Professional Documents

Culture Documents

VIN Solenoid Valve DSL103series

VIN Solenoid Valve DSL103series

Uploaded by

Andres Cardenas MoyaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VIN Solenoid Valve DSL103series

VIN Solenoid Valve DSL103series

Uploaded by

Andres Cardenas MoyaCopyright:

Available Formats

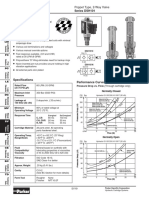

Catalog HY15-3501/US Spool Type, 3-Way Valve

Technical Information Series DSL103

CV

General Description

Valves

3-Way Spool Valves. For additional information

Check

see Technical Tips on pages SV1-SV6. DSL103A

SH (2)

Features

High flow capacity with reduced space requirements

Shuttle

Valves

Standard valve bodies and common cavities (3) (1)

LM One-piece encapsulated coil with minimal amperage draw

Manual overrides, seal variations and other options

Load/Motor

available

Controls

No dynamic seals

Construction/Symbols

FC

Variety of coil terminations

DSL103A

Polyurethane D-Ring

All external parts zinc plated

Controls

(1)

Flow

Specifications (2) (3)

PC

Rated Flow DSL103A (2) (2) (2)

Pressure

Controls

N.O. 22.7 LPM (6.0 GPM)

N.C. 17.0 LPM (4.5 GPM)

Selector 17.0 LPM (4.5 GPM) (3) (1) (3) (1) (3) (1)

LE DSL103B Normally Closed Normally Open Selector

N.C. 30.2 LPM (8.0 GPM)

Elements

Selector 30.2 LPM (8.0 GPM)

Logic

DSL103C DSL103B

N.O. 30.2 LPM (8.0 GPM)

DSL103N

DC (1)

N.O. 18.8 LPM (5.0 GPM)

Directional

N.C. 18.8 LPM (5.0 GPM)

Controls

Selector 30.2 LPM (8.0 GPM) (2) (3)

(2) (2)

Maximum Inlet 250 Bar (3600 PSI)

MV Pressure

(3) (1) (3) (1)

Leakage at 120 cc/min. (7.5 in3/min.)

Manual

Valves

150 SSU (32 cSt) DSL103B - 180 cc/min. (11 in3/min.) Normally Closed Selector

Minimum 85% of rated voltage at DSL103C

SV Operating Voltage 20C (72F).

Solenoid

Response Time 50 ms to 100 ms

Valves

(1)

Cartridge Material All parts steel. All operating

parts hardened steel. (2) (3)

PV

Proportional

(2)

Operating Temp. -45C to +93.3C (D-Ring)

Valves

Range/Seals (-50F to +200F)

-31.7C to +121.1C (Fluorocarbon) (3) (1)

(-25F to +250F)

CE Normally Open

Fluid Mineral-based or synthetic with

Electronics

Compatibility/ lubricating properties at viscosities DSL103N

Coils &

Viscosity of 45 to 2000 SSU (6 to 420 cSt)

Filtration ISO Code 16/13, (1)

BC SAE Class 4 or better

(2) (3)

Bodies &

Cavities

Approx. Weight .19 kg (.42 lbs.)

(2) (2) (2)

Cavity C10-3

TD (See BC Section for more details)

(3) (1) (3) (1) (3) (1)

Technical

Form Tool Rougher NFT10-3R

Finisher NFT10-3F Normally Closed Normally Open Selector

Data

SV81 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3501/US Spool Type, 3-Way Valve

Series DSL103

CV

Dimensions Millimeters (Inches)

Valves

Check

8.4 43.4 66.5

(.33) (1.71) (2.62)

7-10 Nm 22.0 SH

(5-7 lb. ft.) (0.86)

Torque

Shuttle

Valves

50.0 36.0

(1.97) (1.43) LM

MADEINU.S.A.

PAT.XXXXXXX

CAX XXX H

XXVDC XXW

Load/Motor

69.6

(2.74)

Controls

See Super Coil

5/8" I.D.

115.3 Information For

(4.54) Terminal Connectors

FC

1" Hex.

Controls

50-56 Nm (37-41 lb. ft.)

Flow

11.2 Torque

(.44)

7/8-14 UNF-2A

(3) Thread PC

Pressure

Controls

(2)

15.8 (1) LE

(.62)

Elements

THIRD-ANGLE

Logic

PROJECTION

Ordering Information DC

Directional

Controls

DSL103

10 Size Style Override Seals Coil Coil Coil Diode Body Port

MV

Solenoid Valve Option Type Voltage Termination Material Size

Manual

Valves

Code Style Code Override Options Code Coil Voltage Code Diode

(2) Omit None Omit Without Coil Omit None

A P Pull & Release D012 12 VDC R Diode SV

T Push & Twist D024 24 VDC

Solenoid

(3) (1)

Valves

A120 120/110 VAC, 60/50 Hz Code Body Material

(2) Code Seals / Kit No. A240 240/220 VAC, 60/50 Hz Omit Steel

B Omit D-Ring / (SK10-3) A Aluminum

PV

N Nitrile / (SK10-3N) SP* U

Proportional

(3) (1)

V Fluorocarbon / Coil Coil Termination Coil Code Port Size Body Part No.

Valves

(2)

(SK10-3V) Omit Without Coil Omit Omit Cartridge Only

C C Conduit With Leads C 4P 1/4 NPTF (B10-3-*4P)

Code Coil Type D DIN Plug Face D 6P 3/8 NPTF (B10-3-*6P) CE

(3) (1) 8P 1/2 NPTF (B10-3-*8P)

Electronics

Omit Without Coil A Amp Jr. Timer

6T SAE-6 (B10-3-*6T)

Coils &

(2)

SP* Super Coil - 28 Watts S Dual Spade

8T SAE-8 (B10-3-*8T)

N U Unicoil - 20 Watts W Dual Screw

6B 3/8 BSPG (B10-3-6B)

*Recommended L Dual Lead Wire W

(3) (1)

8B 1/2 BSPG (B10-3-*8B) BC

H Molded Deutsch * Add A for aluminum, omit for steel.

Bodies &

*Recommended Steel bodies only.

Cavities

DC Only

TD

Technical

Data

SV82 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3501/US Spool Type, 3-Way Valve

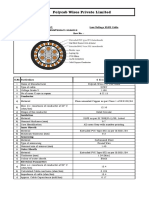

Performance Curves Series DSL103

CV

Pressure Drop vs. Flow (Through cartridge only) Shift Limit Characteristics (Min. Operating Voltage)

PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt) PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt)

Valves

Check

150 10 4000 276

Operating Pressure - PSI

125 9

Pressure Drop ( P)

SH DSL103A 3000 207

100 7 3 to 1

DSL103A 1 to 3

Shuttle

Valves

75 5 2000 138

o1 o2 1 to 2

3t 1t

50 3

LM 1000 69

25 2

Load/Motor

2 to 1

Controls

0 0

LPM 8 15 23 30 LPM 8 15 23 30

0 0

GPM 2 4 6 8 GPM 2 4 6 8

Flow (Q) Flow (Q)

FC

Pressure Drop vs. Flow (Through cartridge only) Shift Limit Characteristics (Min. Operating Voltage)

Controls

Flow

PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt) PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt)

150 10 4000 276

Operating Pressure - PSI

PC 125 9

Pressure Drop ( P)

DSL103B 3000 207

Pressure

100 7 3 to 2

Controls

to

1 DSL103B 2 to 1

2 to 3

75 5 r2 2000 138

2o

o

3t

50 3 1 to 2

LE

1000 69

25 2

Elements

Logic

0 0

LPM 8 15 23 30 LPM 8 15 23 30

0 0

GPM 2 4 6 8 GPM 2 4 6 8

DC Flow (Q) Flow (Q)

Directional

Controls

Pressure Drop vs. Flow (Through cartridge only) Shift Limit Characteristics (Min. Operating Voltage)

PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt) PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt)

150 10 4000 276

MV

Operating Pressure - PSI

125 9

Pressure Drop ( P)

DSL103C 3000 207

Manual

Valves

100 7 2 to 1

DSL103C 3 to 1

o1 1 to 2

75 5 3t 2000 138

or

SV o2

1t

50 3 1 to 3

1000 69

Solenoid

Valves

25 2

0 0

LPM 8 15 23 30 LPM 8 15 23 30

PV 0 0

GPM 2 4 6 8 GPM 2 4 6 8

Proportional

Flow (Q) Flow (Q)

Valves

Pressure Drop vs. Flow (Through cartridge only) Shift Limit Characteristics (Min. Operating Voltage)

PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt) PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt)

CE 150 10 4000 276

Operating Pressure - PSI

Electronics

125 9

Pressure Drop ( P)

Coils &

DSL103N 3000 207

2 to 1

100 7 1 to 2

DSL103N 3 to 2

2 to 3

2

BC 75 5 3 to 2000 138

or

o1

2t

Bodies &

50 3

Cavities

1000 69

25 2

0 0

TD LPM 8 15 23 30 LPM 8 15 23 30

0 0

GPM 2 4 6 8 GPM 2 4 6 8

Technical

Flow (Q) Flow (Q)

Data

SV83 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3501/US

Technical Tips Solenoid Valves

CV

INTRODUCTION

This technical tips section is designed to help familiarize you with the Parker line of Solenoid Valves. In this

Valves

Check

section we highlight new products to this catalog as well as some design features of our solenoid valves. In

addition we present common options available to help you in selecting products for your application. Finally, we

SH

give a brief synopsis of the operation and applications of the various products offered in this section. Some tips in

applying and selecting our products are provided throughout this guide.

Shuttle

Valves

LM NEW PRODUCTS

Load/Motor

There are several new additions and product improvements to our Solenoid Valve

Controls

product line.

Nylon Insert Nut

FC Here are just some of the design Nylon inserted jam nut resists

vibration preventing the nut

features and advantages to the from backing out.

product line.

Controls

Flow

PC

Pressure

Controls

New Super Coil

LE Exceeds IP69K

specifications with

Elements

Deutsch molded

Logic

connector.

DC

Directional

Controls

Crimp Design

Fold over crimp provides

secure holding and

D-Ring

MV eliminates the need

Standard 4301 Polyurethane Seal

for adhesive.

eliminates the need for backup rings

providing easier manifold installation.

Manual

Valves

(For more information on D-Ring

see Technical Data Section)

SV

Solenoid

Valves

PV New Parker SUPER COIL Now Available!

Proportional

*Exceeds IP69k Specifications

Valves

After exhaustive testing, the new Super Coil has clearly distanced itself from the competition. This coil was

subjected to the rigors of this environmental standard and the results were excellent. This coil stands up to

CE most rugged of environmental conditions including weather, dust, and extreme temperature variations.

Electronics

*Water Dunk Test Qualified

Coils &

The Super Coil was taken to task in a repeated water dunk thermal cycle test program with alternate

exposure to high and low temperature, only to perform with outstanding results.

BC *Endurance Tested

The goal of this test was to cycle the coil to high temperature extremes in order to validate the coils ability to

Bodies &

perform in extreme temperature environments.

Cavities

*Water Spray and Chemical Solvent Compatibility

The Super Coil was subjected to numerous chemical solvents in a rigorous test which established the fact

TD that these coils can withstand harsh and unusual environments. Also, the coils were subjected to a high

pressure water spray test. Once again, the Super Coil passed this test.

Technical

*Deutsch molded connector is highly recommended.

Data

SV1 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3501/US

Technical Tips Solenoid Valves

CV

COMMON OPTIONS down on the knob and twists is clockwise. Once the

As you will see, Parker offers a variety of solenoid pin is seated in the slotted groove, the operator can

Valves

Check

valve products. As such, some of the options remove pressure and the valve will stay actuated.

mentioned below may not be available on all valves.

Consult the model coding and dimensions for each In addition to the push and twist style override, SH

valve for more specifics. Here are some of the normally closed (pull style tube) 2 position valves can

Shuttle

common options available. be ordered with a pull and release override. Normally

Valves

open (push style) 2 position valves are available with

Seals: The Winners Circle products feature a flush style and extended style overrides. These

standard Polyurethane D-Ring. The D-Ring LM

overrides are not detented. Each style is shown below.

Load/Motor

eliminates the need for backup rings. For more

Controls

information on the D-Ring see the Technical Data

section of the catalog. The majority of the products are 13.1

34.2

available in Nitrile or Fluorocarbon Seals. You should 29.9

(1.35)

(.52)

FC

(1.18) 22.1

always match the seal compatibility to the temperature Normal Shifted

(.87)

and fluid being used in your application.

Controls

Flow

Coils: Coils can be ordered as part of the full

assembly or separately. Various terminations and Pull and Release Flush Extended PC

voltages are available. For detailed information on the Manual Override Manual Override Manual Override

Pressure

coil options consult the coil section of the catalog. The

Controls

ordering information for each valve will direct you to 3 Position valves are offered with a Push / Pull style

the proper coil. override. This override is not detented. Springs hold

the spool of the valve in the center position of the LE

Manual Overrides: Many of our solenoid valves are valve. When the knob is pulled, the spool is moved

Elements

also offered with a manual override. The override upward simulating the action of the upper coil. When

Logic

allows the user to shift the valve when coil force is not the override is pushed, the spool moves downward

available. They provide a means of shifting the simulating the action of the lower coil. When no

solenoid valve due to a loss of power or a coil failure. DC

pressure is applied to the knob, it centers the spool.

Directional

Overrides are intended for infrequent usage and are

Controls

not designed to be used as a primary method of valve

actuation.

The most common override option for the 2 Position 28.6 31.5 34.5 MV

(1.24) (1.36)

valves is the push & twist style shown below. With a (1.12)

Manual

Valves

normally closed valve or a pull style tube, the valve is

in normal operation (or de-energized)

when the pin is

Push Normal Pull SV

seated in the 34.2 Position Position Position

29.7

slotted groove (1.17) (1.35)

Solenoid

Valves

Shifted

at the lowest Normal

Screens: 2 way valves can be ordered with a small

position. To

mesh screen (60 x 60 mesh) placed over the cage of

shift the valve PV

the cartridge valve. This screen is intended for cursory

manually, the

Proportional

operator pushes protection of the internal components of the solenoid

Valves

down on the knob Normally Closed Pull Type Tube valve. It should not be used as the primary method of

and twists it counterclockwise. When the pressure is filtration. The mesh catches small

removed from the knob, an internal spring pushes the pieces of debris that could impede CE

pin up the slotted groove to the upper position of the spool or poppet movement. Note that

Electronics

override. With a normally open valve, or push style a screen will trap debris from both

Coils &

tube, the actuation is reversed. The valve is in the directions. Thus, any debris coming

normal position from the nose of the cartridge would

(or de-energized) be trapped inside the valve. As such, BC

when the pin is 38.2 33.6

we recommend that screens be implemented in only

Bodies &

Cavities

in the upper (1.50)

Normal

(1.32) applications where hydraulic fluid passes through the

Shifted

position of the cartridge from the side of the cage to the nose. It

override. To should also be noted that the pressure drop through

shift the valve the cartridge will be increased slightly due to the small TD

manually, the restriction of the mesh. As the screen fills with debris,

Technical

operator pushes pressure drop will continue to rise.

Data

Normally Open Push Type Tube

SV2 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3501/US

Technical Tips Solenoid Valves

CV

PRODUCT TYPES / APPLICATIONS

Valves

Check

Two Way Poppet Valves

Two way poppet valves are pilot operated, low leakage solenoid actuated valves. Two way poppet valves control

SH

the flow of a two way function by blocking flow in one direction (similar to a check valve). They are generally

selected due to their low leakage and ability to meet higher flow requirements. Poppet valves are often used on

Shuttle

Valves

single operation actuators or in unloading functions. They are available in normally closed and normally open

types. In addition, free reverse flow and fast response versions are available.

LM

Load/Motor

Controls

Normally Closed Poppet

Normally closed two way poppet

FC valves act as a check valve when

de-energized, blocking flow from one direction and

Out

Controls

allowing restricted free flow in the reverse condition. (1)

Flow

When energized, the poppet lifts allowing free flow

from the side to the nose of the cartridge. Should the In (2)

PC application require free flow in both directions, the free

reverse flow option should be chosen.

Pressure

Controls

OPERATION - The valve pilot is held on its seat by spring force, blocking pilot flow. This allows pressure at the

LE inlet (port 2) to hold the poppet on its seat, thus, preventing flow through the valve (2-1). If the nose of the

cartridge (port 1) is pressurized, the pressure will overcome the spring force, pushing the poppet off of its seat,

Elements

allowing free flow through the cartridge (1-2). When the coil is energized, the valve pilot is pulled off of its seat.

Logic

This vents the pressure inside the poppet to port 1, creating a pressure imbalance across the main poppet. This

differential lifts the poppet allowing flow from the side to nose (2-1). Since poppet valves are piloted operated, a

DC

minimum amount of pressure differential (25-50 psi) and flow between ports 2 and 1 must be present to overcome

Directional

the spring and lift the poppet.

Controls

MV Normally Open Poppet

Normally open two way poppet

Manual

valves, when de-energized, allow

Valves

free flow from the side (port 2) of the cartridge to the

Out

SV

nose (port 1). Flow in the reverse direction is restricted. (1)

Should free flow be required in both directions, the free

Solenoid

reverse flow option should be specified. Once the coil is In (2)

Valves

energized the normally open poppet valve acts as a

check valve, blocking flow from one direction and

PV allowing restricted free flow in the reverse condition.

Proportional

Valves

OPERATION - The valve pilot is held off its seat by spring force. Pilot flow is vented to port 1, creating a pressure

imbalance that moves the main poppet. This differential lifts the poppet allowing flow from the side to nose (2-1).

CE Since poppet valves are piloted operated, a minimum amount of pressure differential (25-50 psi) between ports 2

and 1 must be present to overcome the spring and lift the poppet. When the coil is energized, the coil force

Electronics

overcomes the spring force to drive the valve pilot and main poppet into their seats, thus blocking flow from port

Coils &

2-1. If the nose of the cartridge (port 1) is pressurized, the pressure will overcome the spring force and solenoid

force, pushing the poppet off of its seat, allowing restricted flow through the cartridge (1-2).

BC

Bodies &

Cavities

TD

Technical

Data

SV3 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3501/US

Technical Tips Solenoid Valves

CV

Free Reverse Flow

The free reverse flow versions

Valves

Check

are available on both the normally

closed and normally open poppet Out

(1) SH

valves. As mentioned above, the

operation is the same as the In (2)

Shuttle

Valves

standard poppet valve except flow

through the reverse direction is

not restricted. The free reverse LM

Load/Motor

flow option is only needed if the Out

Controls

application requires flow to pass (1)

through the cartridge valve from

the nose to side (port 1 to port 2). In (2)

FC

Fast Response

Controls

Since poppet valves are pilot operated valves, a few milliseconds are needed to move the pilot and allow the

Flow

poppet to lift. Should a faster response time be required on normally closed poppet valves, this option can be

chosen. The fast response is accomplished by reducing the movement of the pilot. Thus, the flow capacity of the PC

poppet valve is also decreased.

Pressure

Controls

Two Way Spool Valves LE

Two way spool valves are direct acting, fast responding solenoid actuated valves. Like the poppet valves

Elements

described earlier, they block the flow of a two way function. Unlike two way poppet valves, spool valves block flow

Logic

from both the side port and the nose port. They do not have the check like function of the poppet valve, thus they

are either open or closed. Spool valves are directed operated, so they respond more quickly to coil voltage than DC

poppet valves. Spool valves operate via a sliding spool, thus, some leakage will be present due to the required

Directional

Controls

spool clearance. Spool valves block flow in both directions, but the preferred flow path is still from the side of the

cartridge to the nose due to the flow forces acting on the spool. Two way spool valves are available in normally

open and normally closed types.

MV

Normally Closed Spool

Manual

Valves

When de-energized, the spool is

positioned by the spring force to

cover both the side (2) and nose (1) ports of the valve. Out SV

Thus, no flow is allowed from either direction. Once the (1)

Solenoid

coil is energized, the spool shifts exposing a flow path

Valves

between the two ports. Flow can then be passed through In (2)

the valve from either direction.

PV

Proportional

Normally Open Spool

Valves

When de-energized, the spool is

positioned by the spring force so

that a flow path between the side (2) and nose (1) ports CE

Out

Electronics

is exposed, allowing flow through the valve from either (1)

Coils &

direction. Once the coil is energized, the spool shifts to

cover both the side (2) and nose (1) ports of the valve. In (2)

Thus, no flow is allowed from either direction. BC

Bodies &

Cavities

TD

Technical

Data

SV4 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3501/US

Technical Tips Solenoid Valves

CV

Bi-Directional Poppet Valve

Bi-directional poppet valves combine

Valves

Check

the dual blocking function of spool

(2)

valves with the lower leakage capabilities

SH of poppet valves. Bi-directional poppet valves are (1)

not recommended for load holding applications.

Shuttle

Valves

These valves also have a limited flow capacity

compared to standard poppet or spool valves.

LM

Load/Motor

Controls

Two Position,

Three Way Spool Valve

FC Three way spool solenoid valves

provide directional control of flow. Each three way valve

Controls

has a special internal spool which connects two of the (1)

Flow

three valve ports. When actuated, the spool connects a

PC

different combination of valve ports. These valves are (2) (3)

often used for raise and lower functions of a single acting

Pressure

cylinder, control of a uni-directional motor, or as a circuit selector.

Controls

OPERATION - In the de-energized mode, the spool is positioned by spring force. When energized, the coil force

LE directly shifts the spool against the spring, thus changing the flow through the valve. Each spool type can be used

as a normally open, normally closed, or selector valve. To explain this we will review the DSL103A which is

Elements

pictured here. When the valve is de-energized, ports 1 and 2 are open to one another. When energized, ports 1

Logic

and 3 are connected.

DC

Directional

Thus, if we use (2) If we use port 2 as If we use port 1 (2)

Controls

port 3 as our our pressure port, (2) as our pressure

pressure port, we have a port, we have a

we have a (3) (1) normally selector valve. (3) (1)

MV

normally closed open valve. The (3) (1) The pressure port (1)

valve. The pressure port (3) is pressure port (2) is connected to is either connected to port (2) or port

Manual

Valves

blocked, while the actuator port (1) the actuator port (1), and the tank (3). Thus, it is selecting which port

is drained to tank (2). port (3) is blocked. will get the system pressure and flow.

SV

Solenoid

Note that in all three examples, we were using the same valve. The flow forces acting on the spool change

Valves

depending on which port is pressurized. Thus, if you will be shifting the three way valve under full flow and

pressure, it is important to review the shift limit characteristics for the flow paths you have chosen to be sure the

PV

coil has enough force to shift the spool. Various spools are available in this catalog to maximize the flow and

Proportional

pressure capacities for the desired flow function.

Valves

CE

Electronics

Coils &

BC

Bodies &

Cavities

TD

Technical

Data

SV5 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3501/US

Technical Tips Solenoid Valves

CV

Two Position,

Four Way Spool Valve

Valves

Check

Four way spool solenoid valves (2) (3) (4)

provide directional control of flow. Each four way valve

has a special internal spool which connects some SH

(1)

combination of the four valve ports together. When

Shuttle

Valves

actuated, the spool connects a different combination of

valve ports. These valves are often used for the raise /

lower function of a double acting cylinder, or as a LM

Load/Motor

forward / reverse function of bi-directional motors.

Controls

OPERATION - In the de-energized mode, the spool is positioned by spring force. When energized, the coil force

directly shifts the spool against the spring, thus changing the flow through the valve. Each spool type is

FC

customized to provide the flow combination desired. The flow forces acting on the spool change depending on

which port is pressurized. Thus, if you will be shifting the four way valve under full flow and pressure, it is

Controls

important to review the shift limit characteristics for the flow paths you have chosen to ensure the coil has enough

Flow

force to shift the spool. Various spools are shown in this catalog to maximize the flow and pressure capacities for

the desired flow function. PC

Pressure

Controls

Three Position,

Four Way Spool Valve LE

Three position, four way spool

Elements

solenoid valves provide directional control of

Logic

flow. Each four way valve has a special internal (2) (3) (4)

spool which connects some combination of the DC

four ports together. When one coil is actuated, (1)

Directional

Controls

the spool connects a different combination of

valve ports. When the other coil is actuated a

third combination of valve ports are connected. These valves are often

used for the raise / lower function of a double acting cylinder, or as a forward / reverse function of bi-directional MV

motors. The center position can be used to stop the actuator in mid-stroke, or dump the pump flow.

Manual

Valves

OPERATION - In the de-energized mode, the spool is positioned by spring force. When energized, the coil force

directly shifts the against the spring, thus changing the flow through the valve. Each spool type is customized to SV

provide the flow combination desired. The flow forces acting on the spool change depending on which port is pres-

Solenoid

surized. Thus, if you will be shifting the four way valve under full flow and pressure, it is important to review the

Valves

shift limit characteristics for the flow paths you chosen to ensure the coil has enough force to shift the spool.

Various spools are shown in this catalog to maximize the flow and pressure capacities for the desired flow function.

PV

Proportional

Valves

CE

Electronics

Coils &

BC

Bodies &

Cavities

TD

Technical

Data

SV6 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3501/US

Contents Technical Data

CV

DESCRIPTION PAGE NO.

Valves

Check

Basic Hydraulic Formulas ........................................................................................................................................ TD1

SH

Ratings and Testing ................................................................................................................................................. TD1

Shuttle

Valves

Temperature Ratings ............................................................................................................................................... TD1

Viscosity .................................................................................................................................................................. TD1

LM

Load/Motor

Pressure Ratings ..................................................................................................................................................... TD1

Controls

Thermal Shock ........................................................................................................................................................ TD1

Service and Components ........................................................................................................................................ TD1 FC

Limitations in Use ................................................................................................................................................... TD1

Controls

Flow

Seal Material Selection ............................................................................................................................................ TD2

PC

Hydraulic Fluids ....................................................................................................................................................... TD3

Pressure

Controls

Hydraulic Filtration .................................................................................................................................................. TD3

Application of Product ............................................................................................................................................. TD3

LE

Offer of Sale ............................................................................................................................................................ TD4

Elements

Logic

DC

Directional

Controls

MV

Manual

Valves

SV

Solenoid

Valves

PV

Proportional

Valves

CE

Electronics

Coils &

BC

Bodies &

Cavities

TD

Technical

Data

Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3501/US

Technical Information Technical Data

CV

INTRODUCTION VISCOSITY

Valves

In this section you will find a variety of technical Catalog data is from tests conducted on mineral oil at

Check

information pertinent to general hydraulics as well as a viscosity of 30 cSt (140 SSU) using an ISO VG:46

SH cartridge valve technology. test fluid.

HYDRAULIC FORMULAS Product should ideally be used at viscosities in the

Shuttle

Valves

range of 15 to 50 cSt (80 to 230 SSU).

Below are a few of the common hydraulic formulas to

assist you in calculating the requirements for your Product will perform with reduced efficiency in the

LM ranges, 5 to 15 cSt (42 to 80 SSU) and 50 to 500 cSt

system:

Load/Motor

(230 to 2300 SSU). These extreme conditions must be

Controls

Voltage = Current Resistance evaluated by the user to establish suitability of the

Flow = Volume Unit of Time products performance.

FC

Pressure = Force Area PRESSURE RATINGS

Controls

Horsepower = Flow Pressure (1714 Efficiency) Unless otherwise stated, all Parker cartridges have a

Flow

continuous duty pressure ratings as shown in the

p (Bar) x flow rate (LPM)

PC Hydraulic power (kW) = catalog. All pressure ratings are based on the cartridge

600 valve only. Exposure to elevated pressures may affect

where p = pressure drop

Pressure

Controls

the performance and fatigue life of the product. The

material chosen for the body or carrier may affect the

p (PSI) x flow rate (GPM) pressure rating we recommend. Parker does not

LE

Hydraulic power (HP) =

1714 recommend the use of cartridge valves in aluminum

bodies at pressures above 207 bar (3000 psi).

Elements

RATINGS & TESTING

Logic

All Parker cartridge valve products have been perfor-

THERMAL SHOCK

DC mance tested with the results shown on the individual It is unreasonable to expect product to withstand rapid

Directional

valve catalog pages. The performance data shown temperature changes - this could affect both perfor-

Controls

represents typical operation characteristics of the mance and life and care should be taken to protect the

product. In addition, our valves are endurance tested. product from such situations.

MV Validation is conducted by testing or similarity in

designs. SERVICE & COMPONENTS

Note: Not every cartridge option is endurance tested. One of the advantages of integrated hydraulic circuits

Manual

Valves

In other words, one three way spool is endurance is their serviceability. Should a valve need to be

tested, and the others are assumed by similarity. replaced for any reason, a user only needs to unscrew

SV the valve from the manifold and screw the replacement

TEMPERATURE RATINGS into the cavity. As such, there are few replacement

Solenoid

Valves

Product operating limits are broadly in the range -30C parts available for the Parker cartridge products. As

to 150C (-20F to 300F) but satisfactory operation with any hydraulic system, the operator should bleed

PV within the specification may not be accomplished. off any trapped pressure and consult machine service

Proportional

Leakage and response will be affected when used at manuals prior to service. Parker does not offer any

service parts for internal components, but external

Valves

temperature extremes and it is the users responsibility

to determine acceptability at these levels. components such as coils, knobs, and seals are

available.

CE Seals used in these products generally have the

Electronics

following temperature limitations: LIMITATIONS IN USE

Coils &

Nitrile (Buna N) -30C to 100C (-20F to 210F) Parker cartridge valves are designed for a wide variety

of industrial and mobile applications. Despite their

BC Fluorocarbon -20C to 150C (-4F to 300F)

flexibility, Parker Hannifin does not recommend or

Hytrel -54C to 135C (-65F to 275F) support the use of our cartridge valves in any on

Bodies &

Cavities

highway or aerospace applications. We also do not

GTPFE -30C to 150C (-20F to 300F)

recommend our products for use in the transport of

TD explosive products or in hazardous environments.

Technical

Data

TD1 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3501/US

Technical Information Technical Data

CV

SEAL MATERIAL SELECTION Thus, the D-Ring outperforms standard polyurethane

o-rings, especially when using high water content fluids

Valves

You should match the seal compatibility to the tem-

Check

perature and fluid being used in your application. at elevated temperatures. The D-Ring is compatible

with most water-glycol, water/oil emulsions, and high

Parker offers three seal materials to meet your applica- SH

tion requirements. Parkers standard material is a 4301 grade petroleum based hydraulic fluids at tempera-

Polyurethane RESILON material D-Ring. We also tures between -45C to +93C (-50F to +200F)

Shuttle

Valves

offer Fluorocarbon and Nitrile seals. A brief synopsis of The unique shape of the Parker D-Ring also provides

each seal material is given below to help you choose a variety of design advantages. The seal is molded into

the best seal for your application. LM

a D shape where the seal is higher in the middle and

Load/Motor

lower on the ends. This prevents the seal edge from

Controls

D-Ring (4301 Polyurethane RESILON Material)

The D-Ring is the standard seal material on the folding over on a corner inside the manifold during

Winners Circle threaded cartridge valves. The D- installation. In addition, this design has a minimal lip,

Ring is molded of a special 4301 Polyurethane thus, friction is reduced. Another unique feature of the FC

RESILON. Polyurethane materials exhibit better D-Ring is its symmetrical design, resulting in no

Controls

performance degradation from the reverse direction, or

wear resistance and tensile strength than standard

Flow

Nitrile or Fluorocarbon material. In addition, it has an worry of backward installation. The D-Ring is also

excellent resistance to compression set. This in- equipped with pressure pedestals to reduce the PC

effects of blow-by common in reverse cycling. The pres-

creased strength eliminates the need for back-rings

Pressure

sure pedestals increase the sealing capability of the

Controls

and simplifies installation.

D-Ring, by reducing the radial pressure forces that

The 4301 compound is a Parker exclusive material compress the sealing face of the o-ring. The drawing

designed to prevent hydrolysis at high temperatures. below depicts the shape and highlights the features. LE

Elements

Logic

No Backup Rings 4301 RESILON Material

The increased wear resistance and Specially designed Parker exclusive

strength of polyurethane eliminates 4301 Polyurethane RESILON

the need for backup rings, thus prevents hydrolosis better than other DC

Directional

minimizing installation issues. polyurethane materials.

Controls

MV

Manual

Valves

D Shape

Unique D shape provides

sealing in the critical areas Pressure Pedestals Reduced Lip SV

while reducing the chance Specially molded pressure The unique shape reduces

Solenoid

of a seal being cut during pedestals help reduce the the lip and thus the amount

Valves

manifold installation. effects of blow-by of wear due to friction.

Nitrile Fluorocarbon PV

Nitrile o-rings are also compatible with most water- Fluorocarbon o-rings are compatible with most phos-

Proportional

glycol, water/oil emulsions, and high grade petroleum phate ester fluids and phosphate ester blends. Parker

Valves

based hydraulic fluids. Parker only recommends Nitrile only recommends Fluorocarbon seals for temperatures

o-rings for temperatures between -40C to +93C between -32C to +121C (-25F to +250F). Fluoro-

(-40F to +200F). Nitrile o-rings do require a full back- carbon o-rings do require a full back-up ring, or two CE

Electronics

up ring, or two half back-ups. half back-ups.

Coils &

BC

Bodies &

Cavities

TD

Technical

Data

TD2 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3501/US

Technical Information Technical Data

CV

HYDRAULIC FLUIDS There is no direct correlation between using a specific

ISO cleanliness classification. Numerous other variables

Valves

Parker recommends using top-quality mineral based or

Check

synthetic hydraulic fluids with lubricating properties at should be considered such as particulate ingression,

actual flow through filters, and filter location.

SH viscosities of 45 to 2000 SSU (6 to 420 cSt) at 38C

(100F). The absolute viscosity range 80 to 1000 SSU A number of interrelated system factors combine to

(16 to 220 cSt.). Fluids should have high anti-wear determine proper media and filter combinations. To

Shuttle

Valves

characteristics and be treated to protect against accurately determine which combination is ideal for

oxidation. your system, all these factors need to be accounted

LM

for. With the development of filtration sizing software

Load/Motor

HYDRAULIC FILTRATION such as Parker inPHorm, this information can be used

Controls

Hydraulic systems that include Parker valves should to compute the optimal selection. In many instances

be carefully protected against fluid contamination. The the information available may be limited. In these

FC proper cleanliness level for Parker cartridge valves cases, rules of thumb based on empirical data and

should be maintained at an ISO cleanliness level of proven examples are applied to get an initial starting

Controls

18/16/13. point.

Flow

75% of all system failures are a direct result of con- APPLICATION OF PRODUCT

PC tamination. Contamination interferes with four functions

of hydraulic fluids. CAUTION - It is important to note that the Parker

Pressure

Controls

Hydraulic Cartridge Systems Division makes a variety

1. To act as an energy transmission medium. of valves, many of which fit into the same cavity.

2. To lubricate internal moving parts of components. However, their functionality may differ considerably

LE from one valve type to another. Accordingly fit

3. To act a heat transfer medium. interchangeability does not necessarily mean form

Elements

or function interchangeability. Users should ensure

Logic

4. To seal clearances between moving components.

that the appropriate valve is installed in the cavity by

DC A properly selected filter will provide adequate protec- cross checking the part number stamped on the valve

tion and reduce operating cost. This is achieved by with that published in approved service literature or in

Directional

Controls

increasing the expected life of the valves and reducing the installation drawing.

the cost of maintenance and repairs. Operation will be

smoother and more precise.

MV

Manual

Valves

SV

Solenoid

Valves

PV

Proportional

Valves

CE

Electronics

Coils &

BC

Bodies &

Cavities

TD

Technical

Data

TD3 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3501/US

Technical

Offer of Sale

Information Technical Data

CV

The items described in this document and other documents or descriptions provided by Parker Hannifin Corporation, its subsidiaries and its authorized

distributors are hereby offered for sale at prices to be established by Parker Hannifin Corporation, its subsidiaries and its authorized distributors. This

Valves

offer and its acceptance by any customer (Buyer) shall be governed by all of the following Terms and Conditions. Buyers order for any such items,

Check

when communicated to Parker Hannifin Corporation, its subsidiary or an authorized distributor (Seller) verbally or in writing, shall constitute acceptance

of this offer.

SH

1. Terms and Conditions of Sale: All descriptions, quotations, proposals, by Buyer. Unless otherwise agreed, Seller shall have the right to alter,

offers, acknowledgments, acceptances and sales of Sellers products are discard or otherwise dispose of any special tooling or other property in its

Shuttle

Valves

subject to and shall be governed exclusively by the terms and conditions sole discretion at any time.

stated herein. Buyers acceptance of any offer to sell is limited to these 8. Buyers Property: Any designs, tools, patterns, materials, drawings,

terms and conditions. Any terms or conditions in addition to, or inconsistent confidential information or equipment furnished by Buyer or any other

with those stated herein, proposed by Buyer in any acceptance of an offer items which become Buyers property, may be considered obsolete and LM

by Seller, are hereby objected to. No such additional, different or inconsistent may be destroyed by Seller after two (2) consecutive years have elapsed

Load/Motor

terms and conditions shall become part of the contract between Buyer and without Buyer placing an order for the items which are manufactured using

Controls

Seller unless expressly accepted in writing by Seller. Sellers acceptance such property, Seller shall not be responsible for any loss or damage to

of any offer to purchase by Buyer is expressly conditional upon Buyers such property while it is in Sellers possession or control.

assent to all the terms and conditions stated herein, including any terms 9. Taxes: Unless otherwise indicated on the face hereof, all prices and

in addition to, or inconsistent with those contained in Buyers offer, charges are exclusive of excise, sales, use, property, occupational or like FC

Acceptance of Sellers products shall in all events constitute such assent. taxes which may be imposed by any taxing authority upon the manufacture,

2. Payment: Payment shall be made by Buyer net 30 days from the date sale or delivery of the items sold hereunder. If any such taxes must be paid

Controls

of delivery of the items purchased hereunder. Amounts not timely paid by Seller or if Seller is liable for the collection of such tax, the amount

Flow

shall bear interest at the maximum rate permitted by law for each month thereof shall be in addition to the amounts for the items sold. Buyer agrees

or portion thereof that the Buyer is late in making payment. Any claims by to pay all such taxes or to reimburse Seller therefore upon receipt of its

Buyer for omissions or shortages in a shipment shall be waived unless invoice. If Buyer claims exemption from any sales, use or other tax PC

Seller receives notice thereof within 30 days after Buyers receipt of the imposed by any taxing authority, Buyer shall save Seller harmless from

shipment. and against any such tax, together with any interest or penalties thereon

Pressure

Controls

3. Delivery: Unless otherwise provided on the face hereof, delivery shall which may be assessed if the items are held to be taxable.

be made F.O.B. Sellers plant. Regardless of the method of delivery, 10. Indemnity For Infringement of Intellectual Property Rights: Seller

however, risk of loss shall pass to Buyer upon Sellers delivery to a carrier. shall have no liability for infringement of any patents, trademarks, copyrights,

Any delivery dates shown are approximate only and Seller shall have no trade dress, trade secrets or similar rights except as provided in this Part LE

liability for any delays in delivery. 10. Seller will defend and indemnify Buyer against allegations of

Elements

4. Warranty: Seller warrants that the items sold hereunder shall be free infringement of U.S. Patents, U.S. Trademarks, copyrights, trade dress

from defects in material or workmanship for a period of 18 months from and trade secrets (hereinafter Intellectual Property Rights). Seller will

Logic

date of shipment from Parker Hannifin Corporation. THIS WARRANTY defend at its expense and will pay the cost of any settlement or damages

COMPRISES THE SOLE AND ENTIRE WARRANTY PERTAINING TO awarded in an action brought against Buyer based on an allegation that

ITEMS PROVIDED HEREUNDER. SELLER MAKES NO OTHER an item sold pursuant to this contract infringes the Intellectual Property DC

WARRANTY, GUARANTEE, OR REPRESENTATION OF ANY KIND Rights of a third party. Sellers obligation to defend and indemnify Buyer

Directional

WHATSOEVER. ALL OTHER WARRANTIES, INCLUDING BUT NOT is contingent on Buyer notifying Seller within ten (10) days after Buyer

Controls

LIMITED TO, MERCHANTABILITY AND FITNESS FOR PURPOSE, becomes aware of such allegations of infringement, and Seller having sole

WHETHER EXPRESS, IMPLIED, OR ARISING BY OPERATION OF control over the defense of any allegations or actions including all

LAW, TRADE USAGE, OR COURSE OF DEALING ARE HEREBY negotiations for settlement or compromise. If an item sold hereunder is

DISCLAIMED. NOTWITHSTANDING THE FOREGOING, THERE ARE subject to a claim that it infringes the Intellectual Property Rights of a third MV

NO WARRANTIES WHATSOEVER ON ITEMS BUILT OR ACQUIRED party, Seller may, at its sole expense and option, procure for Buyer the

WHOLLY OR PARTIALLY, TO BUYERS DESIGNS OR right to continue using said item, replace or modify said item so as to make

Manual

Valves

SPECIFICATIONS. it noninfringing, or offer to accept return of said item and return the

5. Limitation Of Remedy: SELLERS LIABILITY ARISING FROM OR IN purchase price less a reasonable allowance for depreciation.

ANY WAY CONNECTED WITH THE ITEMS SOLD OR THIS CONTRACT Notwithstanding the foregoing, Seller shall have no liability for claims of

SHALL BE LIMITED EXCLUSIVELY TO REPAIR OR REPLACEMENT infringement based on information provided by Buyer, or directed to items SV

OF THE ITEMS SOLD OR REFUND OF THE PURCHASE PRICE PAID delivered hereunder for which the designs are specified in whole or part

BY BUYER, AT SELLERS SOLE OPTION. IN NO EVENT SHALL by Buyer, or infringements resulting from the modification, combination or

Solenoid

Valves

SELLER BE LIABLE FOR ANY INCIDENTAL, CONSEQUENTIAL OR use in a system of any item sold hereunder. The foregoing provisions of

SPECIAL DAMAGES OF ANY KIND OR NATURE WHATSOEVER, this Part 10 shall constitute Sellers sole and exclusive liability and Buyers

INCLUDING BUT NOT LIMITED TO LOST PROFITS ARISING FROM sole and exclusive remedy for infringement of Intellectual Property Rights.

OR IN ANY WAY CONNECTED WITH THIS AGREEMENT OR ITEMS If a claim is based on information provided by Buyer or if the design for an PV

SOLD HEREUNDER, WHETHER ALLEGED TO ARISE FROM BREACH item delivered hereunder is specified in whole or in part by Buyer, Buyer

Proportional

OF CONTRACT, EXPRESS OR IMPLIED WARRANTY, OR IN TORT, shall defend and indemnify Seller for all costs, expenses or judgments

Valves

INCLUDING WITHOUT LIMITATION, NEGLIGENCE, FAILURE TO resulting from any claim that such item infringes any patent, trademark,

WARN OR STRICT LIABILITY. copyright, trade dress, trade secret or any similar right.

6. Changes, Reschedules and Cancellations: Buyer may request to 11. Force Majeure: Seller does not assume the risk of and shall not be

modify the designs or specifications for the items sold hereunder as well liable for delay or failure to perform any of Sellers obligations by reason CE

as the quantities and delivery dates thereof, or may request to cancel all of circumstances beyond the reasonable control of Seller (hereinafter

Electronics

or part of this order, however, no such requested modification or cancellation Events of Force Majeure). Events of Force Majeure shall include without

Coils &

shall become part of the contract between Buyer and Seller unless limitation, accidents, acts of God, strikes or labor disputes, acts, laws,

accepted by Seller in a written amendment to this Agreement. Acceptance rules or regulations of any government or government agency, fires,

of any such requested modification or cancellation shall be at Sellers floods, delays or failures in delivery of carriers or suppliers, shortages of

discretion, and shall be upon such terms and conditions as Seller may materials and any other cause beyond Sellers control. BC

require. 12. Entire Agreement/Governing Law: The terms and conditions set

7. Special Tooling: A tooling charge may be imposed for any special forth herein, together with any amendments, modifications and any

Bodies &

Cavities

tooling, including without limitation, dies, fixtures, molds and patterns, different terms or conditions expressly accepted by Seller in writing, shall

acquired to manufacture items sold pursuant to this contract. Such special constitute the entire Agreement concerning the items sold, and there are

tooling shall be and remain Sellers property notwithstanding payment of no oral or other representations or agreements which pertain thereto. This

any charges by Buyer. In no event will Buyer acquire any interest in Agreement shall be governed in all respects by the law of the State of Ohio. TD

apparatus belonging to Seller which is utilized in the manufacture of the No actions arising out of the sale of the items sold hereunder or this

Technical

items sold hereunder, even if such apparatus has been specially converted Agreement may be brought by either party more than two (2) years after

or adapted for such manufacture and notwithstanding any charges paid the cause of action accrues.

Data

9/91-P

TD4 Parker Hannifin Corporation

Hydraulic Cartridge Systems

You might also like

- Tube Settler - CalculationDocument3 pagesTube Settler - CalculationJai Kumar88% (17)

- Ingersoll Rand M37 & M45 Ops & Maint ManualDocument31 pagesIngersoll Rand M37 & M45 Ops & Maint ManualjiangshencaoNo ratings yet

- JLN-205 Servic EmanualDocument43 pagesJLN-205 Servic EmanualPrasad Dharmarathna100% (2)

- Standard Pilot Assisted Load ControlDocument28 pagesStandard Pilot Assisted Load ControlOscar GuaricalloNo ratings yet

- Series DSL082 Technical Information General DescriptionDocument2 pagesSeries DSL082 Technical Information General DescriptionDaniel MarNo ratings yet

- 155 - Series DSH103Document2 pages155 - Series DSH103gerardo floresNo ratings yet

- Unloading Relief ValvesDocument6 pagesUnloading Relief ValvesStar SealNo ratings yet

- Coax Switches: Series CCR-33S/CR-33SDocument10 pagesCoax Switches: Series CCR-33S/CR-33SMuhammad ArslanNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.rajesh1200No ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.rajesh1200No ratings yet

- 2 5px3cywystrfrlsDocument2 pages2 5px3cywystrfrlsKrish0% (1)

- Datasheet 3sfsDocument14 pagesDatasheet 3sfsbrokenfilament60No ratings yet

- 2 Way Poppet Type Solenoid ValveDocument16 pages2 Way Poppet Type Solenoid ValveFrancisco Javier BurgosNo ratings yet

- Sealed Ultra Subminiature Basic Switch D2JWDocument5 pagesSealed Ultra Subminiature Basic Switch D2JWMuhamad PriyatnaNo ratings yet

- 2 Way Poppet Type Bi-Directional Solenoid ValveDocument16 pages2 Way Poppet Type Bi-Directional Solenoid ValveJonathan GiraldoNo ratings yet

- MSV 8Document3 pagesMSV 8Han LinNo ratings yet

- 2 5px12cywyfrlsstrDocument2 pages2 5px12cywyfrlsstramzad aliNo ratings yet

- Electro Valvulas TitanDocument4 pagesElectro Valvulas TitanAlvaro Escalona GtzNo ratings yet

- Polycab 10mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 10mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- CBAT54Document3 pagesCBAT54SatriaWahyuEkaSaputraNo ratings yet

- Manual Do Sensor Capacitivo Da UWTDocument35 pagesManual Do Sensor Capacitivo Da UWTLeandrodeLemosNo ratings yet

- 2c x1.5 FAS CableDocument1 page2c x1.5 FAS CableSanjay KumarNo ratings yet

- Polycab 16mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 16mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- Series B02E3F Technical Information General DescriptionDocument13 pagesSeries B02E3F Technical Information General DescriptionhoiNo ratings yet

- En 57530 ICO3 SDocument3 pagesEn 57530 ICO3 Skev YNo ratings yet

- D04B2Document2 pagesD04B2Elisabet Carreras MarcosNo ratings yet

- D19 HT Switchgear-Ds-ADocument6 pagesD19 HT Switchgear-Ds-Aprati121No ratings yet

- BCP53 Series PNP Silicon Epitaxial Transistors: Medium Power High Current Surface Mount PNP TransistorsDocument5 pagesBCP53 Series PNP Silicon Epitaxial Transistors: Medium Power High Current Surface Mount PNP Transistorstatoddo2017No ratings yet

- Sr. No. 3A Datasheet 4PX3CYWY 100Document2 pagesSr. No. 3A Datasheet 4PX3CYWY 100hemantmech099200No ratings yet

- RD 102Document2 pagesRD 102Ventas Control HidráulicoNo ratings yet

- 190 - Series K2A005Document1 page190 - Series K2A005helderfgmNo ratings yet

- NUF2221W1T2 USB Upstream Terminator With ESD ProtectionDocument6 pagesNUF2221W1T2 USB Upstream Terminator With ESD ProtectionZoltán ÁgostonNo ratings yet

- 4V Drive NCH MOSFET: RHU002N06 FRADocument5 pages4V Drive NCH MOSFET: RHU002N06 FRAHenryRamirezNo ratings yet

- Cat Valvula PARKER.p65Document2 pagesCat Valvula PARKER.p65Felipe VenturiniNo ratings yet

- Stn3Nf06L: N-Channel 60 V, 0.07 Ω Typ., 4 A Stripfet™ Ii Power Mosfet In A Sot-223 PackageDocument12 pagesStn3Nf06L: N-Channel 60 V, 0.07 Ω Typ., 4 A Stripfet™ Ii Power Mosfet In A Sot-223 Packageramesh sahukhalNo ratings yet

- Baumer Tdp02 Tdpz02 Ds enDocument4 pagesBaumer Tdp02 Tdpz02 Ds enQamar ZiaNo ratings yet

- JP04C3100NDocument2 pagesJP04C3100NmaurofpivettaNo ratings yet

- PNP Silicon Surface Mount Transistor With Monolithic Bias Resistor NetworkDocument10 pagesPNP Silicon Surface Mount Transistor With Monolithic Bias Resistor Networkyesid velasco ninaNo ratings yet

- SCT2H12 DatasheetDocument14 pagesSCT2H12 DatasheetKartik ShuklaNo ratings yet

- Ico4-Pst Electromagnetic Actuated, Directly ControlledDocument7 pagesIco4-Pst Electromagnetic Actuated, Directly ControlledSergio Gana GonzalezNo ratings yet

- DatasheetDocument21 pagesDatasheetKunal SononeNo ratings yet

- Ce Const2 132kv CB Siemens 2012 PDFDocument12 pagesCe Const2 132kv CB Siemens 2012 PDFOctavio EspañaNo ratings yet

- CCR 33s CR 33s LatchingDocument9 pagesCCR 33s CR 33s LatchingStanley Ochieng' OumaNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.maharia_22No ratings yet

- SCT3030AL: 650V V R (Typ.) 30mDocument14 pagesSCT3030AL: 650V V R (Typ.) 30mSas Pro EletronicaNo ratings yet

- LVIS09CXSFYL004C010SA001SDocument1 pageLVIS09CXSFYL004C010SA001Ssuvir VigneshNo ratings yet

- Pcsection prh081Document2 pagesPcsection prh081Taller PahrNo ratings yet

- MD-3 Technical Specification SheetDocument9 pagesMD-3 Technical Specification SheetleoNo ratings yet

- Data Sheet AgitatorDocument10 pagesData Sheet AgitatorEdi KurniawanNo ratings yet

- Service Manual: MODEL NO.:MCD-510Document44 pagesService Manual: MODEL NO.:MCD-510Freddy PerezNo ratings yet

- 3SFL 2core Power Cable SpecsDocument1 page3SFL 2core Power Cable Specssandeep bagulNo ratings yet

- SCT3022AL: V 650V R (Typ.) 22m I 93A P 339WDocument14 pagesSCT3022AL: V 650V R (Typ.) 22m I 93A P 339Walgnben1746No ratings yet

- AZ1085CDocument21 pagesAZ1085CReginaldo AliagaNo ratings yet

- Technical Submittal For MV - Cable Data SheetsDocument4 pagesTechnical Submittal For MV - Cable Data SheetskhaledelgamalNo ratings yet

- Lvbs09cxswy2004c1 5sa002sDocument1 pageLvbs09cxswy2004c1 5sa002sKrishNo ratings yet

- Fsis09cxswyl004c006sa (FR LSH)Document1 pageFsis09cxswyl004c006sa (FR LSH)pkNo ratings yet

- 4NF20L STMicroelectronics PDFDocument12 pages4NF20L STMicroelectronics PDFTiago eletrônicaNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.rajesh1200No ratings yet

- Description Features: Aec-Q100, 60 To 220 MHZ, 0.1 To 0.25 PPM, Elite Platform™ Precision Super-TcxoDocument35 pagesDescription Features: Aec-Q100, 60 To 220 MHZ, 0.1 To 0.25 PPM, Elite Platform™ Precision Super-TcxoMtfNo ratings yet

- Sr. No. 3B Datasheet 1.5PX6CYWY 100Document2 pagesSr. No. 3B Datasheet 1.5PX6CYWY 100hemantmech099200No ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- Ata 29 30 32Document11 pagesAta 29 30 32anilmathew244No ratings yet

- Accession Natural Arts 457-465Document7 pagesAccession Natural Arts 457-465Lielet Matutino100% (1)

- StructuresDocument3 pagesStructuresRondon LabosnogNo ratings yet

- VFA FittingsCatalogueDocument164 pagesVFA FittingsCatalogueDimitar KondinskiNo ratings yet

- Inventory of Existing FacilitiesDocument2 pagesInventory of Existing FacilitiesChed PerezNo ratings yet

- Solar PVT Final 1Document69 pagesSolar PVT Final 1afshooabadaniNo ratings yet

- PAES 221 2017 Design of Canal Structures Road Crossing Drop Siphon and Elevated FlumesDocument5 pagesPAES 221 2017 Design of Canal Structures Road Crossing Drop Siphon and Elevated FlumesJade Ann CamposNo ratings yet

- ASC Audit Preparation Checklist Shrimp v1.1Document23 pagesASC Audit Preparation Checklist Shrimp v1.1Ragil Satriyo GumilangNo ratings yet

- An Interview With Joyce HartmanDocument76 pagesAn Interview With Joyce HartmanEsmeralda_County100% (1)

- Lot-01-WWTP-01 System PresentationDocument44 pagesLot-01-WWTP-01 System PresentationMesfinNo ratings yet

- Accepted Manuscript: Bioresource TechnologyDocument34 pagesAccepted Manuscript: Bioresource TechnologyGraciaVelitarioNo ratings yet

- Migrant Impact On Gulshan-E-Ravi Infrastructure and Environment Using Gis & Remote Sensing TechniquesDocument52 pagesMigrant Impact On Gulshan-E-Ravi Infrastructure and Environment Using Gis & Remote Sensing TechniquesMalinda RobinsonNo ratings yet

- AcetaminophenDocument7 pagesAcetaminophenAndika MetrisiawanNo ratings yet

- WreDocument12 pagesWrepratik maneNo ratings yet

- 7 EG-3 Approved Dec 03 Air-Cooled Heat ExchangersDocument25 pages7 EG-3 Approved Dec 03 Air-Cooled Heat Exchangersparag7676No ratings yet

- Water: Induwara Thisarindu 6-GDocument15 pagesWater: Induwara Thisarindu 6-GNiklesha TharushiNo ratings yet

- World's Greatest Books 19 Travel&AdventureDocument152 pagesWorld's Greatest Books 19 Travel&AdventureBrindusacNo ratings yet

- Clean Water Act in KawitDocument19 pagesClean Water Act in Kawitc23-5044-01No ratings yet

- Guide To Conducting Pumping TestsDocument10 pagesGuide To Conducting Pumping TestsSALES-ZARAHHGROUPNo ratings yet

- 12 Five Year Plan of IndiaDocument20 pages12 Five Year Plan of IndiaAppan Kandala VasudevacharyNo ratings yet

- Dayoc Research PaperDocument21 pagesDayoc Research PaperTata Duero Lachica100% (1)

- FAO Small Irrigation Structure Full PDFDocument656 pagesFAO Small Irrigation Structure Full PDFrgscribd61100% (8)

- Cargo Ventilation and Precautions To Minimise SweatDocument5 pagesCargo Ventilation and Precautions To Minimise SweatAysun GençcanNo ratings yet

- Major Project Report On Water Cum Air Cooler (By Nikhil Kumar 7074021ME)Document13 pagesMajor Project Report On Water Cum Air Cooler (By Nikhil Kumar 7074021ME)somya samalNo ratings yet

- Terrestrial, Aquatic, Marine Ecology and CommunitiesDocument26 pagesTerrestrial, Aquatic, Marine Ecology and CommunitiesArnel AngelesNo ratings yet

- Samadhan 1 - MergedDocument109 pagesSamadhan 1 - MergedPranjal Raj SinghNo ratings yet

- Tutorials 1-5 (Building Technology)Document14 pagesTutorials 1-5 (Building Technology)Heiriq LeeNo ratings yet