Professional Documents

Culture Documents

Logbook Data (Dec 13) 09

Logbook Data (Dec 13) 09

Uploaded by

Amit shahOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Logbook Data (Dec 13) 09

Logbook Data (Dec 13) 09

Uploaded by

Amit shahCopyright:

Available Formats

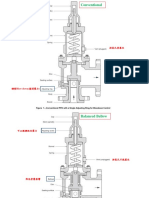

PIU found that at Fab.

Shop during hydro testing 3

valves # VT -1672 Size 14x600, VT 1698 Size 18x150

and VT - 1699 Size 18x150 have Rust on flange raised

face Serration has been damaged more than Accepted

PIU found that at Fab. Shop of RT/DHT Project, 12

value of (MSS-SP-44- steel pipe line flange) 2001.

flange raised

Contractor

Violation of SAEP-351

face Serration

is advised to follow

Para.

has been

4.3 the Flange Logbook Data of Project 10-0006

damage during

recomendation

face particularly for

blasting

termination violating SAEP-351 Para.box 4.3 i.e AndforSAIC L-2014

seating inside

theLogbook/Surveillancearea Shall field be junction

no damage or as individually

per (MSS-

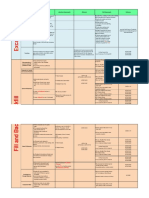

S# Date Sur# Location item A2. Flange

shielded twisted face particularly the Description

seating area shall

SP-44- steel pipemultipair/triad

line flange) 2001. shall bethree

All heat shrink

valves

besleeveno damage insulated or as from perthe Accepted

cable Value end

jacket of (MSS-SP-44-

up to the

187 10/18/2009 15:12 1017097 BeContractor

informed that cable rejected.

Tray installed beneath Raised

pointsteelofpipe lineis flange)

termination

advised2001. to useList

to keep the

pulleys

foil

or sheaves

of shielding

spools and to

flange

intact and

Floor in PIB

maintain a minimumof DHT not bending having radiusprovison of 20% spare

on horizontal bends

190 10/18/2009 15:09 1017090 free from accidental size grounds. attached. the shield drain wire shall

space for future expansion.

and vertical pull and these pulleys should be anchored This violates Standard

be insulated from foil end to terminal. Approximately

54 10/20/2009 10:56 1017889 to theSAES-J-902

structural steels Secn 9.6 not and to the NEC cableARTtray 396(B).

due to the

two inches of heat shrink tubing shall be applied over

force that can be applied during pulling due to this it

73 10/5/2009 13:58 1012000 Contractor is advised to protect cable glands10.2.8.

the jacket end as per SAES-J-902 Section in severe

will damage cable or cable tray as required by NEMA VE

corrosive environment from corrosion either by a heat

76 10/3/2009 16:56 1011339 Be informed that at2the 5.4 entrance

(b) and (c). of PIB building of DHT

shrink sleeve, anti corrosion tape or PVC shroud as per

i.e in 900 mm cable tray Instrument and Power cable

88 10/4/2009 10:43 1011500 Contractor

Armored cableisSec 10.2.3

advised

from toofmaintain

instrument SAES-J-902. spacing between

routed in Same tray that ViolatestoSAES-J-902 field junction box

Section

instrument,

shall be routed controlon a and

cable power

tray cables

per within

section 9.8 the of pullpit

SAES-

102 11/21/2009 7:33 1029842 Contractor shall submit14.3.1. cable splicing and termination

in All

J-902. DHT Area

unused

The considering

knockout holes

armored signal ofbe segregation

electrical boxes i.e. and

Noise

procedure at leastcable 30 days shall prior routed

to startindependently

of work as

106 10/11/2009 8:09 1014162 of Susceptibility

enclosures

existing overhead shallasbe per

tray SAES-J-902

covered

systems as used Sec

required for 14.2.6

by NEC

"home-run"

required

The locations by section 4.1, attachment

of underground cables,VIconduits to Schedule or duct Q

110.12A.cables. Contractor

The unsupportedis advised end toof cover these at

the cable openings

the

97 8/8/2009 10:41 992694 banks shall and beitem markedno. 1.1 of SATIP-P-104-02.

in accordance with SA standard

prior to the installation

instrument shall be looped; of suspended this loopceiling and raised

shall take into

drawing nos. AB-036273 or AB-036326 as required by

105 8/8/2009 10:00 992666 account the bending floorradiustiles. of the cable. The

section During10.8

During installtion of SAES-P-104

surveillance in and

flare section

area found 13.2 of

that SAES-J-

for

unsupported lengthofoffeed cable stripper

at the bottom instrument exchanger

shall be

113 8/11/2009 15:51 994242 installation

( the E of

J88minimum 303 pipe A-K8) in in 902.

rack

DHTusing area chain block

found that without

water is

length required to provide the service

Nyloncoming slings.It

out frombydirectly contact

thesectionequipment to the

while pipe 2 locations

119 8/11/2009 17:07 994310 loop as required 13.1.1.2 ofremoving

SAES-J-902. the

coverAs per plateSAES from L-nozzle

350 para in shell 8 , handling

side. It shows 8.2-( that needafter to

During survillence found that in SRU Area Equipment

127 7/22/2009 15:49 985907 Hydrotest of equipment use nylon water slings.)

Is not fully drained from

-Temper

1. NAME water

PLATE surge FORdrum GEARBOX ( J87 MISSING. D 01082.FOR ) Name

the system It need to be dry layup while shipping from

130 8/23/2009 11:27 998830 plate Install inLUB

COMPRESSOR up sideOIL PIPING,down . ItMATCHING need to beFLANGES rectify

orgin. Ref in standard SAES A 007 dry layup 5.2.3 .

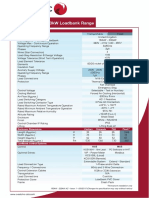

ARE SS AND SOME DISSIMILAR, BUT BOLTS USED IN

131 9/2/2009 13:40 1002458 During surveilance found that equipment 1. phosphate

THIS FLANGES ARE CS. THE ACTUAL CONDITION AT

injection package,2. corrossion inhibitor and

134 7/12/2009 15:51 980883 SITE NOWwitnessing

During elevation IS " RUSTofAND CORRODED.

phosphate injection unit

3.antifoaming unit for these three equipment side glass

( J87 U- 0301 ) in SRU AREA ,found that foundation is

142 7/20/2009 7:26 984538 vent

During line 1/2 ss threaded

survillence found that jointelectrode

broken. Need was find to rectify.

in cold

16mm lower level as per surveyor report. Informed to

condition in portable oven due to not plug in power at

146 8/16/2009 11:24 996143 contractor QC and need to rectify

SRU area.It is voilation as per standard SAES- W- 011

During survillence found that in SRU, Equipment

147 9/29/2009 16:51 1010067 Attachment -1 ( faiz pid )

Temper

During water surge

surveillance in drum

SRU -(area J87 forD the 0108alignment) Nameof

During survillence found that in SRU, Equipment

151 8/18/2009 11:47 997143 Equipment 2 & 3 up

plate Install in side downJ87

condensor( . It- need to be rectify.

E - 0107/109 ) found

DuringTemper water surge

receiving inspection drumfound ( J87 that D coalescer

0108 ) Name drum (

that foundation is 40mm in lower level.Need to be

152 8/18/2009 11:47 997142 plate

J88 Install

D -304in) up side under

saddle down .bottom It needplate to beisrectify.

heavly

rectifyreceiving

During By adjusting inspection springfound support that knob ( or) damage

physical adjust

corroded and need to be proper cleaning and painting

164 9/15/2009 12:08 1006764 in equipment

During receiving with

1. Feed pipeline

inspection stripper toof equipment.

bottom

flare stack exchanger

(PARA

J89 11.1.10( shell

F- 101

before

Most installation.

of) the static per 32 SAMSS 007

andsideJ89 J88 F- 102 E )equipment

- found

303 C that 2. Leanin DHT

bottom DGA found that in

charcoal

liquid seal

skirt

filter

drum

165 8/26/2009 13:46 1000037 During

area forreceiving

fire inspectionPAGE 39

for Lean amine cartridge

( drain

external line)have 415proofing

flanges

KF 0202 insulation

located Need used

inside

13 mm

to rectify

the skirt. with square

Asproper

per

filter ( 415

nuts

During spacedKF -0201A/B

alignment 450 mm ) found

center

inspection in that

of bothname

static directionplateper

equipment paint

-

170 8/22/2009 7:17 998310 instruction

standard SAES- D- 001 PARA 7.1.13 states that flange from vendor

peel offtrim

international

vapour and coolerneed

standard to

in rectify ( by

PIP VEFV1123, painting But with correct

in aramco

connection should beDHT outside J88 the E skirt 107

. AsAB per& thisCD-

178 8/29/2009 14:08 1000895 sewon standardcollen SAES

corp B specification

korea 006 specifies

) found that to

in refer

slidling aramco

end the

criteria

InDuring

SRU the

receiving

Furnace equipment

inspection

chamber is( J87

not

for J88 matching E with

F -0101 0303 our

A K

standard

saddle isdrawing not AC uniformly

resting 036915 mention

in structural bolt) space

refractory

support. 300

181 10/15/2009 8:31 1015933 ( FEED/STRIPPER

production requirements.

samples BOTTOM

for Need

castable tothere

EXCHANGER) be rectify

is Found thatin

discrepancy

mm . 10mm

Nearly As action gapwe findneed to followsaddle

in between our standard before

and structural.

equipment

laboratory test saddle

reportsupport for casting under , itthe basemeeting

is not plate isas

183 11/11/2009 7:28 1026188 It shows that fire saddle proofingis notstarts.100% flat and it get

corroded.

per Aramco And it need mentioned

standard to be rectifyinas SAES per 32N-110 SAMSS Para

distortation

During receiving . As perinspectionstandard drawing found that for saddlewas it not

185 8/24/2009 14:49 999315 11.3.4. The values 007 PARA is outside11.1.10 thePAGE 39 gasket

acceptance range due

mentioned

damage in thewatertolerance.wash Need drum,toIt get need information

to be rectify from

to sample examined in room temperature instead of

191 11/29/2009 15:11 1032275 before pre-commissioning vendor. of the plant even though it

drying at 110 degree centigrade as per vendor

showing positive pressure in seal end. Bank 1 : gasket

192 12/13/2009 7:30 1036930 CB # 26 & 28 arerecommendation. accepted, however for CB # 27, it

damage - F 9909B F 9909C Bank 5 : Gasket damage

does not meet Para.4.6.2 & 4.6.3 of SAES S-020.

196 9/17/2009 11:37 1007475 F 9914 E F 9914 F

Contractor shall re-design the affected paving area and

202 11/18/2009 17:17 1029205 The @ DHTfollowing issue

Area,were the new following

coated RFI(APCSaccordingly.

violation 113A) were andfoundshifted forto

@ SRU, J87-D-0104 and J87-D-0108 were both coated

cable tray andconducting

DHT without junction box the support.

following; 1. Unacceptable

surface prep

204 8/9/2009 17:41 993390 with Sigma NO VENT PaintsPIPE APCS PIPE 17AAS and PER APCSSTANDARD.

2A respectively,

Surface preparation;

inspection, post application 2. Sagging

inspection, wereDFT visible and

inspection

while during the touch up repair for J87-D-0104

132 10/22/2009 9:51 1018690 and holiday testing insuffecient DFT g

RB-728961-0320-04-J88-P-0984-

Ameron

For the paint third were time, used coating while J87-D-0108(ORC)

subcontractor were SIPCO were

SPR- 18" RB-728321-033-02-J88-FW-0403-06-SP 02-

133 10/26/2009 10:39 1020136 caught in the act while paints,

using used (contaminated)

12"itRB-728321-033-02-J88-FW-0403-06-SP

is observed that several spool are laying01- 12" RB-

directly

garnet, this is in violation to SAES-H-100 para 5.2.1 &

149 10/18/2009 8:59 1016903 contact

During728321-019-02-J88-FW-0401-04-SP

toseatthehydroground test, insidewe and outside

found one 02-valve

the

gate 12" has

fabrication

para 5.2.2.. Supervisor were recommended to remove

shop,

leakage flangethrough facethe alsobehind not protected with plywood. this

150 9/14/2009 15:58 1006460 from theseat proj.rings. As per API 598

isisa not

violation

permitted of aramcosee 3.9.2. standard We reject refer to that SAES-L-350

valve as

OTC personnel were not complying with manufacturer

154 9/22/2009 9:16 1008107 details given below.PARA TAG 7.1 NO and AF4VH3N, 7.4. VT NO 448, Size

data sheet and SAES-100 during application

4 inch diameter, rating 600, body heat no 22D37,P/O

168 9/14/2009 15:53 1006456 "continuous agitating of paint during application"

NO:-4500042444/CRC1-M98-04-V003-DA,valve

169 9/22/2009 9:35 1008109 manufacturer name :-PKVALVE CO.,LTD

Proactive Notification : Please advice the contractor, if

Junction box supports @ SRU were being coated

possible they have to use the crane in lifting the spools

without proper surface preparation, contaminants were

or ifDuringthey want material to use receiving

the forklift, inspection,

paddingit must has been be fixed

173 12/6/2009 7:58 1034590 observed that the visible

Explosion-proof Low Voltage

first prior to lifting to avoid severe damage to the

Installation

PanelboardsofJ88-222-PP-005 scaffolding nearand theJ88-222-PP-009

equiptment should did

180 9/14/2009 15:56 1006458 coating.

have

not atleast

meet the 2"requirements

to 3" clearance of to avoid damage

16-SAMSS-518 to the

section

Pro Active Notification : Contractor must advice the

182 12/6/2009 8:04 1034597 coating

As 5.7 which

proactive of the states, equiptment

notification, Panelboards or thehas

SAPID insulation

shall be

observed amaterials.

ofblasted factory-

that the

As part of SAPID

subcontractor Q/A toAssessment,

handle properly it has thebeen observed

At

UPS lay

sealed

that the cable down

Panel design area,

Cabinets to 1).

allow

trays expansion stone the

installation were

load on used

sidethe as

branch

raised

guide clamps installed stopper floor for

circuit atat

184 9/14/2009 15:55 1006457 spools/pipes to avoid contamination.

coated

the

theconnections

UPS pipes.

room,

following 2).

to PIB be

locations,someaccessed

building, coated

along DHT Cpipes

while the

Area,

Street,still

main

were laying

Pipenot wayon

circuit astheis

per

no.

Calibration

During for

surveillancethe inspection

itground.

has been instrument observedwere are required.

that the

188 9/14/2009 15:51 1006455 12, energized.

the

DuringDHTmanufacturers

surveillance

Main The

Pipe Panelboards

mounting

inspection,

rack, SRU Main mentioned

recommendation.

it has

Pipe been

rack observed

and not

The

Flare

And compressor

Contractors and

testing airless

personnel spray was machine

utilizing calibration

a non-to

factory-sealed

fabricated

that

Area thedoes cablesteel

not design

channel

trench

have and

of the

sufficient does

supports installed

gapnot werehave

for not

medium

the provision

aligned

cable voltage

tray

194 9/14/2009 15:48 1006454 Ascalibrated certificates

proactive notification,

Torque andWrench tags it has were

for been not

tightening available.

observed MVtoand that LVthe

the allow

cables base

thermalthe

that load

mounting

supplies

expansionside holesbranch

power of to

movement. thecircuit

theUPS connections

cabinets

Power

The Transformers

mentioned to be

provide

58 12/6/2009 9:04 1034613 contractor

terminals.

accessed has

Moreover,commenced

while the the main the

Calibration installation

circuit Certificate

is energizedof Cathodic

of the

adequate

at the Transformer

expansion and

clamps stable anchoring

yard, beSubstation of the equipments.

no.allow222,movement

DHT Area The

Protection

TorqueisWrench (CP)shall onwas some designed

areas. Theto contractor notis

Contractor

were forpartially

thermal requested

covered

expansion tonot

(approx.

and

available

rectify 50and

contraction percent)

and

provide wasadequate

by the

during thelean

59 8/30/2009 10:11 1001192 requested

submitted totosubmit SAPID. the construction

Furthermore, theCP mentioned

drawings to

Channel

concrete

variation supports

for

of climate the for

proposed stability

temperature. Stormand safe

Water

Moreover, mounting

Channelthe CSD of the

(e.g.

method

theTorqueCathodic WrenchProtection has no and Coating

sticker from Unit the of the

calibration for

60 8/26/2009 14:18 1000054 U-ditch).

ofreview

fastening As per of equipment

SAES-P-104

the expansion mentioned.

section

guide 10.13

clamps which

was states,

not as

agency.

During and

Thisapproval

surveillance is a violation prior to Schedule

inspection, theit starthas of

Q

been work Attach.as per

observed IV

direct

per thebeen

Itsection

has buried

requirements. cables, conduits

observed Theand

that beam or

theSAES-X-500

cable ducttrays

clamps banksthat shall

hold 4.2.

Expansion not

the

61 9/27/2009 17:25 1009330 SAES-X-400

that Duringthe 7.1section

Contractor which 5.1.1

surveillance states,

has The

commenced

inspection, CONTRACTOR

the the section

installation

Contractor shall

has of

Guide be

expansion

Clampsinstalled guide

installeddirectly

clamp at above

thedown or

are

following belownot asparallel

locations, per the along

identify,

cables

commenced maintain,

without the the form control,

installation

works for adjust,

and and calibrate

completion

the casting all

of the

of concrete

85 11/14/2009 18:01 1027530 C manufacturers

Street, underground

Pipeinstruments

way mounting

no. 12,and piping.

recommendation.

DHT Mainmeasuring

Pipe rack, The SRU

tools,

cable

Storm gauges,

trays

Water permanent

Channel supports.near

(U-ditch) other

Thisthe is aTransformer

violation and of

Contractor

Main Pipe rackis advised

and Flare to Areainstalldoes the correct

not have expansion

sufficient

86 11/17/2009 13:21 1028592 testing

SAES-P-104

yard devices

sectionused

of Substation 3.2no. for

andcontrolling

NEC 392.6 quality.

(B)J88. which

gap forguide the cable clamps tray per 222

as thermal at DHT

the expansion

manufacturers Area

movement

states,

Unfortunately, Each run of cable tray

underneath the shall proposed be completed

concrete

89 11/28/2009 14:48 1032185 and it does not function recommendation. as an Expansion Guide clamp.

before

channelthe were installation

previously of cables.

installed Presently, direct buried a portion

Medium of

This is a violation to NEMA VE2 section 4.3.2. Moreover,

101 11/5/2009 11:21 1024202 the cablepower

Voltage tray runs feeder were cables still for on athe temporary

Substations supports.Power

Need drawing for GPR

the torque value was not applied, clamps were loose area at S/S #222. SAES-T-887

Transformers

PAR:4.1.2 When which runs parallelfacility approximately 28

110 12/6/2009 9:14 1034616 (falling-off) and communications

does not allow uniform expansion. with metallic

Need drawing

meters. Thisisiswithin with the GPR

a violation of area

SAES-P-104 for S/S 211. section SAES-T-

10.11

Thememberhot bending 1.0

of REQUIRE km

PVCcommunications

(NEMA of power TC WARNINGfacility,

8) conduit a GPR

in the

115 12/5/2009 13:19 1034261 TRs 887 at PIB

PAR:4.1.2 87 & When 88 FIRE facility LIGHT

with

PIB 87will

analysis

feild TRnot Lighting

shall bebeAND in and

done.

permitted theBased 10.13.

looks

because lik the

on it of

may not

calculated

the meet

difficulty GPR the

of

TR OUTSIDE

metallic

walls

TRs in member

need

both OF

PIB to is

have ABOVE

within

two

87 &SAES-T-911

88 reqire 1.0

coatsTR km DOOR.

of of

firepower 4.3.9.2

retardant Fire

facility, whiteaof

205 11/24/2009 8:01 1031214 requirments

voltages, quality of SAES-T-916

appropriate

control. protection PAR;power 4.4.2.12

devices panel.

PAR:4.5.10.3.1 and SAES-T-

(Lighting

grounding

Protection

paint

916 GPR analysis

onshall

Par: all Anwalls

4.4.2.14 ionization

shall all be

Powerthe fire

done.

waypanels detector

toBased

the

for on

roofor

dedicatedequivalent

the

of calculated

TR. SAES-T-

electricalshall

Telecommunications Rooms

be incorporated in the design of the and Closets shall be a

206 11/18/2009 11:13 1028994 beGPR provided

voltages, in telecommunication

appropriate

916 PAR: protection equipment devices rooms

and

minimum service

communications

Contractor

Contractor

of shall

540

backfilled

is

be

lux

relocating

provided

(50

facility. trench The4.3.7.1

footcandles)

pedestal

in

cable

without

a TR

that

when

measured

design

putting

will or

be

active 91 cm

location

marker

serving

when:

grounding

equipment Specified

isshall

planned bebyincorporated

the

orGPR communications

installed. in the

Lighting proponent.

designfixtures of the

shall

207 10/17/2009 8:27 1016412 (3 feet)

shall be suchabove that the the finished

tape floor

exposure

in. level.does Locate

not light

exceed

There

SAES substation

ispowered

communications

Q-011, a firePara.6.1.2 that

detection maybe

facility. system

The

states within present

cable

that GPR

design

"When ZONE

in type

the

or OF

building.

location

of grout

not

50% be

fixturesof the a minimum from

cable coreto- the

of 2.6 telecommunication

sheathmeters (8 feet.rating.

dielectric equipment

6 inches) GPR

The

shallINFLUENCE.This

detector

be such shall

thatby the shall

have abe coordinated

remote lightdoes with

extended Saudi from

208 10/31/2009 9:17 1021957 is not

above specified

calculations, the finished

grounding in GPR

floor. equipment

theand Use exposure

room. white

recommended Manufacturer

paint to not exceed

enhance

protectionepoxy

its Aramco

circuit

50% lighting.

grout of

shall to

thebe Communications

a

cablelocation

used coreto- outside sheath Standards

the main

dielectric Committee

entrance

rating. GPR door.

209 12/10/2009 8:33 1035988

room equipment

Chairman

Emergency

shall

reprentative.beforprovided

any of the

lighting

SAES-T-903as is following

partrequired.)You

of thesituations;

par:4.1.2.1 project have

This is required

calculations, so itand may be identified as the

1- Equipment

dark

design tiles

package. ongrounding

with

theOnly driver

floor if and

there

recommended

horsepower

walls not 500

is uncertainty white (373protection

going kW)

regarding toor

greaterequipment

equipment 2- shall

Equipment room bedetector

provided

with when

speeds as part activated.

greaterof the The

project

than 3600

210 11/18/2009 11:28 1029007 ceiling.

provided design, interpretations shall be provided

proponent

design RPM package.

3- shallofinspectOnly ifthat andhas

there maintain

isauncertainty the detector

regarding in

After

through theEquipment

evaluation Saudicombined Aramco Communications fire combined

smoke damper weight (CFSD)

Standard

211 10/31/2009 9:37 1021975 (machine,

by fireaccordance

provided design,

& driver,

smoke and to

damper manufacture

interpretations

baseplate) remediation guidelines.

ofshall

greater be provided

committee, than 2,270 16

Committee Chairman. A copy of the GPR analysis shall

through

kg (5,000

pieces theof

out Saudi

lbs). 48 4- Aramco

totalAll quantities Communications

reciprocating were machinery

not complyingStandard

with

212 11/16/2009 13:00 1028163 be included with the design package.

Committee

driver

with

During horsepower

S.A. Chairman.

requirements

surveillance greater A and

inspection copy than ofin50

thereforethe (37

DHT, GPR foranalysis

kW).

rejected Hence,(check

Galvanized shallits

213 11/16/2009 13:05 1028168 thehighlylist

pipe, be

with

coatedincluded

recommended

PMT). with with

However,

APCS the

to include 113A, design

there the

I arepackage.

grout

notice three thattypeCFSD info(two

during in

Upon Wallrequest

telephone outlettobox not placed at 1220 mm in(D-

the list ofthe

1000X650 &by one PMT

equipments

at1200X700)

inspect

which toequipment

consequently

be evaluated pedestal

toand be If

214 10/29/2009 14:13 1021542 Ittightening,

changing

is noticed

0304- Coalescer thattooth

room the Drum)

of the

PIB88.

sub-contractor

on

wrench

BICSI

Aug-15, CHAP they5 used

internal

PID PG

found

leaves

5-101

audit thehas

distributed

thesesharp aremarkssingleto to allsection

concerned

the pipe CFSDs and parties

then they

causes fordamaged

their

are reference

in violation

not been1-conducted

followings; Additional sogrout far where thethe

forHowever, progressthe

modification

to

of

15 8/13/2009 16:47 995352 ofcoating

Saudi Aramco and pipe20% and

requirements.

surface. use. if these

wereis3in

percentage

shim plates is not

is over properly ascured ofTouch

May-15,

for

up 2009.

the

repair This

last three days

CFSDs executedare multiple withoutsections any then they

inspection forare theacceptable.

surface

35 5/25/2009 11:00 955138 Prime aftercontractors

grouting. violation2-HVACAnchor toQC Sch. has

bolts Q leftPara.7.2.

locatedthe job south siteside withoutof

Contractor

preparation.

Although, itshall

was verify

Therefore,

stated these three

the integrity

clearly in Q, our CFSDsfor andresponse

the

official invitearea

repair PID in

replacement.

fixed saddle are not This violates

plumbed Sch. and attach.VI,

they have Para.2.1

been bent

122 6/24/2009 14:09 972234 isregard

questionable.

It is to Refractory

observed This forisProcedure

that re-inspection.

infor violation

MH 22& that to101 SATIP-H-100-01/a

all metal

started surfaces

the

inandorder

Although, Table-VI-2.

toit meetstated

was A dedicated

the horizontal

clearly inproper

distance.

our replacement

official 3- response

Projection is in

3.6

application(Nesma/SSA

shall be grit

of Hold point

blasted

Renderoc "SSPC

FCnot asandSP6"

surfaceSAper ispreparation

Witness

SAES N-110, point).

prior

123 7/12/2009 15:20 980843 of anchor

regard required

all bolts ASAP.

found Nagi enoughB. ElBashir

to metal

accommodate

Para8.2,

to Thisto

coal LBE

tar

Refractory

butepoxy is

it wasentered Procedure

discovered

coating. onPara. behalf that

that

18.8.f

all

ofduring

Dino-Coating

of

surfaces

discussion

SAES-S-070

basebe

shall plate, washer "SSPC

grit blasted and two SP6" nuts. per Contractor

SAES N-110, is

135 8/17/2009 7:31 996567 with

states It subcon

that (SRI) Inspector.

theyll apply the coating while the

requested

Para8.2, is to"Site

observed

but analyze

it was

testing

that forfor shall

discoveredroot take

MHcause 22& place

that101 analysis

during

priorand

started tothe

discussion

backfill

initiate

andmetal

application / orsurface

application

of is brush

Renderoc of cleaned

protective

FC as surfaceonly.

coatings".Please,SAPMT

preparation advice prioris

144 8/16/2009 9:13 996051 with subcon (SRI) a corrective

theyll apply action.

the coating while the

Nesma

requestedcoal&tar

tometal SRI

toepoxy to comply

advice contractor to Para.

above requirement

to18.8.f

conduct the leak to avoid test

surface is coating.

brush cleaned only. Please, of SAES-S-070 advice

156 11/5/2009 15:27 1024368 prior

states to anyany non-conformity.

surface repair andtake Nagi

the ElBashir

applied Renderoc FC

Nesmathat & SRI "Site to testing

comply shall to above requirement place prior totobackfill

avoid

material

and at these MHs

/ or application of shall

protective be removed coatings". immediately.

SAPMT is

167 11/5/2009 15:27 1024369 any non-conformity.

The type of RTR flange used for the cleanout of OWS Nagi ElBashir

Please, note

requested to advice that there contractor are more than one

to conduct thejoint leakfor test

Upon and aDGA lines is not

surveillance visit gastight

to J88, nor

found watertight

that twoinworkers case

198 7/5/2009 11:18 977255 prior

Upon toaany visit surface

to Fab. some

repair

shop atMHs.

and SRU thearea applied for RTR Renderoc piping, FC

they are used without

doing pipe jointing while they dont hold RTR JCC cards. gasket as per requirement of

material

PID found atthatthese the MHs

spool shallwhich be removed

was leaking immediately.

during the

199 8/2/2009 17:52 990636 This is SAES S-020, Para.

in violation to SAES 4.11.4. S-070, Nagi Para.8B. Elbashir.

which is also

Please, note

hydro-test of fire that thereline

water areeast more of than

substation,one joint was forre-

repeated

During more thanfor

inspection once. the contractor

MV cable shall not utilize

installation for

200 7/5/2009 11:18 977255 prepared and fixed and some ready MHs. for re-using. This incident

other

During

feeder non-approved

Aserveillance

at c times workers

it was noticed

street(RFI#J31/88-EL-019), for thethat, job of dueRTR ittowas jointing.

the rain

found

found Asseveral

a proactive and was highlighted

notification, during surveillance during weekly

201 12/7/2009 13:14 1035051 cable that drawpits

without near

any Nagi

to the

approved B. pipeElbashir rack, partially

procedure, filled with

contractor

meeting. This

inspection it was is aobserved

violationthat, to SAES contractorS-070. installed

Nagi B.

water. The

repaired damage contractor portionis of requsted

the cables to closeouterproperlyjacket. It allis

203 8/27/2009 13:22 1000395 electrical vertical cable ElBashir trays with hold down clamps in

thea violation of SAES-P-104, NEC article 110.12water

cable entry and unused openings to avoid and

front

VAF- of J87- SS-211

During surveillance out side, near toit battery room. As

53 12/7/2009 13:45 1035059 schedule Qentering attachment ininspection

toIVthe 2.1. ducts. was found

Prior to start any

that,

per section

during cable pulling 4.2.4 and the figure cable tray 4.9Cfor of 13.8kV

NEMA VE-2, feeder the A

special process like cable damage repair, contractor

55 10/5/2009 16:48 1012154 become severe mounting clamps shall

damage/bend at be many L places

type. between

shall obtain approval for the procedure from the

column# 58 to 146 along the "c" street. It is a violation

56 11/8/2009 14:13 1025211 concerned.

of section 4.1 of SAES-P-104 and NEC-110.12 & 392.5.

57 9/16/2009 11:34 1007104

During surveillance inspection it was observed that,

contractor is ready to install Aircraft Warning Light

system without any material receiving inspection on

During surveillance

J87-F-0104 (Thermal inspection

Oxidizer it wasatobserved

Stack) SRU J87that, plant

As a proactive notification, it has been observed that,

contractor contractor installed terminated exposed power PVC conduitscable 3-C 1-1/4

XSATIP

4mm2 X 2 ea

the As area.

contractor

a AS per

proactive has Schedule

installedQdiscontinuous

notification, and during approved cable trays

surveillance

with

(12AWG) offsetwith through 50AT the

circuit concretebreaker/Fuse pedestalfrom of structural

PDP-01

contractor

(i.e.a horizontal

As proactive shall toconduct

vertical

notification, material

runs)

it that

has receiving

atbeenSubstation observed inspection

J87 SS-

that,

94 12/7/2009 7:38 1034939 toinspection,

platform

04 to Marshalling forit wasthe observed

task

prior to cabinet lighing. in

installation.

Asfor

rack per

roomthe power

sectionof PIB 8.3cable

atofJ87

211contractor

the at J87 SRU

installation, is

contractor Area.

planning These

not to discontinuous

energize

following the the UPS section

SAES-P-104 and of&

the

SAES-P-104, conduit above ground in severe

SRU(DWG#J87-P-RA-729359-001Rev.2 & RA-729360-corrosive

the

battery

NEC cable trays shall

systems

requirements at in J87 bePower provided

SRU Area. with

Distribution ThePVC bonding

contractor

Panels jumper

at shall

PIB

96 11/17/2009 11:03 1028555 environments shall

001 Rev.2). Contractor does not comply with the be GRS with coated

as per

procure

rack room theat

all the requirements

SRUrequired J87. The safetyofcontractor

NEMAitemsVE2 andsection to follow 4.7, the

requirements of SAES-P-100 and Table removed 310.16 ofouter NEC.

99 9/16/2009 16:45 1007234 Saudi Figure

Aramco

jacket/sheath 4.59Typical to assure

for the cables

Inspection

thebreakerpower electricalPlan inside continuity.

(SATIP) the for their

conduit

The 50AT circuit cant protect 12AWG

installation

nipple and also and the Pre-commissioning

filling percentage activities

is higher asthanper the the

104 11/18/2009 9:16 1028946 The contractor is advised conductor. to cover all outdoor electrical

requirements

allowable.

As a proactive of

AsSchedule

per NEC Q

notification, 312.5 sectionthe cable

during 6.4.1 and Project

sheath

surveillance is

equipments

During surveillance (which is open

inspection partiallyit and for

was extend testing

observed & pre

108 9/16/2009 16:40 1007232 continuous

inspection,through it was Quality

the

observed racePlan way

that 7.5. contractor in that,

to the

installed

commissioning)

As a proactive

contractor applied andPVC

notification, all pulled thecable

electrical contractor ends shall thebe13.8kV

is reminded sealed to

enclosure

data link beyond(Belden#

cables the fitting nottape

DATATWIST less over that 6mm.

CAT-5 4PR-The

109 11/19/2009 15:35 1029561 assure properly

conductor to

the resistance

for protect

feeder from

value

A in the

of8groundea unexpected

location conductor and rain.1 from

ea

filling

24AWG) percentage

through of ladderthe conductor

type control shall cable be as trayper at NECEL.

the grid to

location onbus feeder bar prior B at U/G to use anytrench grounding system

112 9/23/2009 7:22 1008188 4650 from chapter 9 table-1

J87-211-PMS-001 and cable notes

to Switchgear to tablenear 4. to the

& MCC at

for temporary power supply.

splicing point at SS-91 J31/88 area. As per section 5.6 This shall comply with the

SS-211 J87 SRU. Data link cables shall not be routed in

114 9/9/2009 10:53 1004762 of SAES-P-104 requirements and attachmentof SAES-P-111 III ofsection Schedule 8.3.Q, If any

the same conduit, duct or tray with other instrument

accidental

During surveillance damage during in J06 installation,

& 50,51 Areas the, damage

it was found shall

118 9/14/2009 11:21 1006244 cables (SAES-J-902 Section 12.3.2)

bethat verified and repaired

the contractor using as expired

per approved welding procedure

power

During routine surveillance , it was found that piping

120 11/16/2009 16:38 1028346 supplies machines prior and to the welding backfilling. machine customer

spools

Duringstored TIE-INnot properly and directly attaching

(J06-19,J06-20,J06-21,J015 ) fire on water the

serial

During

RB-728445-078-02 areTIE-IN

(PM-5750, (J78-19,

line PM-5799 J06-10,

no:-J87-HSG-0207-01, DW J06-11,124) J0-13) IN J06 SPOOL-2,area

fire

129 9/9/2009 13:44 1004819 ground

systemwhich inspection, is not it permited

was found by SAES-L-350

that the flange para under7.1.

and

diameter (PM-5626,PM-5800)

water 30 system inches inspection,

is coming in 50

itclose ,51

was found area

to structure, and

that the this is

crossto

the fire hydrant become under ground, but according

172 12/12/2009 15:51 1036793 standard

contractor

bracing. violation

Thedecided according

to do service to Para test 19.2

.ButSAES-W-011.

according to

First

Para

DuringLogbook

7.2.2 TIE-IN&gap entry 1between

fig(J06-19, suggested

SAES-B-017 pipe

J06-20, the and

thisJ06-21,

cross

removal

flange braces

of installed

should

J0-15)

only

be

fire

Para20

pre-cast 12.6 mm. SAES-B-017

This

Electl/Instrument line is itcoming

is required

Manhole from to do hydro

J87-E-0107/9

#32-8 and test at

resume

176 11/21/2009 14:30 1030074 Contractor water system above ground

inspection, with it was 100 found mm. that the

connected psi forissued

Equipments

200

excavation 4toJ88-D-0301,

hours.

toJ87-C-0101; an

meettothe

RFI for

andrequiredupwhileplacement

J88-D-0302

till now aselevation

per there andis

and

isometric compaction

J88-D-303

asnoper replay

line

IFC it

contractor

of

was aggregates

installed decidedin base

Steel do service

course

Structure for testGrid

duct

#31 .But Line

bank according

in between

BC 1, 2, to

177 12/12/2009 15:58 1036802 will

First beLogbook

drawing; for

insulated. this

however

entry issue

This from

is a violation

during

suggested contractor

a surveillance

the of Aramco

removal side. visit,

of standard

PID

installed

Para

3,MH38-2 12.6

Elev.and

atSAES-L-310 SAES-B-017

+5000 MHPara 33-6

without it, is171 required

column meters toindo

base hydro

restoration

plate testofto

grouting

refer

noticed that contractor 12.4 which stated thatandminimum

195 11/21/2009 14:18 1030065 pre-cast

It

Asphalt

and is releaseElectl/Instrument

observed

Road, Itthat

from 200

was psidoing

several

steel observed

structure4the

forManhole

spoolshours. chipping/breaking

thatprior #32-8

are laying

Contractortoobstruction

resume

directly

equipment already

on

gap

top

excavation between

portion to of pipe

pre-cast

meet and

the any

manhole

required permanent in order

elevation to

as get

per the

IFC

contactplace to

installation,thethe base groundcourse

leveling without

plate materials end without

installed cover is for & Materials

flange face

structure

179 11/24/2009 16:06 1031506 During

required surveillance

elevation should

it during

causing was be a50mm.

observed

the deformation that scrap material

of installed

notdrawing;

Receiving

stability protected

only

however

Inspection.

and bynot wooden toFDT sheet.

has

withstand

surveillance

been Ittheisdone aadditional visit,

violation

for sixPID of SAof

holes

load

and

FBE

noticed painted

reinforcing

Routine that piping

contractor

visit bars

at SRU spools

and doing

this are

affecting the

morning placed the together

integrity

chipping/breaking

Sept. 06, inof

2009 SRU

the on

193 11/19/2009 7:20 1029318 the standard

andequipment,

all ref:-SAES

failed; Contractorbolt tightening L-350

is requested of Para

the 7.1&7.4.

to remove

anchor bolts allin

area.

structure

top Contractor

portion

particularly not of only

at should

pre-castat thePit

Sulfur maketop

manhole

where quarantine

portion, in but area

in materials

order

electrical also

to get to avoid

the

wiring thetwo

filled

theDHC-PIU and

foundations compacted

noticed is not

that base

yet course

tightened

pipingpiping construction and to and

be

alreadydone to

197 11/30/2009 16:23 1032530 J-87 openings.

required

Contractor

installation damage

elevation

issued

was As on per an to RFIpainted

observation

causing

progress forthe and spools.

deformation

placement

including evaluation,

and

cable of thepit,

installed

compaction

pulling

submit

installed afteranother

grouting

pipes atsampleand

local for

curing

support sieve ofLS-13, analysis

seven days

14-7, test from

prior

14-2, to the

14-3,

installed

FBE

of

DCHPIU

Routine aggregates pre-cast

reinforcing

noticed

site visit base manhole

bars

that

@ SRU and

course

cable main is rejected

affecting

for

pullingpipe duct the

pit

rack bank

orand contractor

integrity

in

electrical

area between

found ofhandthe

that is

16 8/27/2009 11:38 1000348 installation

14-4,required source

14-6, and of to

any be witness

equipment.

LS-15 without structural by PID

SAPMT in-charge.

and Contractor

alignment and

structure

hole MH38-2

while wall isnot

and

structural to MHconstruct/install

only

constructedsteel at the

33-6 ,

using

alignment top portion,

171 meters

4 a

inches

and new in

high one

but per

also the

restoration

Concrete

strength site

Hollowtwo

of

bolt

are

base requested

grouting.

Contractor to remove

SAPMT

submitted RFIthe

and forequipment,

Contractorinspection are of re-check

requesting

structural theto

42 8/4/2009 16:16 991467 Asphaltopenings.

Block

tightening Road,AsIt

instead ofper

was

freshly conditions.

observation

observed concrete. and

that evaluation,

Contractor

Aramco the

already

Standards

submit; alignment,

alignment RFIandoffor torqueing

grout

Inspection

Compressor and was

cured justbefore

of Structural

Shelter 1finished

Grid installingat

alignment

1-3 line the

LineA1-C, 1a

prior to

installed

5drawingplace pre-cast

the base

DA-950136-001 manhole

course is

materialsrejected

Electrical without and contractor

Materials is

43 10/10/2009 13:47 1013822 and grid

to grouting,

DHC-PIU A toRFI

during C. inspection

Construction

for equipment.

Inspection group

observed of Manhole immediately

Non-Shrink

that

andGrout

some

Hand

start

steel

hole required

Receiving was

installing made to

Inspection.

pipe construct/install

upspool of FDT

freshly has

on second a

been

concrete. new

level done one

Also

of pipe per

for six

from site

rack holes

IFC

preparation

members

Routine are

siteand formworks,

dirty

visit and

at D some415 RFIwith for inspection

damage of

galvanized Non-

44 8/4/2009 14:10 991348 and

drawing

support alleven

failed;

no JMixing, 87Contractor

P RA-729557

structural conditions. is area

foundation requested

sheet

last Nov.remove

no to

installation 001 rev

02, 2009

no all

00as

Shrink

coating.

During notice Grout RFI was

that

inspection stairs of Placement

rejected

for

on two

going as

rack per and PIP

support

internal Sampling

STS05130

liningaround aswas well

Para.

two

installation

not

thisfilled

yet hand andhole

complete. compactedor cable

Grouting base

pulling course

installation pit materials

shall

was be not and

constructed

yet doneto

46 10/20/2009 8:26 1017785 6.1.1

ofequipmentcuring

and

sulfur pit for

SAIC-M-2004

forwith 7SRU,days

reference prior

Item

it for

has to

A4, pipe

drawing

been Al l

noted installation.

materials

no.that 415-A-NA- are

installed kept

submit

made

between upanother

of

baseconcrete sample

plate not

and sieve

concrete

concrete analysis

hollow

foundation test

block. from

DCHPIU

pedestal. the

free of dirt,

576262-001 grease and other foreign matter. to Contractor

47 8/26/2009 12:43 1000004 structural

Document

require

Installationsource steel

SAPMT oftowas

support

review beand

additional

permanently

and

witness insurveillance

bottom

Contractor

load by (pipe

PID installed

slab

to of the

inspection

in-charge.

demolish

spool)

ladder

was

pit

thisonwas

not

ismaderequested

foundation up and with

of to raising

clean

galvanized andRFISub retouch

tosteelcheck damage

alignment togalvanized

anddrain bolt

Transformer

structure

meetingRoutine the Yards

Saudi replace at

Aramco SRUinmild accordance

InspectionStation welded on installed

with

ChecklistIFC stainless

drawing

SAIC M

50 9/24/2009 15:22 1008504 coating

tightening.

steel

pipe plate

from assiteper

anchor.

visit

Attachment

containmentstandard at D

Welding

415

IV procedure

wall toof area

Schedule

to

last

galvanized

catch prior Nov.

Q

basin; to 02,

section

mild based

2009

erection.

steel 1.2

on to

mention

1069

notice in compliance

noted

that in the for

stairs remarks to Aramco

two rackthatsupport Standards

support drawing

foundation

around two

IFCand section

stainless

drawing steel 1.3iswas

with drawing being

prohibited no violated.

simply

J87 Q Contactor

because

RA-731576 shall

it was

sheet

2 9/7/2009 16:20 1004176 released

equipment is neededwithPlan stated.

prior for drawing

reference structural no.or415-A-NA-

equipment

follow

dissimilar

no 001 the Quality

metal.

rev no Issued 3A this asFor perConstruction

drain Schedule

pipe hereby wasQmade Requirement.

drawing up of calls

installation.

576262-001SAPMT/Contractor was permanently is installed to advice

ladder to

25 11/5/2009 8:03 1024120 schedulefor stainless

80 steel

PVC pipe. (SS316)

Aramcoload shall

Standard be used for all

requirement

refrain installing additional

foundation with out raising RFI to check alignment and unless structural

embedded per SAES

Contractor / miscellaneous

Sis 20advisedparagraph steel

to maintain 4 drain installedthepipe inside

from this

clearance theofpit.

41 10/14/2009 12:36 1015579 bolt tightening.foundation Attachment is complete IV toand Schedule release Q section

Issue

structure

crossed was raised

Oil

underground Filled contractor

Transformer

piping and conduitsSAPMT

containment for immediate

wall to

45 11/23/2009 13:57 1030961

1.2 and section

Routine site visit notedaction 1.3 was the contractor is startingside

being and violated. at

Contactoreast for of

shall

catch

RTR-DHT basin near shall CR-062 used theasapproved per SAES-P-104 materialSection mention

follow the Quality to

cable termination Plan theasinstrumentation

per Schedule Qcabinets Requirement. while

on 10.13.paragraph minimum 5 section 5.1.1.1 crossingofwith orthis standard. SAPMT

48 11/5/2009 8:11 1024122 some ofThe cabinets are covered parallel

blankets, clearance

cables

and between

Contractor required

direct buriednot tocables

remove or and conduits replaced and this

underinspection

During the raised offloor

the dressed

installation of nor Fieldarainged,

Junction

49 9/15/2009 14:56 1006876 underground piping,are material

including hydrocarbon pipelines

extralength of cables

Box in Pipe Rack area of RTR-DHT it was observed that rolled not cut forien materials

70 10/7/2009 8:13 1012733 that fall outside the scope not cleaned. of SAES-B-064, shall be 300

there

cable are some bedamaged steel plate where thattag number

mm.tray For to conduits, suported the crossingin such away

clearance only

may one

be

95 7/8/2009 13:40 978940 is attached

splicing and

joint riveted

is allowable on the cover

between of FJB

two suports.and creates

reduced to 80 mm, if underground obstructions make it

holes on the loosed rivet, and it will lost the integrity of

7 9/4/2009 7:42 1002983 difficult to meet the 300 mm requirement. For direct

the enclosure as a NEMA Type 4X or IEC 60529 Type IP

buried cables, the same reduction is permitted if the

66Contractor

which will is violate theto requirements of SAES-J-902

8 9/4/2009 7:45 1002984 cable is installed advised in a PVC sleeve followatthe theinstallation

crossing. Direct of

SomeSection

supports installed

7.1

for hanger

which

the cablestates support

tray that at was

Enclosures

Pipe not

rack comlying

areain severe with

buried cables,

Contractor is M advised conduits, to install or duct supports banksinshall vertical not per

as be

cable

20 10/18/2009 8:39 1016898 corrosive

SAES-P-104 SAES environments

Section 100 Sec 9.5. Dshall. It be

Location need NEMAof rectification

Type 4X

Supports for orcable

IEC

installed

tray elbowdirectly above or below

as per requirement of NEMA parallel VE-2underground

Sec. 4.4.1.

60529 Type IP

tray systems shall piping. 66. Enclosure must

be in accordance with the be raintight,

98 12/3/2009 11:26 1033621 Vertical cable tray elbows at the top of runs should be

watertight, and corrosion

recommendations of NEMAresistant. VE-2. Splice Fix the plates damaged

(joints)

supported

Contractor at eachisthe advice end.that At the beforebottom of runsthe

installing should

Field be

100 12/12/2009 7:45 1036479 shall cover

not be with located manufacturers

over supportsrecommendation and shall be located

supported

Junction Boxes at theput toptouch of the upelbowcoatings andat within

any bare 600mm metal (2

between supports and quarter points. No more than

107 12/3/2009 8:54 1033532 for allft.) theofsupports

the lower at extremity

Pipe Rack of area theofelbows. RTR-DHT as

one splice shall be located between two adjacent

per SAES-P-104 Section 8.10.2. Also, provide grounding

116 12/3/2009 10:59 1033607 supports.

for all the enclosure for field instrument (Field Junction

121 12/7/2009 13:24 1035053 Box) as per SAES-J-902 Section 17.2.2.

3 9/1/2009 19:01 1002230

4 9/1/2009 19:09 1002232

5 9/1/2009 19:11 1002233 During this RFI verification, PID found that the distance

from the high point of pavement to catch basin # 41 in

6 9/1/2009 19:17 1002235 the compressor

During area exceedsPID

the RFI verification, thefound

limit stated

that theindistance

SAES S-

After discussion between SSA and PMT, its agreed that

020,

fromPara.4.6.2 and the

the high point slope resulted

of pavement is less

to catch than

basin 1.5%

# 35 in

9 9/6/2009 18:42 996905 the area was designed for SWS and not OWS. Per the

as compressor

the stated in SAES

areaS-020, Para.4.6.3.

exceeds the limitPlease,

stated inprovide

SAES aS-

SWS design, the required minimum velocity is

10 8/9/2009 19:19 993433 correction

020, for this

Para.4.6.2 and violation

the slopeand issue a new

of resulted RFI.

is less than

maintained. However, PMT confirmation is required to

1.5% as stated in SAES S-020, Para.4.6.3. Please,

12 8/9/2009 19:19 993433 close the issue.

provide a correction for this violation and issue a new

17 8/9/2009 18:55 993420 RFI.

22 9/21/2009 13:21 996918

Cancelled because of continuous rain. Raise another

During RFI inspection, two pockets out of 12 found

23 12/6/2009 5:08 1034555 PID found that theRFI base whenplates ready.

are not coated. Correct

containing filler board material sticking to internal

and re-invite PID. This violates 12 SAMSS-007, Para.

24 11/30/2009 16:55 1032553 surface which need to be removed. Issue new RFI.

6.3.1.6 that states "The bottom of base plates shall be

27 12/7/2009 5:13 1034914 clean and free of any rust or corrosion.".

No confirmation yet by PMT regarding the change in

28 11/24/2009 18:32 1031605 pavements segment.

No confirmation yet by PMT regarding the change in

29 11/24/2009 18:30 1031603 pavements segment.

For compressor B, one pocket found out of plumbness.

32 12/7/2009 5:15 1034915 Base plates found uncoated, job not ready.

Need

During correctionofand

inspection re-inspection.

panelboard However, for

J87-211-PP-007 found

36 12/5/2009 12:19 1034228 that, the comressor

circuit breakersA, itand

is acceptable.

branch connections in

For the cable entry at cabinet, contractor does not

62 11/2/2009 16:58 1023172 same enclosure.

comply This is a violation

the requirements of 16-SAMMS-518

of NEC 110.12 & 312.5

For the cable

section 5.7. AS entry

per at cabinet, contractor

16-SAMSS-518 sectiondoes5.7,not

in

63 11/2/2009 17:06 1023179 comply the

electrically requirements

classified area, the of NECpanel110.12

boards&shall312.5be a

For the cable entry at cabinet, contractor does not

factory sealed and design with the branch circuit

64 11/2/2009 17:12 1023185 comply the materials

Electrical requirements shallofbeNEC 110.12from

traceable & 312.5

the

connections and the breakers in separate

manufacturer and supplier through delivery, storage,

67 11/30/2009 6:11 1032308 Damaged MVerection, compartments.

cables shall be repaired. Cable trays and

fabrication, installation, repair, modification

The Interface

supports Relay Panel

installation shallno. J88-IRP-01and

beAttachment

completed doesapproved

not have

68 12/5/2009 17:55 1034524 and use as

Contractor per Schedule

Should ProvideQLoad Calculation IV, or

Section

Cable3.fill

space

prior toheater which is aand

the inspection requirement

acceptance onof16-SAMSS-514

the MV cable

71 12/8/2009 11:20 1035180 Thereport

cable wether this 150mm

trays expansion guide cable tray installed

clamps satisfy the does

installation as per thesection. SATIP. 7.4. No cable tray covers shall

requirement of SAES-J-902

not have sufficient gap for Section

the cable9.6&9.7.also

tray thermal sharp

be installed until the whole system from Substation no.

72 11/18/2009 17:17 1029204 edges should

expansion movement andbe removed.

it does not function as a

91 to Substation no. 222 has been cleared from the

expansion guide clamp. Supports on the vertical cable

75 12/9/2009 17:27 1035913 SAPID and the Proponent.

tray elbows shall be installed as per NEMA VE2. This is

77 11/29/2009 15:10 1032274 Contractor is using notcalibration

acceptable.testing equipment

Testing equipments/instruments calibration agency shall

calibratedCable

Electrical by Fugro

traysSuhami

from which no.

column is not

13approved

to party.

24 at the by

78 11/3/2009 19:19 1023676 be approved by Saudi Aramco as a third

Saudi

DHTAramco.

Main Contractor

piperack doesto follow

not complyschedule the"Q"and

(1)Maintain parallel clearance between the toConduit

79 11/28/2009 12:36 1032162 requirements AttachmentIV para

The7.

RTR PIPE in SubofStation

NEMA Side. VE2. (2) cable should

Rebar tray onbe

80 11/11/2009 15:15 1026421 adjustable splice plate (swivel)supports

installed in PIB Side. were more than

Space

600 mm. heater shallbesplice

Expansion provided

plates within

werethe notpanel as per

provided on

81 12/8/2009 11:18 1035187 every 20 meters 16-SAMSS-514

(Grid 18-19).para 7.4.1 guide clamps

Expansion

Testing equipments/instruments calibration agency shall

does not function as a guide clamps and does allow

82 11/3/2009 19:19 1023676 Thebecable

approved by Saudi Aramco

trays expansion as a third

guide clamps party.does

installed

movement

The contractor for expansion.

has utilizedBeam two (2) clamps

Digitalwere installed

Multi-meters

not have sufficient gap for the cable tray thermal

83 12/9/2009 5:19 1035582 as guide

for the Dischargeclamps

testand hold-down

of the UPS andclamps.

Battery DC

expansion movement and it does not function as a

system without calibration sticker and calibration

84 12/4/2009 5:22 1033907 expansion guide clamp.

certificate. This is a violation of Schedule Q Attach. IV

87 11/17/2009 18:34 1028849 section 6.1.

Contractor does not comply SAES-P-104 section 9 and

VAF-Contractor

The cable trays does not comply NEMA

expansion VE-2, section

does9

90 12/8/2009 15:27 1035499 The cable trays expansion NEMA guide VE-2. clamps

guide

installed

clamps installed does

ofnot

SAES-P-104 and section

have sufficient gap for9.1 theofcable

SAES-P-111 for the

tray thermal

not have sufficient gap for the cable tray thermal

91 11/10/2009 16:58 1026106 expansion movementinstallation and of itcable

doestray.

not function as a

expansion movement and it does not function as a

expansion guide clamp. Furthermore, The beam clamps

92 11/29/2009 15:10 1032274 expansion guide clamp.

that hold the expansion guide clamp down are not as

1. Item A8 not in compliance to standard, rectify and

93 12/4/2009 5:22 1033907 per the manufacturers mounting recommendation.

issue another RFI. 2. Install missing labels on Fire

124 10/17/2009 17:37 1016767 damper access doors (2 Nos.)

Not meeting

False items were

ceiling Panels no. A2installed

and A3 in ofinstrument

SAIC -K-4017. rack

125 10/22/2009 15:13 1018860 room and thats Correct whyand re issue another

inspection couldnt be RFIcarried out.

Not meeting items no. A2 and A3 of SAIC -K-4017.

Contractor shall re-schedule the RFI whenever these

126 10/22/2009 15:04 1018847 Correct and re issue another RFI

panels are removed to verify all related inspection items

Base bolt holes in equipment saddle in fixed end is not

128 10/19/2009 6:25 1017259 per the checklist.

matching with original ( final drawings ).Need to be

137 8/25/2009 16:39 999786 retify by vendor recommendation.

145 9/23/2009 8:24 1008190

148 10/7/2009 17:17 1012454 Samsung cancel this RFI,,,, surface still not ready

153 10/2/2009 8:02 1010437 job not ready, scaffold not yet fix...

155 10/20/2009 10:54 1017887 does not comply with the requirements

166 11/14/2009 16:45 1027482 work not yet ready,

13 8/14/2009 16:09 995471

Alignment check was needed prior to install grout or

Alignment check on stair was required prior to install

19 10/26/2009 18:15 1020372 concrete

Installed at thefoundation

stair concrete foundation. RFI is required

was not in compliance per

grout orcovering

Required concreteofatexisting

concrete foundation.

re-routed ductRFIbankforfor

SAES Q 005 sec 4.3.2 item C and standards drawing

21 11/1/2009 16:58 1022684 alignment

alarm detector was check for stair is with

not complying needed.SAES P 104

AB-036106 sht no 002-rev 01 detail 2. Contractor were

table 2 note 2 and 3. SAPMT and Contractor to modify

26 10/26/2009 18:15 1020372 advice to rectify

this duct bank or access way to satisfy the required

30 11/6/2009 10:54 1024535 covering of duct bank to grade surface

This RFI is REJECTED east side of Road way from 151A

Construct stair foundation per SAES Q 005 sec 4.3.2

31 10/26/2009 18:15 1020372 to J 89 pipe rack was already one time backfilled up to

item

ThisCisand

a nonstandards

sense RFI drawing AB-036106

east side of Roadsht waynofrom002-

7th layer. Contractor is advice to remove the backfilled

34 10/26/2009 18:15 1020372 151A to J 89 pipe rack was rev 01 already on time backfill up

materials and re-back fill / compacted it layer by layer

to 7th layer. Contractor is advice to remove the backfill

37 11/18/2009 8:51 1028938 per requirement of SAES A 114 Aramco standards

materials

This RFI isand re-backeast

REJECTED fill / side

compacted

of Roadlayerway itfrom

by layer

151A

38 11/18/2009 8:38 1028930 toperJ 89requirement

pipe rack was of SAES

already A 114

one Aramco standards

time backfilled up to

OneInstalled

supportfoundation

missing for was not compliance

the horizontal 90 theto attached

degree elbow

7th layer. Contractor is advice to remove backfilled

39 10/26/2009 18:15 1020372 IFC Drawing

( within 600mm) and SAESrack

at pipe Q 005

top.sec.4.3.2

Cable item

tray c be

shall

materials

One supportand re-back

missing forfillthe

/ compacted

horizontal 90 it layer

degree by elbow

layer

Stair structure

grounded as perelement

section installedofat first level was not

40 11/18/2009 8:55 1028940 ( per requirement

within 600mm) at SAES9.1.1

of pipe A 114

rack

SAES-

top.Aramco

P-111.

Cable tray

Cable

standards

shall be

align.

tray Contractor

support field is cutting

advice to andrectify

weldedandarea

raiseshall

another

be

grounded as per section 9.1.1 of SAES- P-111. Cable

33 11/20/2009 9:17 1029760 touch up with RFI upon complition

approved coating. Expansion guide

tray support field cutting and welded area shall be

clamps are installed not properly, no sufficent clearence

69 11/25/2009 18:06 1031934 touch up with approved coating.

for the thermal expansion movment. It is a violation of

74 11/25/2009 18:06 1031934 SAES-P-104 section 9 and NEMA VE-2.

Durring site visit it was observed that CS rollers and

lifting chains are used for stainless steel pipes handling.

171 11/23/2009 13:33 1030939 J88 this is not permitted due to metllurgical view.

In DHT area large piping circuits are connected with

heat exchangers nozzles. These circuits are not

provided any temporary supports. The only sporting

elements in these circuits are exchanger nozzle

connections which cause the maximum stresses at the

nozzles. So contractor advice to provide temporary

174 11/15/2009 17:02 1027956 J88 supports to avoid any problems.

durring rutine site vist it was observed that the spools

are laying direct on the ground and als not protected by

end covers which cause the soil and other foriegn

materials in to the spools.this may also cause the flange

face serration damge. this is voileted as per SAES L-350

186 10/17/2009 16:39 1016732 J88 para 7.1, 7.4, 7.2

During site visit it was observed that calibration of 5

welding machines expired but contractor still using

those machines without calibration of the machines. it

189 12/12/2009 15:53 1036795 J88 was violated as per W-11 para 19.2

1 9/7/2009 9:27 1003986 Not accepted

11 9/7/2009 7:55 1003938

14 9/8/2009 8:08 1004278

18 8/8/2009 13:01 992757 IT WAS REJECTED

51 9/7/2009 9:27 1003986 yu

WITHOUT EQUIPMENTit ID

During surveillance wasAND DESCRIPTION

noticed that for theRFI

141 8/27/2009 15:55 1000504 RAISED AND IT

instrument cable tagging the WAS REJECTED.

contractor doesnot comply

with the requirements os SAES-J-902 paragraph

157 12/6/2009 12:57 1034706

16.2.1.1 which states that all homerun cables shall be

Nchor bolts in P1 foundation is short of 23-38mm,

103 12/6/2009 10:25 1034638 J88 tagged with assigned "IC" cable number.

Contractor is requested to submit repair procedure prior

Top reiforcing bars was exposed during installation of

136 8/25/2009 15:21 999743 to erection of equipment.

leveling plate, waiting for repair procedure from

Anchor boltas at foundation P1 was short of 23-38mm,

138 8/13/2009 16:54 995361 contractor.

contractor are requested to submit repair procedure

139 8/25/2009 15:24 999744 prior to erection of equipment.

As a proactive notification, contractor is advised to

maintain the cable filling percentage inside cable trays

as it is required by SAES-J-902 Sec 9.7 and NEC Art

140 9/6/2009 15:35 1003785 During Surveillance,

SAES-J-902 JobSecnot 13.3.3 It was

ready states

and observed

itthat Cable

isWhere thattrays

rejected. some of the

beneath

1.A For direct

392.9

scratch (B) which

paper buried

was statescable,

being that

usedPower cables

onbolts adaily

ladder

a cabinets and or and

work

wire

raised is

ducts incomplete,

floor orshall

guttersbe found

inside

adequately that

marshallingbase

identified arebasis

using missing

are full

suitable

instrumentation

ventilated

the proper trough

log cables

was cable shall

filled tray

in cross

having at aright

usable angles(90

inside

143 9/5/2009 15:32 1003388 with signal and

permanent cables, not properly

which

tagmaintaining

plates. is at

These the

installed.

not tag end

acceptable

plates of shall

the asday.

itbeis

depthdegrees)

Persons 150while

of other mm than (6the in.)Welding

or less the required

contains

Consumable separation

multiconductor

Controller

required

installed by at Seceach7.9.3 end, of Tee

34-SAMSS-820,

connection states

and at that

threethe

52 11/10/2009 13:37 1025963 Control distances

and/or

were intervals.

signing outas

signal per SAES-J-902

cables

electrodes. only,

2.Welding the Secsum14.2.10.

of the

consumables cross-

maximum

meter plastic wire

The duct

tag fill (including

plates shall be located spare capacity)

so that

sectional

were issuedareas of all to

directly cables

welders at any and cross

not section

the Weldingshall

65 10/4/2009 8:08 1011461 it is clearly shall not exceed

visible. The tag 75% plates of its depth.

shall contain, as a

not

The exceed

connection

Foreman/supervisor 50 percent

list for of the interior

asinstrument

required. cross-sectional

wiring

Welders and

were tubing

also

minimum,

Contractor received the noise susceptibility

some pipe supportslevel of the circuits

at fabrication

66 9/28/2009 16:48 1009677 (SRU/Flare

During

returningour visitUnit)

their area

Yesterday

own of

Document theJune

rods. cable

No.13,2009

3.Sign-out tray. of to

J87-J-RE730126 the NESMA

70S used

Fab.

shop

1. enclosed

fabricated

Welders, not (per in section

NESMA

Welding 14.1)

Dammam.

Foreman, source, 1)PID

checking and thewire

was

out not

rods

for

Shop wiring/termination

was @ Dhahran

not always Werecordedinside

found instrument

non-conformities

in the log. 4.Atcabinets as

times is not

follows:

the

111 11/17/2009 16:11 1028763 Nesma

noticed failed

for 2. to Nonotify

receiving destination.

SaudiofAramco of being

the vacation

RFI forofis

from

approved

1)There issuer.

welding isand

no Issued

foremanQC available.

wouldforinspection

records

just

70S(there

Construction.

2)WPS

walk

wire

is The

not

into

is no

the posted

room

recorded

contractoratandfab.

Mr.issued

receiving

when Khalid

inspection

orShubbar, for the Supervisor

material of QC in

before infabrication).

Nesma

117 11/14/2009 8:53 1027194 a advised

Shop.

grabFabrication

new box toreturned.

3)4 offollow

welders

wireatand the This

havebring

will

approvednoitresulttodrawings.

Aramco

the field

traceability

JCC.

2)This

issues. 3. activity

Logs Shop,

are wasnot not least

beingincluded30 days

signed. in 4. ahead

two weeks

Scratch of without

his

look is

paper

4)Baking/holding

having recorded ovens

itvacation. in the are

log.not 5.Whileworking.(calibration

we were there,

158 6/20/2009 8:24 969528 ahead. used 3)Contractor

as the This

daily logviolates

fabricated

prior to Schedule

the saddleQ.

transferring supportthe not

sticker expired).

two welders came 5)Welders used electrode

in for electrodes and the 7018issuerwithout

was

as per aramco

paperwork. drawings.

5. portable

The consumable a)All welding

issuer shall

was an beassistant

sealed

159 6/14/2009 11:47 966493 going to issue them even ovensafter (quivers).our discussion. This

weld.

and b)Open

Nesma saidwindow

the original has sharp issueredge was shall

no longer be groundthere.

action was stopped. 6.The Consumable Controller is not

160 6/14/2009 7:47 966357 radius.

The assistant had limited knowledge to be in this

signing

The doorthe of daily

baking logovenreports as required.

for welding Some previous

consumables in the

position. 6. inspection,