Professional Documents

Culture Documents

A2309Sampling Hay Silage

A2309Sampling Hay Silage

Uploaded by

Lochi GmCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Final Bangus Value ChainDocument8 pagesFinal Bangus Value ChainSandy SandyNo ratings yet

- Pathophysiology - ESRDDocument5 pagesPathophysiology - ESRDheiyu100% (3)

- BPJPH - Current Status of Halal Policy and Regulation in IndonesiaDocument26 pagesBPJPH - Current Status of Halal Policy and Regulation in IndonesiaTeenagespirits100% (1)

- Directorate of Advanced Studies Sindh Agriculture University Tandojam PakistanDocument7 pagesDirectorate of Advanced Studies Sindh Agriculture University Tandojam PakistanLochi GmNo ratings yet

- Sindh Agriculture University Tandojam: ADMISSION / REGISTRATION FORM (For Subsequent Semester)Document2 pagesSindh Agriculture University Tandojam: ADMISSION / REGISTRATION FORM (For Subsequent Semester)Lochi GmNo ratings yet

- Lecture 8Document22 pagesLecture 8Lochi GmNo ratings yet

- Digestive System: G.M LochiDocument11 pagesDigestive System: G.M LochiLochi GmNo ratings yet

- Curriculum Vitae: Irfan Ali MagsiDocument2 pagesCurriculum Vitae: Irfan Ali MagsiLochi GmNo ratings yet

- Sub: Request For Appoint Me As Lab Assistant/ Junior ClerkDocument2 pagesSub: Request For Appoint Me As Lab Assistant/ Junior ClerkLochi GmNo ratings yet

- Multiple Choice Questions - Answers: 1. A B C DDocument2 pagesMultiple Choice Questions - Answers: 1. A B C DLochi GmNo ratings yet

- Determination of Dry Matter and AshDocument2 pagesDetermination of Dry Matter and AshLochi GmNo ratings yet

- Application Form (Teach) - 2Document7 pagesApplication Form (Teach) - 2Lochi GmNo ratings yet

- Exercise No. 6 Ammoniation of Wheat StrawDocument1 pageExercise No. 6 Ammoniation of Wheat StrawLochi GmNo ratings yet

- Q.#.1. Fill in The Blanks: Subject Gre TestDocument3 pagesQ.#.1. Fill in The Blanks: Subject Gre TestLochi GmNo ratings yet

- Goat AnatomyDocument8 pagesGoat AnatomyLochi GmNo ratings yet

- Damron.5ed - Ch.07.feedstuffs ClassificationDocument35 pagesDamron.5ed - Ch.07.feedstuffs ClassificationLochi GmNo ratings yet

- Facility Vulnerability and Security Measures Summary: Department of Homeland Security U.S. Coast GuardDocument3 pagesFacility Vulnerability and Security Measures Summary: Department of Homeland Security U.S. Coast GuardBobbaloo SmeedledumNo ratings yet

- Olive Oil - Liquid Gold: One Can Also Cook Food Using Olive OilDocument4 pagesOlive Oil - Liquid Gold: One Can Also Cook Food Using Olive OilHemant JaluthriaNo ratings yet

- Modified Systemic Approach To Answering QuestionsDocument26 pagesModified Systemic Approach To Answering QuestionsMotolani ArogunjoNo ratings yet

- Insecticide Resistance To Anopheles Spp. Mosquitoes (Diptera: Culicidae) in Nigeria: A ReviewDocument9 pagesInsecticide Resistance To Anopheles Spp. Mosquitoes (Diptera: Culicidae) in Nigeria: A ReviewYusuf UmarNo ratings yet

- 01 - Process Description & Sequence of OperationDocument33 pages01 - Process Description & Sequence of OperationSayed Abo ElkhairNo ratings yet

- PBF KIBAR - Update Stock 1 Oktober 2021Document158 pagesPBF KIBAR - Update Stock 1 Oktober 2021Anonymous aaAQ6dgNo ratings yet

- Gold FlakeDocument2 pagesGold Flakechakrabor100% (1)

- FbbforcrossfitDocument11 pagesFbbforcrossfitAdam CzarneckiNo ratings yet

- Main MiddletonDocument7 pagesMain MiddletonSheila BalatayoNo ratings yet

- Transforming Shame in Context Practical Applications and Exercises For GrowthDocument2 pagesTransforming Shame in Context Practical Applications and Exercises For GrowthjohanakuninNo ratings yet

- Frequency of Odontogenic Cysts and Tumors ADocument6 pagesFrequency of Odontogenic Cysts and Tumors AThành Luân NguyễnNo ratings yet

- Spent WashDocument8 pagesSpent WashSuresh Kumar MittapalliNo ratings yet

- Mental Health Resources-3Document1 pageMental Health Resources-3api-492010604No ratings yet

- Charecteristics of A CounsellorDocument13 pagesCharecteristics of A CounsellorVaruni Gupta100% (2)

- Scrub Nurse (Mastectomy)Document6 pagesScrub Nurse (Mastectomy)Jeroham R. CoNo ratings yet

- ITRC 2009 - LNAPL Guidance DocumentDocument157 pagesITRC 2009 - LNAPL Guidance DocumentFelipe NaretaNo ratings yet

- Homework 2Document9 pagesHomework 2Alexis R. CamargoNo ratings yet

- Nebivolol Drug StudyDocument4 pagesNebivolol Drug Studyalteahmichaella.mintuNo ratings yet

- Difference Between Developed Countries and Developing Countries (With Comparison Chart) - Key DifferencesDocument1 pageDifference Between Developed Countries and Developing Countries (With Comparison Chart) - Key DifferencesHeather ClarchickNo ratings yet

- Mweheyo Andew Handover ReportDocument4 pagesMweheyo Andew Handover ReportDaphne christineNo ratings yet

- 218WKS 4 Chemicals Chemicals and Fuels On FarmsDocument44 pages218WKS 4 Chemicals Chemicals and Fuels On FarmsHarun KorindoNo ratings yet

- Purvi ResumeDocument3 pagesPurvi ResumePurvi BhojakNo ratings yet

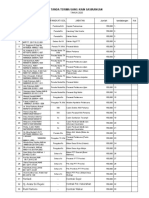

- Table of ContentsDocument8 pagesTable of ContentsEmmanuel BeresoNo ratings yet

- A Case Study On Renal CancerDocument30 pagesA Case Study On Renal Cancersongkyo100% (1)

- Order On SJ MotionsDocument45 pagesOrder On SJ MotionsinforumdocsNo ratings yet

- Sample Business Plan For Ambulatory Surgery CenterDocument6 pagesSample Business Plan For Ambulatory Surgery CenterafkneppuoNo ratings yet

- Absen 2019Document19 pagesAbsen 2019siska damayantiNo ratings yet

A2309Sampling Hay Silage

A2309Sampling Hay Silage

Uploaded by

Lochi GmCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A2309Sampling Hay Silage

A2309Sampling Hay Silage

Uploaded by

Lochi GmCopyright:

Available Formats

A2309

Sampling Hay and Silage for Analysis

Dan Undersander, Neal Martin, Terry Howard, Randy Shaver and Jim Linn

RELIABLE FORAGE ANALYSIS can improve your livestock vest and store it, and note the approximate number of bales

or the silo depth. The entire height and width of one face of

feeding program. Determining the feed value of forage allows

the hay lot should be exposed for visual evaluation and

you to balance rations more accurately and buy hay based on

sampling.

nutritive value.

The distribution of leaves, stems, weeds and other material is

The key to successful forage analysis is taking a good, repre-

not uniform in most forage packages. Knowledge of forage

sentative forage sample on the farm. Laboratory analysis can

stratification within a storage structure is critical to adequate

determine the quality of a submitted forage sample, but this

sampling for analysis. Use a technique that will obtain a repre-

will not help you balance rations if the submitted sample does

sentative sample of the various concentrations of leaves and

not represent forage actually being fed to your animals. The

stems in the forage.

largest error in forage analysis is improper sampling methods

on the farm. You need to take a representative sample of for-

age from every hay or silage lot. These samples will reflect How to sample

the variation in forage quality that occurs across your fields Baled, loose or chopped hay

and during harvesting.

A hay bale is not uniform in composition. The baling process

What to Sample (picking up, transferring and packing hay) affects the leaf and

stem distribution within the bale. Hay condition, environmen-

A lot of hay or silage is the forage harvested within one day tal conditions at baling and hay-making practices also affect

from one field. It is taken from the same cutting, the same bale structure.

stage of maturity, and is uniform in its amount of grass,

weeds or rain damage. A hay or silage lot also is uniform in The small, rectangular two-string bale has been studied more

visual qualityodor, amount of mold, color, stem texture than others. The leaves in these bales tend to concentrate

and size, and leafiness. toward the tight and solid sides of the bale (figure 1). The

best place to core sample small rectangular bales is through

To efficiently sample each lot, you must keep a complete the center of one end. For other bale types, inspect each bale

inventory of hay and silage lot. Segregate each lot as you har- for the distribution of leaves and stems and core sample from

Loose side

Cut side

Fore

Butt end Slice

Highest concentra-

tion of leaves Tight side

Solid side

Figure 1. Alfalfa hay bale structure

2. Take 15 to 20 widely separated sores or samples from

3 each lot.

Crude Protein Sample Variation

2 3. Use a bale core sampler to reduce error. The core sam-

pler should have an internal diameter of at least 3/8-inch

Crude Protein (%)

1 and a length of 12 to 18 inches. Keep the core sampler tip

sharp so it cuts through bales rather than pushes stems

Mean aside. The core sampler works with either a variable

speed 1/2-inch drill or a hand brace. Using the drill or

-1

brace, insert the core sampler its entire length into the

center of the end of the bale, at a right angle to the end

-2

face (figure 1).

-3

5 10 15 20 25 4. Mix the cores in a clean pail. Place the entire sample in a

Number of Cores in Sample clean plastic bag or other container and seal tightly. Do not

divide the sample. It is normal for the leaves and stems to

separate and settle in the sample.

5. Label each container with your name, address, a sample

40 number and forage type (e.g. alfalfa, alfalfa-timothy, or red

30 Relative Feed Value Sample Variation clover).

20

Haylage and silage at harvest

10

Sampling the forage at harvest gives you advance knowledge

RFV

Mean

of the quality of forage stored in silos. You can inventory by

-10

quality and plan for purchasing supplemental feedstuffs based

-20 on forage quality needs.

-30

While some fractions can show significant change during the

-40

fermentation following ensiling, crude protein and fiber frac-

5 10 15 20 25 tions (ADF and NDF) show little change where forage has

been ensiled properly and normal fermentation occurs

Number of Cores in Sample

(table 1). Analysis will change when:

Figure 2. Bale sample variation due to number of cores per

Forage is ensiled at too high a moisture content and

sample. For example, if a sample analysis from three cores seepage occurs (crude protein and nonfibrous loss result-

resulted in a mean crude protein of 21%, the actual protein con- ing in higher fiber)

tent of the hay lot has a 95% chance of being between 18.4 and Forage is ensiled too dry and heats excessively (acid

23.6. However, for the same result from a sample of 20 cores,

detergent fiber and acid detergent insoluble nitrogen

the actual crude protein of the hay lot has a 95% chance of being

between 20.5 and 21.5. increase)

Fermentation is faulty.

areas that do not contain disproportionate concentrations of

either leaves or stems. Due to variation among bales from Distribution of leaves and stems will not be uniform through-

the same lot, it is important to sample from several bales. out the chopper wagon because leaves are lighter than stem

parts and often accumulate towards the back and sides of a

Using a core sampler is better than taking a grab sample chopper wagon while the center front will have a higher con-

because it causes less separation of leaves and stems. Many centration of stems. These fractions are mixed as the wagon

cores taken from the same lot will yield a more accurate is unloading and as the lot is distributed in the silo.

analysis (figure 2). Combine 15 to 20 cores from a hay lot

into one sample for analysis. 1. Sample legume, legume-grass, grass haylage, low-moisture

corn or other silages from each field.

1. Test each forage lot separately. Mark the location of each

lot in the barn or storage shed for easy reference when 2. Collect three to five handfuls of haylage or silage from the

feeding. middle of the load as the wagon is unloading. Place them in

a plastic bag and immediately refrigerate or freeze. Follow

Ensiled material from tower silos

Table 1. Forage quality analysis before and after ensiling

during 1988 and 1989, University of Wisconsin Ashfield It is easier to sample silage at harvest rather than sampling

Research Station

ensiled material as it is being fed. In addition, analysis results

are available long before the forage is fed to allow more accu-

Before/after Dry matter CP ADF NDF rate ration balancing and time to purchase supplements.

ensiling

If you do sample from the silo, do not sample the spoiled

Alfalfa haylage material at the top. Remove 2 to 3 feet of silage first.

before 44.1 19.9 32.3 40.5

after 42.4 20.7 34.8 40.4 1. Collect a 1 to 2 lb sample from the silo unloader while it is

operating. Collect samples from morning and evening

Red clover haylage

feedings of the same day.

before 45.5 15.9 32.1 45.9

after 46.6 15.9 33.7 48.9 2. Combine the samples and mix well. Place the entire sample

Corn silage in a clean plastic bag or other container and seal tightly.

Store immediately in a freezer or other cold place until

before 34.4 9.7 29.2 49.5

after 34.1 11.1 29.0 48.8 shipping.

3. Label each container with your name, address, the sample

aCP=crude protein; ADF=acid detergent fiber; NDF=neutral detergent fiber number, forage type and mixture.

Ensiled material from bunker silos

the same procedure for several loads of forage throughout

the day. 1. If feeding a total mixed ration (TMR)Load silage from

bunker into TMR mixer and mix well. Take several grab

3. Combine refrigerated samples from a single harvested field samples to collect a 1 to 2 lb total sample.

and mix well. Place the entire sample in a clean plastic bag

or other container and seal tightly. If not feeding a TMRCollect a 1 to 2 lb total sample

from the different vertical layers of the silo face. Grab sev-

4. Label each container with your name, address, the sample eral handfuls from freshly exposed forage after the days

number and forage type. feeding has been removed. Do not sample the spoiled

material on top of the silo.

5. Repeat for each field if more than one field is harvested in

any one day. 2. Combine handfuls and mix well. Place the entire sample in

a clean plastic bag or other container and seal tightly.

6. For tower silos or silo tubes, keep an inventory of where Store immediately in a freezer or other cold place until

each lot is in the silo or tube. Feeding colored plastic shipping.

strips through the blower at the end of each lot may help

identify the lots later. (A bushel of corn may also be used 3. Label each container with your name, address, the sample

to mark haylage lots.) number and forage type (e.g. alfalfa, alfalfa-timothy, or red

clover).

7. Silos with seepage should be resampled upon feeding

because seepage contains nitrogen and nonstructural car- Where to send samples

bohydrates. Loss of these nutrients will increase dry mat-

ter, acid detergent fiber and neutral detergent fiber, and For accurate results, forage samples should be analyzed at a

will decrease crude protein. Similarly, at feeding resample laboratory that participates in the National Forage Testing

silos that were filled with forage containing less than 50 Association certification program. Laboratories participating

percent moisture. These forages may have overheated, in the NIRS Forage and Feed Consortium with the

causing increased acid detergent fiber and acid detergent Universities of Minnesota and Wisconsin verify that their

fiber insoluble nitrogen. near-infrared instruments are working properly and that the

equations they are using are appropriate for samples being

8. Recheck dry matter of silages at feed out. Fiber and pro-

tested.

tein are not likely to change significantly during storage,

except as mentioned previously, but moisture can change. You can obtain forage sampling information sheets from your

county Extension agent, nutritionist or forage testing labora-

tory. Fill out an information sheet for each lot, answering all Neutral Detergent Fiber (NDF)

questions. It is important to label forage types clearly and to

note when silage has had ammonia or urea added at ensiling. NDF is the percentage of cell wall material in forages. It is the

most accurate predictor of how much dry matter an animal

Keep silage samples frozen in airtight containers. Place con- can eat. An increase in NDF means poorer forage quality, and

tainers in insulated bags, and mail them early in the week an animal will eat less of that forage. Rations must then be

rather than over the weekendto prevent molding and adjusted to minimize the effect of lower intake of poor for-

decay, which might change the analysis results. ages.

For example, a 1% point increase in NDF results in a 1.2%

Using Forage Analyses (1 lb) drop in milk yield. While this is largely due to the ani-

mal eating less, there is also a decrease in forage digestibility

Chemical analysis of forage has little value unless you use it to

(increased ADF) associated with the higher NDF.

formulate rations or to sell or buy hay. To compare feeds

and formulate rations, you need an accurate estimate of dry

The opposite is also true, a 1% decrease in NDF (higher for-

matter in forages, since water provides no nutrients and

age quality) can result in a 1.2% increase in milk production.

dilutes the nutrient density of a feed. Three important esti-

mates of different dry matter components are protein (CP), Acid Detergent Fiber (ADF)

neutral detergent fiber (NDF), and acid detergent fiber

(ADF). Acid detergent fiber is the percentage of cellulose, lignin and

ash in forages. It provides the best estimate of the energy

Protein (digestible fiber) available to an animal from forages. Low

ADF results in greater energy density and greater milk yield

Use protein analysis to determine the amount of additional

per ton of forage. A 1% point increase in ADF (a less

protein needed to provide a balanced ration for profitable

digestible forage) reduces milk yield by 0.6 lb milk/cow each

milk or meat production.

day; reduces the milk production potential of a ton of forage

dry matter by 50 lb/t; and reduces the milk production value

Both overfeeding and underfeeding protein are costly to pro-

of forage by $5 to $6.50 per ton.

duction. If a dairy operator underestimates the protein con-

tent of forage by 2%, the operator is spending $3 to $4 per

ton of grain for unnecessary supplemental protein in the grain Relative Feed Value (RFV)

mixture.

Relative feed value is an index which ranks cool season

Likewise, if a dairy operator overestimates the protein con- legumes, grasses and mixtures by potential digestible dry mat-

tent of forage, the operator probably will not feed the herd ter intake. It should be used to allocate forages to the proper

enough protein to achieve top production. A shortage of 0.44 livestock class with a given level of expected performance. It

lb in crude protein can be corrected by feeding 1 lb soybean can also be used to relate price and forage quality when buy-

meal per cow. If all other nutrients are adequate, the added ing or selling hay.

protein from the soybean meal will yield 5 to 7 lb more milk

per cow. Thus, spending $0.08 to $0.12 per cow may return For additional information on forage types, analysis and

$0.60 to $0.80 worth of milk. rationing, contact your county Extension agent.

This publication is a revision of Taking an Accurate Forage Sample, by D.A. Rohweder, W.T. Howard and L.J. Miller. The authors gratefully acknowl-

edge this earlier work.

Authors: Dan Undersander is a forage agronomist and Terry Howard and Randy Shaver are dairy nutritionists with the College of Agricultural and

Life Sciences, University of Wisconsin-Madison, and University of Wisconsin-Extension Cooperative Extension. Neal Martin is a forage agronomist

and Jim Linn is a dairy nutritionist with University of Minnesota and Minnesota Extension Service. Produced by Cooperative Extension Publications,

University of Wisconsin-Extension.

University of Wisconsin-Extension, Cooperative Extension, and Minnesota Extension Service, in cooperation with the U.S. Department of

Agriculture and Wisconsin counties, publishes this information to further the purpose of the May 8 and June 30, 1914 Acts of Congress; and pro-

vides equal opportunities in employment and affirmative action in employment and programming.

This publication is available from your Wisconsin or Minnesota county Extension office, or from:

Cooperative Extension Publications, University of Minnesota

Rm. 245, 30 N. Murray St., Distribution Center

Madison, Wisconsin 53715; 3 Coffey Hall, 1420 Eckles Ave.

phone 608-262-3346. St. Paul, MN 55108-6064

(612) 625-8173

A2309 Sampling Hay and Silage for Analysis

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Final Bangus Value ChainDocument8 pagesFinal Bangus Value ChainSandy SandyNo ratings yet

- Pathophysiology - ESRDDocument5 pagesPathophysiology - ESRDheiyu100% (3)

- BPJPH - Current Status of Halal Policy and Regulation in IndonesiaDocument26 pagesBPJPH - Current Status of Halal Policy and Regulation in IndonesiaTeenagespirits100% (1)

- Directorate of Advanced Studies Sindh Agriculture University Tandojam PakistanDocument7 pagesDirectorate of Advanced Studies Sindh Agriculture University Tandojam PakistanLochi GmNo ratings yet

- Sindh Agriculture University Tandojam: ADMISSION / REGISTRATION FORM (For Subsequent Semester)Document2 pagesSindh Agriculture University Tandojam: ADMISSION / REGISTRATION FORM (For Subsequent Semester)Lochi GmNo ratings yet

- Lecture 8Document22 pagesLecture 8Lochi GmNo ratings yet

- Digestive System: G.M LochiDocument11 pagesDigestive System: G.M LochiLochi GmNo ratings yet

- Curriculum Vitae: Irfan Ali MagsiDocument2 pagesCurriculum Vitae: Irfan Ali MagsiLochi GmNo ratings yet

- Sub: Request For Appoint Me As Lab Assistant/ Junior ClerkDocument2 pagesSub: Request For Appoint Me As Lab Assistant/ Junior ClerkLochi GmNo ratings yet

- Multiple Choice Questions - Answers: 1. A B C DDocument2 pagesMultiple Choice Questions - Answers: 1. A B C DLochi GmNo ratings yet

- Determination of Dry Matter and AshDocument2 pagesDetermination of Dry Matter and AshLochi GmNo ratings yet

- Application Form (Teach) - 2Document7 pagesApplication Form (Teach) - 2Lochi GmNo ratings yet

- Exercise No. 6 Ammoniation of Wheat StrawDocument1 pageExercise No. 6 Ammoniation of Wheat StrawLochi GmNo ratings yet

- Q.#.1. Fill in The Blanks: Subject Gre TestDocument3 pagesQ.#.1. Fill in The Blanks: Subject Gre TestLochi GmNo ratings yet

- Goat AnatomyDocument8 pagesGoat AnatomyLochi GmNo ratings yet

- Damron.5ed - Ch.07.feedstuffs ClassificationDocument35 pagesDamron.5ed - Ch.07.feedstuffs ClassificationLochi GmNo ratings yet

- Facility Vulnerability and Security Measures Summary: Department of Homeland Security U.S. Coast GuardDocument3 pagesFacility Vulnerability and Security Measures Summary: Department of Homeland Security U.S. Coast GuardBobbaloo SmeedledumNo ratings yet

- Olive Oil - Liquid Gold: One Can Also Cook Food Using Olive OilDocument4 pagesOlive Oil - Liquid Gold: One Can Also Cook Food Using Olive OilHemant JaluthriaNo ratings yet

- Modified Systemic Approach To Answering QuestionsDocument26 pagesModified Systemic Approach To Answering QuestionsMotolani ArogunjoNo ratings yet

- Insecticide Resistance To Anopheles Spp. Mosquitoes (Diptera: Culicidae) in Nigeria: A ReviewDocument9 pagesInsecticide Resistance To Anopheles Spp. Mosquitoes (Diptera: Culicidae) in Nigeria: A ReviewYusuf UmarNo ratings yet

- 01 - Process Description & Sequence of OperationDocument33 pages01 - Process Description & Sequence of OperationSayed Abo ElkhairNo ratings yet

- PBF KIBAR - Update Stock 1 Oktober 2021Document158 pagesPBF KIBAR - Update Stock 1 Oktober 2021Anonymous aaAQ6dgNo ratings yet

- Gold FlakeDocument2 pagesGold Flakechakrabor100% (1)

- FbbforcrossfitDocument11 pagesFbbforcrossfitAdam CzarneckiNo ratings yet

- Main MiddletonDocument7 pagesMain MiddletonSheila BalatayoNo ratings yet

- Transforming Shame in Context Practical Applications and Exercises For GrowthDocument2 pagesTransforming Shame in Context Practical Applications and Exercises For GrowthjohanakuninNo ratings yet

- Frequency of Odontogenic Cysts and Tumors ADocument6 pagesFrequency of Odontogenic Cysts and Tumors AThành Luân NguyễnNo ratings yet

- Spent WashDocument8 pagesSpent WashSuresh Kumar MittapalliNo ratings yet

- Mental Health Resources-3Document1 pageMental Health Resources-3api-492010604No ratings yet

- Charecteristics of A CounsellorDocument13 pagesCharecteristics of A CounsellorVaruni Gupta100% (2)

- Scrub Nurse (Mastectomy)Document6 pagesScrub Nurse (Mastectomy)Jeroham R. CoNo ratings yet

- ITRC 2009 - LNAPL Guidance DocumentDocument157 pagesITRC 2009 - LNAPL Guidance DocumentFelipe NaretaNo ratings yet

- Homework 2Document9 pagesHomework 2Alexis R. CamargoNo ratings yet

- Nebivolol Drug StudyDocument4 pagesNebivolol Drug Studyalteahmichaella.mintuNo ratings yet

- Difference Between Developed Countries and Developing Countries (With Comparison Chart) - Key DifferencesDocument1 pageDifference Between Developed Countries and Developing Countries (With Comparison Chart) - Key DifferencesHeather ClarchickNo ratings yet

- Mweheyo Andew Handover ReportDocument4 pagesMweheyo Andew Handover ReportDaphne christineNo ratings yet

- 218WKS 4 Chemicals Chemicals and Fuels On FarmsDocument44 pages218WKS 4 Chemicals Chemicals and Fuels On FarmsHarun KorindoNo ratings yet

- Purvi ResumeDocument3 pagesPurvi ResumePurvi BhojakNo ratings yet

- Table of ContentsDocument8 pagesTable of ContentsEmmanuel BeresoNo ratings yet

- A Case Study On Renal CancerDocument30 pagesA Case Study On Renal Cancersongkyo100% (1)

- Order On SJ MotionsDocument45 pagesOrder On SJ MotionsinforumdocsNo ratings yet

- Sample Business Plan For Ambulatory Surgery CenterDocument6 pagesSample Business Plan For Ambulatory Surgery CenterafkneppuoNo ratings yet

- Absen 2019Document19 pagesAbsen 2019siska damayantiNo ratings yet