Professional Documents

Culture Documents

Design of Compression Members Based On IS 800-2007 AND IS 800-1984-COMPARISON

Design of Compression Members Based On IS 800-2007 AND IS 800-1984-COMPARISON

Uploaded by

akshay kothiyalCopyright:

Available Formats

You might also like

- Counteracting Structural Loads - Treatment in ASCE Standard 7-05 PDFDocument4 pagesCounteracting Structural Loads - Treatment in ASCE Standard 7-05 PDFsaber javid100% (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Design of Compression Members Based On IS 800-2007 AND IS 800-1984-COMPARISONDocument5 pagesDesign of Compression Members Based On IS 800-2007 AND IS 800-1984-COMPARISONHeather CarterNo ratings yet

- Limit State DesignDocument12 pagesLimit State DesignEzhil KumarNo ratings yet

- PRC 1Document24 pagesPRC 1saadNo ratings yet

- Pce 411 Structural Steel Design: Module 2: Philosophies of DesignDocument5 pagesPce 411 Structural Steel Design: Module 2: Philosophies of DesignJonathan LlegoNo ratings yet

- Term Paper1-Arijit DeyDocument6 pagesTerm Paper1-Arijit DeyarijitNo ratings yet

- IS: 800 - Indian Code of Practice For Construction in Steel: Comparison With International CodesDocument49 pagesIS: 800 - Indian Code of Practice For Construction in Steel: Comparison With International CodesARYA100% (1)

- Design Basis: CE 315-Design of Concrete Structure - I Instructor: Dr. E. R. LatifeeDocument2 pagesDesign Basis: CE 315-Design of Concrete Structure - I Instructor: Dr. E. R. LatifeeShafiqul HasanNo ratings yet

- " Tability of Tructures With Application To Practical DesignDocument55 pages" Tability of Tructures With Application To Practical DesignKarthick Murugesan100% (3)

- SESSIONALSDocument11 pagesSESSIONALSVijayNo ratings yet

- Marine Structural Design-26-30Document5 pagesMarine Structural Design-26-30Mohamed AttiaNo ratings yet

- Timber Design Lesson 1 Update ShareDocument14 pagesTimber Design Lesson 1 Update Sharepkimani10098No ratings yet

- Lect 1 Limit State DesignDocument31 pagesLect 1 Limit State DesignWaleed Yahia100% (1)

- Evaluation of Reduction Factor For Reinforced Concrete Buildings Retrofitted With CFRP JacketsDocument11 pagesEvaluation of Reduction Factor For Reinforced Concrete Buildings Retrofitted With CFRP JacketsAnna SanchezNo ratings yet

- Pile Design and Installation Specification Based On ConceptDocument4 pagesPile Design and Installation Specification Based On ConceptMoe Oo HtunNo ratings yet

- Design Procedure For Steel Frame Structures According To Bs 5950Document46 pagesDesign Procedure For Steel Frame Structures According To Bs 5950Chong Chee Yen100% (2)

- Lecture Notes Stab 2 Class 5&6Document8 pagesLecture Notes Stab 2 Class 5&6Bhavanen RungapenNo ratings yet

- Limit State MethodDocument15 pagesLimit State Methodvishal tomarNo ratings yet

- Term Paper-Arijit DeyDocument6 pagesTerm Paper-Arijit DeyarijitNo ratings yet

- Direct Static FEM Approach To Limit and ShakedownDocument15 pagesDirect Static FEM Approach To Limit and ShakedownAdamNo ratings yet

- JSTEFebruary 18 RP04Document6 pagesJSTEFebruary 18 RP04girumNo ratings yet

- 03 Design Methodology-1Document9 pages03 Design Methodology-1Abdul RehmanNo ratings yet

- Chapter 2Document9 pagesChapter 2Senai21dragoNo ratings yet

- Engineering Structures: SciencedirectDocument14 pagesEngineering Structures: SciencedirectMaria AngelNo ratings yet

- RC-I Chapter 2 PDFDocument36 pagesRC-I Chapter 2 PDFWendimu TolessaNo ratings yet

- GL IV - Chapter4Document40 pagesGL IV - Chapter4pandi muthuppandiNo ratings yet

- Influence of Imperfections On Axial BucklingDocument10 pagesInfluence of Imperfections On Axial BucklingJuan BrazalezNo ratings yet

- One Way Joist FlorrDocument15 pagesOne Way Joist Florrak47_uziiNo ratings yet

- Seismic Performance Evaluation of Egyptian Code-Designed Steel Moment Resisting FramesDocument13 pagesSeismic Performance Evaluation of Egyptian Code-Designed Steel Moment Resisting Framesaxl_calin82No ratings yet

- AISI LRFD Method For Cold-Formed Steel Structural MembersDocument31 pagesAISI LRFD Method For Cold-Formed Steel Structural MembersHernan Ramiro Suyo LarutaNo ratings yet

- Reinforced Concrete DesignDocument6 pagesReinforced Concrete DesignJohndee IsipNo ratings yet

- General Design Considerations: Bridge EngineeringDocument11 pagesGeneral Design Considerations: Bridge EngineeringEna Mie CambaNo ratings yet

- Design of Simply Supported Deep Beams Using Strut-and-Tie ModelsDocument10 pagesDesign of Simply Supported Deep Beams Using Strut-and-Tie ModelsDereje bedoreNo ratings yet

- Philosophies of Design by Limit State Method: Instructional ObjectivesDocument6 pagesPhilosophies of Design by Limit State Method: Instructional ObjectiveshghjjjkNo ratings yet

- What Makes A Special Moment Frame SpecialDocument3 pagesWhat Makes A Special Moment Frame SpecialMehdi FarrokhiNo ratings yet

- Study of Comparison Between Static and Dynamic Analysis Subjected To Wind and Earthquake LoadDocument6 pagesStudy of Comparison Between Static and Dynamic Analysis Subjected To Wind and Earthquake LoadAnonymous kw8Yrp0R5rNo ratings yet

- Engineering Structures: Kapil Khandelwal, Sherif El-TawilDocument9 pagesEngineering Structures: Kapil Khandelwal, Sherif El-TawiltirursachinNo ratings yet

- 3.1 Study of IS 875 1987 and IS 456 2000Document9 pages3.1 Study of IS 875 1987 and IS 456 2000Sumanth SangemNo ratings yet

- Chapter17 SeismicResistantDesignDocument54 pagesChapter17 SeismicResistantDesignaasimNo ratings yet

- Strut and Tie MethodDocument74 pagesStrut and Tie MethodJuan Mario Guevara PenarandaNo ratings yet

- (Unit) Title of The Chapter Name of FacilitatorDocument35 pages(Unit) Title of The Chapter Name of FacilitatorDipesh BasnetNo ratings yet

- Design Procedure For Steel Frame Structures According TO BS 5950Document46 pagesDesign Procedure For Steel Frame Structures According TO BS 5950Uvie M. PtwolanNo ratings yet

- Engineering Structures: Simon Benson, Anuar Abubakar, Robert S. DowDocument15 pagesEngineering Structures: Simon Benson, Anuar Abubakar, Robert S. DowNguyễn Huy VũNo ratings yet

- Engineering Structures: Simon Benson, Anuar Abubakar, Robert S. DowDocument15 pagesEngineering Structures: Simon Benson, Anuar Abubakar, Robert S. DowNguyễn Huy VũNo ratings yet

- Buildings: An Introduction To The Methodology of Earthquake Resistant Structures of Uniform ResponseDocument19 pagesBuildings: An Introduction To The Methodology of Earthquake Resistant Structures of Uniform Responsereza muhamad ilyasNo ratings yet

- Design of Steel Frames - BS 5950Document46 pagesDesign of Steel Frames - BS 5950Rashy PR100% (1)

- Engineering Analysis of Tension Structures Theory and PracticeDocument11 pagesEngineering Analysis of Tension Structures Theory and PracticeNora AngelicaNo ratings yet

- Performance-Based Analysis and Design For Internal Stability of MSE WallsDocument13 pagesPerformance-Based Analysis and Design For Internal Stability of MSE WallsSubha Sankar ChowdhuryNo ratings yet

- Design I Topic IDocument6 pagesDesign I Topic IJames MumoNo ratings yet

- Tabeshpour A 10 57 1 77f3196Document9 pagesTabeshpour A 10 57 1 77f3196Irfan KhanNo ratings yet

- J Strusafe 2014 12 002Document10 pagesJ Strusafe 2014 12 002manasha majhiNo ratings yet

- Ayyub 2000 Ship Wave LRFDDocument56 pagesAyyub 2000 Ship Wave LRFDbrian_dutraNo ratings yet

- Seismic Design Requirements For Building Structures: Chapter C12Document3 pagesSeismic Design Requirements For Building Structures: Chapter C12Akagami ShanksNo ratings yet

- PIIS2352012414000034Document10 pagesPIIS2352012414000034Miguel MNo ratings yet

- Lecture On Limit State Design by Manish BhutaniDocument27 pagesLecture On Limit State Design by Manish BhutaniTarunNo ratings yet

- Introduction to Design of Building StructuresFrom EverandIntroduction to Design of Building StructuresRating: 4 out of 5 stars4/5 (22)

- Site Plan Name of Work:-Proposed Construction of 90Mtr. Span Steel Giirder Bridge On Tapovan-Karchho Motor Road at K.M. 02 Plan - A & BDocument1 pageSite Plan Name of Work:-Proposed Construction of 90Mtr. Span Steel Giirder Bridge On Tapovan-Karchho Motor Road at K.M. 02 Plan - A & Bakshay kothiyalNo ratings yet

- Design Basis ReportDocument2 pagesDesign Basis Reportakshay kothiyalNo ratings yet

- BBS of Office Room and BathroomDocument6 pagesBBS of Office Room and Bathroomakshay kothiyalNo ratings yet

- Steel Truss Bridge 85 MT Bowarch Pedestrian BridgeDocument19 pagesSteel Truss Bridge 85 MT Bowarch Pedestrian Bridgeakshay kothiyalNo ratings yet

- MR - Mahesh Chand Tiwari at CottageDocument1 pageMR - Mahesh Chand Tiwari at Cottageakshay kothiyalNo ratings yet

- TH ND: 2) The Results Are Related To The Test Performed at Location Shown by ClientDocument16 pagesTH ND: 2) The Results Are Related To The Test Performed at Location Shown by Clientakshay kothiyalNo ratings yet

- Mom 14-9-15Document4 pagesMom 14-9-15akshay kothiyalNo ratings yet

- New Doc 2019-03-11 13.29.47Document3 pagesNew Doc 2019-03-11 13.29.47akshay kothiyalNo ratings yet

- Dog Legged Staircase 463Document2 pagesDog Legged Staircase 463errinchenw100% (1)

- TH ND: ULR - TC752118000000253FDocument10 pagesTH ND: ULR - TC752118000000253Fakshay kothiyalNo ratings yet

- A B D C: Floor HT 3300 Landing LVL 1650Document1 pageA B D C: Floor HT 3300 Landing LVL 1650akshay kothiyalNo ratings yet

- Produced by An Autodesk Educational Product: Foundation LEV.507.00 Foundation LEV.507.00 Foundation LEV.507.00Document1 pageProduced by An Autodesk Educational Product: Foundation LEV.507.00 Foundation LEV.507.00 Foundation LEV.507.00akshay kothiyalNo ratings yet

- 105mt Steel Struss BridgeDocument1 page105mt Steel Struss Bridgeakshay kothiyalNo ratings yet

- For Zeptech - 1Document1 pageFor Zeptech - 1akshay kothiyalNo ratings yet

- Sony World Bore Hole Location - (09.08.2018)Document1 pageSony World Bore Hole Location - (09.08.2018)akshay kothiyalNo ratings yet

- Design and Construction of Pre Stressed Concrete Ground AnchorsDocument1 pageDesign and Construction of Pre Stressed Concrete Ground Anchorsakshay kothiyalNo ratings yet

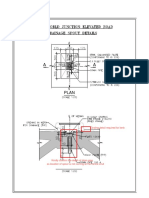

- Comment - 1drainage Spout DetailsDocument1 pageComment - 1drainage Spout Detailsakshay kothiyalNo ratings yet

Design of Compression Members Based On IS 800-2007 AND IS 800-1984-COMPARISON

Design of Compression Members Based On IS 800-2007 AND IS 800-1984-COMPARISON

Uploaded by

akshay kothiyalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Compression Members Based On IS 800-2007 AND IS 800-1984-COMPARISON

Design of Compression Members Based On IS 800-2007 AND IS 800-1984-COMPARISON

Uploaded by

akshay kothiyalCopyright:

Available Formats

JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN

CIVIL ENGINEERING

DESIGN OF COMPRESSION MEMBERS BASED ON

IS 800-2007 AND IS 800-1984- COMPARISON

M. KRISHNAMOORTHY, D.TENSING

M.Tech (Structures) Student, PRIST University, Thanjavur

Principal, ASL Pauls College of Engineering and Technology, Coimbatore

dtensing@rediffmail.com, m.krishk@yahoo.com

ABSTRACT: The design methodologies for the steel structures namely, working stress design method and limit

state design methods are briefly explained. The importance of limit state design method is highlighted. Columns

form the main component of a structure which serves the basic purpose of supporting and transmitting the

entire loads both vertical and horizontal for which the overall structure is intended to the foundation system.

Beams are generally subjected only to flexure about the horizontal axis whereas columns are subjected to axial

load along with bending moment about the major axis. The minor axis moment in columns are generally nil or

very nominal since in standard structural system, the columns are so oriented that the frames along the major

axis of the columns are moment resistant frames, and column bracings are provided in the frames along the

other perpendicular direction. This paper focuses entirely to the procedure involved in design of compression

members. Typical problem have been worked out using allowable stress design methods and limit state method

and comparative studies is made.

ALLOWABLE STRESS DESIGN be built. The various primary loads and other

With the development of linear elastic theories in the secondary effects required to be considered for Indian

19th century the stress-strain behavior of new condition m while computing maximum stresses in a

materials like wrought iron & mild steel could be structure are mainly as follows

accurately represented. The first attainment of yield a) Dead load b) imposed load or live load c) wind

stress of steel was generally taken to be the inset of load d) seismic load e) erection load f) Secondary

failure. The limitations due to non-linearity and effects due to contraction or expansion resulting from

buckling were neglected. The allowable stress is temperature changes, shrinkage, creep in

defined in terms of a factor of safety which compression members etc.

represented a margin for overload and other unknown As a general approach, a structure is analyzed for all

factors which could be tolerated by the structure. the probable primary load cases and their

combinations are mentioned above. Only for special

Yield Stress structures or under stringent conditions, the

Allowable stress = secondary effects are considered in the overall

Factor of Safety

analysis and in the design of connections of the

LIMIT STATE DESIGN

structural components. While designing a structure

An improved design philosophy to make allowances

using the popular Allowable stress design method,

for the shortcomings in the allowable stress design

the above load combinations are considered with an

was developed in the late 1970s and has been

individual load factor of unity. As per IS: 800-1984,

extensively corporated in design standards and codes

the permissible stress can be increased upto 33%,

formulated in all the developed countries. Although

whenever wind or seismic load is taken in to

there are many variations between practices adopted

consideration.

in different countries the basic concept is broadly

In the proposed Limit state method of design also the

similar. The probability of operating conditions not

above load combinations are considered, but with

reaching failure conditions forms the basis of Limit

variable load factors called the partial safety factor

States Design adopted in all countries. Ultimate

for load as described in Table4. This variable load

limit states are those catastrophic states, which

factors basically account the loading and thus enable

require a larger reliability in order to reduce the

to use steel efficiently and economically in different

probability of its occurrence to a very low level.

structural systems.

Serviceability limit state refers to the limits on

Similarly, to determine the strength of the member to

acceptable performance of the structure.

be designed against the factored loads as described

LOAD AND LOAD COMBINATIONS

above, a reduction factor for strength called partial

To design a structure, it is analyzed first for its

safety factor for material is taken into consideration,

intended structural configuration and assumed

which accounts for uncertainty in material strength

sectional properties against various loads individually

and quality as well as manufacture tolerance. Various

and in combination with each other in a way by

material safety factors as have been adopted in IS:

which the structure may be subjected any time or at

800-2007 are given in the table 5

all time during the life of the structure for which is to

ISSN: 0975 6744| NOV 11 TO OCT 12 | Volume 2, Issue 1 Page 73

JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN

CIVIL ENGINEERING

The detail design procedure of compression member

using allowable stress design method as per IS: 800-

1984 and also limit state design method as per IS:

DESIGN PROCEDURES 800-2007 have been discussed with the help of

example and comparatives study as been done

DESIGN A MEMBER SUBJECTED HAVING A

SPAN OF 3M WHICH IS FIXED @ BOTH ENDS

LSM (As per IS: 800-2007) The section is Compact

Let us take ISMB 200 @ 254 N/m

Area = 3233mm2 Step 2: Determination of Effective Length

Depth (d) = 200mm Leff = 0.65 x 3000 = 1950mm

Width of flange (b) = 100mm

Thickness of the flange (tf) = 10.8mm, Step 3: Calculate the Slenderness Ratio

Thickness of the web (tw) = 5.7mm

Step 1: Type of the Section KL l x 1950

23.43

b

100

d

9.259 178 rx rx 83.2

t f 10.8

31.22

tw 5.7

ISSN: 0975 6744| NOV 11 TO OCT 12 | Volume 2, Issue 1 Page 74

JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN

CIVIL ENGINEERING

COMPARATIVE STUDY

KL l y 1950

90.69 In this study we have compared Columns fixed at

ry ry 21.5 both ends, column fixed at one end and hinged at

other, column pinned at both ends for a column

Step 4: Determination of Non Dimensional length of 2m, 2.25m, 2.5m, 2.75m, 3m, 3.25m, 3.5m,

3.75m & 4m and also Graphical study has done for

2 the Strength Vs Section and Strength Weight Ratio

KL Vs Section. The Fig. 1, Fig. 2, Fig. 3 show the

fy

fy r 250 x 23.432 comparative study of columns fixed at both ends of

x 0.26382m, 3m, and 4m length. The Fig. 4, Fig. 5 and Fig. 6

f cc E2

x 2 x10

2 5

show the comparison between the S/w ratio Vs

Section for a length of 2m, 3m and 4m. Similarly the

2

KL Fig.7 and Fig. 8 shows the section Vs the constants

fy like stress reduction factor, and effective

fy r 250 x 90.69 2

y 1 .020

slenderness ratio.

f cc 2

E 2 5

x 2 x10

COMPARISON OF LOAD CARRYING

Step 5: Calculation of CAPACITY VS DIFFERENT SECTIONS

0.51 0.2 2

0.51 .341.02 0.2 1.02 2 1.16

Step 6: Calculation of Stress Reduction Factor

1 1

2

2 0.5

[1.16 (1.16 2 1.02 2 )]

0.58

Step 7: Determination of design Compressive Stress

fcd

f y / mo Fig.1

f cd

2 =

2 0.5

fy f

y 132.64

mo mo

Step 8: Determination of Compressive stress Pd

Pd A f cd 428.82kN

WSM (As per IS: 800-1984)

Fig.2

Let us take ISMB 200 @ 254 N/m

Area = 3233mm2

Depth (d) = 200mm

Width of flange (b) = 100mm

Thickness of the flange (tf) = 10.8mm

Thickness of the web (tw) = 5.7mm

Step1: Determination of Effective Length

Leff = 3000 x 0.65= 1950

Fig.3

Step 2: maxleff/rmin = 83.33

COMPARISON BETWEEN THE STRENGTH

Step3: Calculation of Compressive Stress WEIGHT RATIO VS SECTION

ac = 89.4 N/mm2

Step 4: Load Carrying Capacity

ac x Area = 289.030 kN

ISSN: 0975 6744| NOV 11 TO OCT 12 | Volume 2, Issue 1 Page 75

JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN

CIVIL ENGINEERING

increase in size of the sections to the maximum of

15%

From Fig.4, 5 &6, it was found that for ISMB

100,125 and 150 the strength-weight ratio was

approximately the same. For ISMB 150,

175,200,225,250 & 300 strength-weight ratio was

found to increase with increase in size of the sections.

For ISMB 300,350 and 400 the strength-weight ratio

remains the same and for ISMB 400,450,500,550 and

600, it was found to increase with increase in size of

the sections.

Fig. 7 & 8 shows the curves drawn for the Stress

Reduction factor, inclination of tension field and

effective slenderness ratio with respect to different

Indian Standard Medium Beams.

Fig: 4

Fig: 7

Fig: 5

Fig: 8

CONCLUSION

1. The load carrying capacity of the compression

members as per IS 800-2007 is controlled by stress

Fig: 6 reduction factor, inclination of tension field stress in

From the chart it was found that the best fit curve for web and effective slenderness ratio. The slenderness

describing the behavior of steel sections with respect ratio is inversely proportional to the stress reduction

strength is two degree binomial. On comparison of factor. The design compressive stress is directly

the strength of sections calculated using old and new proportional to stress reduction factor.

code, it was found that the strength increases with

ISSN: 0975 6744| NOV 11 TO OCT 12 | Volume 2, Issue 1 Page 76

JOURNAL OF INFORMATION, KNOWLEDGE AND RESEARCH IN

CIVIL ENGINEERING

2. In IS 800-1984 for the design of compression

member is controlled by slenderness ratio which is

inversely proportional to the permissible stress in

axial compression.

3. The percentage increase in load carrying capacity

as per IS 800-1984 is marginally higher than IS 800-

2007. The maximum increase was found to be a

maximum of 5%.

4. The behavior of steel sections with respect to load

carrying capacity follows two degree binomial curve

for the design of sections as per both the codes.

5. The behavior of steel sections under strength-

weight ratio is controlled by the weight per unit

length.

6. The load carrying capacity of built-up columns

using ISA sections for various back to back widths as

well as for various lengths were found to vary for

smaller sections and for higher sections the values

become same irrespective of change in widths or

lengths.

REFERENCES

1.Arijit Guha and Dr.T.K. Bandyopandhya,

Structural Member Design Based on Draft IS: 800

(Limit State Method), Insdags steel journal,

Institute for steel development & Growth, Jan 2004,

Volume5.

2. N. Pandian, Arul Jayachandran, S. Seetharamal,

Structural Efficiencies of New Indian Wide Flanged

Sections Compared With the Existing Rolled

Sections, Insdags Steel Journal, Institute for steel

development & Growth, Jan 2004, Volume5.

3.Rangachar Narayanan, V.Kalayanarman, etal

Teaching Resource on Structural Steel Design

Volume 1 of 3, Institute For Steel Development &

Growth.

4.Indian Standard General Construction in Steel-

Code of Practice IS: 800-2007, December 2007.

5.Indian Standard General Construction in Steel-

Code of Practice IS: 800-1984.

ISSN: 0975 6744| NOV 11 TO OCT 12 | Volume 2, Issue 1 Page 77

You might also like

- Counteracting Structural Loads - Treatment in ASCE Standard 7-05 PDFDocument4 pagesCounteracting Structural Loads - Treatment in ASCE Standard 7-05 PDFsaber javid100% (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Design of Compression Members Based On IS 800-2007 AND IS 800-1984-COMPARISONDocument5 pagesDesign of Compression Members Based On IS 800-2007 AND IS 800-1984-COMPARISONHeather CarterNo ratings yet

- Limit State DesignDocument12 pagesLimit State DesignEzhil KumarNo ratings yet

- PRC 1Document24 pagesPRC 1saadNo ratings yet

- Pce 411 Structural Steel Design: Module 2: Philosophies of DesignDocument5 pagesPce 411 Structural Steel Design: Module 2: Philosophies of DesignJonathan LlegoNo ratings yet

- Term Paper1-Arijit DeyDocument6 pagesTerm Paper1-Arijit DeyarijitNo ratings yet

- IS: 800 - Indian Code of Practice For Construction in Steel: Comparison With International CodesDocument49 pagesIS: 800 - Indian Code of Practice For Construction in Steel: Comparison With International CodesARYA100% (1)

- Design Basis: CE 315-Design of Concrete Structure - I Instructor: Dr. E. R. LatifeeDocument2 pagesDesign Basis: CE 315-Design of Concrete Structure - I Instructor: Dr. E. R. LatifeeShafiqul HasanNo ratings yet

- " Tability of Tructures With Application To Practical DesignDocument55 pages" Tability of Tructures With Application To Practical DesignKarthick Murugesan100% (3)

- SESSIONALSDocument11 pagesSESSIONALSVijayNo ratings yet

- Marine Structural Design-26-30Document5 pagesMarine Structural Design-26-30Mohamed AttiaNo ratings yet

- Timber Design Lesson 1 Update ShareDocument14 pagesTimber Design Lesson 1 Update Sharepkimani10098No ratings yet

- Lect 1 Limit State DesignDocument31 pagesLect 1 Limit State DesignWaleed Yahia100% (1)

- Evaluation of Reduction Factor For Reinforced Concrete Buildings Retrofitted With CFRP JacketsDocument11 pagesEvaluation of Reduction Factor For Reinforced Concrete Buildings Retrofitted With CFRP JacketsAnna SanchezNo ratings yet

- Pile Design and Installation Specification Based On ConceptDocument4 pagesPile Design and Installation Specification Based On ConceptMoe Oo HtunNo ratings yet

- Design Procedure For Steel Frame Structures According To Bs 5950Document46 pagesDesign Procedure For Steel Frame Structures According To Bs 5950Chong Chee Yen100% (2)

- Lecture Notes Stab 2 Class 5&6Document8 pagesLecture Notes Stab 2 Class 5&6Bhavanen RungapenNo ratings yet

- Limit State MethodDocument15 pagesLimit State Methodvishal tomarNo ratings yet

- Term Paper-Arijit DeyDocument6 pagesTerm Paper-Arijit DeyarijitNo ratings yet

- Direct Static FEM Approach To Limit and ShakedownDocument15 pagesDirect Static FEM Approach To Limit and ShakedownAdamNo ratings yet

- JSTEFebruary 18 RP04Document6 pagesJSTEFebruary 18 RP04girumNo ratings yet

- 03 Design Methodology-1Document9 pages03 Design Methodology-1Abdul RehmanNo ratings yet

- Chapter 2Document9 pagesChapter 2Senai21dragoNo ratings yet

- Engineering Structures: SciencedirectDocument14 pagesEngineering Structures: SciencedirectMaria AngelNo ratings yet

- RC-I Chapter 2 PDFDocument36 pagesRC-I Chapter 2 PDFWendimu TolessaNo ratings yet

- GL IV - Chapter4Document40 pagesGL IV - Chapter4pandi muthuppandiNo ratings yet

- Influence of Imperfections On Axial BucklingDocument10 pagesInfluence of Imperfections On Axial BucklingJuan BrazalezNo ratings yet

- One Way Joist FlorrDocument15 pagesOne Way Joist Florrak47_uziiNo ratings yet

- Seismic Performance Evaluation of Egyptian Code-Designed Steel Moment Resisting FramesDocument13 pagesSeismic Performance Evaluation of Egyptian Code-Designed Steel Moment Resisting Framesaxl_calin82No ratings yet

- AISI LRFD Method For Cold-Formed Steel Structural MembersDocument31 pagesAISI LRFD Method For Cold-Formed Steel Structural MembersHernan Ramiro Suyo LarutaNo ratings yet

- Reinforced Concrete DesignDocument6 pagesReinforced Concrete DesignJohndee IsipNo ratings yet

- General Design Considerations: Bridge EngineeringDocument11 pagesGeneral Design Considerations: Bridge EngineeringEna Mie CambaNo ratings yet

- Design of Simply Supported Deep Beams Using Strut-and-Tie ModelsDocument10 pagesDesign of Simply Supported Deep Beams Using Strut-and-Tie ModelsDereje bedoreNo ratings yet

- Philosophies of Design by Limit State Method: Instructional ObjectivesDocument6 pagesPhilosophies of Design by Limit State Method: Instructional ObjectiveshghjjjkNo ratings yet

- What Makes A Special Moment Frame SpecialDocument3 pagesWhat Makes A Special Moment Frame SpecialMehdi FarrokhiNo ratings yet

- Study of Comparison Between Static and Dynamic Analysis Subjected To Wind and Earthquake LoadDocument6 pagesStudy of Comparison Between Static and Dynamic Analysis Subjected To Wind and Earthquake LoadAnonymous kw8Yrp0R5rNo ratings yet

- Engineering Structures: Kapil Khandelwal, Sherif El-TawilDocument9 pagesEngineering Structures: Kapil Khandelwal, Sherif El-TawiltirursachinNo ratings yet

- 3.1 Study of IS 875 1987 and IS 456 2000Document9 pages3.1 Study of IS 875 1987 and IS 456 2000Sumanth SangemNo ratings yet

- Chapter17 SeismicResistantDesignDocument54 pagesChapter17 SeismicResistantDesignaasimNo ratings yet

- Strut and Tie MethodDocument74 pagesStrut and Tie MethodJuan Mario Guevara PenarandaNo ratings yet

- (Unit) Title of The Chapter Name of FacilitatorDocument35 pages(Unit) Title of The Chapter Name of FacilitatorDipesh BasnetNo ratings yet

- Design Procedure For Steel Frame Structures According TO BS 5950Document46 pagesDesign Procedure For Steel Frame Structures According TO BS 5950Uvie M. PtwolanNo ratings yet

- Engineering Structures: Simon Benson, Anuar Abubakar, Robert S. DowDocument15 pagesEngineering Structures: Simon Benson, Anuar Abubakar, Robert S. DowNguyễn Huy VũNo ratings yet

- Engineering Structures: Simon Benson, Anuar Abubakar, Robert S. DowDocument15 pagesEngineering Structures: Simon Benson, Anuar Abubakar, Robert S. DowNguyễn Huy VũNo ratings yet

- Buildings: An Introduction To The Methodology of Earthquake Resistant Structures of Uniform ResponseDocument19 pagesBuildings: An Introduction To The Methodology of Earthquake Resistant Structures of Uniform Responsereza muhamad ilyasNo ratings yet

- Design of Steel Frames - BS 5950Document46 pagesDesign of Steel Frames - BS 5950Rashy PR100% (1)

- Engineering Analysis of Tension Structures Theory and PracticeDocument11 pagesEngineering Analysis of Tension Structures Theory and PracticeNora AngelicaNo ratings yet

- Performance-Based Analysis and Design For Internal Stability of MSE WallsDocument13 pagesPerformance-Based Analysis and Design For Internal Stability of MSE WallsSubha Sankar ChowdhuryNo ratings yet

- Design I Topic IDocument6 pagesDesign I Topic IJames MumoNo ratings yet

- Tabeshpour A 10 57 1 77f3196Document9 pagesTabeshpour A 10 57 1 77f3196Irfan KhanNo ratings yet

- J Strusafe 2014 12 002Document10 pagesJ Strusafe 2014 12 002manasha majhiNo ratings yet

- Ayyub 2000 Ship Wave LRFDDocument56 pagesAyyub 2000 Ship Wave LRFDbrian_dutraNo ratings yet

- Seismic Design Requirements For Building Structures: Chapter C12Document3 pagesSeismic Design Requirements For Building Structures: Chapter C12Akagami ShanksNo ratings yet

- PIIS2352012414000034Document10 pagesPIIS2352012414000034Miguel MNo ratings yet

- Lecture On Limit State Design by Manish BhutaniDocument27 pagesLecture On Limit State Design by Manish BhutaniTarunNo ratings yet

- Introduction to Design of Building StructuresFrom EverandIntroduction to Design of Building StructuresRating: 4 out of 5 stars4/5 (22)

- Site Plan Name of Work:-Proposed Construction of 90Mtr. Span Steel Giirder Bridge On Tapovan-Karchho Motor Road at K.M. 02 Plan - A & BDocument1 pageSite Plan Name of Work:-Proposed Construction of 90Mtr. Span Steel Giirder Bridge On Tapovan-Karchho Motor Road at K.M. 02 Plan - A & Bakshay kothiyalNo ratings yet

- Design Basis ReportDocument2 pagesDesign Basis Reportakshay kothiyalNo ratings yet

- BBS of Office Room and BathroomDocument6 pagesBBS of Office Room and Bathroomakshay kothiyalNo ratings yet

- Steel Truss Bridge 85 MT Bowarch Pedestrian BridgeDocument19 pagesSteel Truss Bridge 85 MT Bowarch Pedestrian Bridgeakshay kothiyalNo ratings yet

- MR - Mahesh Chand Tiwari at CottageDocument1 pageMR - Mahesh Chand Tiwari at Cottageakshay kothiyalNo ratings yet

- TH ND: 2) The Results Are Related To The Test Performed at Location Shown by ClientDocument16 pagesTH ND: 2) The Results Are Related To The Test Performed at Location Shown by Clientakshay kothiyalNo ratings yet

- Mom 14-9-15Document4 pagesMom 14-9-15akshay kothiyalNo ratings yet

- New Doc 2019-03-11 13.29.47Document3 pagesNew Doc 2019-03-11 13.29.47akshay kothiyalNo ratings yet

- Dog Legged Staircase 463Document2 pagesDog Legged Staircase 463errinchenw100% (1)

- TH ND: ULR - TC752118000000253FDocument10 pagesTH ND: ULR - TC752118000000253Fakshay kothiyalNo ratings yet

- A B D C: Floor HT 3300 Landing LVL 1650Document1 pageA B D C: Floor HT 3300 Landing LVL 1650akshay kothiyalNo ratings yet

- Produced by An Autodesk Educational Product: Foundation LEV.507.00 Foundation LEV.507.00 Foundation LEV.507.00Document1 pageProduced by An Autodesk Educational Product: Foundation LEV.507.00 Foundation LEV.507.00 Foundation LEV.507.00akshay kothiyalNo ratings yet

- 105mt Steel Struss BridgeDocument1 page105mt Steel Struss Bridgeakshay kothiyalNo ratings yet

- For Zeptech - 1Document1 pageFor Zeptech - 1akshay kothiyalNo ratings yet

- Sony World Bore Hole Location - (09.08.2018)Document1 pageSony World Bore Hole Location - (09.08.2018)akshay kothiyalNo ratings yet

- Design and Construction of Pre Stressed Concrete Ground AnchorsDocument1 pageDesign and Construction of Pre Stressed Concrete Ground Anchorsakshay kothiyalNo ratings yet

- Comment - 1drainage Spout DetailsDocument1 pageComment - 1drainage Spout Detailsakshay kothiyalNo ratings yet