Professional Documents

Culture Documents

Perlite Concrete Mix Design

Perlite Concrete Mix Design

Uploaded by

HaniAminCopyright:

Available Formats

You might also like

- Abrams LawDocument2 pagesAbrams LawShazwanShahNo ratings yet

- Manual For ConcretingDocument43 pagesManual For Concretinglwin_oo2435No ratings yet

- ASTM C 1645-16 Freeze Thaw of Interlock Paving UnitsDocument3 pagesASTM C 1645-16 Freeze Thaw of Interlock Paving UnitsHaniAminNo ratings yet

- Fire Protection For Structural Steel in BuildingsDocument91 pagesFire Protection For Structural Steel in BuildingsHamada Shoukry MohammedNo ratings yet

- Concise Eurocode 2 For Bridges PDFDocument142 pagesConcise Eurocode 2 For Bridges PDFChris Dunlop100% (2)

- Millennium Product DataDocument15 pagesMillennium Product DataAnonymous ZizCrNlQkpNo ratings yet

- Hyper CreteDocument2 pagesHyper CretedjgiumixNo ratings yet

- High Slump Concrete Mix Design 2 PDFDocument68 pagesHigh Slump Concrete Mix Design 2 PDFBernie QuepNo ratings yet

- Compressive Strength of Concret by Fly AshDocument16 pagesCompressive Strength of Concret by Fly AsheranjanishuklaNo ratings yet

- TDS - Flowcable 50Document2 pagesTDS - Flowcable 50Venkata RaoNo ratings yet

- Is Concrete Mix DesignDocument21 pagesIs Concrete Mix DesignahmedanyNo ratings yet

- Concrete Mix Design CalculationDocument9 pagesConcrete Mix Design Calculationezarul321No ratings yet

- 45mpa Mix DesignDocument2 pages45mpa Mix DesignSamuel YekoNo ratings yet

- Spec For Sand CementDocument5 pagesSpec For Sand CementHüseyin EkiciNo ratings yet

- DoE Mix Design ExamplesDocument8 pagesDoE Mix Design Examplesعابد خواجہNo ratings yet

- Concrete Mix DesignDocument21 pagesConcrete Mix DesignPratyush Kumar DoraNo ratings yet

- Normal Concrete Mix DesignDocument4 pagesNormal Concrete Mix Designmurnal0% (1)

- Lean Concrete Base Mix DesignDocument18 pagesLean Concrete Base Mix DesignZaher J. Yazeji0% (1)

- Properties and Uses of Concrete AdmixturesDocument5 pagesProperties and Uses of Concrete AdmixturesDS20CE017Bhaskar WabhitkarNo ratings yet

- Sika UK Concrete Handbook 2013Document131 pagesSika UK Concrete Handbook 2013Ahmed TahaNo ratings yet

- Test Report of MetakaolinDocument14 pagesTest Report of MetakaolinAbdul Falahitawan UfalNo ratings yet

- Foamed ConcreteDocument14 pagesFoamed ConcretemilanNo ratings yet

- Foam Concrete - Experimental Investigation of Its PropertiesDocument7 pagesFoam Concrete - Experimental Investigation of Its PropertiesIJASRETNo ratings yet

- BASF Introduces Smart Dynamic ConcreteDocument4 pagesBASF Introduces Smart Dynamic ConcreteNurul Hidayati100% (1)

- Lightweight Concrete and AggregatesDocument23 pagesLightweight Concrete and Aggregatesahmed ElshaibaniNo ratings yet

- Astm C1688-08Document3 pagesAstm C1688-08Sergio Vidal ArcosNo ratings yet

- Flyash Based Geopolymer ConcreteDocument11 pagesFlyash Based Geopolymer ConcreteDharma RajanNo ratings yet

- Mortar Cement BrochureDocument6 pagesMortar Cement BrochureAlbert Valentinus Christy WibowoNo ratings yet

- ACI Method of Mix DesignDocument5 pagesACI Method of Mix DesignHaris AlamNo ratings yet

- Chapter 5. Admixtures For ConcreteDocument17 pagesChapter 5. Admixtures For ConcreteKhaled Al-SwairkiNo ratings yet

- Towards Sustainable ConcreteDocument2 pagesTowards Sustainable ConcreteJouber FerreiraNo ratings yet

- Mitigating The Effect of Clay Content of Sand On Concrete StrengthDocument7 pagesMitigating The Effect of Clay Content of Sand On Concrete Strengthbpkndl7943No ratings yet

- Concrete Mix DesignDocument25 pagesConcrete Mix DesigngauravrediffmailNo ratings yet

- Fly Ash As Binder in ConcreteDocument10 pagesFly Ash As Binder in ConcreteZuhair NadeemNo ratings yet

- Lightweight ConcreteDocument14 pagesLightweight ConcreteTatiana Espinoza EusebioNo ratings yet

- Polymer Impregnated Concrete - Uses, Properties of Polymers in ConcreteDocument4 pagesPolymer Impregnated Concrete - Uses, Properties of Polymers in ConcretesahilkaushikNo ratings yet

- Concrete Mix DesignDocument4 pagesConcrete Mix DesignZakir AliNo ratings yet

- Mix Design - ADM QCC ManualDocument1 pageMix Design - ADM QCC ManualSyed AbuthahirNo ratings yet

- Seminar On AdmixturesDocument24 pagesSeminar On AdmixturesimdgameNo ratings yet

- UNIT-1 Cement Mortar & Concrete: Prepared By-Deepti Singh (Assistant Professor)Document39 pagesUNIT-1 Cement Mortar & Concrete: Prepared By-Deepti Singh (Assistant Professor)Harkamal Singh DevgunNo ratings yet

- Comparing Concrete Durability Testing MethodsDocument3 pagesComparing Concrete Durability Testing MethodsHoang An TranNo ratings yet

- Silica FumeDocument24 pagesSilica FumeRatna Sai0% (1)

- Reference Notes - Tests For ConcreteDocument21 pagesReference Notes - Tests For ConcreteMitali KhedkarNo ratings yet

- 04 - TDS Meyco FlowcableDocument3 pages04 - TDS Meyco FlowcablebossbobNo ratings yet

- Mix Design Foam ConcreteDocument13 pagesMix Design Foam ConcreteVirga PriyoNo ratings yet

- Partial Replacement of Cement To Concrete by Marble Dust PowderDocument12 pagesPartial Replacement of Cement To Concrete by Marble Dust PowderIJMTST-Online JournalNo ratings yet

- 7-SCC C60 Mix Design MDC 2Document1 page7-SCC C60 Mix Design MDC 2Kelly JuarezNo ratings yet

- ArticledesignandconstructionofliquidtightconcretestrucDocument3 pagesArticledesignandconstructionofliquidtightconcretestrucalbertoxinaNo ratings yet

- Ds - Concrete Mix DesignDocument51 pagesDs - Concrete Mix DesignDarshan ShahNo ratings yet

- Test 1 - Concrete Mix Design DishanDocument20 pagesTest 1 - Concrete Mix Design DishanYasndra AbeygunewardhaneNo ratings yet

- Effect of Rapidite On Strength of ConcreteDocument66 pagesEffect of Rapidite On Strength of ConcreterizwansstaadNo ratings yet

- Delvo Crete Stabiliser: Liquid Hydration Inhibitor For ConcreteDocument2 pagesDelvo Crete Stabiliser: Liquid Hydration Inhibitor For ConcreteShoyeeb AhmedNo ratings yet

- Air Content in Concrete - Concrete Air Test - The Concrete NetworkDocument4 pagesAir Content in Concrete - Concrete Air Test - The Concrete NetworkPritha DasNo ratings yet

- By Yuvraj KocharDocument32 pagesBy Yuvraj KocharShivangi KocharNo ratings yet

- Concrete Mix DesignDocument7 pagesConcrete Mix Designtangudusrikanth513gmNo ratings yet

- Cement and Concrete - An IntroductionDocument23 pagesCement and Concrete - An Introductionandica248No ratings yet

- Conplast SP432MSDocument2 pagesConplast SP432MSTori Small100% (1)

- 2 Cement HydrationDocument50 pages2 Cement HydrationMelinda GordonNo ratings yet

- Numerical Methods and Implementation in Geotechnical Engineering – Part 1From EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 1No ratings yet

- Perlite Concrete Mix Designs: Materials Per Cubic Yard Based On 100% YieldDocument1 pagePerlite Concrete Mix Designs: Materials Per Cubic Yard Based On 100% YieldMJundiNo ratings yet

- Effects of CementDocument8 pagesEffects of CementshariqabideenNo ratings yet

- Quailty Assurance of CementDocument30 pagesQuailty Assurance of Cementabdullah100% (3)

- Moisture Lnduced Damage: Resistance of Compactad Asphalt Mixture ToDocument8 pagesMoisture Lnduced Damage: Resistance of Compactad Asphalt Mixture ToGabith Quispe ApazaNo ratings yet

- Determination of Thermal Resistance of Loose-Fill Building Insulation in Side Wall ApplicationsDocument9 pagesDetermination of Thermal Resistance of Loose-Fill Building Insulation in Side Wall ApplicationsHaniAminNo ratings yet

- Manual Thickness Gauges Flakiness IndexDocument2 pagesManual Thickness Gauges Flakiness IndexHaniAminNo ratings yet

- Ilnas-En 12390-1:2021Document8 pagesIlnas-En 12390-1:2021HaniAminNo ratings yet

- Astm C 1853 - 17Document6 pagesAstm C 1853 - 17HaniAminNo ratings yet

- NCMA Astm c140 PDFDocument4 pagesNCMA Astm c140 PDFHaniAminNo ratings yet

- ASTM C331-2010 Light Weight Aggregates For MasonryDocument4 pagesASTM C331-2010 Light Weight Aggregates For MasonryHaniAminNo ratings yet

- Annex A - SpecificationsDocument5 pagesAnnex A - SpecificationsDesigners Eng'gConsultancyNo ratings yet

- Construction Checklist: Refference YES NO NA SAE SDE Aggregate For Concrete Material: SL. NO. Check ItemDocument3 pagesConstruction Checklist: Refference YES NO NA SAE SDE Aggregate For Concrete Material: SL. NO. Check Itemnilesh kumar VermaNo ratings yet

- CESL-POG-CS-GEN-SPC-004 Rev C1 PDFDocument14 pagesCESL-POG-CS-GEN-SPC-004 Rev C1 PDForode franklynNo ratings yet

- Dozvan Company Method of Statement For The RFQ-21627 - Crossover - Bridge - 10 - Line - at - FSKDocument41 pagesDozvan Company Method of Statement For The RFQ-21627 - Crossover - Bridge - 10 - Line - at - FSKAva GhaziNo ratings yet

- Box Culvert 633 (Orogun) : Wing Wall ElevationDocument1 pageBox Culvert 633 (Orogun) : Wing Wall ElevationOseni MomoduNo ratings yet

- Design of Well FoundationsDocument3 pagesDesign of Well Foundationssharathr22100% (1)

- DRT 104 - 1Document59 pagesDRT 104 - 1Sir ArtNo ratings yet

- Sample Intellibuild EstimateDocument23 pagesSample Intellibuild EstimateRomani Noel S. Chavez Jr.No ratings yet

- Early Striking and Improved Back Pro PingDocument2 pagesEarly Striking and Improved Back Pro PinglawkkNo ratings yet

- 128 FPDocument6 pages128 FPRajesh KumarNo ratings yet

- Recent WritingtopicsDocument21 pagesRecent Writingtopics11CT1-15- Đặng Bá KimNo ratings yet

- Screed Bases and In-Situ FlooringsDocument28 pagesScreed Bases and In-Situ Flooringsrekcah ehtNo ratings yet

- SSPC Painting Manual: SSPC: The Society For Protective Coatings 40 24th Street, 6th Floor Pittsburgh, PA 15222Document6 pagesSSPC Painting Manual: SSPC: The Society For Protective Coatings 40 24th Street, 6th Floor Pittsburgh, PA 15222Moeen Khan RisaldarNo ratings yet

- Technical Information Schoeck Dorn LD (2967) PDFDocument20 pagesTechnical Information Schoeck Dorn LD (2967) PDFEdmond TakacsNo ratings yet

- Transportation Engineering Lab ManualDocument42 pagesTransportation Engineering Lab ManualSubzar BhatNo ratings yet

- PINKBAR Reinforced Concrete Innovation 20231015Document41 pagesPINKBAR Reinforced Concrete Innovation 20231015SpinoWebNo ratings yet

- Bleeding of ConcreteDocument3 pagesBleeding of ConcreteANo ratings yet

- Modified Kodad - Revoor Road RenewalsDocument418 pagesModified Kodad - Revoor Road RenewalsSRIHARINo ratings yet

- Kim Lighting VRB Series Vandal Resistant Bollard Brochure 1993Document12 pagesKim Lighting VRB Series Vandal Resistant Bollard Brochure 1993Alan MastersNo ratings yet

- EzeeplastDocument2 pagesEzeeplastSourabh BansalNo ratings yet

- Rain PDFDocument166 pagesRain PDFShaikh AafrinNo ratings yet

- A Prototype Construction Duration: Estimating System (CODES) For Mid-Rise Building ConstructionDocument57 pagesA Prototype Construction Duration: Estimating System (CODES) For Mid-Rise Building ConstructionAdonis AlabiNo ratings yet

- Report Bka PDFDocument20 pagesReport Bka PDFFatin Nadia DieyaNo ratings yet

- Novolac ScreedDocument4 pagesNovolac Screedmd_kureshiNo ratings yet

- SS 557 2010 Preview PDFDocument9 pagesSS 557 2010 Preview PDFdhruvNo ratings yet

- Design of Reinforced Cement Concrete ElementsDocument14 pagesDesign of Reinforced Cement Concrete ElementsSudeesh M SNo ratings yet

- DESIGN REPORT OF Kalanki RESIDENCEDocument23 pagesDESIGN REPORT OF Kalanki RESIDENCESuyogya DahalNo ratings yet

- 7.5 Hooks: Using ACI Equation 12-1 With K 0Document5 pages7.5 Hooks: Using ACI Equation 12-1 With K 0محمد الذيبانيNo ratings yet

Perlite Concrete Mix Design

Perlite Concrete Mix Design

Uploaded by

HaniAminOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Perlite Concrete Mix Design

Perlite Concrete Mix Design

Uploaded by

HaniAminCopyright:

Available Formats

P.O.

Box 158

Gold Hill, NC 28071

Phone: (704) 279-2325 Perlite Concrete Mix Design

Fax: (704) 279-8818

www.carolinaperlite.com

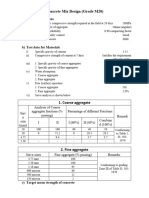

Below is a chart with mix design information. The 1:6 mix has been used most for lightweight concrete roof deck applications and

the 1:4 mix for interstitial floors. The cement to aggregate ratio is for cubic feet using the old standard 1 ft3 sack of cement. Perlite is

packaged in a 4 ft3 bag.

A plaster type mixer or a ready-mix truck is recommended. (See Transit Mix Perlite Concrete brochure for details). We

recommend adding the perlite last at the job site unless the job is extremely close to the ready-mix plant. DO NOT OVER-MIX. Perlite

particles are fragile and over-mixing will cause the perlite to pulverize, resulting in a loss of yield. CHECK THE TRUCK AT 75

REVOLUTIONS AND PROBABLY DISCHARGE AT 120 REVOLUTIONS. Perlite concrete should have a thick shaving cream texture.

If you have to pump, DO NOT use a piston-type pump as this will destroy the perlite and result in a serious loss of yield. USE A

ROTOR/STATOR (PROGRESSIVE CAVITY) PUMP.

Air entraining agent improves yield and workability and you may wish to use one that you have or we can provide a powder

detergent type air entraining agent (Witconate AOK). Use approximately 2 fluid ounces or less Witconate AOK per bag of perlite

depending upon water quality. Eight fluid ounces per yard of concrete is a good starting point. Always begin with less rather than more.

Please call with any questions and thank you for considering perlite lightweight concrete.

Typical Properties, Specification Properties & Mix Formulations for Perlite Aggregate Insulating Concrete*

TYPICAL PROPERTIES SPECIFICATION PROPERTIES MATERIALS PER CUBIC YARD

Cement to Compressive Thermal Wet Density Compressive

Oven Dry Coefficient Thermal Dry Density Range,

Aggregate Strength, 28 Conductivity, Range, When Strength Range, Cement Sacks Perlite, ft3 Water, gal. A.E.A

Density, pcf Expansion, Per Unit Per F 28 Days, pcf

Ratio (mix) Days, psi k Placed, pcf 28 Days, psi

1:4 36 350 0.83 0.0000061 48-56 36-42 300-520 6.75 27 61 **

1:5 30 230 0.71 0.0000055 42-50 30-36 230-300 5.40 27 59.5 **

1:6 27 140 0.64 0.0000048 38-44 24-30 125-200 4.50 27 54 **

1:8 22 80 0.54 0.0000043 34-40 18-24 80-125 3.38 27 54 **

*Pittsburg Testing Laboratory & R.W. Hunt Company Engineers under sponsorship of Perlite Institute, Inc.

**Air entraining agent: Neutralized vinsol resin or other air entrainment agent as recommended by perlite manufacturer.

From 1985 ASHRE Guide and Data Book at 75F mean temperature.

You might also like

- Abrams LawDocument2 pagesAbrams LawShazwanShahNo ratings yet

- Manual For ConcretingDocument43 pagesManual For Concretinglwin_oo2435No ratings yet

- ASTM C 1645-16 Freeze Thaw of Interlock Paving UnitsDocument3 pagesASTM C 1645-16 Freeze Thaw of Interlock Paving UnitsHaniAminNo ratings yet

- Fire Protection For Structural Steel in BuildingsDocument91 pagesFire Protection For Structural Steel in BuildingsHamada Shoukry MohammedNo ratings yet

- Concise Eurocode 2 For Bridges PDFDocument142 pagesConcise Eurocode 2 For Bridges PDFChris Dunlop100% (2)

- Millennium Product DataDocument15 pagesMillennium Product DataAnonymous ZizCrNlQkpNo ratings yet

- Hyper CreteDocument2 pagesHyper CretedjgiumixNo ratings yet

- High Slump Concrete Mix Design 2 PDFDocument68 pagesHigh Slump Concrete Mix Design 2 PDFBernie QuepNo ratings yet

- Compressive Strength of Concret by Fly AshDocument16 pagesCompressive Strength of Concret by Fly AsheranjanishuklaNo ratings yet

- TDS - Flowcable 50Document2 pagesTDS - Flowcable 50Venkata RaoNo ratings yet

- Is Concrete Mix DesignDocument21 pagesIs Concrete Mix DesignahmedanyNo ratings yet

- Concrete Mix Design CalculationDocument9 pagesConcrete Mix Design Calculationezarul321No ratings yet

- 45mpa Mix DesignDocument2 pages45mpa Mix DesignSamuel YekoNo ratings yet

- Spec For Sand CementDocument5 pagesSpec For Sand CementHüseyin EkiciNo ratings yet

- DoE Mix Design ExamplesDocument8 pagesDoE Mix Design Examplesعابد خواجہNo ratings yet

- Concrete Mix DesignDocument21 pagesConcrete Mix DesignPratyush Kumar DoraNo ratings yet

- Normal Concrete Mix DesignDocument4 pagesNormal Concrete Mix Designmurnal0% (1)

- Lean Concrete Base Mix DesignDocument18 pagesLean Concrete Base Mix DesignZaher J. Yazeji0% (1)

- Properties and Uses of Concrete AdmixturesDocument5 pagesProperties and Uses of Concrete AdmixturesDS20CE017Bhaskar WabhitkarNo ratings yet

- Sika UK Concrete Handbook 2013Document131 pagesSika UK Concrete Handbook 2013Ahmed TahaNo ratings yet

- Test Report of MetakaolinDocument14 pagesTest Report of MetakaolinAbdul Falahitawan UfalNo ratings yet

- Foamed ConcreteDocument14 pagesFoamed ConcretemilanNo ratings yet

- Foam Concrete - Experimental Investigation of Its PropertiesDocument7 pagesFoam Concrete - Experimental Investigation of Its PropertiesIJASRETNo ratings yet

- BASF Introduces Smart Dynamic ConcreteDocument4 pagesBASF Introduces Smart Dynamic ConcreteNurul Hidayati100% (1)

- Lightweight Concrete and AggregatesDocument23 pagesLightweight Concrete and Aggregatesahmed ElshaibaniNo ratings yet

- Astm C1688-08Document3 pagesAstm C1688-08Sergio Vidal ArcosNo ratings yet

- Flyash Based Geopolymer ConcreteDocument11 pagesFlyash Based Geopolymer ConcreteDharma RajanNo ratings yet

- Mortar Cement BrochureDocument6 pagesMortar Cement BrochureAlbert Valentinus Christy WibowoNo ratings yet

- ACI Method of Mix DesignDocument5 pagesACI Method of Mix DesignHaris AlamNo ratings yet

- Chapter 5. Admixtures For ConcreteDocument17 pagesChapter 5. Admixtures For ConcreteKhaled Al-SwairkiNo ratings yet

- Towards Sustainable ConcreteDocument2 pagesTowards Sustainable ConcreteJouber FerreiraNo ratings yet

- Mitigating The Effect of Clay Content of Sand On Concrete StrengthDocument7 pagesMitigating The Effect of Clay Content of Sand On Concrete Strengthbpkndl7943No ratings yet

- Concrete Mix DesignDocument25 pagesConcrete Mix DesigngauravrediffmailNo ratings yet

- Fly Ash As Binder in ConcreteDocument10 pagesFly Ash As Binder in ConcreteZuhair NadeemNo ratings yet

- Lightweight ConcreteDocument14 pagesLightweight ConcreteTatiana Espinoza EusebioNo ratings yet

- Polymer Impregnated Concrete - Uses, Properties of Polymers in ConcreteDocument4 pagesPolymer Impregnated Concrete - Uses, Properties of Polymers in ConcretesahilkaushikNo ratings yet

- Concrete Mix DesignDocument4 pagesConcrete Mix DesignZakir AliNo ratings yet

- Mix Design - ADM QCC ManualDocument1 pageMix Design - ADM QCC ManualSyed AbuthahirNo ratings yet

- Seminar On AdmixturesDocument24 pagesSeminar On AdmixturesimdgameNo ratings yet

- UNIT-1 Cement Mortar & Concrete: Prepared By-Deepti Singh (Assistant Professor)Document39 pagesUNIT-1 Cement Mortar & Concrete: Prepared By-Deepti Singh (Assistant Professor)Harkamal Singh DevgunNo ratings yet

- Comparing Concrete Durability Testing MethodsDocument3 pagesComparing Concrete Durability Testing MethodsHoang An TranNo ratings yet

- Silica FumeDocument24 pagesSilica FumeRatna Sai0% (1)

- Reference Notes - Tests For ConcreteDocument21 pagesReference Notes - Tests For ConcreteMitali KhedkarNo ratings yet

- 04 - TDS Meyco FlowcableDocument3 pages04 - TDS Meyco FlowcablebossbobNo ratings yet

- Mix Design Foam ConcreteDocument13 pagesMix Design Foam ConcreteVirga PriyoNo ratings yet

- Partial Replacement of Cement To Concrete by Marble Dust PowderDocument12 pagesPartial Replacement of Cement To Concrete by Marble Dust PowderIJMTST-Online JournalNo ratings yet

- 7-SCC C60 Mix Design MDC 2Document1 page7-SCC C60 Mix Design MDC 2Kelly JuarezNo ratings yet

- ArticledesignandconstructionofliquidtightconcretestrucDocument3 pagesArticledesignandconstructionofliquidtightconcretestrucalbertoxinaNo ratings yet

- Ds - Concrete Mix DesignDocument51 pagesDs - Concrete Mix DesignDarshan ShahNo ratings yet

- Test 1 - Concrete Mix Design DishanDocument20 pagesTest 1 - Concrete Mix Design DishanYasndra AbeygunewardhaneNo ratings yet

- Effect of Rapidite On Strength of ConcreteDocument66 pagesEffect of Rapidite On Strength of ConcreterizwansstaadNo ratings yet

- Delvo Crete Stabiliser: Liquid Hydration Inhibitor For ConcreteDocument2 pagesDelvo Crete Stabiliser: Liquid Hydration Inhibitor For ConcreteShoyeeb AhmedNo ratings yet

- Air Content in Concrete - Concrete Air Test - The Concrete NetworkDocument4 pagesAir Content in Concrete - Concrete Air Test - The Concrete NetworkPritha DasNo ratings yet

- By Yuvraj KocharDocument32 pagesBy Yuvraj KocharShivangi KocharNo ratings yet

- Concrete Mix DesignDocument7 pagesConcrete Mix Designtangudusrikanth513gmNo ratings yet

- Cement and Concrete - An IntroductionDocument23 pagesCement and Concrete - An Introductionandica248No ratings yet

- Conplast SP432MSDocument2 pagesConplast SP432MSTori Small100% (1)

- 2 Cement HydrationDocument50 pages2 Cement HydrationMelinda GordonNo ratings yet

- Numerical Methods and Implementation in Geotechnical Engineering – Part 1From EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 1No ratings yet

- Perlite Concrete Mix Designs: Materials Per Cubic Yard Based On 100% YieldDocument1 pagePerlite Concrete Mix Designs: Materials Per Cubic Yard Based On 100% YieldMJundiNo ratings yet

- Effects of CementDocument8 pagesEffects of CementshariqabideenNo ratings yet

- Quailty Assurance of CementDocument30 pagesQuailty Assurance of Cementabdullah100% (3)

- Moisture Lnduced Damage: Resistance of Compactad Asphalt Mixture ToDocument8 pagesMoisture Lnduced Damage: Resistance of Compactad Asphalt Mixture ToGabith Quispe ApazaNo ratings yet

- Determination of Thermal Resistance of Loose-Fill Building Insulation in Side Wall ApplicationsDocument9 pagesDetermination of Thermal Resistance of Loose-Fill Building Insulation in Side Wall ApplicationsHaniAminNo ratings yet

- Manual Thickness Gauges Flakiness IndexDocument2 pagesManual Thickness Gauges Flakiness IndexHaniAminNo ratings yet

- Ilnas-En 12390-1:2021Document8 pagesIlnas-En 12390-1:2021HaniAminNo ratings yet

- Astm C 1853 - 17Document6 pagesAstm C 1853 - 17HaniAminNo ratings yet

- NCMA Astm c140 PDFDocument4 pagesNCMA Astm c140 PDFHaniAminNo ratings yet

- ASTM C331-2010 Light Weight Aggregates For MasonryDocument4 pagesASTM C331-2010 Light Weight Aggregates For MasonryHaniAminNo ratings yet

- Annex A - SpecificationsDocument5 pagesAnnex A - SpecificationsDesigners Eng'gConsultancyNo ratings yet

- Construction Checklist: Refference YES NO NA SAE SDE Aggregate For Concrete Material: SL. NO. Check ItemDocument3 pagesConstruction Checklist: Refference YES NO NA SAE SDE Aggregate For Concrete Material: SL. NO. Check Itemnilesh kumar VermaNo ratings yet

- CESL-POG-CS-GEN-SPC-004 Rev C1 PDFDocument14 pagesCESL-POG-CS-GEN-SPC-004 Rev C1 PDForode franklynNo ratings yet

- Dozvan Company Method of Statement For The RFQ-21627 - Crossover - Bridge - 10 - Line - at - FSKDocument41 pagesDozvan Company Method of Statement For The RFQ-21627 - Crossover - Bridge - 10 - Line - at - FSKAva GhaziNo ratings yet

- Box Culvert 633 (Orogun) : Wing Wall ElevationDocument1 pageBox Culvert 633 (Orogun) : Wing Wall ElevationOseni MomoduNo ratings yet

- Design of Well FoundationsDocument3 pagesDesign of Well Foundationssharathr22100% (1)

- DRT 104 - 1Document59 pagesDRT 104 - 1Sir ArtNo ratings yet

- Sample Intellibuild EstimateDocument23 pagesSample Intellibuild EstimateRomani Noel S. Chavez Jr.No ratings yet

- Early Striking and Improved Back Pro PingDocument2 pagesEarly Striking and Improved Back Pro PinglawkkNo ratings yet

- 128 FPDocument6 pages128 FPRajesh KumarNo ratings yet

- Recent WritingtopicsDocument21 pagesRecent Writingtopics11CT1-15- Đặng Bá KimNo ratings yet

- Screed Bases and In-Situ FlooringsDocument28 pagesScreed Bases and In-Situ Flooringsrekcah ehtNo ratings yet

- SSPC Painting Manual: SSPC: The Society For Protective Coatings 40 24th Street, 6th Floor Pittsburgh, PA 15222Document6 pagesSSPC Painting Manual: SSPC: The Society For Protective Coatings 40 24th Street, 6th Floor Pittsburgh, PA 15222Moeen Khan RisaldarNo ratings yet

- Technical Information Schoeck Dorn LD (2967) PDFDocument20 pagesTechnical Information Schoeck Dorn LD (2967) PDFEdmond TakacsNo ratings yet

- Transportation Engineering Lab ManualDocument42 pagesTransportation Engineering Lab ManualSubzar BhatNo ratings yet

- PINKBAR Reinforced Concrete Innovation 20231015Document41 pagesPINKBAR Reinforced Concrete Innovation 20231015SpinoWebNo ratings yet

- Bleeding of ConcreteDocument3 pagesBleeding of ConcreteANo ratings yet

- Modified Kodad - Revoor Road RenewalsDocument418 pagesModified Kodad - Revoor Road RenewalsSRIHARINo ratings yet

- Kim Lighting VRB Series Vandal Resistant Bollard Brochure 1993Document12 pagesKim Lighting VRB Series Vandal Resistant Bollard Brochure 1993Alan MastersNo ratings yet

- EzeeplastDocument2 pagesEzeeplastSourabh BansalNo ratings yet

- Rain PDFDocument166 pagesRain PDFShaikh AafrinNo ratings yet

- A Prototype Construction Duration: Estimating System (CODES) For Mid-Rise Building ConstructionDocument57 pagesA Prototype Construction Duration: Estimating System (CODES) For Mid-Rise Building ConstructionAdonis AlabiNo ratings yet

- Report Bka PDFDocument20 pagesReport Bka PDFFatin Nadia DieyaNo ratings yet

- Novolac ScreedDocument4 pagesNovolac Screedmd_kureshiNo ratings yet

- SS 557 2010 Preview PDFDocument9 pagesSS 557 2010 Preview PDFdhruvNo ratings yet

- Design of Reinforced Cement Concrete ElementsDocument14 pagesDesign of Reinforced Cement Concrete ElementsSudeesh M SNo ratings yet

- DESIGN REPORT OF Kalanki RESIDENCEDocument23 pagesDESIGN REPORT OF Kalanki RESIDENCESuyogya DahalNo ratings yet

- 7.5 Hooks: Using ACI Equation 12-1 With K 0Document5 pages7.5 Hooks: Using ACI Equation 12-1 With K 0محمد الذيبانيNo ratings yet