sheet SAV-200hp-EAU-125psi-Water 6-26-20 PDFDocument1 pageCAGI Data Sheet SAV-200hp-EAU-125psi-Water 6-26-20 PDFCarlos MNo ratings yet

- BH410,600mm, 12.0m-Vertical 2Document1 pageBH410,600mm, 12.0m-Vertical 2Mohamed AskarNo ratings yet

- Abbreviation DescriptionsDocument17 pagesAbbreviation DescriptionsRicell James AdrianoNo ratings yet

- SLC410 PDFDocument2 pagesSLC410 PDFThomas SellersNo ratings yet

- Sunpower Residential Ac Module: Sunpower E-Series: E20-327 - E19-320Document5 pagesSunpower Residential Ac Module: Sunpower E-Series: E20-327 - E19-320lovnishNo ratings yet

- Enphase-System Summary1687371477068Document4 pagesEnphase-System Summary1687371477068harry HendersonNo ratings yet

- Fields of Activity PDFDocument1 pageFields of Activity PDFÍcaro VianaNo ratings yet

- Enphase-System SummaryDocument4 pagesEnphase-System SummaryafafNo ratings yet

- Compressor Data Sheet in Accordance With Federal Uniform Test Method For Certain Lubricated Air CompressorsDocument1 pageCompressor Data Sheet in Accordance With Federal Uniform Test Method For Certain Lubricated Air Compressorsgustavo rodriguesNo ratings yet

- New Vistas On Automotive Embedded Systems: Edited and Presented by Alberto Sangiovanni-Vincentelli UC BerkeleyDocument25 pagesNew Vistas On Automotive Embedded Systems: Edited and Presented by Alberto Sangiovanni-Vincentelli UC BerkeleyAnita IonelaNo ratings yet

- FD290CG PRINTOUT 22238 LowestDocument2 pagesFD290CG PRINTOUT 22238 Lowestasep1994No ratings yet

- GA 132 VSD - 150 Psi - Air Cooled - 2015 Rev 0Document1 pageGA 132 VSD - 150 Psi - Air Cooled - 2015 Rev 0esteban muñozNo ratings yet

- Necessities For Future High Speed Rolling StockDocument39 pagesNecessities For Future High Speed Rolling StockRailway 20No ratings yet

- XC975 EV 英语译文Document2 pagesXC975 EV 英语译文abangNo ratings yet

- Time Code Reception ICDocument5 pagesTime Code Reception ICLjubisa DjordjevicNo ratings yet

- Design Operating Data Performance Data: Rotary Positive Displacement Pump Data SheetDocument2 pagesDesign Operating Data Performance Data: Rotary Positive Displacement Pump Data SheetBachir GeageaNo ratings yet

- JKS 8K 12K SG04LP3 EuDocument2 pagesJKS 8K 12K SG04LP3 EuMwagachristianNo ratings yet

- Matriz Sod PDF FreeDocument3 pagesMatriz Sod PDF Freeviniciusbaleeiro.mosNo ratings yet

- Building A Common Battery ArchitectureDocument19 pagesBuilding A Common Battery Architecturesam.elnemaisNo ratings yet

- CarMax Lending PlatformDocument12 pagesCarMax Lending PlatformEnakshi ManoharNo ratings yet

- Freebooters On The Frontier 2e - Playbook - Magic-UserDocument2 pagesFreebooters On The Frontier 2e - Playbook - Magic-UserMax HadesNo ratings yet

- Sin0058 Sin4112 UpdatedDocument6 pagesSin0058 Sin4112 Updatedmohamed sabryNo ratings yet

- Control Desk-Wagon TipplerDocument9 pagesControl Desk-Wagon TipplerShishram ChoudharyNo ratings yet

- Elmeasure Im CatalogDocument2 pagesElmeasure Im CatalogNMP Kumar UNo ratings yet

- Sample List EquipmentDocument1 pageSample List EquipmentRusihan HSENo ratings yet

- Inverter Vendor GTP: 18002-EA-EVD-001-00Document3 pagesInverter Vendor GTP: 18002-EA-EVD-001-00Venkataramanan SNo ratings yet

- Leaflet UVES NMC Color BWDocument4 pagesLeaflet UVES NMC Color BWJohnNo ratings yet

- Cagi Data Sheet - Ts32sc-600lacDocument1 pageCagi Data Sheet - Ts32sc-600laclletsumenNo ratings yet

- Technical Offer - Crude Booster PumpsDocument12 pagesTechnical Offer - Crude Booster PumpsKKNo ratings yet

- Charging System Installation - RocioDocument40 pagesCharging System Installation - RocioMarvin Sarmiento TalimonganNo ratings yet

- Espina, Joselito - PRESENTATION - AT10 (Circuit Failures)Document22 pagesEspina, Joselito - PRESENTATION - AT10 (Circuit Failures)Marvin Sarmiento TalimonganNo ratings yet

- Auto Electronics and Electrical Related Tools, Measuring Instrument, and EquipmentDocument34 pagesAuto Electronics and Electrical Related Tools, Measuring Instrument, and EquipmentMarvin Sarmiento TalimonganNo ratings yet

- Technological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToDocument5 pagesTechnological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToMarvin Sarmiento TalimonganNo ratings yet

- Fundamentals OF ElectricityDocument37 pagesFundamentals OF ElectricityMarvin Sarmiento TalimonganNo ratings yet

- (OK) Auto Electronics and Electrical Related - LAYUGDocument48 pages(OK) Auto Electronics and Electrical Related - LAYUGMarvin Sarmiento TalimonganNo ratings yet

- Automotive NC II and Assessment For Driving NC II (Light Vehicle) Driving NC III (StraightDocument1 pageAutomotive NC II and Assessment For Driving NC II (Light Vehicle) Driving NC III (StraightMarvin Sarmiento TalimonganNo ratings yet

- Technological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToDocument4 pagesTechnological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToMarvin Sarmiento TalimonganNo ratings yet

- I. Vision: College of Industrial TechnologyDocument6 pagesI. Vision: College of Industrial TechnologyMarvin Sarmiento TalimonganNo ratings yet

- CHED Sample OBE Syllabus AT 2 AUTO MECHANICALDocument7 pagesCHED Sample OBE Syllabus AT 2 AUTO MECHANICALMarvin Sarmiento TalimonganNo ratings yet

- Anna Joy Evangelista 2062 Edison ST - Brgy San Isidro Makati CityDocument2 pagesAnna Joy Evangelista 2062 Edison ST - Brgy San Isidro Makati CityMarvin Sarmiento TalimonganNo ratings yet

- Technological University of The PhilippinesDocument7 pagesTechnological University of The PhilippinesMarvin Sarmiento TalimonganNo ratings yet

- CHED Sample OBE Syllabus AT 7okDocument6 pagesCHED Sample OBE Syllabus AT 7okMarvin Sarmiento Talimongan0% (1)

- Assessment Candidates Uli #Document123 pagesAssessment Candidates Uli #Marvin Sarmiento TalimonganNo ratings yet

- Vaa-Erd: Technological University of The PhilippinesDocument6 pagesVaa-Erd: Technological University of The PhilippinesMarvin Sarmiento TalimonganNo ratings yet

- CHED Sample OBE Syllabus AT 3okDocument6 pagesCHED Sample OBE Syllabus AT 3okMarvin Sarmiento TalimonganNo ratings yet

- CHED Sample OBE Syllabus AT 1 AUTOMOTIVE ENGINEERING SYSTEMDocument6 pagesCHED Sample OBE Syllabus AT 1 AUTOMOTIVE ENGINEERING SYSTEMMarvin Sarmiento TalimonganNo ratings yet

- Ok Task A - Steering, Suspension and Brake SystemsDocument13 pagesOk Task A - Steering, Suspension and Brake SystemsMarvin Sarmiento TalimonganNo ratings yet

- Ok Task B - Electrical SystemDocument10 pagesOk Task B - Electrical SystemMarvin Sarmiento TalimonganNo ratings yet

- First Gear Technical Institute and Assessment Center Inc.: (Dir. Rolando V. Dela Torre)Document5 pagesFirst Gear Technical Institute and Assessment Center Inc.: (Dir. Rolando V. Dela Torre)Marvin Sarmiento TalimonganNo ratings yet

- 14264A Construction Mechanic Basic Chapters 14 PDFDocument77 pages14264A Construction Mechanic Basic Chapters 14 PDFMarvin Sarmiento TalimonganNo ratings yet

- Talimongan, Marvin S. Mamitag, Renato O.: Prepared By: Approved byDocument1 pageTalimongan, Marvin S. Mamitag, Renato O.: Prepared By: Approved byMarvin Sarmiento TalimonganNo ratings yet

- Final ScoreDocument1 pageFinal ScoreMarvin Sarmiento TalimonganNo ratings yet

- Stabilization of Dispersive Soil by Blending PolymDocument4 pagesStabilization of Dispersive Soil by Blending Polymnagy_andor_csongorNo ratings yet

- Drill Daily Check SheetDocument3 pagesDrill Daily Check SheetNikhil MadaneNo ratings yet

- Shetlandish Dialect PDFDocument180 pagesShetlandish Dialect PDFLuis PNo ratings yet

- Volume Kerja English Year 4Document6 pagesVolume Kerja English Year 4kamiliamawaddahNo ratings yet

- Health Talk ExcerciseDocument5 pagesHealth Talk ExcerciseNyalen Hakom100% (1)

- Organisational Analysis of Hero Motocorp and Eicher Motors: Group 9Document7 pagesOrganisational Analysis of Hero Motocorp and Eicher Motors: Group 9Rupanshi JaiswalNo ratings yet

- Taylor's Scientific ManagementDocument7 pagesTaylor's Scientific Managementsipanjegiven0% (1)

- Module 1 An Overview of ArtDocument4 pagesModule 1 An Overview of ArtAngeline AdezaNo ratings yet

- Laporan Kasus (Stroke NHS)Document4 pagesLaporan Kasus (Stroke NHS)keluargacendanaNo ratings yet

- Table of Specifications Grade 5Document3 pagesTable of Specifications Grade 5rene balayoNo ratings yet

- Designing Steam Reformers For Hydrogen Production: Keep These Important Factors in Mind When Designing, Revamping or TroubleshootingDocument7 pagesDesigning Steam Reformers For Hydrogen Production: Keep These Important Factors in Mind When Designing, Revamping or TroubleshootingdjinxdNo ratings yet

- Neonatal Questions and Controversies Neurology 4th Edition Perlman Jeffrey M Inder Terrie Jeffrey M Perlman Terrie InderDocument70 pagesNeonatal Questions and Controversies Neurology 4th Edition Perlman Jeffrey M Inder Terrie Jeffrey M Perlman Terrie Inderclaude.moore690100% (12)

- Jack Goldestone - THE PROBLEM OF THE EARLY MODERN WORLD - TEXT PDFDocument36 pagesJack Goldestone - THE PROBLEM OF THE EARLY MODERN WORLD - TEXT PDFBojanNo ratings yet

- Department of Business Administration: Submitted ToDocument15 pagesDepartment of Business Administration: Submitted Topinky271994No ratings yet

- Solución: R T β T R (T) = 1000 Ω ΩDocument6 pagesSolución: R T β T R (T) = 1000 Ω ΩDuvan BayonaNo ratings yet

- Techniques & Structure PDFDocument6 pagesTechniques & Structure PDFfrank sinatraaNo ratings yet

- Sprovieri (Final Assignment)Document9 pagesSprovieri (Final Assignment)Paulo Thiago SprovieriNo ratings yet

- PhilosophyDocument4 pagesPhilosophyJudalineNo ratings yet

- SyntaxDocument9 pagesSyntaxVeronicaTurtusanNo ratings yet

- IB Chemistry - SL Topic 7 Questions 1Document19 pagesIB Chemistry - SL Topic 7 Questions 1vaxor16689No ratings yet

- Resource Guide For New ChrosDocument23 pagesResource Guide For New Chroslane.a.mcfNo ratings yet

- Submarine Cable Installation ContractorsDocument19 pagesSubmarine Cable Installation Contractorswiji_thukulNo ratings yet

- Nakshtra Swami and BhramanDocument12 pagesNakshtra Swami and Bhramansagar_m26100% (1)

- CDP+ Version 10 (Guide)Document124 pagesCDP+ Version 10 (Guide)Pew IcamenNo ratings yet

- People vs. PradesDocument2 pagesPeople vs. PradesMayr TeruelNo ratings yet

- FEG Token Litepaper v2.1Document15 pagesFEG Token Litepaper v2.1TelorNo ratings yet

- Induction of Aircraft in Pakistan (Ano-019-Awrg-3.0)Document9 pagesInduction of Aircraft in Pakistan (Ano-019-Awrg-3.0)Tayyab ButtNo ratings yet

- Puzzles: The Question: There Is Only One Correct Answer To This Question. Which Answer Is This? AnsDocument7 pagesPuzzles: The Question: There Is Only One Correct Answer To This Question. Which Answer Is This? AnsSk Tausif ShakeelNo ratings yet

Marking Forms With Aspects Automobile Technology Draft

Marking Forms With Aspects Automobile Technology Draft

Uploaded by

Marvin Sarmiento TalimonganCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Marking Forms With Aspects Automobile Technology Draft

Marking Forms With Aspects Automobile Technology Draft

Uploaded by

Marvin Sarmiento TalimonganCopyright:

Available Formats

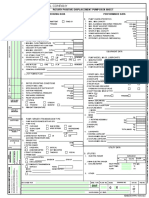

Mark Summary

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology

Competitor Name Member

Marking Scheme Lock Final Mark Lock

Marks Awarded Total

Criterion ID Criterion Description

Day 1 Day 2 Day 3 Day 4 Award

Max

A Petrol Engine Tune

Actual

ft

Max

B Steering, Suspension and Brake System

Actual

Max

C Electrical System

Actual

Max

D Engine Mechanical

Actual

ra

Max

E Automatic Transmission

Actual

Max

Actual

Max

Actual

Max

Actual

D

Max 100.00

Total

Actual

Sub Marks Awarded Total

Sub Criterion Description

Criterion ID Day 1 Day 2 Day 3 Day 4 Award

Max

A 1 Health, Safety and House Keeping

Actual

Max

A 2 Diagnose and repair engine to start and run

Actual

Max

A 3 Repair Engine due to Poor Drive Ability

Actual

Max

A 4 Checks, Measurements and Record on Report Form

Actual

Max

B 1 Health, Safety and House keeping

Actual

Max

B 2 Remove / replace one side Front Strut Assembly

Actual

Max

B 3 Install one side Front Strut Assembly

Actual

Max

B 4 Front Brake Calliper & Disc Brake Measurement

Actual

Max

B 5 Perform the necessary Wheel Alignment Adjustment

Actual

Page 1 / 3 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Mark Summary

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology

Competitor Name Member

Marking Scheme Lock Final Mark Lock

Sub Marks Awarded Total

Sub Criterion Description

Criterion ID Day 1 Day 2 Day 3 Day 4 Award

Max

B 6 Replace Brake Master Cylinder Assembly

Actual

ft

Overhaul Rear Calliper (RHS only) and check the conditions of all Max

B 7

Brake Pads Actual

Max

B 8 Hydraulic Brake System Air Bleeding

Actual

Max

B 9 Check the operation of the ABS and rectify by using GTS

Actual

ra

Max

C 1 Preparation, Safety and Housekeeping

Actual

Max

C 2 Headlight Operation

Actual

Max

C 3 Washer and wiper system

Actual

Max

C 4 Power Window Operation

Actual

Max

C 5 Power Mirror Operation

Actual

D

Max

C 6 Central Locking System

Actual

Max

C 7 Reverse Light Operation

Actual

Max

C 8 Charging system

Actual

Max

D 1 Health, Safety and House Keeping

Actual

Max

D 2 Remove Engine External and Internal Components

Actual

Max

D 3 Cylinder Bore and Piston Measurements

Actual

Max

D 4 Crankshaft and Bearing Measurements

Actual

Max

D 5 Valve & Valve Mechanism Measurements

Actual

Max

D 6 Assembling Engine External and Internal Components

Actual

Max

E 1 Health, Safety and House keeping

Actual

Max

E 2 Vehicle test on the P and N Start Function

Actual

Max

E 3 Disassemble Auto. Transmission (on Stand)

Actual

Max

E 4 Disassemble Clutches and Pistons Assembly

Actual

Page 2 / 3 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Mark Summary

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology

Competitor Name Member

Marking Scheme Lock Final Mark Lock

Sub Marks Awarded Total

Sub Criterion Description

Criterion ID Day 1 Day 2 Day 3 Day 4 Award

Max

E 5 Assemble Clutches and Pistons Assembly

Actual

ft

Max

E 6 Assembling Auto. Transmission

Actual

Max

E 7 Parts Condition, Measurements (Report Form)

Actual

Max

Actual

ra

Max

Actual

Max

Actual

Max

Actual

Max

Actual

Max

Actual

D

Max

Actual

Max

Actual

Max

Actual

Max

Actual

Max

Actual

Max

Actual

Max

Actual

Max

Actual

Max

Actual

Max

Actual

Max

Actual

Max 100.00

Total

Actual

Page 3 / 3 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Health, Safety and House Keeping Sub Criterion ID A1

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 1

1

0.20

0.10

0.10

Checked all equipment first

Checked all instructions

Selected the correct test equipment

ra

O4 1 0.10 Used logical working procedure

O5 1 0.50 Proper tools handling

O6 1 0.50 Proper parts handling

O7 1 0.10 Checked oil level

O8 1 0.10 Checked coolant level

D

O9 1 0.10 Choked tires

O10 1 0.10 Used fender covers

O11 1 0.10 Used seat covers

O12 1 0.10 Used steering wheel cover

O13 1 0.10 Used floor matt

O14 1 0.30 Calibrate Multi-meter

O15 1 0.10 Clean up the working area

O16 1 0.10 Clean up tools and equipment

O17 1 0.10 Clean up the test vehicle

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Diagnose and repair engine to start and run Sub Criterion ID A2

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 1

3

0.20

0.20

0.40

Using Service manual or CD ROM correctly.

Check battery voltage

Check supply to UEC

ra

O4 3 0.30 Check Start Stop Button Supply

O5 3 0.20 Check Fuse IG SW1

O6 3 0.40 Check Relay IG1 Off

O7 3 0.40 Check ABCM supply

O8 3 0.20 Check Fuse FS 13 (BCM)

D

O9 3 0.20 Check Fuse FS 15 (Meter)

O10 3 0.50 Check CAN BUS Signal (at DLC)

O11 3 0.50 Rectify CAN BUS Signal Fault

O12 3 0.30 Check Relay Low Starter

O13 3 0.30 Check Starter solenoid supply

O14 3 0.30 Engine can be cranked

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Repair Engine due to Poor Drive Ability Sub Criterion ID A3

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 4

4

0.20

0.30

0.30

Connect PADT-II

Check engine rotation

Replace Crankshaft Angle Sensor with torque

ra

O4 4 0.30 Check fuel pressure

O5 4 0.20 Check Relay Fuel Pump

O6 4 0.30 Check Fuel Pump Ground

O7 4 0.40 Check wire terminal 21 (UEC) to IG Coil Cylinder 2

O8 4 0.30 Visual check on Plug Coil

D

O9 4 0.30 Check Spark Plug Gap

O10 4 0.30 Replace Spark Plug with torque

O11 4 0.30 Replace Plug Coil with torque

O12 4 0.40 Power Balance Test

O13 4 0.20 Remove injectors with fuel rail

O14 4 0.30 Visual check on injectors

O15 4 0.40 Install good injectors with torque

O16 4 0.30 Check Oil Control Valve function

O17 4 0.40 Replace Oil Control Valve

O18 4 0.30 Visual check on Coolant Temperature sensor (CTS)

O19 4 0.50 Measure resistance of CTS

O20 4 0.30 Replace CTS

O21 4 0.30 Engine running smooth and idle

Page 1 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Repair Engine due to Poor Drive Ability Sub Criterion ID A3

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O22

O23

O24

ft 4

4

0.30

0.40

0.30

Reconnect vacuum hose

Check Oxygen Sensor voltage (idling)

Clear all faults

ra

O25 4 0.20 Disconnect PADT-II

O26 4 0.30 Connect exhaust gas analyser

O27 4 0.50 Calibrate exhaust gas analyser

O28 4 0.40 Check and print exhaust gas reading

O29 4 0.30 Disconnect exhaust gas analyser

D

Page 2 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Checks, Measurements and Record on Report Form Sub Criterion ID A4

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 4

4

0.30

0.30

0.30

Measurement of injector 1

Measurement of injector 2

Measurement of injector 3

ra

O4 4 0.30 Measurement of injector 4

O5 4 0.30 Measurement of coil 1

O6 4 0.30 Measurement of coil 2

O7 4 0.30 Measurement of coil 3

O8 4 0.30 Measurement of coil 4

D

O9 4 0.30 Measurement of Oxygen Sensor

O10 4 0.40 Measurement of exhaust gas value (idling)

O11 4 0.40 Measurement of exhaust gas value (2000rpm)

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Health, Safety and House keeping Sub Criterion ID B1

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 1

1

0.10

0.10

0.10

Check & prepare all equipment

Use workshop manual

Apply logical working procedure

ra

O4 1 0.10 Check engine oil level

O5 1 0.10 Check coolant level

O6 1 0.10 Ramp lowered on stops

O7 1 0.10 Jacks, pads used

O8 1 0.10 Parking Brake applied to maximum

D

O9 1 0.10 Chock tires

O10 1 0.10 Use fender covers

O11 1 0.10 Use seat covers

O12 1 0.10 Use steering wheel cover

O13 1 0.10 Use gear shift lever cover

O14 1 0.10 Use floor mats

O15 1 0.20 Did not wear any metal objects

O16 1 0.20 Voice out to alert others

O17 1 0.50 Use of safety goggle during brake bleeding activity

O18 1 0.50 Proper tools handling

O19 1 0.50 Precision tools not dropped

O20 1 0.50 No brake fluid spilled over on any part of vehicle body

O21 1 0.10 Wipe out all initial markings made

Page 1 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Health, Safety and House keeping Sub Criterion ID B1

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O22

O23

O24

ft 1

1

0.10

0.10

0.10

Clean up tools and equipment

Clean up the test models & work area

Close front engine hood

ra

O25 1 0.10 Hand over vehicle key to judge

D

Page 2 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Remove / replace one side Front Strut Assembly Sub Criterion ID B2

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 5

5

0.10

0.10

0.10

Brief judge on the task activity

Loosen wheel nuts before lifting up

Raise vehicle to suitable height

ra

O4 5 0.10 Mark the wheel nut position

O5 5 0.10 Remove the front wheel

O6 5 0.10 Remove brake hose bracket

O7 5 0.10 Remove Front Strut Assembly & Self Locking Nut

O8 5 0.10 Loosen Flange Nuts

D

O9 5 0.10 Remove Front Strut Assembly

O10 5 0.10 Remove coil spring from Front Strut

O11 5 0.10 Verbal Inspection Report - Front coil spring

O12 5 0.10 Verbal Inspection Report - Lower Spring Insulator

O13 5 0.10 Verbal Inspection Report - Front s/absorber assembly

O14 5 0.10 Verbal Inspection Report - Rubber Spring Bumper

O15 5 0.10 Verbal Inspection Report - Absorber Lock Nut

O16 5 0.10 Verbal Inspection Report - Dust Seal

O17 5 0.20 Check condition of the Front Strut

O18 5 0.10 Replace the Strut Assembly

O19 5 0.20 Reassemble all Components correctly

O20 5 0.20 Update judge on critical assembling points with manual

O21 5 0.10 Temporary tighten the Lock Nut

Page 1 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Remove / replace one side Front Strut Assembly Sub Criterion ID B2

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

ft

ra

D

Page 2 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Install one side Front Strut Assembly Sub Criterion ID B3

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 5

5

0.10

0.10

0.10

Install Front Strut Assembly to the vehicle

Install & tighten the 3 Flange Nuts

Tighten Front Strut Assembly Bolt & Self Locking nut to

specifications

ra

O4 5 0.10 Torque the stabilizer link nut

O5 5 0.10 Install Wheel Sensor Harness Clip

O6 5 0.10 Install Brake Hose Bracket

D

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Front Brake Calliper & Disc Brake Measurement Sub Criterion ID B4

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 5

5

0.10

0.10

0.10

Update judge on the task activity

Temporarily relocate front caliper assembly via metal hook

Torque all 5 wheel nuts correctly

ra

O4 5 0.30 Mount DTI on the strut assembly

O5 5 0.50 Check run-out of front brake disc

O6 5 0.50 Measure thickness of brake disc

O7 5 0.20 Measure thickness of brake pads

O8 5 0.10 Install the caliper & torque

D

O9 5 0.10 Re-installed brake pads correctly

O10 5 0.20 Accurate data on report sheet

O11 5 0.10 Fix back the wheel to the initially marked position

O12 5 0.10 Tighten the wheel nut to recommended specification

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Perform the necessary Wheel Alignment Adjustment Sub Criterion ID B5

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 4

4

0.10

0.20

0.10

Update judge on the task activity

Check tire pressures and correct if necessary

Check conditions of wheel bearings

ra

O4 5 0.10 Check joints

O5 5 0.10 Remove / replace one side tie-rod end

O6 4 0.10 Check lower ball joints unloaded

O7 4 0.10 Check vehicle level

O8 4 0.10 Check wheel base

D

O9 4 0.10 Set program on computer alignment

O10 4 0.10 Mount Wheel Clamps correctly

O11 4 0.30 Handle Sensors with care

O12 5 0.10 Mount Sensors correctly

O13 4 0.20 Perform all wheels run-out compensation

O14 4 0.10 Position turntable correctly

O15 4 0.10 Apply parking brake (hand brake)

O16 4 0.10 Set the turn table to zero

O17 4 0.10 Position Rear Wheels Slip Plate

O18 4 0.10 Bounce the car

O19 4 0.10 Remove the turn table pins

O20 4 0.10 Set levelling sensor to centre position

O21 4 0.10 Use brake pedal depressor

Page 1 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Perform the necessary Wheel Alignment Adjustment Sub Criterion ID B5

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O22

O23

O24

ft 4

1

0.10

0.10

0.20

Check Caster Angle

Check KPI/SAI Angle Ball Joint

Centre Steering Wheel Straight ahead position

ra

O25 5 0.10 Lock steering wheel

O26 5 0.20 Interpret Camber Angle on screen

O27 5 0.20 Interpret Caster Angle on screen

O28 4 0.20 Interpret Toe Angle on screen

O29 4 0.20 Correct Front Toe Adjustment

D

O30 4 0.10 Tighten Tie-rod end lock nut

O31 5 0.10 Check steering wheel position

O32 5 0.10 Print out (after adjustment)

O33 4 0.10 Remove all sensors

O34 1 0.10 Reset program

O35 5 0.10 Car lowered to ground

O36 4 0.10 Remove brake pedal depressor and tools

Page 2 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Replace Brake Master Cylinder Assembly Sub Criterion ID B6

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 4

4

0.20

0.30

0.40

Recover the brake fluid from the master cylinder reservoir

Pumped brake pedal several times to remove vacuum from the

brake booster

Remove / replace the Brake Master Cylinder Assembly

ra

O4 4 0.30 Bleed the brake hydraulic system once again

O5 4 0.20 Confirm the status of the brake hydraulic system

D

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Overhaul Rear Calliper (RHS only) and check the conditions of all Brake

Sub Criterion Pads Sub Criterion ID B7

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 4

4

0.10

0.10

0.10

Update judge on the task activity

Remove rear calliper assembly

Disassemble rear caliper assembly

ra

O4 5 0.10 Verbal Inspection Report - Caliper piston

O5 4 0.10 Verbal Inspection Report - Dust cover

O6 4 0.10 Verbal Inspection Report - Rubber seal

O7 4 0.10 Verbal Inspection Report - Caliper bracket

O8 4 0.10 Verbal Inspection Report - Sliding mechanism

D

O9 4 0.30 Reassemble the caliper assembly

O10 4 0.20 Update judge on critical assembling points with manual

O11 4 0.20 Measure thickness of brake pads

O12 4 0.20 Measure thickness of brake disc

O13 4 0.20 Re-install brake pads correctly

O14 4 0.20 Install caliper and tighten to torque

O15 4 0.20 Accurate info on report sheet

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Hydraulic Brake System Air Bleeding Sub Criterion ID B8

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 5

5

0.10

0.10

0.20

Update judge on the task activity

Install brake fluid dispenser unit

Perform brake bleeding correctly

ra

O4 5 0.10 Check functions of brake system

O5 4 0.10 Update judge on the status

D

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Check the operation of the ABS and rectify by using GTS Sub Criterion ID B9

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 4

4

0.10

0.10

0.20

Connect GTS to diagnostic socket

Update judge on ABS diagnosis status

Confirm wheel speed sensor power supply & circuitry status

ra

O4 4 0.10 Replace defective rear wheel speed sensor

O5 4 0.30 Validate speed sensor status via GTS signal waveform

O6 4 0.20 Erase trouble code in the ABS control module

O7 4 0.10 Remove the GTS connection

O8 4 0.20 Accurate info on report sheet

D

O9 4 0.10 Exit the GTS function

O10 4 0.10 Inform judge to verify the status

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Preparation, Safety and Housekeeping Sub Criterion ID C1

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 1

1

0.10

0.10

0.20

Select the correct common tools

Check all instructions

Use workshop manual correctly

ra

O4 1 0.10 Apply logical working procedure

O5 1 0.20 Calibrate Multimeter

O6 1 0.10 Use seat cover

O7 1 0.10 Use fender cover

O8 1 0.10 Use floor mat

D

O9 1 0.10 Use steering cover

O10 1 0.10 Check oil level

O11 1 0.10 Check coolant level

O12 1 0.10 Check battery voltage

O13 1 0.10 Clean up the test vehicle

O14 1 0.10 Clean up the working area

O15 1 0.10 Clean up tools and equipment

O16 1 0.20 Clear all fault codes after repair (using MMDS)

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Headlight Operation Sub Criterion ID C2

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 3

3

0.10

0.20

0.20

Check function of headlights system

Check Hi-beam Fuse

Rectify Hi-beam Fuse problem

ra

O4 3 0.20 Check Hi-beam relay function

O5 3 0.40 Check continuity of LH Hi-beam ground to G03

O6 4 0.40 Check continuity terminal A to 1M

O7 5 0.40 Check continuity terminal 2X to E

O8 4 0.40 Check continuity terminal 2V to E

D

O9 4 0.40 Check continuity terminal A to C Headlight HI relay

O10 4 0.10 Check headlights for proper function

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Washer and wiper system Sub Criterion ID C3

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 3

3

0.10

0.30

0.50

Check function of the washer and wiper system

Check 20A fuse

Check continuity between FBCM and wiper motor

ra

O4 3 0.40 Check function of the wiper switch

O5 3 0.30 Check ground connection

O6 3 0.40 Check wiper motor park position

O7 3 0.30 Check washer motor circuit

O8 4 0.10 Check function after replacing parts

D

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Power Window Operation Sub Criterion ID C4

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 3

3

0.20

0.30

0.30

Check function of power window system

Check 7.5 A fuse (F-02)

Check 25 A fuse (F-02)

ra

O4 3 0.30 Check motor power window main switch voltage supply

O5 3 0.30 Check voltage at FRT RH power window motor

O6 3 0.30 Visual check on glass runner

O7 3 0.30 Check voltage between fuse Power Window 2 to pin 1L

O8 4 0.30 Check circuit system

D

O9 5 0.30 Check ground connection

O10 4 0.30 Check switch FRT LH

O11 4 0.30 Rectify switch FRT LH problem

O12 4 0.10 Check function after replacing parts

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Power Mirror Operation Sub Criterion ID C5

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 3

3

0.10

0.30

0.30

Check function of the Power mirror system (Passenger Side)

Check ACC Relay

Check ground continuity

ra

O4 3 0.20 Check supply voltage at switch

O5 4 0.50 Check continuity between power mirror control switch and motor

O6 5 0.10 Check function after replacing parts

D

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Central Locking System Sub Criterion ID C6

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 3

3

0.10

0.20

0.30

Check function of the central locking system

Check 25 A fuse

Check supply voltage at switch

ra

O4 4 0.20 Check supply voltage at door actuator

O5 5 0.50 Check continuity from RBCM to door actuator

O6 4 0.10 Check function after replacing parts

O7 4 0.20 Check remote control function

D

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Reverse Light Operation Sub Criterion ID C7

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 3

3

0.10

0.30

0.20

Check function of the back up light system

Check voltage (12V) at pin 2I (RBCM)

Check fuse F01 - 10 A (meter)

ra

O4 3 0.20 Check continuity between 4S to A

O5 3 0.20 Check positive voltage at reverse lamp

O6 3 0.20 Check bulb condition

O7 4 0.20 Check ground condition

O8 5 0.10 Connect MMDS in correct order

D

O9 4 0.40 Check Medium Speed CAN BUS (using MMDS)

O10 4 0.40 Rectify Medium Speed CAN BUS fault (using multimeter)

O11 4 0.10 Disconnect MMDS in correct order

O12 4 0.10 Check function after replacing parts

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Charging system Sub Criterion ID C8

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 3

3

0.10

0.20

0.20

Check function of charging system

Check continuity between Main Fuse to terminal 1A Generator

Check supply to Generator pin 2B

ra

O4 3 0.20 Check Generator standard voltage (Idling)

O5 4 0.40 Remove Generator Assembly from engine

O6 5 0.40 Dismantle Removed Generator Assembly

O7 4 0.30 Check Diodes condition

O8 4 0.20 Check Continuity between Slip Rings to Rotor Body

D

O9 4 0.30 Check Rotor Body and both Ball Bearings Physical Condition

O10 4 0.20 Check Resistance of Rotor Winding

O11 4 0.20 Check Continuity of Carbon Brushes

O12 4 0.20 Check Continuity of all Stator Coils

O13 4 0.40 Install new Generator assembly

O14 4 0.10 Check function after replacing new alternator

O15 4 0.20 Check output voltage

O16 4 0.40 Check output amperes

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Health, Safety and House Keeping Sub Criterion ID D1

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 1

1

0.30

0.10

0.10

Working procedure according to Service manual

Check all equipment

Check all instructions

ra

O4 1 0.10 Select the correct tools

O5 1 0.60 Proper tools handling

O6 1 1.00 Proper handling spare parts

O7 1 0.10 Use logical working procedure

O8 1 0.10 Clean up the working area

D

O9 1 0.10 Clean up tools and equipment

O10 1 0.10 Clean up the test models

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Remove Engine External and Internal Components Sub Criterion ID D2

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 5

5

0.10

0.10

0.10

Remove water pump with pulley

Remove alternator

Remove air cond. compressor

ra

O4 5 0.10 Remove top coils

O5 5 0.10 Remove cylinder cam cover

O6 5 0.20 Remove TV damper

O7 5 0.10 Remove spark plugs

O8 5 0.10 Remove timing belt front upper cover

D

O9 5 0.10 Remove timing belt front lower cover

O10 5 0.30 Set timing mark in the correct position

O11 5 0.10 Remove timing belt tensioner

O12 5 0.10 Remove timing belt

O13 5 0.10 Remove crankshaft timing sprocket

O14 5 0.30 Use Special tool to loosen sprocket bolt

O15 5 0.10 Remove intake camshaft sprocket

O16 5 0.30 Use Special tool to loosen exhaust camshaft sprocket bolt

O17 5 0.10 Remove exhaust camshaft sprocket

O18 5 0.30 Loosen camshaft caps bolts correctly

O19 5 0.10 Remove camshaft oil seals

O20 5 0.20 Remove camshafts

O21 5 0.10 Remove Hydraulic Lash Adjuster

Page 1 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Remove Engine External and Internal Components Sub Criterion ID D2

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O22

O23

O24

ft 5

5

0.40

0.20

0.10

Loosen Cylinder Head Bolts in correct order

Remove Cylinder Head Bolts

Remove Cylinder Head

ra

O25 5 0.10 Remove Cylinder Head Gasket

O26 5 0.30 Remove 1 set of Valves and Springs

O27 5 0.20 Remove Oil Pan Assembly

O28 5 0.20 Remove Connecting Rod Bearing Caps

O29 5 0.30 Remove 1 Piston with Connecting Rod

D

Page 2 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Cylinder Bore and Piston Measurements Sub Criterion ID D3

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 4

4

0.30

0.30

0.30

Set up bore gauge and micrometer

Correct usage of bore gauge

Correct usage of micrometer

ra

O4 4 0.20 Measure Piston Diameter

O5 4 0.20 Measure Cylinder Bore in A1

O6 4 0.20 Measure Cylinder Bore in B1

O7 4 0.20 Measure Piston Ring Side Clearance

O8 4 0.20 Measure Piston Ring End Gap

D

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Crankshaft and Bearing Measurements Sub Criterion ID D4

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 4

4

0.30

0.30

0.30

Set up of micrometer and dial gauge

Correct usage of micrometer

Correct usage of dial gauge

ra

O4 4 0.30 Correct usage of plastic gauge

O5 4 0.20 Measure Main Journal Diameter

O6 4 0.20 Measure Oil Clearance Main Journal

O7 4 0.20 Measure Crank Pin Diameter

O8 4 0.20 Measure Crank Pin Side Clearance

D

O9 4 0.20 Measure Oil Clearance Crank Pin

O10 4 0.20 Measure crankshaft end play

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Valve & Valve Mechanism Measurements Sub Criterion ID D5

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 4

4

0.30

0.40

0.40

Set up of micrometer and Vernier Caliper

Correct usage of micrometer

Correct usage of Vernier caliper

ra

O4 4 0.20 Measure inlet valve stem

O5 4 0.20 Measure exhaust valve stem

O6 4 0.20 Measure valve spring height

O7 4 0.20 Measure cam height

D

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Assembling Engine External and Internal Components Sub Criterion ID D6

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 5

5

0.10

0.20

0.20

Lubricate components before assembling

Install Piston Ring in correct setting

Install Piston to Cylinder Block

ra

Install and tighten Connecting Rod Bearing Cap to Crankshaft

O4 5 0.20

Journal with torque

O5 5 0.20 Install Oil Pan with sealant

O6 5 0.20 Torque Oil Pan bolts

O7 5 0.20 Install 1 set of Valves and Springs

O8 5 0.10 Install Hydraulic Lash Adjuster

D

O9 5 0.10 Install cylinder head gasket

O10 5 0.20 Install cylinder head

O11 4 0.40 Measure cylinder head bolts length

Install cylinder head bolts and tighten in correct sequence to

O12 5 0.30

specified torque

O13 5 0.10 Apply sealant to both camshaft front caps

O14 5 0.20 Install camshafts in correct position

Install camshaft caps and tighten in correct order and specified

O15 5 0.20

torque

O16 5 0.10 Install camshaft oil seals with special tool

O17 5 0.20 Install exhaust camshaft sprocket according to service manual

Tighten exhaust camshaft sprocket to specified torque using

O18 5 0.20

special tool

O19 5 0.20 Install intake camshaft sprocket according to service manual

Tighten intake camshaft sprocket to specified torque using

O20 5 0.20

special tool

O21 5 0.10 Install crankshaft timing sprocket

Page 1 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Assembling Engine External and Internal Components Sub Criterion ID D6

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O22

O23

O24

ft 5

5

0.50

0.30

0.10

Set the timing mark correctly

Install and torque timing belt tensioner

Install timing belt

ra

O25 5 0.30 Adjust timing belt tension

O26 5 0.10 Install cylinder head cam cover

O27 5 0.10 Install timing belt front lower cover

O28 5 0.10 Install timing belt front upper cover

O29 5 0.10 Install spark plugs

D

O30 5 0.20 Torque spark plugs

O31 5 0.10 Install top coils

O32 5 0.10 Install water pump with pulley

O33 5 0.20 Install crankshaft TV Damper and tighten to specified torque

O34 5 0.10 Install alternator

O35 5 0.10 Install drive belt tensioner

Page 2 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Health, Safety and House keeping Sub Criterion ID E1

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 1

1

0.10

0.10

0.10

Use logical working procedure

Proper tools handling

Check coolant level

ra

O4 1 0.10 Check engine oil level

O5 1 0.10 Choke tires

O6 1 0.10 Use fender covers

O7 1 0.10 Use seat covers

O8 1 0.10 Use steering wheel cover

D

O9 1 0.10 Use floor matt

O10 1 0.10 Clean up the working area

O11 1 0.60 Parts Damage/Safety/Negligence

O12 1 0.50 DROP TOOLS / COMPONENTS

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Vehicle test on the P and N Start Function Sub Criterion ID E2

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 4

4

0.10

0.10

0.40

Check engine starting function

Check gear position (meter indicator)

Check gearshift SOL Relay K3

ra

O4 4 0.40 Check ground pin 6 at gearshift module (D-22)

O5 4 0.40 Check continuity from Fuse F6 to terminal A3 Brake Switch

O6 5 0.40 Check Brake Switch Function

O7 5 0.30 Set and operate PADT-ll correctly

O8 5 0.30 Crank engine & Clear all fault code

D

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Disassemble Auto. Transmission (on Stand) Sub Criterion ID E3

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 4

4

0.10

0.30

0.10

Remove Torque Convertor

Set and calibrate Dial gauge, measure input shaft end play

Remove Pulse Generator (A & B)

ra

O4 5 0.10 Remove Cooler Feed Tube, Eye Bolt and Gasket

O5 5 0.10 Remove manual control lever and inhibitor switch

O6 5 0.10 Remove valve body cover

O7 5 0.10 Remove Manual Control lever shaft and parking pawl rod

O8 5 0.10 Remove manual control shaft detent

D

O9 5 0.10 Remove the valve body assembly

O10 5 0.10 Remove strainer

O11 5 0.10 Remove second brake retainer oil seal

O12 5 0.10 Remove accumulator

O13 5 0.10 Remove torque converter housing

O14 5 0.20 Remove torque convertor housing O ring

O15 5 0.10 Remove differential unit

O16 5 0.10 Remove oil filter

O17 5 0.20 Remove oil pump and gasket

O18 5 0.10 Remove oil pump outer groove O ring

Remove input shaft, under-drive clutch and under-drive clutch

O19 5 0.10

hub

O20 5 0.10 Remove rear cover

O21 5 0.20 Remove rear cover O rings

Page 1 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Disassemble Auto. Transmission (on Stand) Sub Criterion ID E3

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O22

O23

O24

ft 5

5

0.10

0.10

0.10

Remove thrust bearing, reverse and overdrive clutch

Remove thrust bearing & over-drive clutch hub

Remove planetary reverse sun gear

ra

O25 5 0.10 Remove thrust bearing and planetary sun gear

O26 5 0.10 Remove snap ring, second-brake piston and return spring

O27 5 0.10 Remove pressure plate, second-brake disc and plate

O28 5 0.10 Remove Planetary carrier assembly

O29 5 0.10 Remove snap ring, reaction plate.

D

Remove snap ring, low-reverse brake discs, plates, pressure

O30 5 0.10

plate and wave spring.

O31 5 0.10 Remove parking roller support shaft, paws case & roller support

Remove snap ring, one-way clutch inner race, spring retainer,

O32 5 0.10

return spring.

O33 5 0.10 Apply compress air to remove Low-reverse brake piston

O34 5 0.10 Remove transfer drive gear

Page 2 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Disassemble Clutches and Pistons Assembly Sub Criterion ID E4

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 5

5

0.10

0.10

0.10

Remove under-cover clutch input shaft snap ring

Remove snap ring, clutch reaction plates, clutch disc, clutch

plate.

Remove snap ring

ra

O4 5 0.10 Remove under drive-clutch spring retainer & return spring

O5 5 0.10 Remove under-drive clutch spring retainer D Ring

O6 5 0.15 Apply compress air to remove under- drive clutch piston

O7 5 0.10 Remove under-drive clutch piston D Ring

Remove reverse and over-drive clutch snap ring, reaction plate,

O8 5 0.10

clutch discs & clutch plate

D

O9 5 0.10 Remove reverse-clutch piston & D ring

O10 5 0.10 Remove snap ring, spring retainer & return spring

O11 5 0.10 Remove over-drive spring retainer D ring

O12 5 0.15 Apply compress air to remove over-drive clutch piston

O13 5 0.10 Remove over-drive clutch piston D ring

O14 5 0.10 Remove second-brake retainer D ring

O15 5 0.10 Remove second-brake piston D ring

O16 5 0.10 Remove low-reverse brake piston inner D ring

O17 5 0.10 Remove low-reverse brake piston outer D ring

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Assemble Clutches and Pistons Assembly Sub Criterion ID E5

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 5

5

0.10

0.10

0.10

Check condition & install oil pump outer groove O ring

Check condition & install reverse clutch piston D ring

Check condition & install of over-drive clutch piston D ring

ra

O4 5 0.10 Check condition & install reverse clutch spring retainer D ring

Install over-drive clutch piston, return spring, spring retainer and

O5 5 0.10

snap ring

Measure reverse clutch clearance between the snap ring and the

O6 5 0.20

return spring

Install reverse and over-drive clutch, discs, plate, reaction plate

O7 4 0.10

& snap ring.

O8 4 0.10 Check condition & install second-brake piston D ring

D

O9 5 0.10 Check condition & install second-brake retainer D ring

O10 5 0.10 Check condition & install low-reverse brake outer D ring

O11 5 0.10 Check condition & install low-reverse inner D ring

O12 5 0.10 Check condition & install under-drive clutch piston D ring

Check condition & install under-drive clutch spring retainer D

O13 5 0.10

ring

Install under-drive clutch piston, return spring, spring retainer

O14 5 0.10

and snap ring

Install under-drive clutch plate, disc, reaction plates and snap

O15 5 0.10

ring

O16 5 0.10 Install under-cover clutch input shaft snap ring

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Assembling Auto. Transmission Sub Criterion ID E6

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 5

5

0.20

0.20

0.20

Install transfer drive gear

Tightening & torque transfer gear mounting bolts to specified

torque

Install low-reverse brake piston, return spring, spring retainer,

one-way clutch inner race & snap ring

ra

O4 5 0.20 Install low-reverse brake disc, plate, special tool and snap ring

O5 5 0.20 Install second brake disc, second brake plate and special tool

O6 5 0.30 Set and calibrate Dial gauge, Measure second brake end play

O7 5 0.10 Reverse the transmission

Set and calibrate Dial gauge, Measure low-reverse brake end

O8 5 0.30

play

D

O9 5 0.10 Install parking roller support shaft, paws case & roller support

O10 5 0.10 Install planetary carrier assembly and reverse sun gear

Install low-reverse wave spring, brake disc, plate, snap ring,

O11 4 0.10

reaction plate snap ring

Install second-brake disc, plate, return spring, second brake

O12 5 0.10

piston and snap ring

Install planetary reverse sun gear thrust bearing (Check direction

O13 5 0.20

of thrust bearing)

O14 5 0.10 Install over-drive clutch hub & thrust bearing

Install reverse and overdrive clutch thrust bearing (Check

O15 5 0.20

direction of thrust bearing)

O16 5 0.20 Install rear cover O rings

O17 5 0.20 Install rear cover and tighten mounting bolts to specified torque

O18 5 0.10 Install under drive-clutch hub

Install reverse and under-drive clutch hub thrust bearing (Check

O19 5 0.20

direction of thrust bearing)

O20 5 0.10 Install input shaft and under-drive clutch

O21 5 0.20 Check & install oil pump outer groove O ring

Page 1 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Assembling Auto. Transmission Sub Criterion ID E6

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O22

O23

O24

ft 5

5

0.20

0.20

0.30

Install oil pump and gasket

Tighten and torque the oil pump mounting bolts

Set and calibrate Dial gauge, measure input shaft end play

ra

O25 5 0.10 Install oil filter

O26 5 0.10 Install differential unit

O27 5 0.20 Install torque convertor housing O ring

Install torque converter housing and tighten mounting bolts to

O28 5 0.20

specified torque

O29 5 0.10 Install manual control lever shaft & parking pawl rod

D

O30 5 0.20 Checked / identified accumulator springs

O31 5 0.10 Install accumulator pistons.

O32 5 0.10 Install strainer

O33 5 0.10 Install second brake retainer oil seal

O34 5 0.20 Install valve body , gasket and two (2) steel balls

O35 5 0.20 Tighten valve body mounting bolts to specified torque

O36 5 0.10 Install manual controlled shaft

Install valve body cover and tighten mounting bolts to specified

O37 5 0.20

torque

O38 5 0.10 Install inhibitor switch and manual control lever

O39 5 0.10 Install Pulse generator (A & B)

O40 5 0.10 Install Cooler Feed Tube, Eye Bolt and Gasket

O41 5 0.10 Install torque converter

Page 2 / 2 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

Objective Marking

ASC2016 Kuala Lumpur

Skill Number 33 Skill Automobile Technology Competition Day

Competitor Name Member

Sub Criterion Parts Condition, Measurements (Report Form) Sub Criterion ID E7

Marking Scheme Lock Mark Entry Lock

Aspect WSSS Max Requirement or Result or Mark

Aspect of Sub Criterion - Description

ID Section Mark Nominal Size Actual Value Awarded

O1

O2

O3

ft 4

4

0.10

0.10

0.10

Measurement of input shaft end play (before dismantle)

Condition of oil pump outer groove O ring

Condition of under-drive clutch spring retainer D ring

ra

O4 4 0.10 Condition of under-drive clutch piston D ring

O5 4 0.10 Condition of low-reverse inner D ring

O6 4 0.10 Condition of low-reverse outer D ring

O7 4 0.10 Condition of second-brake retainer D ring

O8 4 0.10 Condition of second-brake piston D ring

D

Measurement of reverse-clutch clearance between the snap ring

O9 4 0.10

and return spring

O10 4 0.10 Condition of over-drive clutch spring retainer D ring

O11 4 0.10 Condition of over-drive clutch piston D ring

O12 4 0.10 Condition of reverse-clutch piston D ring

O13 4 0.10 Measurement of second brake end Play

O14 4 0.10 Measurement of low-reverse brake end play

O15 4 0.10 Measurement of input shaft end play (after assemble)

Page 1 / 1 22-09-2016 07:33:36

CIS software provided courtesy of WorldSkills International www.worldskills.org Copyright WorldSkills International 2016. All rights reserved

You might also like

- Events API DocumentationDocument5 pagesEvents API Documentationmario librerosNo ratings yet

- Bse8klna en v220413Document2 pagesBse8klna en v220413danilo Mendoza0% (1)

- MS1920 ENGIRO-MS1920 Official Electric Motor INFODocument7 pagesMS1920 ENGIRO-MS1920 Official Electric Motor INFOJoan Ferrao GenescàNo ratings yet

- FINAL Marking Scheme in CIS Format - v1.3Document52 pagesFINAL Marking Scheme in CIS Format - v1.3Marvin Sarmiento TalimonganNo ratings yet

- Winters PreviewDocument265 pagesWinters PreviewcqpresscustomNo ratings yet

- WSC2007 13 MSF Autobody RepairDocument2 pagesWSC2007 13 MSF Autobody Repairmy.hostNo ratings yet

- DP computerSMARTIII ENDocument2 pagesDP computerSMARTIII ENJovan NikolicNo ratings yet

- DC Locomotive System PDFDocument2 pagesDC Locomotive System PDFRizki Fajar NovantoNo ratings yet

- GA 250 VSD - 125 Psi - Water Cooled - 2015 Rev 0Document1 pageGA 250 VSD - 125 Psi - Water Cooled - 2015 Rev 0Vi Na Ridho ChabieNo ratings yet

- Smart Iii: ComputerDocument2 pagesSmart Iii: ComputerfaikNo ratings yet

- Engiro Datasheet 205a 04016 ABC v001Document6 pagesEngiro Datasheet 205a 04016 ABC v001Francisco Palacios López100% (1)

- Nissan Leaf Teardown (Part 1) - MarkLines Automotive Industry PortalDocument11 pagesNissan Leaf Teardown (Part 1) - MarkLines Automotive Industry PortalHtek Thu ThwinNo ratings yet

- Draft Power System Design and Setting Data SheetDocument87 pagesDraft Power System Design and Setting Data SheetMohamed HamdallahNo ratings yet

- Maxon A Max Catalog Data2 PDFDocument28 pagesMaxon A Max Catalog Data2 PDFM. Luthfi Alhadi ZNo ratings yet

- Cagi zr250 VSD 8.6 125psigDocument2 pagesCagi zr250 VSD 8.6 125psigHabib ur RehmanNo ratings yet

- Atlazo Technology Applied Ventures Oct 2021Document18 pagesAtlazo Technology Applied Ventures Oct 2021Kevin G. DavisNo ratings yet

- Atlas Copco: Xair-CooledDocument6 pagesAtlas Copco: Xair-Cooledthiyagarajan v100% (1)