Professional Documents

Culture Documents

StructureScan Thru-hullTransducer IM en 988-0179-15 A W

StructureScan Thru-hullTransducer IM en 988-0179-15 A W

Uploaded by

John JensenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

StructureScan Thru-hullTransducer IM en 988-0179-15 A W

StructureScan Thru-hullTransducer IM en 988-0179-15 A W

Uploaded by

John JensenCopyright:

Available Formats

*988-0179-15A*

StructureScan Thru-hull Transducer

Introduction

This document describes how to install the StructureScan Thru-

hull transducer.

Installation instructions for the StructureScan LSS-1 Black box is

included with the LSS-1 package.

Installation restrictions

The StructureScan Thru-hull transducer should NOT be

installed on wood-hull vessels, or on vessels where the dead

rise angle is more than 23. Max 23

Mounting the transducer requires drilling holes through the hull. Make sure the

installation does not cause the vessel to leak. Also ensure that any mounting holes are in

a safe position, and that they do not weaken the boats structure. If in doubt, consult a

qualified boat builder.

Never mount the StructureScan Thru-hull transducer without securing the

unit with the anti-rotation bolt.

Parts included in package

Item Number Description

A 1 StructureScan Thru-hull transducer, including 9 m (30) cable

C

B 1 Fairing block

F B C 1 1-8 Nylon Hex Nut

E

D 1 M5 x 80 Hex Bolt

E 1 M5 Washer

A F 1 M5 Hex Nut

1 Warranty

D

1 This manual

Required tools and supplies

5 mm (#8) drill 8 mm and 1.5 wrenches

26 mm (1)

Drill bit or adjustable wrench

hole saw

Marine grade above- or below- waterline sealant

StructureScan Thru-hull transducer | 1

Installation

Mounting location

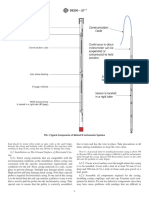

The transducer must be mounted in a location that is always underwater and has a

smooth flow of water when the boat is moving.

Recommended location will usually be aft midships in front of the propeller, behind hull

irregularities, and away from water intake, discharge openings or anything else that may

create turbulence.

The location must be easy accessible from the inside for cable routing.

The mounting location should be as close to the center line as required to ensure that

the hull not interfere with side scanning.

Two transducers can be connected to the LSS-1 on vessels with a large dead rise angle.

Refer to the separate LSS-1 Installation manual.

Leveling the transducer

The transducer must be mounted as parallel to the water line as possible.

min 5 mm (0.2)

The dead rise angle of the hull will angle the transducer, affecting the quality of the

transducer signal.

For hulls with no dead rise angle the fairing block should be used to ensure proper

alignment and a secure fit (A).

For hulls with a dead rise angle the fairing block should be cut and used to compensate

for the dead rise angle (B).

A A B B

No dead rise angle 0 < dead rise angle <23

Mounting the transducer

1 Drill a pilot hole, max 5 mm (0.2)

2 Use the pilot hole and drill from the outside a 26 mm (1) hole with the hole saw,

perpendicular to the water line. This is for the transducers main shaft

3 Sand and clean the hole and the area around it on the inner and outer side of the

hull

4 If required, cut the fairing block and use both pieces to level the transducer

parallel to the water line

5 Temporarily install the transducer to check the hole and the leveling

6 Apply marine-grade sealant or epoxy inside the hole, on the sanded surfaces and

on the mating edges of the fairing block

7 Mount the StructureScan transducer according the mounting indication on the unit

8 Use the hole on the fairing block as guide and drill a 5 mm hole through the hull

for the anti rotation bolt

2 | StructureScan Thru-hull transducer

9 Secure the installation by tightening the nuts

10 Remove any excess adhesive on the outside to avoid water turbulence

Do not overtighten the nuts!

Immediately after installing the transducer, be sure to check for leaks, and dont leave

the vessel in the water for more than three hours before checking it again.

Wiring

LTW

LTW

Ref. Description

B C or B A StructureScan LSS-1 Black box

LTW

LTW

B StructureScan Transducer cable

B

C StructureScan Y-cable

LTW

LTW

2* Single

Thru-hull Thru-hull

transducers transducer

Maintenance

Do not expose the transducers face or plastic housing to gasoline or strong solvents,

such as acetone. These solvents can penetrate and degrade many plastics and reduce

their strength.

Check the transducer regularly, and if required clean the transducer of heavy debris or

foul sea growth. Use sanding sparingly, as repeated sanding may affect the transducers

performance at high speeds. For lighter cleaning, the surface may be wet-sanded with

#220 or finer wet/dry sandpaper.

Ensure to not scratch the surfaces!

Painting

Cover or remove the transducer when repainting the hull.

If painting over the transducer, use only one coat of non-metallic anti-fouling paint.

Remove the previous coat of paint by sanding it lightly.

Painting the transducer could reduce the depth performance slightly.

Spare parts and accessories

Item Part no. Description

LSS-1 Thru-hull transducer, including fairing

000-00099-003

block and 9 m (30) cable

Transducer Extension cable,

000-00099-006

WTL

LTW

3 m (10)

StructureScan Y-cable,

LTW

000-10202-001

LTW

0.3 m (11.8)

LTW

StructureScan Thru-hull transducer | 3

Technical specifications and drawings

Mechanical

Dimensions:.......................................................................... See illustration below

Material:.................................................................................................... Plastic

Transducer cable length:......................................................................... 9 m (30)

Y-cable length (option):......................................................................0,3 m (11.8)

Transducer Extension cable length (option).................................................3 m (10)

Environmental

Operating temperature:..................................................-10 - +50C (14 - 122F)

Storage temperature:..................................................-35 - +80C (-31 - +176F)

Sidescan specification

Max range:...........................................455 kHz; 150 m (500 ft) 75 (250) per side

800 kHz; 90 m (300 ft) 45 (150) per side

Max speed for tracking digital depth:..............................30 knots / 35 mph / 56 kmh

Max speed to see/find objects/structure:......................... 13 knots / 15 mph / 24 kmh

Optimum speed:................................................8.5 knots / 10 mph / 16 kmh or less

Downscan specifications

Max depth:.......................................................................... 455kHz; 90 m (300 ft)

800kHz; 30 m (100 ft)

Max speed for tracking digital depth:..............................48 knots / 55 mph / 88 kmh

Max speed to see/find objects/structure..........................30 knots / 35 mph / 56 kmh

Optimum speed.................................................8.5 knots / 10 mph / 16 kmh or less

193 mm (7.6) 66 mm (2.6)

Cut-out holes:

Main shaft: 26 mm (1)

Anti-rotation bolt: 5 mm (0.197)

38 mm

(1.5) 127.5 mm

(5)

27 mm

(1.06)

Contact and service information

For spare parts or service information, please contact one of our local sales offices or

visit our websites;

www.lowrance.com or www.simrad-yachting.com.

4 | StructureScan Thru-hull transducer

You might also like

- Fabrication ProcedureDocument17 pagesFabrication ProcedureThi Pham100% (9)

- Basketball Court Construction SampleDocument17 pagesBasketball Court Construction Sampleashenafi girmaNo ratings yet

- Tamiya Colour ChartDocument7 pagesTamiya Colour Chartmike_hobbs_6100% (3)

- Well CompletionDocument29 pagesWell CompletionAkol MajookNo ratings yet

- Completion EquipmentDocument41 pagesCompletion Equipmenteng20072007No ratings yet

- Part 3 Well Completion Equipment PDFDocument91 pagesPart 3 Well Completion Equipment PDFRanim Hisham100% (1)

- Paint IndustryDocument27 pagesPaint IndustryVishal VinitNo ratings yet

- User Manual of Product 1:: Lowrance 000-10802-001 Skimmer Transom Mount Tranducer For Lss-2 Structurescan HD FishfinderDocument17 pagesUser Manual of Product 1:: Lowrance 000-10802-001 Skimmer Transom Mount Tranducer For Lss-2 Structurescan HD Fishfinder薛泽绵No ratings yet

- SS3D Transducer IM 988-10971-001Document16 pagesSS3D Transducer IM 988-10971-001DAFUNo ratings yet

- LS Series Linear Variable Differential Transformer Instruction ManualDocument23 pagesLS Series Linear Variable Differential Transformer Instruction Manualravi_fdNo ratings yet

- Garmin Clearvü Transducer Transom/ Trolling Motor Mount: Installation InstructionsDocument4 pagesGarmin Clearvü Transducer Transom/ Trolling Motor Mount: Installation InstructionsJose Meseguer BañoNo ratings yet

- Humminbird Wide Optic ManualDocument32 pagesHumminbird Wide Optic ManualLaurent Chandezon50% (2)

- Hummingbird 300TX ManualDocument28 pagesHummingbird 300TX ManualDale Wells100% (1)

- HumminbirdWide3DVistaUsersManual465808 891224972Document38 pagesHumminbirdWide3DVistaUsersManual465808 891224972Radojko TomitoNo ratings yet

- TRANSOM TRANSDUCER Installation GuideDocument16 pagesTRANSOM TRANSDUCER Installation GuideFlorin PloscarNo ratings yet

- Installation Instructions Owner'S Guide &: StructurescanDocument8 pagesInstallation Instructions Owner'S Guide &: StructurescanOlegNo ratings yet

- Manual Sonda Humminbird 350txDocument28 pagesManual Sonda Humminbird 350txJose Meseguer BañoNo ratings yet

- 6613 Issue 2 Offshore Impressed Current SystemDocument3 pages6613 Issue 2 Offshore Impressed Current SystemFethi BELOUISNo ratings yet

- 393Document1 page393ALBERTO ANTONINo ratings yet

- Style 390-1: Supplied PartsDocument1 pageStyle 390-1: Supplied Partsjoaquin ferNo ratings yet

- H3C S6805-54HT Switch InstallationDocument1 pageH3C S6805-54HT Switch InstallationJaka maulanaNo ratings yet

- Fishfinder-Raytheon L265Document79 pagesFishfinder-Raytheon L265Jonathan McQuadeNo ratings yet

- Transducer Placement Guide EN-USDocument16 pagesTransducer Placement Guide EN-US2010tegNo ratings yet

- Cable Buddy ManualDocument8 pagesCable Buddy Manualخالد العتيبيNo ratings yet

- Cap InstallationDocument32 pagesCap InstallationLucio CastrillonNo ratings yet

- cv86 MeDocument18 pagescv86 Mecuongnv_19No ratings yet

- Hose Inflation Kit Sales SheetDocument2 pagesHose Inflation Kit Sales SheetForum PompieriiNo ratings yet

- A-Conventional Offshore Course - Part2pipelines and Risers PDFDocument99 pagesA-Conventional Offshore Course - Part2pipelines and Risers PDFMuhammad Geovani100% (3)

- Back Off String ShotDocument16 pagesBack Off String ShotChoayb Seller100% (1)

- Sprinkler Alarm: Model: SdgaDocument3 pagesSprinkler Alarm: Model: SdgaAbdul RawoofNo ratings yet

- Delta Medical Implants and DisposblesDocument41 pagesDelta Medical Implants and DisposblesquydocaoNo ratings yet

- Cm599 Owners GuideDocument2 pagesCm599 Owners GuideJose MariaNo ratings yet

- Pull Wire and Trip Switch PDFDocument76 pagesPull Wire and Trip Switch PDFBrion Bara IndonesiaNo ratings yet

- Military Refueling Nozzle: 341GF SeriesDocument2 pagesMilitary Refueling Nozzle: 341GF SeriesCRISTIAN CMAILO CABALLERONo ratings yet

- Elite 5 Elite 5m ManualDocument52 pagesElite 5 Elite 5m ManualCosmin GheorgheNo ratings yet

- Astm d6230 - Part 2Document4 pagesAstm d6230 - Part 2leegoon82No ratings yet

- Pamphlet On DC Track Circuit Maintenance Ver2Document8 pagesPamphlet On DC Track Circuit Maintenance Ver2amarsingh choudharyNo ratings yet

- Check Valve CV1 08: UcsonDocument2 pagesCheck Valve CV1 08: UcsonpavankumarNo ratings yet

- Well Intervention OperationsDocument53 pagesWell Intervention OperationsLuis Arturo Gómez LunaNo ratings yet

- WK 6 Anchors and Moors - LecturerDocument21 pagesWK 6 Anchors and Moors - LecturerPushkar Lamba100% (1)

- 2020 Water Wastewater Standards ManualDocument739 pages2020 Water Wastewater Standards Manualbartsi1No ratings yet

- Digital Coriolis Mass Flowmeters Installation Guidelines and Quick Start - HARTDocument12 pagesDigital Coriolis Mass Flowmeters Installation Guidelines and Quick Start - HARTPhaniNo ratings yet

- 6612 Issue 2 Offshore Sacrificial Anode SystemDocument2 pages6612 Issue 2 Offshore Sacrificial Anode SystemFethi BELOUISNo ratings yet

- dp45 Low Pressure Variable Reluctance SensorDocument4 pagesdp45 Low Pressure Variable Reluctance SensorLuis OrtizNo ratings yet

- Airmar Transducer External Mounting1Document4 pagesAirmar Transducer External Mounting1vedranNo ratings yet

- Livescope_Plus_LVS34_Install_EN-USDocument20 pagesLivescope_Plus_LVS34_Install_EN-US薛泽绵No ratings yet

- Waw Rbcvt4 ManualDocument16 pagesWaw Rbcvt4 ManualSebastián Meneses PortillaNo ratings yet

- Porta Fusible Canister para 34.5 KVDocument24 pagesPorta Fusible Canister para 34.5 KVjryamNo ratings yet

- Nearshore CPT ENGDocument7 pagesNearshore CPT ENGAntónio Pedro TavaresNo ratings yet

- 5 de 5) VÁLVULA DE RETENCIÓN Marca TYCO (Inglés)Document6 pages5 de 5) VÁLVULA DE RETENCIÓN Marca TYCO (Inglés)Maximiliano StaitiNo ratings yet

- IronRidge Flush Mount Installation ManualDocument12 pagesIronRidge Flush Mount Installation ManualAnonymous nrE2hFsvNo ratings yet

- Downhole Flow Control ProductDocument16 pagesDownhole Flow Control Producthosam aliNo ratings yet

- Hose OEM MaintenanceDocument54 pagesHose OEM MaintenanceBayu Jatmiko100% (1)

- 3-Way Flanged Ball Valves: EconomicalDocument12 pages3-Way Flanged Ball Valves: EconomicalFelipe Ribeiro da CostaNo ratings yet

- TS-L.C Quick GuideDocument20 pagesTS-L.C Quick GuideFrancisco Javier Esparza ReyesNo ratings yet

- 09040913362876Document81 pages09040913362876John AngenentNo ratings yet

- Cameron Diverter SystemsDocument26 pagesCameron Diverter Systemscarlos14jrNo ratings yet

- gdm-5410 Sun Chassis g1 PDFDocument63 pagesgdm-5410 Sun Chassis g1 PDFbarrilonNo ratings yet

- Long Range TX Antenna InstallDocument19 pagesLong Range TX Antenna InstallRyan KeyNo ratings yet

- Manual CV-861Document18 pagesManual CV-861aladin namlunNo ratings yet

- Mounting Adjusting Pump UnitDocument2 pagesMounting Adjusting Pump UnitRalf JonesNo ratings yet

- Panoptix_Livescope_Install_ENDocument14 pagesPanoptix_Livescope_Install_EN薛泽绵No ratings yet

- Para-Flex Couplings: Includes ATEX Certified Couplings Instruction ManualDocument4 pagesPara-Flex Couplings: Includes ATEX Certified Couplings Instruction Manualrrobles011No ratings yet

- Coatings Word December 2013Document52 pagesCoatings Word December 2013sami_sakrNo ratings yet

- Repair Manual PDFDocument16 pagesRepair Manual PDFDianNo ratings yet

- Module Painting RawDocument4 pagesModule Painting Rawphilmark dalitNo ratings yet

- Catálogo Plastruc PDFDocument148 pagesCatálogo Plastruc PDFmanuel_fernandez_74No ratings yet

- WAX WTFluorescentWaterDispersionsDocument3 pagesWAX WTFluorescentWaterDispersionsaparnaNo ratings yet

- Bill OF Quan Tity & Price Sche Dule: Name of Project: Name of Work: Trench & Cable Trestle WorkDocument14 pagesBill OF Quan Tity & Price Sche Dule: Name of Project: Name of Work: Trench & Cable Trestle WorkAkd DeshmukhNo ratings yet

- ArtsDocument14 pagesArtsPhantomNo ratings yet

- Harper ChemicalDocument4 pagesHarper ChemicalABC527100% (2)

- C1315Document4 pagesC1315baher74100% (1)

- Quality System Audit Check Sheet (190722)Document21 pagesQuality System Audit Check Sheet (190722)swapon kumar shillNo ratings yet

- Molasses: General Properties of MolassesDocument5 pagesMolasses: General Properties of MolassesVu Hong ThangNo ratings yet

- Bentec P-2Document2 pagesBentec P-2Rama KrishnanNo ratings yet

- Painters Exterior TimberDocument24 pagesPainters Exterior TimbershreyuputtaNo ratings yet

- Formulation and Manufacturing ProcessDocument40 pagesFormulation and Manufacturing ProcessAhmad AlShahrourNo ratings yet

- Daniel Smith Watercolor GuideDocument16 pagesDaniel Smith Watercolor GuideEmmaJacobs100% (8)

- Uog-Ctc Boq Non PricedDocument68 pagesUog-Ctc Boq Non PricedHavanah AshuNo ratings yet

- ElektekkDocument14 pagesElektekkprayogaandiNo ratings yet

- 01 Samss 005Document5 pages01 Samss 005Moustafa BayoumiNo ratings yet

- Orbital Contribution To Magnetic MomentDocument25 pagesOrbital Contribution To Magnetic MomentSonali MahuleNo ratings yet

- PcsDocument19 pagesPcsArun Prasad100% (1)

- Wood Coatings For Display and Storage Cases - Studies in Conservation - 1986Document12 pagesWood Coatings For Display and Storage Cases - Studies in Conservation - 1986bbbbbbbNo ratings yet

- Sspc-Ab 1 PDF PDFDocument5 pagesSspc-Ab 1 PDF PDFLetth Dur'No ratings yet

- Hydro-Gloss: Technical Data SheetDocument2 pagesHydro-Gloss: Technical Data SheetNippon Paint PakistanNo ratings yet

- Chemical Stripping: John SteinhauserDocument4 pagesChemical Stripping: John SteinhauserNgô Trung NghĩaNo ratings yet

- Automation of Masking and De-Masking in Powder Coating ProcessDocument4 pagesAutomation of Masking and De-Masking in Powder Coating ProcessPraveenNo ratings yet

- 07 Ceiling & LiningDocument30 pages07 Ceiling & LiningAjithkumarNo ratings yet