Professional Documents

Culture Documents

Visual Test Procedure: P & S Technical Consultant and Serviced Co.,Ltd Visual Examination Report

Visual Test Procedure: P & S Technical Consultant and Serviced Co.,Ltd Visual Examination Report

Uploaded by

pstechnical_43312697Copyright:

Available Formats

You might also like

- Sample BMRDocument16 pagesSample BMRspp94% (18)

- HKSMM4 - Building Works (4th Edition-2005) RevDocument221 pagesHKSMM4 - Building Works (4th Edition-2005) RevSiu Eric100% (4)

- RT Film ReviewDocument1 pageRT Film Reviewpriti kumariNo ratings yet

- Welding Procedure For BOXNR Wagon (WPS)Document8 pagesWelding Procedure For BOXNR Wagon (WPS)Shekher Nikhil100% (1)

- Keyway Sizing ChartDocument1 pageKeyway Sizing Chartpstechnical_43312697No ratings yet

- JAFZA Construction Regulation - Third Edition 2003Document73 pagesJAFZA Construction Regulation - Third Edition 2003Abdul JabbarNo ratings yet

- Pin BrazingDocument10 pagesPin BrazingNguyen Ninh BinhNo ratings yet

- Welder Qualification ReportDocument2 pagesWelder Qualification ReportSyed Mahmud Habibur RahmanNo ratings yet

- Pci-Pr-64-08 Procedure Magnetic Particle ExaminationDocument8 pagesPci-Pr-64-08 Procedure Magnetic Particle ExaminationAbdallahNjehNo ratings yet

- SSIS Visual Examination Report FormatDocument1 pageSSIS Visual Examination Report FormatSalman KhanNo ratings yet

- Wps Imco Is-101801-17 Saw Twin Arc - Aws d1.1 Rev 01Document14 pagesWps Imco Is-101801-17 Saw Twin Arc - Aws d1.1 Rev 01Mark AnthonyNo ratings yet

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiNo ratings yet

- RTCC Manual WPS Approval WE-WPS-001Document7 pagesRTCC Manual WPS Approval WE-WPS-001Akansha SharmaNo ratings yet

- CV of Engineer MD Sazid Alam1Document8 pagesCV of Engineer MD Sazid Alam1Alam MD SazidNo ratings yet

- Ut 4 PDFDocument42 pagesUt 4 PDFtusharNo ratings yet

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

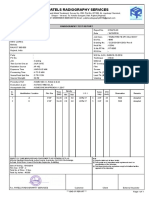

- Radio Graphic Examination Report: International GroupDocument1 pageRadio Graphic Examination Report: International GroupMuhammed Abo-FandoodNo ratings yet

- Paut 16Document4 pagesPaut 16maroof mNo ratings yet

- Welder Performace Qualification Report 2014..Document132 pagesWelder Performace Qualification Report 2014..Kayra Riri ChirulNo ratings yet

- RT SoftDocument16 pagesRT SoftMaged Lotfy Abdel-aalNo ratings yet

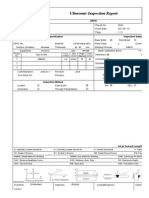

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 pagesUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mNo ratings yet

- Ultrasonics Blank ReportDocument3 pagesUltrasonics Blank ReportSteven GoughNo ratings yet

- AsuuuuuuuuuuuuDocument22 pagesAsuuuuuuuuuuuuyusuf akbar100% (1)

- T.C.L. Co. - Test & Control LaboratoriesDocument2 pagesT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταNo ratings yet

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Document2 pagesPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorldNo ratings yet

- M 2 SAW D1.1 2015 Form PDFDocument1 pageM 2 SAW D1.1 2015 Form PDFyounessNo ratings yet

- SAIC-W-2077 Weld Joint Identification SystemDocument1 pageSAIC-W-2077 Weld Joint Identification Systemkarioke mohaNo ratings yet

- Demo SUMDocument27 pagesDemo SUMRudolph RednoseNo ratings yet

- 4845 PDFDocument1 page4845 PDFRavi patelNo ratings yet

- API 1104 ComplateDocument24 pagesAPI 1104 ComplateAwale UdinNo ratings yet

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- Test Report 11 Pcs Padeyes THR Room GCIIIDocument6 pagesTest Report 11 Pcs Padeyes THR Room GCIIIJurand Juri100% (1)

- Novotest T Ud3Document2 pagesNovotest T Ud3bejoNo ratings yet

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Visual Examination Procedure: 1 - PurposeDocument4 pagesVisual Examination Procedure: 1 - PurposeElvin MenlibaiNo ratings yet

- Epz NCS RT 02Document1 pageEpz NCS RT 02Mijanur RahmanNo ratings yet

- Indt QCP RT HJ 05NDocument14 pagesIndt QCP RT HJ 05NAsad Bin Ala QatariNo ratings yet

- All 24.05.16Document139 pagesAll 24.05.16Siva Prasad100% (1)

- Ultrasonic Angle-Beam Contact Testing: Standard Practice ForDocument9 pagesUltrasonic Angle-Beam Contact Testing: Standard Practice ForNubia BarreraNo ratings yet

- Asme Questions and Answers Part IIIDocument6 pagesAsme Questions and Answers Part IIIYan FerizalNo ratings yet

- Porosity in WeldingDocument13 pagesPorosity in Weldingbn pandeyNo ratings yet

- Form PAUTDocument2 pagesForm PAUTLuong Ho Vu100% (1)

- BPVC Ix Qw-484aDocument1 pageBPVC Ix Qw-484aTC Capulcu Mustafa MNo ratings yet

- VT Report UpDocument1 pageVT Report UpRakesh Kumar MundaNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- 05-Welder Certification PDFDocument11 pages05-Welder Certification PDFAnonymous bfxeE1zvY100% (1)

- New Microsoft Excel WorksheetDocument6 pagesNew Microsoft Excel Worksheetravi00098No ratings yet

- Aws It 201611Document41 pagesAws It 201611AngelTinocoNo ratings yet

- Procedure Qualification Record (PQR) FormDocument1 pageProcedure Qualification Record (PQR) FormEarl HarbertNo ratings yet

- Comparison ASTM A 3388 & ISO 11496Document1 pageComparison ASTM A 3388 & ISO 11496Rahul MoottolikandyNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Radiographic Examination ReportDocument1 pageRadiographic Examination ReportKareem AbdelazizNo ratings yet

- Positive Material IdentificationDocument2 pagesPositive Material IdentificationGovindKrishnan100% (1)

- M 2 GTAW SMAW D1.1 2015 Form PDFDocument1 pageM 2 GTAW SMAW D1.1 2015 Form PDFRameshBaskaranNo ratings yet

- Liquid Penetrant Test Procedure: Document No.: SP-1.5 Rev. 1.2Document12 pagesLiquid Penetrant Test Procedure: Document No.: SP-1.5 Rev. 1.2Anas PratamaNo ratings yet

- Examination Procedure: G.C. Van Der Stoep Procedure TechnicianDocument30 pagesExamination Procedure: G.C. Van Der Stoep Procedure TechnicianEdAlmNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- Welder Qualification Test CertificateDocument1 pageWelder Qualification Test CertificateManivannanMudhaliar100% (1)

- QW-483 (Red) PQR No.: Tme 358Document1 pageQW-483 (Red) PQR No.: Tme 358Sudhir KotkarNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report NumberDocument6 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Numbersudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00195Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00195sudipta dasNo ratings yet

- Inspection & Test Plan: Dinding Penahan Tanah (DPT) BronjongDocument1 pageInspection & Test Plan: Dinding Penahan Tanah (DPT) BronjongRoy RahadianNo ratings yet

- IR204 - Siddheswari Evaluation - SUD 06.08.21Document2 pagesIR204 - Siddheswari Evaluation - SUD 06.08.21sudipta dasNo ratings yet

- แบบโต๊ะตัดDocument32 pagesแบบโต๊ะตัดpstechnical_43312697No ratings yet

- Project Completion Report 7Document1 pageProject Completion Report 7pstechnical_43312697No ratings yet

- Daily Activities Report 16-11-2017Document1 pageDaily Activities Report 16-11-2017pstechnical_43312697No ratings yet

- Daily Activities Report 15-11-2017Document1 pageDaily Activities Report 15-11-2017pstechnical_43312697No ratings yet

- BLCP Outage Work Schedule & Progress Rev.2 9-11-2017Document1 pageBLCP Outage Work Schedule & Progress Rev.2 9-11-2017pstechnical_43312697No ratings yet

- Daily Activities Report 13-11-2017Document1 pageDaily Activities Report 13-11-2017pstechnical_43312697No ratings yet

- Daily Activities Report 5-11-2017Document1 pageDaily Activities Report 5-11-2017pstechnical_43312697No ratings yet

- BLCP Outage Work Schedule & Progress Rev.2 13-11-2017Document1 pageBLCP Outage Work Schedule & Progress Rev.2 13-11-2017pstechnical_43312697No ratings yet

- TJELDaily Activities Report 25,10,17Document1 pageTJELDaily Activities Report 25,10,17pstechnical_43312697No ratings yet

- Bar ChartDocument1 pageBar Chartpstechnical_43312697No ratings yet

- BLCP Outage Work Schedule & Progress Rev.2 12-11-2017Document1 pageBLCP Outage Work Schedule & Progress Rev.2 12-11-2017pstechnical_43312697No ratings yet

- Daily Activities Report 12-11-2017Document1 pageDaily Activities Report 12-11-2017pstechnical_43312697No ratings yet

- 8790-85-0005 - 01 PLC Integral IODocument1 page8790-85-0005 - 01 PLC Integral IOpstechnical_43312697No ratings yet

- Daily Activities Report 6-11-2017Document1 pageDaily Activities Report 6-11-2017pstechnical_43312697No ratings yet

- 8790-85-1002 - 01 Local Control Panel Internal LayoutDocument1 page8790-85-1002 - 01 Local Control Panel Internal Layoutpstechnical_43312697No ratings yet

- 2 - Boiler HydrotestDocument22 pages2 - Boiler HydrotestMY NAME IS NEERAJ..:):)No ratings yet

- 8790-85-0021 - 01 Field Wiring (Control)Document1 page8790-85-0021 - 01 Field Wiring (Control)pstechnical_43312697No ratings yet

- M.E. (2013 Pattern)Document557 pagesM.E. (2013 Pattern)HimanshuNo ratings yet

- Module 6Document58 pagesModule 6Zbor ZborNo ratings yet

- SMMT AQMS FMEA Alignment AIAG and VDA - en PDFDocument32 pagesSMMT AQMS FMEA Alignment AIAG and VDA - en PDFNilton de OliveraNo ratings yet

- Alfatech Company ProfileDocument21 pagesAlfatech Company ProfileEugen Ionescu100% (1)

- Freeecbav3questionbank 170228143946Document31 pagesFreeecbav3questionbank 170228143946Sagar NaiduNo ratings yet

- Modular Coordination of Clay and Concrete Masonry Units: Standard Guide ForDocument4 pagesModular Coordination of Clay and Concrete Masonry Units: Standard Guide ForsanthakumarNo ratings yet

- How Microsoft Lost Its Mojo: Steve Ballmer and Corporate America's Most Spectacular Decline - Vanity FairDocument3 pagesHow Microsoft Lost Its Mojo: Steve Ballmer and Corporate America's Most Spectacular Decline - Vanity FairnebukadnezarNo ratings yet

- 5 6096094323005196623Document5 pages5 6096094323005196623Krish KashyapNo ratings yet

- Enterprise Resource Planning SystemsDocument242 pagesEnterprise Resource Planning SystemsBrenda100% (1)

- Ag BeltDocument759 pagesAg BeltAlexandru Stratulat100% (2)

- Precommisioning and CommissioningDocument24 pagesPrecommisioning and CommissioningPablo Quiroga L.100% (3)

- Turkish Metal Industry Report: Republic of Turkey Prime MinistryDocument25 pagesTurkish Metal Industry Report: Republic of Turkey Prime MinistryRoman SuprunNo ratings yet

- Project Completion ReportDocument363 pagesProject Completion ReportTony Sinambela100% (1)

- Transportation Engineering I CE 304Document37 pagesTransportation Engineering I CE 304Vibhanshu MishraNo ratings yet

- Connector Tooling GuideDocument180 pagesConnector Tooling GuideReginaldoNo ratings yet

- Nov. 30 Metro Board AgendaDocument19 pagesNov. 30 Metro Board AgendaMetro Los AngelesNo ratings yet

- Section G - Administration Instructions and Project Controls Page 24 of 51Document2 pagesSection G - Administration Instructions and Project Controls Page 24 of 51rajkumar4684No ratings yet

- VELCOM 2014-MSDS-Hydrokit-EU-webDocument4 pagesVELCOM 2014-MSDS-Hydrokit-EU-webAlexander Alberto Farfan MartinezNo ratings yet

- M250 C30 R3M OmmDocument13 pagesM250 C30 R3M OmmturboshaftNo ratings yet

- Introduction-To-Itil-4-And-It-Service-Management-22-2048 (20 Files Merged)Document20 pagesIntroduction-To-Itil-4-And-It-Service-Management-22-2048 (20 Files Merged)Ashish BhardwajNo ratings yet

- Breaking Communication Barriers2Document11 pagesBreaking Communication Barriers2Daniel Patrick ConnollyNo ratings yet

- Saskatchewan Detailed Occupational Outlook 2019 To 2023Document30 pagesSaskatchewan Detailed Occupational Outlook 2019 To 2023libra0009No ratings yet

- TeamForge 620 User GuideDocument336 pagesTeamForge 620 User GuidegiorgioviNo ratings yet

- 17.00 Loïc Pottier, Fives FCBDocument11 pages17.00 Loïc Pottier, Fives FCBMohd AliNo ratings yet

- Amararaja Batteries LTDDocument43 pagesAmararaja Batteries LTDMonish Rm100% (2)

- Pleasure Boat Thrusters WebDocument4 pagesPleasure Boat Thrusters WebCatalin CataNo ratings yet

- Sample CVDocument3 pagesSample CVmarvinjosephandalNo ratings yet

Visual Test Procedure: P & S Technical Consultant and Serviced Co.,Ltd Visual Examination Report

Visual Test Procedure: P & S Technical Consultant and Serviced Co.,Ltd Visual Examination Report

Uploaded by

pstechnical_43312697Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Visual Test Procedure: P & S Technical Consultant and Serviced Co.,Ltd Visual Examination Report

Visual Test Procedure: P & S Technical Consultant and Serviced Co.,Ltd Visual Examination Report

Uploaded by

pstechnical_43312697Copyright:

Available Formats

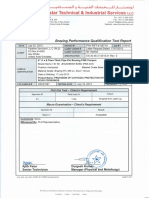

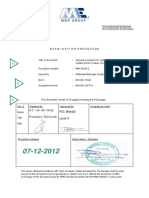

VISUAL TEST PROCEDURE

P & S Technical Consultant and Serviced Co.,Ltd

Visual Examination Report

Report No.: VT-U1-011 Examination Date: 20-8-15 Weldmap.: 130 BLADE STOP Unit 1

Client: BALTEC INLET & Project : Amata Bowin Combined Cycle

Job No.: V17488

EXHAUST SYSTEMS Congregating Plant Project

Part Examined: Drawing No.: 8614MA-130-0710

Material: SS400 Thickness:15 mm.,10 mm.

Reference Procedure Specification: Surface Condition: Good

Acceptance Criteria : AWSD 1:1:2010 Surface Temperature: 30 C

Method Description Equipment and Tools

Precleaning Method: Brushing/grinding Mirrors: X

Type of examination: Direct Welding Gauges: 1401

Lighting: Required Magnifiers: X

Stage of examination: After weld Borescope:

Other:

Joint No.

1. ST-001 9 17 25

2. ST-002 10 18 26

3. ST-003 11 19 27

4. ST-004 12 20 28

5. ST-005 13 21

6. ST-006 14 22

7. ST-007 15 23

8. ST-008 16 24

EXAMINATION RESULTS

Acceptable

Name Signature Date

QC. Inspector Ms.Fhontip M 20/8/2014

Client Representative

Authorized Inspector

Page 1 of 2

VISUAL TEST PROCEDURE

P & S Technical Consultant and Serviced Co.,Ltd

Checklist for Welding Examination

1. Before Welding

q Review applicable documentation Yes

q Check welding procedures Yes

q Check welder qualifications Yes

q Establish hold points Yes

q Develop inspection plan Yes

Develop inspection documentation system Yes

q Develop inspection documentation system Yes

q Develop system for identification of rejects Yes

q Check conditions of welding equipment Yes

q Check quality and condition of base and filler materials Yes

q Check joint preparation, fit-up, cleanliness Yes

q Check adequacy of alignment devices Yes

q Check preheat (or initial) temperature N/A

2. During Welding

q Check compliance with WPS provisions Yes

q Check quality, placement of key weld passes Yes

q Check weld bead sequencing and placement Yes

q Check interpass temperature and cleaning Yes

q Check adequacy of back gouging Yes

q Monito any specified in-process NDE N/A

3. After Welding

q Check finished weld appearance and soundness Yes

q Check weld sizes and dimensions Yes

q Check dimensional accuracy of the weldment Yes

Carry our or monitor / evaluate specified NDE Yes

q Monitor any PWHT or other post-weld work Yes

q Finalize and collate inspection documentation N/A

Page 2 of 2

You might also like

- Sample BMRDocument16 pagesSample BMRspp94% (18)

- HKSMM4 - Building Works (4th Edition-2005) RevDocument221 pagesHKSMM4 - Building Works (4th Edition-2005) RevSiu Eric100% (4)

- RT Film ReviewDocument1 pageRT Film Reviewpriti kumariNo ratings yet

- Welding Procedure For BOXNR Wagon (WPS)Document8 pagesWelding Procedure For BOXNR Wagon (WPS)Shekher Nikhil100% (1)

- Keyway Sizing ChartDocument1 pageKeyway Sizing Chartpstechnical_43312697No ratings yet

- JAFZA Construction Regulation - Third Edition 2003Document73 pagesJAFZA Construction Regulation - Third Edition 2003Abdul JabbarNo ratings yet

- Pin BrazingDocument10 pagesPin BrazingNguyen Ninh BinhNo ratings yet

- Welder Qualification ReportDocument2 pagesWelder Qualification ReportSyed Mahmud Habibur RahmanNo ratings yet

- Pci-Pr-64-08 Procedure Magnetic Particle ExaminationDocument8 pagesPci-Pr-64-08 Procedure Magnetic Particle ExaminationAbdallahNjehNo ratings yet

- SSIS Visual Examination Report FormatDocument1 pageSSIS Visual Examination Report FormatSalman KhanNo ratings yet

- Wps Imco Is-101801-17 Saw Twin Arc - Aws d1.1 Rev 01Document14 pagesWps Imco Is-101801-17 Saw Twin Arc - Aws d1.1 Rev 01Mark AnthonyNo ratings yet

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiNo ratings yet

- RTCC Manual WPS Approval WE-WPS-001Document7 pagesRTCC Manual WPS Approval WE-WPS-001Akansha SharmaNo ratings yet

- CV of Engineer MD Sazid Alam1Document8 pagesCV of Engineer MD Sazid Alam1Alam MD SazidNo ratings yet

- Ut 4 PDFDocument42 pagesUt 4 PDFtusharNo ratings yet

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

- Radio Graphic Examination Report: International GroupDocument1 pageRadio Graphic Examination Report: International GroupMuhammed Abo-FandoodNo ratings yet

- Paut 16Document4 pagesPaut 16maroof mNo ratings yet

- Welder Performace Qualification Report 2014..Document132 pagesWelder Performace Qualification Report 2014..Kayra Riri ChirulNo ratings yet

- RT SoftDocument16 pagesRT SoftMaged Lotfy Abdel-aalNo ratings yet

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 pagesUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mNo ratings yet

- Ultrasonics Blank ReportDocument3 pagesUltrasonics Blank ReportSteven GoughNo ratings yet

- AsuuuuuuuuuuuuDocument22 pagesAsuuuuuuuuuuuuyusuf akbar100% (1)

- T.C.L. Co. - Test & Control LaboratoriesDocument2 pagesT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταNo ratings yet

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Document2 pagesPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorldNo ratings yet

- M 2 SAW D1.1 2015 Form PDFDocument1 pageM 2 SAW D1.1 2015 Form PDFyounessNo ratings yet

- SAIC-W-2077 Weld Joint Identification SystemDocument1 pageSAIC-W-2077 Weld Joint Identification Systemkarioke mohaNo ratings yet

- Demo SUMDocument27 pagesDemo SUMRudolph RednoseNo ratings yet

- 4845 PDFDocument1 page4845 PDFRavi patelNo ratings yet

- API 1104 ComplateDocument24 pagesAPI 1104 ComplateAwale UdinNo ratings yet

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- Test Report 11 Pcs Padeyes THR Room GCIIIDocument6 pagesTest Report 11 Pcs Padeyes THR Room GCIIIJurand Juri100% (1)

- Novotest T Ud3Document2 pagesNovotest T Ud3bejoNo ratings yet

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Visual Examination Procedure: 1 - PurposeDocument4 pagesVisual Examination Procedure: 1 - PurposeElvin MenlibaiNo ratings yet

- Epz NCS RT 02Document1 pageEpz NCS RT 02Mijanur RahmanNo ratings yet

- Indt QCP RT HJ 05NDocument14 pagesIndt QCP RT HJ 05NAsad Bin Ala QatariNo ratings yet

- All 24.05.16Document139 pagesAll 24.05.16Siva Prasad100% (1)

- Ultrasonic Angle-Beam Contact Testing: Standard Practice ForDocument9 pagesUltrasonic Angle-Beam Contact Testing: Standard Practice ForNubia BarreraNo ratings yet

- Asme Questions and Answers Part IIIDocument6 pagesAsme Questions and Answers Part IIIYan FerizalNo ratings yet

- Porosity in WeldingDocument13 pagesPorosity in Weldingbn pandeyNo ratings yet

- Form PAUTDocument2 pagesForm PAUTLuong Ho Vu100% (1)

- BPVC Ix Qw-484aDocument1 pageBPVC Ix Qw-484aTC Capulcu Mustafa MNo ratings yet

- VT Report UpDocument1 pageVT Report UpRakesh Kumar MundaNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- 05-Welder Certification PDFDocument11 pages05-Welder Certification PDFAnonymous bfxeE1zvY100% (1)

- New Microsoft Excel WorksheetDocument6 pagesNew Microsoft Excel Worksheetravi00098No ratings yet

- Aws It 201611Document41 pagesAws It 201611AngelTinocoNo ratings yet

- Procedure Qualification Record (PQR) FormDocument1 pageProcedure Qualification Record (PQR) FormEarl HarbertNo ratings yet

- Comparison ASTM A 3388 & ISO 11496Document1 pageComparison ASTM A 3388 & ISO 11496Rahul MoottolikandyNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Radiographic Examination ReportDocument1 pageRadiographic Examination ReportKareem AbdelazizNo ratings yet

- Positive Material IdentificationDocument2 pagesPositive Material IdentificationGovindKrishnan100% (1)

- M 2 GTAW SMAW D1.1 2015 Form PDFDocument1 pageM 2 GTAW SMAW D1.1 2015 Form PDFRameshBaskaranNo ratings yet

- Liquid Penetrant Test Procedure: Document No.: SP-1.5 Rev. 1.2Document12 pagesLiquid Penetrant Test Procedure: Document No.: SP-1.5 Rev. 1.2Anas PratamaNo ratings yet

- Examination Procedure: G.C. Van Der Stoep Procedure TechnicianDocument30 pagesExamination Procedure: G.C. Van Der Stoep Procedure TechnicianEdAlmNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- Welder Qualification Test CertificateDocument1 pageWelder Qualification Test CertificateManivannanMudhaliar100% (1)

- QW-483 (Red) PQR No.: Tme 358Document1 pageQW-483 (Red) PQR No.: Tme 358Sudhir KotkarNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report NumberDocument6 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Numbersudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00195Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00195sudipta dasNo ratings yet

- Inspection & Test Plan: Dinding Penahan Tanah (DPT) BronjongDocument1 pageInspection & Test Plan: Dinding Penahan Tanah (DPT) BronjongRoy RahadianNo ratings yet

- IR204 - Siddheswari Evaluation - SUD 06.08.21Document2 pagesIR204 - Siddheswari Evaluation - SUD 06.08.21sudipta dasNo ratings yet

- แบบโต๊ะตัดDocument32 pagesแบบโต๊ะตัดpstechnical_43312697No ratings yet

- Project Completion Report 7Document1 pageProject Completion Report 7pstechnical_43312697No ratings yet

- Daily Activities Report 16-11-2017Document1 pageDaily Activities Report 16-11-2017pstechnical_43312697No ratings yet

- Daily Activities Report 15-11-2017Document1 pageDaily Activities Report 15-11-2017pstechnical_43312697No ratings yet

- BLCP Outage Work Schedule & Progress Rev.2 9-11-2017Document1 pageBLCP Outage Work Schedule & Progress Rev.2 9-11-2017pstechnical_43312697No ratings yet

- Daily Activities Report 13-11-2017Document1 pageDaily Activities Report 13-11-2017pstechnical_43312697No ratings yet

- Daily Activities Report 5-11-2017Document1 pageDaily Activities Report 5-11-2017pstechnical_43312697No ratings yet

- BLCP Outage Work Schedule & Progress Rev.2 13-11-2017Document1 pageBLCP Outage Work Schedule & Progress Rev.2 13-11-2017pstechnical_43312697No ratings yet

- TJELDaily Activities Report 25,10,17Document1 pageTJELDaily Activities Report 25,10,17pstechnical_43312697No ratings yet

- Bar ChartDocument1 pageBar Chartpstechnical_43312697No ratings yet

- BLCP Outage Work Schedule & Progress Rev.2 12-11-2017Document1 pageBLCP Outage Work Schedule & Progress Rev.2 12-11-2017pstechnical_43312697No ratings yet

- Daily Activities Report 12-11-2017Document1 pageDaily Activities Report 12-11-2017pstechnical_43312697No ratings yet

- 8790-85-0005 - 01 PLC Integral IODocument1 page8790-85-0005 - 01 PLC Integral IOpstechnical_43312697No ratings yet

- Daily Activities Report 6-11-2017Document1 pageDaily Activities Report 6-11-2017pstechnical_43312697No ratings yet

- 8790-85-1002 - 01 Local Control Panel Internal LayoutDocument1 page8790-85-1002 - 01 Local Control Panel Internal Layoutpstechnical_43312697No ratings yet

- 2 - Boiler HydrotestDocument22 pages2 - Boiler HydrotestMY NAME IS NEERAJ..:):)No ratings yet

- 8790-85-0021 - 01 Field Wiring (Control)Document1 page8790-85-0021 - 01 Field Wiring (Control)pstechnical_43312697No ratings yet

- M.E. (2013 Pattern)Document557 pagesM.E. (2013 Pattern)HimanshuNo ratings yet

- Module 6Document58 pagesModule 6Zbor ZborNo ratings yet

- SMMT AQMS FMEA Alignment AIAG and VDA - en PDFDocument32 pagesSMMT AQMS FMEA Alignment AIAG and VDA - en PDFNilton de OliveraNo ratings yet

- Alfatech Company ProfileDocument21 pagesAlfatech Company ProfileEugen Ionescu100% (1)

- Freeecbav3questionbank 170228143946Document31 pagesFreeecbav3questionbank 170228143946Sagar NaiduNo ratings yet

- Modular Coordination of Clay and Concrete Masonry Units: Standard Guide ForDocument4 pagesModular Coordination of Clay and Concrete Masonry Units: Standard Guide ForsanthakumarNo ratings yet

- How Microsoft Lost Its Mojo: Steve Ballmer and Corporate America's Most Spectacular Decline - Vanity FairDocument3 pagesHow Microsoft Lost Its Mojo: Steve Ballmer and Corporate America's Most Spectacular Decline - Vanity FairnebukadnezarNo ratings yet

- 5 6096094323005196623Document5 pages5 6096094323005196623Krish KashyapNo ratings yet

- Enterprise Resource Planning SystemsDocument242 pagesEnterprise Resource Planning SystemsBrenda100% (1)

- Ag BeltDocument759 pagesAg BeltAlexandru Stratulat100% (2)

- Precommisioning and CommissioningDocument24 pagesPrecommisioning and CommissioningPablo Quiroga L.100% (3)

- Turkish Metal Industry Report: Republic of Turkey Prime MinistryDocument25 pagesTurkish Metal Industry Report: Republic of Turkey Prime MinistryRoman SuprunNo ratings yet

- Project Completion ReportDocument363 pagesProject Completion ReportTony Sinambela100% (1)

- Transportation Engineering I CE 304Document37 pagesTransportation Engineering I CE 304Vibhanshu MishraNo ratings yet

- Connector Tooling GuideDocument180 pagesConnector Tooling GuideReginaldoNo ratings yet

- Nov. 30 Metro Board AgendaDocument19 pagesNov. 30 Metro Board AgendaMetro Los AngelesNo ratings yet

- Section G - Administration Instructions and Project Controls Page 24 of 51Document2 pagesSection G - Administration Instructions and Project Controls Page 24 of 51rajkumar4684No ratings yet

- VELCOM 2014-MSDS-Hydrokit-EU-webDocument4 pagesVELCOM 2014-MSDS-Hydrokit-EU-webAlexander Alberto Farfan MartinezNo ratings yet

- M250 C30 R3M OmmDocument13 pagesM250 C30 R3M OmmturboshaftNo ratings yet

- Introduction-To-Itil-4-And-It-Service-Management-22-2048 (20 Files Merged)Document20 pagesIntroduction-To-Itil-4-And-It-Service-Management-22-2048 (20 Files Merged)Ashish BhardwajNo ratings yet

- Breaking Communication Barriers2Document11 pagesBreaking Communication Barriers2Daniel Patrick ConnollyNo ratings yet

- Saskatchewan Detailed Occupational Outlook 2019 To 2023Document30 pagesSaskatchewan Detailed Occupational Outlook 2019 To 2023libra0009No ratings yet

- TeamForge 620 User GuideDocument336 pagesTeamForge 620 User GuidegiorgioviNo ratings yet

- 17.00 Loïc Pottier, Fives FCBDocument11 pages17.00 Loïc Pottier, Fives FCBMohd AliNo ratings yet

- Amararaja Batteries LTDDocument43 pagesAmararaja Batteries LTDMonish Rm100% (2)

- Pleasure Boat Thrusters WebDocument4 pagesPleasure Boat Thrusters WebCatalin CataNo ratings yet

- Sample CVDocument3 pagesSample CVmarvinjosephandalNo ratings yet