Professional Documents

Culture Documents

Palettiertechnik Bs GB PDF

Palettiertechnik Bs GB PDF

Uploaded by

kaniappan sakthivelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Palettiertechnik Bs GB PDF

Palettiertechnik Bs GB PDF

Uploaded by

kaniappan sakthivelCopyright:

Available Formats

Conveying technology Loading technology Palletizing technology Packaging technology Sorting and distribution technology

BEUMER palletizing technology:

quick, gentle and safe stacking.

BEUMER palletizing technology

The very best in stacking quality.

A matter of fact for BEUMER: BEUMER palletizing technology

superior performance. simply efficient.

For over 30 years, BEUMER has been The BEUMER research and development

designing and developing innovative division constantly analyses, redesigns,

packaging technologies for a vast range modifies or upgrades all systems and

of products. Whether for the building machines to meet the latest customer

materials and cement industry, for indi and market demands. One factor is

vidual and bulk products in the chemical always at the focus of our attention:

industry, for humus soils, peat and fer system efficiency, for example factory

tilizers or for the foodstuffs and animal testing by BEUMER reduces commis

feed segment the BEUMER product sioning times after delivery to our cus

programme has always been character tomers and allows a faster and more

ised by first-class stacking quality and effective start of full production.

extreme reliability.

BEUMER everything from a single

The wide variety of tasks demands a source.

graduated and comprehensive range of

products and services. With the BEUMER By request, we deliver as general con

robotpac and BEUMER paletpac lines, tractor complete concepts containing

BEUMER offers ideal solutions for secure everything from product filling and pal

transportation. With superior performance letizing to packaging according to your

levels of up to 5,000 packaging units wishes and coordinated to fulfil your

per hour. precise needs. Qualified engineering,

fast and reliable local service and opti

mised spares logistics complete the

picture and guarantee maximum oper

ational capability.

Summary of palletizing capacities

Bond 3x 5x 6x 7x 8x 10x

Packing pattern

paletpac 600 360 600 450 600 720 500 550 550 650

paletpac 1250 800 1250 1200 1400 1500 1400 1350 1200 1600

paletpac 1800 1200 1800 1350 1800 1800 1800 1800 1800 1800

BEUMER paletpac 1800

BEUMER palletizing technology

Modular construction that leaves nothing

to be desired.

BEUMER: adaptable palletizing

systems.

The pressures of international competi BEUMER service for satisfied the individual control of each separate

tion increase from day to day. In order to customers. Worldwide. component of a palletizer and ensures

maintain a competitive edge in the mar that any faults are quickly found and

ket, businesses need high-performance Our technical customer service supports remedied. The system components not

systems that fulfil the demands on mod you locally regarding matters of installa affected by the fault are automatically

ern machines and systems for instance, tion, operational commissioning as well returned to default positions from which,

extended running times under maximum as the maintenance and repair of all your after the fault has been remedied, nor

load. facilities and systems, and assumes re mal operation can be resumed automat

sponsibility throughout the entire opera ically. This feature prevents the occur

BEUMER palletizing technology pro tional life cycle. If you should have any rence of subsequent faults.

vides ideal system solutions, perfectly urgent questions, you can of course take

tailored to meet the customers specific advantage of the BEUMER Hotline too

requirements and fully compliant with fast and reliable, around the clock.

BEUMER palletizing technology

Outstanding features: always a touch

better.

In addition to their systematic pro

gramme management, BEUMER pal

letizing also stands out because of sev

eral special features. For example, our

operation mode division feature allows

Summary of palletizing capacities

the various wide-ranging product prop Bond 4x 5x 6x 7x 8x 10x

erties of the goods to be packaged. Packing pattern

Thanks to modular construction, individ

ual machines can be simply and quickly

paletpac 2500 1300 2200 1800 2500 2500 2100 2500 2500 2600

upgraded at any time, and without any

paletpac 2500 A 1400 2500 2600 2500 2500 2500 2500 2500 2600

problems, to cope with future increased

production demands.

BEUMER experts know what matters.

Experienced specialists, who really know

everything about the technologies in

volved as well as specific customer re

quirements for the palletizing of a wide

range of materials, are responsible for

the design and construction of our ma

chines and systems. Gentle handling of

packaging units and an ideal appear

ance of the palletized load units

guarantee secure transportation

and positive customer

feedback.

BEUMER paletpac 2500

BEUMER paletpac-product range

With bar or clamp turning device:

BEUMER paletpac 600

BEUMER paletpac 1250

BEUMER paletpac 1800

BEUMER paletpac 2500 with additional

timing conveyor and second pusher

High-performance line with bar turning:

BEUMER paletpac 3000 with double

bar turning device

BEUMER paletpac 4000 with bag

stream splitting and mobile bar turning

device

BEUMER paletpac 5000 with bag

stream splitting and double pusher

Special features:

Programme for all typical packing

patterns

BEUMER paletpac Particularly gentle bag handling

Stacks of impressive and

Low noise and low wear characteristics

thanks to the latest power train

technology

efficient solutions. Easy operating with diagnostics system

Fast parameter settings for optimisation

and adjustment to variable bag and

pallet sizes

BEUMER paletpac the right pal-

letizing system for every package.

Product-specific properties and individual

BEUMER paletpac: gentle handling customer requirements are essential rea

and perfect appearance. sons behind the constant and ongoing

development of the BEUMER paletpac

In case of need, BEUMER paletpac System. At the same time, the focus is

systems offer persuasive solutions with also on differentiating features such as

performance rates of between 600 and palletizer performance, the various drive

5,000 bags per hour regardless of the train components as well as the use of

bag type, paper, PE or PP, and the filling bar or clamp turning devices. The latest

of granulates, salts or fertilizers. They sensoring technologies, optimum elec

are characterised by gentle product tronic control systems and simple oper

handling, outstanding stacking qualities

and extreme reliability, and are constantly Bond 4x 5x 6x 7x 8x 10x

being upgraded to meet the wide-ran Packing pattern

ging demands of changing markets.

Bag length (mm) 600 600 600 600 400 500 450 450 400

The unique system expertise at BEUMER

Bag width (mm) 400 400 300 300 300 330 300 300 300

ensures optimum machinery configur

max. bag height (mm) 180 180 170 170 150 150 150 150 150

ations with appropriate options for all

technical and functional requirements, Layer dimensions 1200 x 1200 x 1200 x 1200 x 1200 x 1160 x 1200 x 1200 x 1200 x

(mm) 800 1000 900 900 700 1000 900 900 1000

even in the field of peripherals.

Performance (bags/h) 2800 4000 3600 4000 4000 4000 5000 5000 5000

ation complete the picture and make the

BEUMER paletpac line the ideal palletiz

ing system for the most demanding cus

tomer requests.

BEUMER paletpac 5000

BEUMER robotpac

From robot to palletizer.

We stack things in your favour.

The BEUMER robotpac palletizes and

depalletizes a wide variety of packaging

units from bags and boxed packages

to cartons and trays at rates of up to 900

units per hour, depending on the version

selected. The geometrical precision and

stability of the palleted stacks ensure

problem-free storage and guarantee se

cure integration into serially connected Upgrade whenever you need.

packaging systems.

Depending on their size and type, more

Thanks to the integration of advanced packaging units can be lifted and

control elements in the BEUMER moved simultaneously to increase the

robotpac system, it is also possible palletizing performance.

to palletize assorted sizes and forms

of unit loads this is the BEUMER way The specially designed lifting modules,

of order picking. such as fork grippers, suction grippers,

pallet grippers, tool changers, etc. can

be exchanged at any time. For example,

the additional installation of a pallet Flexibility is our strong point.

gripper module makes automatic empty

pallet feed possible without the need for The flexibility of the BEUMER robotpac

a separate empty pallet stacker. With makes it ideal for every palletizing task.

the appropriate module installed, the The hard-wearing, tried and tested ma

BEUMER robotpac can also be em chine components in combination with

ployed as an automatic depalletizer. electro-mechanical power transmission

guarantee secure operations.

The control functions of the BEUMER

robotpac are performed by a 4-axis In combination with the BEUMER

continuous path control system, and is packaging technology, the BEUMER

characterised by its outstanding ease of robotpac also offers all-round solutions

operation and its adaptability to changing to meet any requirements of the despatch

situations in use. Complex procedures departments of the building, chemical,

with varying basic parameters are reliably foodstuffs and animal feed industries.

and efficiently absolved.

We are always there when you need us!

Worldwide service.

Our service managers regular

inspections ensure:

Sustained operational capability

of your equipment

Reduction of downtimes

Exchange of experience

Qualification of the maintenance team

Continuous product optimisation

Optimum spares stocking

Fault correction / BEUMER Hotline.

Qualified worldwide support at short

Intelligent solutions from notice

Online fault correction

Worldwide availability of service

the intralogistics experts. engineers

Short-notice deployment option

BEUMER worldwide. Rapid action on the ground service

Technical consulting.

We can advise and train your staff, either in

our own training centre or in your company.

This ensures:

Optimum equipment and system

operation

Qualified evaluation of equipment

condition

Long-term optimisation strategies

Maintenance and repairs.

Personnel specifically qualified for your

equipment

Basis for extreme operational reliability

Qualification of your personnel in the

context of maintenance

We know the way. Worldwide. Our presence on the ground ensures

individual adaptation to regionally vary

As one of the international leaders in ing requirements. Location-relevant

the manufacture of intralogistics for the solutions are the result of our constant

conveying, loading, palletizing, packaging, close cooperation with our customers.

sorting and distribution technologies, we

know the routes your products take and Our corporate philosophy.

their respective specific properties. This

knowledge is integrated into the develop Family spirit is a fundamental factor in

ment and construction processes of all the success of BEUMER as a globally

our equipment and systems. The proximity operating concern. Shareholders, execu

to our customers in every part of the world tive management and staff are essential

is maintained and ensured by a global members of a community in which

sales and service network. constructive cooperation is a significant

element representing our corporate

Our workforce of around 900 people, an philosophy. The owners commitment

annual turnover of 150 million EUR, our to considerable reinvestment in the

own subsidiaries and holding companies company is a prerequisite for securing

on each continent and representatives in the future, and is the basis of the suc

over 70 countries are the solid foundation cess-orientated partnerships between

of our export-orientated activities. our company and our customers.

www.efp.de

FP3.GB.1008

BEUMER

Maschinenfabrik GmbH & Co. KG

PO Box 1254 59267 Beckum Germany

Tel. +49 (0) 25 21 - 24 0

Fax +49 (0) 25 21 - 24 280

E-mail: BEUMER@BEUMER.com

Further information is available at

www.beumer.com

BEUMER reserves the right to make modifications that serve technical

progress.

You might also like

- Software ManualDocument173 pagesSoftware Manualshrus50% (2)

- Beumer Palletizing Technology en 06Document12 pagesBeumer Palletizing Technology en 06mathiNo ratings yet

- Beumer Palletizing Technology enDocument12 pagesBeumer Palletizing Technology en윤홍민No ratings yet

- Conveying & Palletizing: Harmony in MotionDocument32 pagesConveying & Palletizing: Harmony in MotionKien Nguyen TrungNo ratings yet

- EN PC8000 11SE01 - ExcavatorDocument2 pagesEN PC8000 11SE01 - ExcavatorjoseolivapNo ratings yet

- Hronos RichardsonDocument8 pagesHronos Richardsonnmarkov80No ratings yet

- Pallet Handling Technology: High Throughput RatesDocument6 pagesPallet Handling Technology: High Throughput RatesBülent KabadayiNo ratings yet

- Catálogo 7500 7700Document28 pagesCatálogo 7500 7700Carolynne de PaulaNo ratings yet

- BEUMER Autopac Brochure ENDocument4 pagesBEUMER Autopac Brochure ENsemeNo ratings yet

- Packing and Palletizing SolutionsDocument16 pagesPacking and Palletizing Solutionsemmanuel0alvarez-8No ratings yet

- Palletpack 460: Function PackageDocument2 pagesPalletpack 460: Function PackagePrimanedyNo ratings yet

- Axel - Catalogo 2022 - EnGDocument32 pagesAxel - Catalogo 2022 - EnGDanieleNo ratings yet

- BEUMER Packaging TechnologyDocument12 pagesBEUMER Packaging TechnologyAyoub ChouikhNo ratings yet

- Catalogo Comercial Reach Raymond 7000 SeriesDocument28 pagesCatalogo Comercial Reach Raymond 7000 SeriesLeonardo VargasNo ratings yet

- Prefa MAXDocument16 pagesPrefa MAXglaconspromluxNo ratings yet

- BEUMER Chemical Logistics 01 PDFDocument12 pagesBEUMER Chemical Logistics 01 PDFadNo ratings yet

- Newte Bag Palletizing 1Document15 pagesNewte Bag Palletizing 1Kien Nguyen TrungNo ratings yet

- Vacuum Lifters Jumbo and VacuMasterDocument52 pagesVacuum Lifters Jumbo and VacuMasterVladislav GancerisNo ratings yet

- Metabox SpreadsheetDocument40 pagesMetabox SpreadsheetAlex WebNo ratings yet

- Smartpac: Remaining Flexible During Packing and UnpackingDocument9 pagesSmartpac: Remaining Flexible During Packing and UnpackingKelvin FacitelaNo ratings yet

- Raymond End Rider Model 8410 Sell SheetDocument2 pagesRaymond End Rider Model 8410 Sell Sheettimmybuds23No ratings yet

- Brochure AQUAmax PRO WebDocument32 pagesBrochure AQUAmax PRO WebDIPAL PATWANo ratings yet

- Huebsch Is The Answer.: Vended Galaxy 400, 600 Washer-Extractors WithDocument4 pagesHuebsch Is The Answer.: Vended Galaxy 400, 600 Washer-Extractors WithMegatFitriAzizNo ratings yet

- Coating of Polyester Film With Thin Wax LayersDocument37 pagesCoating of Polyester Film With Thin Wax LayersalfredoNo ratings yet

- Romaco strip-ENDocument28 pagesRomaco strip-ENHala HusaynNo ratings yet

- Beumer Autopac®: State-Of-The-Art Loading of Bagged MaterialDocument4 pagesBeumer Autopac®: State-Of-The-Art Loading of Bagged Materialmarjorie loyolaNo ratings yet

- Interroll Foerdermodule MCP-Katalog enDocument131 pagesInterroll Foerdermodule MCP-Katalog enandriNo ratings yet

- BEUMER Abfülltechnik Fillpac E PDFDocument4 pagesBEUMER Abfülltechnik Fillpac E PDFMKPashaPashaNo ratings yet

- Loadmaster 8000ix: On-Board WeighingDocument2 pagesLoadmaster 8000ix: On-Board WeighingMagdalena BujaraNo ratings yet

- Interroll Company ProfileDocument15 pagesInterroll Company ProfileMumu moemoeNo ratings yet

- Demag Product Range 21357544 - EN - DE - 170630Document32 pagesDemag Product Range 21357544 - EN - DE - 170630Thanos Kazakos100% (1)

- Alus Loading Unloading Freeze Dryer 312317Document9 pagesAlus Loading Unloading Freeze Dryer 312317satish.hmthNo ratings yet

- Unicarriers Low LiftingDocument16 pagesUnicarriers Low LiftingpurushmicroNo ratings yet

- STB-1809SS: Servo Side Seal WrapperDocument2 pagesSTB-1809SS: Servo Side Seal Wrappermagiva873No ratings yet

- Structured Packings GasDocument20 pagesStructured Packings GasBowo Edhi WibowoNo ratings yet

- Elite 910-915Document8 pagesElite 910-915Daniel Alejandro Bravo SandovalNo ratings yet

- The Ideal Lifting and Load Handling Solution For: 2 Axle TrucksDocument4 pagesThe Ideal Lifting and Load Handling Solution For: 2 Axle TrucksIrvan SimanjuntakNo ratings yet

- OryxRoboticPalletizer 28 06 10 PDFDocument4 pagesOryxRoboticPalletizer 28 06 10 PDFtintucinbNo ratings yet

- BBX50 BrochureDocument8 pagesBBX50 BrochureHuy Huỳnh QuangNo ratings yet

- Oem Ap114a en PDocument2 pagesOem Ap114a en PCARLOSWAR101No ratings yet

- BEUMER Conveying Technology 01Document12 pagesBEUMER Conveying Technology 01eduardoguidoNo ratings yet

- Utility 3000R Reefer BrochureDocument12 pagesUtility 3000R Reefer BrochureAmaro RazielNo ratings yet

- 8410-Fre60l Ficha TecnicaDocument2 pages8410-Fre60l Ficha TecnicaAlejandro GilNo ratings yet

- Romaco Strip enDocument28 pagesRomaco Strip enAbhineet ShrivastavaNo ratings yet

- Axle & Vehicle: Weighing SystemsDocument8 pagesAxle & Vehicle: Weighing SystemsLyle Patrick HernandezNo ratings yet

- Presentación ILPRADocument45 pagesPresentación ILPRAjohanpataNo ratings yet

- 2Document36 pages2juankudrizNo ratings yet

- RAgmngDocument32 pagesRAgmngRami AloanNo ratings yet

- LR3 (Eu)Document4 pagesLR3 (Eu)Đăng Điệp NguyễnNo ratings yet

- DICO Capping BrochureDocument8 pagesDICO Capping BrochureStuart MelenNo ratings yet

- Itema R9500-2Document30 pagesItema R9500-2ilhammulyalestariNo ratings yet

- Mobile Range: Mobile Light Towers and Dust Suppression CatalogueDocument12 pagesMobile Range: Mobile Light Towers and Dust Suppression CatalogueWidiyanto WibowoNo ratings yet

- Minicrane JekkoDocument20 pagesMinicrane JekkoKhang nguyen KhangNo ratings yet

- Product Catalog - 2020 MirDocument17 pagesProduct Catalog - 2020 MirThơm PhùngNo ratings yet

- Factsheet Vectura ENG WebDocument2 pagesFactsheet Vectura ENG WebFrank SciallaNo ratings yet

- Seaeye Cougar XTDocument6 pagesSeaeye Cougar XTcacalot93No ratings yet

- Robotic Systems: Flexible Parts Management - Fully IntegratedDocument20 pagesRobotic Systems: Flexible Parts Management - Fully IntegratedEduardo SilvaNo ratings yet

- Product Brochure R 9200Document28 pagesProduct Brochure R 9200sutopo am2fastNo ratings yet

- R9200 G7 Brochure - enGB USDocument28 pagesR9200 G7 Brochure - enGB USFrancois SlabbertNo ratings yet

- Central ElevatorDocument17 pagesCentral Elevatorapi-231572454No ratings yet

- Infrastructure Productivity EvaluationDocument106 pagesInfrastructure Productivity Evaluationkaniappan sakthivelNo ratings yet

- Slydring GBDocument58 pagesSlydring GBkaniappan sakthivelNo ratings yet

- ORFS Catalogue PDFDocument92 pagesORFS Catalogue PDFkaniappan sakthivelNo ratings yet

- Bs Image UsDocument32 pagesBs Image Uskaniappan sakthivelNo ratings yet

- 11 Aci Work StationsDocument16 pages11 Aci Work Stationskaniappan sakthivelNo ratings yet

- Rotary GBDocument194 pagesRotary GBkaniappan sakthivelNo ratings yet

- ALFING Automotive Crankshafts: Crankshafts For Series Production, Sports and Formula 1Document20 pagesALFING Automotive Crankshafts: Crankshafts For Series Production, Sports and Formula 1kaniappan sakthivelNo ratings yet

- BE Worm Geared Air MotorsDocument29 pagesBE Worm Geared Air Motorskaniappan sakthivelNo ratings yet

- Pwerstar 4 PumpDocument4 pagesPwerstar 4 Pumpkaniappan sakthivelNo ratings yet

- Camrol: Cam Follower BearingsDocument8 pagesCamrol: Cam Follower Bearingskaniappan sakthivelNo ratings yet

- Jan2009Updated WSDocument8 pagesJan2009Updated WSkaniappan sakthivelNo ratings yet

- KAT Hydraulikzylinder enDocument35 pagesKAT Hydraulikzylinder enkaniappan sakthivelNo ratings yet

- Basics For 2 Way Cartridge Valves LI: ISO 7368 Size From 16 To 100Document4 pagesBasics For 2 Way Cartridge Valves LI: ISO 7368 Size From 16 To 100kaniappan sakthivelNo ratings yet

- Cimbria Indent SeparatorsDocument8 pagesCimbria Indent Separatorskaniappan sakthivelNo ratings yet

- Servocylinders CK With Built-In Position TransducerDocument12 pagesServocylinders CK With Built-In Position Transducerkaniappan sakthivelNo ratings yet

- Digital Position Controllers Z-Ri-Tez, Z-Ri-LezDocument8 pagesDigital Position Controllers Z-Ri-Tez, Z-Ri-Lezkaniappan sakthivelNo ratings yet

- Cleanline Portable FA-FAPC eDocument8 pagesCleanline Portable FA-FAPC ekaniappan sakthivelNo ratings yet

- CH Image EnglDocument6 pagesCH Image Englkaniappan sakthivel100% (1)

- JCD Jog Conveyor DR YerDocument6 pagesJCD Jog Conveyor DR Yerkaniappan sakthivelNo ratings yet

- 1405 FastenersDocument77 pages1405 Fastenerskaniappan sakthivelNo ratings yet

- SEA Next Chrome enDocument12 pagesSEA Next Chrome enkaniappan sakthivelNo ratings yet

- Belt Conveyor GB PDFDocument8 pagesBelt Conveyor GB PDFkaniappan sakthivelNo ratings yet

- Produktuebersicht e 09 07Document16 pagesProduktuebersicht e 09 07kaniappan sakthivelNo ratings yet

- Indented Cylinder GBDocument8 pagesIndented Cylinder GBkaniappan sakthivelNo ratings yet

- ComponentWebCatalog 5a System Access PDFDocument43 pagesComponentWebCatalog 5a System Access PDFkaniappan sakthivelNo ratings yet

- Reverse Tesla CoilDocument17 pagesReverse Tesla Coilmarin_marin88100% (1)

- Bieniawski - Engineering Rock Mass Clasification PDFDocument249 pagesBieniawski - Engineering Rock Mass Clasification PDFJorge Luis Castro Orellana100% (1)

- Operation Manual: SERIES IZ15E-100 (RS232)Document40 pagesOperation Manual: SERIES IZ15E-100 (RS232)mihaita-gabriel basoiNo ratings yet

- Physics Exit 3q1718 .Document16 pagesPhysics Exit 3q1718 .Mikaella Tambis0% (1)

- Toyama Electric ProfileDocument17 pagesToyama Electric Profilesrikant0% (1)

- AA12 - Experience With Particle Breakdown in Gas Suspension CalcinersDocument10 pagesAA12 - Experience With Particle Breakdown in Gas Suspension CalcinerskalaiNo ratings yet

- Ardbot Making Robots With Arduino 3Document7 pagesArdbot Making Robots With Arduino 3gui9871No ratings yet

- FYP Proposal Submission Form: Human Activity Monitoring (Wall and Fence)Document2 pagesFYP Proposal Submission Form: Human Activity Monitoring (Wall and Fence)RizwanAliNo ratings yet

- Caleffi Central HeatingDocument1 pageCaleffi Central HeatingSite OfficeNo ratings yet

- Question Paper (Unit-Test-1) Analog IC Design (MEL G 632) Date: 21-02-2017 Time: 12:00 Hours To 13:00 Hours Closed Book Full-Marks: 15Document2 pagesQuestion Paper (Unit-Test-1) Analog IC Design (MEL G 632) Date: 21-02-2017 Time: 12:00 Hours To 13:00 Hours Closed Book Full-Marks: 15Gaurav PatilNo ratings yet

- Os Practical FileDocument43 pagesOs Practical FileVikram Passy0% (1)

- Pic 2Document1 pagePic 2jose paredesNo ratings yet

- Refrigerated Dryer: Installation Operation Debugging Maintain InstructionsDocument26 pagesRefrigerated Dryer: Installation Operation Debugging Maintain InstructionsHoàng LongNo ratings yet

- Instrumentation Products and Landscape E21 040 0082540 001Document4 pagesInstrumentation Products and Landscape E21 040 0082540 001Ajit SinghNo ratings yet

- Final Report MGT-403Document27 pagesFinal Report MGT-403Ashrafur RahmanNo ratings yet

- Embedded Coder Users Guide R2018a PDFDocument3,766 pagesEmbedded Coder Users Guide R2018a PDFFrancisco Javier Buenavida DuránNo ratings yet

- High-Speed Flight Propulsion SystemsDocument538 pagesHigh-Speed Flight Propulsion SystemsHoàng DavidNo ratings yet

- KarthikeyanRatheesh MRDocument1 pageKarthikeyanRatheesh MRRatheeshKRNo ratings yet

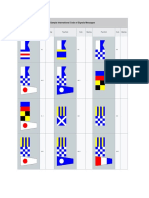

- Sample International Code of Signals MessagesDocument4 pagesSample International Code of Signals MessagesTJames PaulinNo ratings yet

- Agma Gear Rating Suite 3Document1 pageAgma Gear Rating Suite 3mgualdiNo ratings yet

- Ausa C 300 X x4 Parts Manual Katalog DelovaDocument10 pagesAusa C 300 X x4 Parts Manual Katalog Delovastanley100% (53)

- Inversor Automatico de Fuente de Poder Masterpact UA-BADocument38 pagesInversor Automatico de Fuente de Poder Masterpact UA-BARodolfoAntonioLeónCárdenas100% (1)

- Optimization ProcessDocument14 pagesOptimization Processalon0409No ratings yet

- LPC2148 DacDocument14 pagesLPC2148 DacSmruti Pore100% (1)

- Chapter 2 Introduction To MaterialsDocument47 pagesChapter 2 Introduction To MaterialsDDVANNo ratings yet

- CAP Regulation 100-1 - 08/28/2009Document48 pagesCAP Regulation 100-1 - 08/28/2009CAP History LibraryNo ratings yet

- (G6) Orifice Under Varying HeadDocument5 pages(G6) Orifice Under Varying HeadDane JonesNo ratings yet

- Xpelair Ventilation GuideDocument88 pagesXpelair Ventilation Guidemangjit100% (1)

- Daily Mis Report For Heat Treatment (Feb)Document40 pagesDaily Mis Report For Heat Treatment (Feb)YashJhunjhunwalaNo ratings yet