Professional Documents

Culture Documents

IQ Risk Analysis

IQ Risk Analysis

Uploaded by

Nadine LilleOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IQ Risk Analysis

IQ Risk Analysis

Uploaded by

Nadine LilleCopyright:

Available Formats

EU Effective

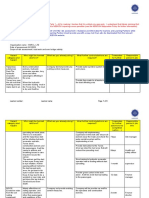

No. Observations Risk Proposed corrective actions Estimated cost Risk assessment after corrective actions Responsible Target date

GMP DD/MM/YY date

ref DD/MM/YY

protect the CFM with an airtight cover: cuboid plastic cover easy to Difficult to find a made to measure one, cost. But

take apart and put back together, easy to clean and airtight on the ? very practical and easy to clean. The space will then

floor (rail). To be found be too small for making the Alkaline bulk

If not possible to find an airtight cover: will make sure the machine is clean (only if cleaning firstly choose

1 other products manufactured in the 3.1 contamination of the capsule filling - clean the CFM before and after each use, the cleaning validation staff time spent validation done) but will take time and staff to do it. the corrective

same room machine (CFM) will then include all the products manufactured in the room on cleaning The space will then be too small for making the action

(Alkaline...) Alkaline bulk

not satisfying because no other place to do it. The

- dedicate the room for the capsules and use the other equipment 0 filtration room (only one under HVAC) is not

somewhere else designed for powders and is too big and difficult to

clean

define 4 areas:

3.1 - risk of contamination of the product by - storage (clothing, protective, cleaning material)

3.6 - human and of humans by the product, - passage With good training of the staff, and drawing and

2 Only one airlock for personnel and

product 3.7 - risk of cross contamination between - pallet of products processed

- pallet of products to be processed 0 labelling of the areas, the risk of contamination and Nadine

3.8 - product to be processed and processed Cf. Suggestion airlock.docx cross contamination will be very low

3.18 products Write the SOP and train the staff. Posters to explain the flow to be

put up

Buy smaller pallets (4 to be comfortable) max size 1.15x1.3m, must

3 Airlock too small to put 2 pallets at the 3.1 - not possible to follow point 1, lot of

same time 3.18 pallets movements be plastic. ex: http://www.masterjack.co.za/pharmaceutical R 1 695.00 each 2 smaller pallets can fit in the airlock Stefan

%20pallet.html

set the HVAC at 45%RH while using the room (also for sampling 0 will increase electricity consumption for the time Marten

room if weighing there). Marten to check if the HVAC can do it the room is used, but if possible will be reliable

if higher than 50% make the powder be

4 HVAC set at <65%RH, supplier

requirement is 40-50% 3.3 sticky and wet, if lower than 40%

increase the static electricity dehumidifyer cost when buying, use electricity, need

or buy a dehumidifyer and set it in the room. See the list of 2,720 to 5,480 proper maintenance, and difficult to clean. Marten Marten/Nadine

dehumidifyers to compare costs between both proposed action

5 no monitoring of the temperature and 3.3 not seeing an out of spec for the logger to be set in the room 0 - recycling satisfactory Stefan

humidity environment loggers

6 insects entering the milling room (and 3.4 contamination of the products and Marten to investigate with pest control companies to find a ? ? Marten

sampling room) equipment satisfactory solution

7 no control of the people entering the 3.5 unhautorised people can mess the add signs on the door "only for authorized people". Also need a sign 10 still need a better control by swipe card or door Marten

room equipment and products with the name of the RP code

8 Non dedicated parts in direct contact 3.6 cross contamination proof of cleaning efficiency must be established during cleaning cleaning depends on the result of the cleaning validation Nadine

with product validation, before cleaning validated, should be dedicated validation cost

not easy to clean, can lead to

9 floor cracked 3.9 contamination if not able to clean put new epoxy to fix the floor 40,000 satisfactory Stefan

properly

change the light fitting to put a smooth one ? satisfactory Marten

environment not easy to clean: light not cleaning properly and letting dust in cover the pipes with a square box ? satisfactory Marten/Stefan

10 fitting not smooth, pipes on the walls, 3.1 the room that can contaminate the

square corners, air vent with recesses product add silicon to round the corners ? satisfactory Marten/Stefan

get small brush to clean in between the grating ? satisfactory Marten

Debra to do a risk assessment for side effects of the products that 0 depends on the result of the risk assessment Debra

can be blown outside and inhaled by people

blowing the powder outside the ficility

11 without a filter, risk for people and 3.12 effects on people inhaling the powder

outside (eg lactose allergen) 5,000/roll, only

environment Marten to check if it is feasible to put a dust filter need small qty will avoid to blow out product, best for safety Marten

of this

weight in the sampling room, empty and clean the room between

3.13 - health risk for the staff, cross each product, only 1 product at a time. Seal the containers and No risk for the sampling room car stays a weighing

12 no laminar flow to weight the powder 3.14 -

3.22 - contamination when opening other transfer to the milling room for blending. Need to buy a bigger scale scale price? step only, just for bigger amounts. Cleaning between

each product so if need to sample, can be done Marten

3.40 product bags in the same room to weigh biggest amounts. Marten to tell what scale capacity is

needed between 2 products

take apart the small parts, seal them in plastic bags of get 2 big

plastic pallet boxes (1 for dirty, 1 for clean product) and transfer to plastic bags or

13 no wash bay to clean the equipment

and machine not moveable

3.36 - not being able to properly wash the

3.37 equipment

the wash bay to clean.

Clean in place the rest of the machine with dry or damp cloth plastic pallet cleaning validation to be performed Nadine

(depends on how easy to clean) boxes price?

http://www.goplasticpallets.com/gobox-1208-hygienic-low.html

14 pipes and plugs not labelled 3.42 could lead to error of use label the pipes and plugs, label flow direction if required 10 satisfactory Marten

no money to hire an engineer to do get the warranty T&C and fine prints if any, signed off by the supplier

15 the installation and training, will have N/A jeopardize the warranty (still waiting for supplier's feedback) 0 will make us know exactly what we can an can't do Nadine

to do it on our own

See Suggestion milling room.docx for room organisation. Do only 1 increase the run enough space if only 1 process is done at a time: will

16 lot of space taken by the CFM, cannot

be moved out N/A not much space left for the other

machines process at a time (sieving, machine out, blending, machine out, time for a increase the time spent per batch but decrease the

amount of staff involved => better specialisation of Nadine

capsulating). process the staff

Send it to Waterkloof for them to mill (production staff to be sent transport, The powder they make will be received as our raw

17 still not space for the big hammer mill N/A not being able to mill big batches there to do the milling). paperwork material (like plant powders we receive from other Marten

suppliers)

vacuum to be installed outside the increasing too much the temperature of

18 room but not possible to put on the N/A the milling room, contamination by the put the pump outside the room: requires additional pipes and drills R 6,000 satisfactory Marten/Stefan

ceiling (as per supplier plan) vacuum pump

? Material to be satisfactory

19 no equipment for cleaning of the room N/A using the stores cleaning material need a dedicated vacuum, broum, brushes stored in the airlock determined Marten

TOTAL

Marten 13

Stefan 6

Debra 1

Nadine 6

You might also like

- IG2 Risk Assessment Report 001Document19 pagesIG2 Risk Assessment Report 001Qasim Ibrar79% (42)

- Ig2 Example 1 v1Document16 pagesIg2 Example 1 v1Abdur Rahman68% (22)

- Unit IG2: Risk Assessment Part 1: BackgroundDocument17 pagesUnit IG2: Risk Assessment Part 1: BackgroundStven Smith100% (6)

- Fasih Ur Rehman IG2 Report.Document16 pagesFasih Ur Rehman IG2 Report.Fasih Ur RehmanNo ratings yet

- #36 IG2-forms-electronic-submissionDocument6 pages#36 IG2-forms-electronic-submissionHassan Alawami100% (3)

- Unit IG2: Risk Assessment: You Should Aim To Complete This Section in 150 - 200 WordsDocument17 pagesUnit IG2: Risk Assessment: You Should Aim To Complete This Section in 150 - 200 WordsMuhammad FaiSal100% (6)

- Pak American FertilizerDocument20 pagesPak American FertilizerMuhammad Asif100% (1)

- Unit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Document16 pagesUnit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1vivek vj67% (3)

- Ig2 ProjectDocument18 pagesIg2 Projectvivek vjNo ratings yet

- Unit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Document9 pagesUnit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1muhammad nadeem100% (1)

- JHA of Painting PDFDocument3 pagesJHA of Painting PDFTanver Ali100% (1)

- Martin Belt Conveyor HandbookDocument223 pagesMartin Belt Conveyor HandbookZahoor Ahmed100% (9)

- PWC Strategy& (Ex-Booz & Co.) - Industry 4.0 - How Digitization Makes Supply Chain More EfficientDocument32 pagesPWC Strategy& (Ex-Booz & Co.) - Industry 4.0 - How Digitization Makes Supply Chain More Efficientapritul3539No ratings yet

- Bomba de EspumaDocument16 pagesBomba de EspumaArmandoAndreNo ratings yet

- Process CostingDocument63 pagesProcess CostingIanne Michael Buenaventura Perez67% (3)

- Curtain Wall EngineeringDocument12 pagesCurtain Wall EngineeringKayBee Datiles100% (2)

- Ig2 Example 1 v1Document16 pagesIg2 Example 1 v1asim zeeshanNo ratings yet

- Site Waste Management PlanDocument8 pagesSite Waste Management Planshane.ramirez1980No ratings yet

- Study of The Abrasion Resistance in The Upholstery of Automobile SeatsDocument7 pagesStudy of The Abrasion Resistance in The Upholstery of Automobile SeatsAnonymous H5wo5gNo ratings yet

- Energy Savinganddustmanagementin Urea BaggingplantDocument10 pagesEnergy Savinganddustmanagementin Urea BaggingplantVINEETH BODANKINo ratings yet

- Re-Use of Scrap Polyurethane in Manufacturing of New Product ApplicationsDocument7 pagesRe-Use of Scrap Polyurethane in Manufacturing of New Product ApplicationsMironNo ratings yet

- Summer Plan - Inspection ChecklistDocument3 pagesSummer Plan - Inspection ChecklistFRAHIM HAIDERNo ratings yet

- Dynamic Devulcanization and Dynamic Vulcanization For Re-Cycling of Crosslinked RubberDocument8 pagesDynamic Devulcanization and Dynamic Vulcanization For Re-Cycling of Crosslinked RubberNima FakherNo ratings yet

- iNSPECTION CHEKLISTDocument3 pagesiNSPECTION CHEKLISTShrikant UtekarNo ratings yet

- Part 2 Correct OneDocument8 pagesPart 2 Correct OneMock ProjectNo ratings yet

- Sponge Jet Dry Abrasive Blasting Technology by PT REIDocument42 pagesSponge Jet Dry Abrasive Blasting Technology by PT REIMogul KhanNo ratings yet

- National Building Research Organization 4-Asbestos Full ReportDocument50 pagesNational Building Research Organization 4-Asbestos Full ReportAnton EdemaNo ratings yet

- Devlopment and Analysis of Natural Banana Fiber CompositeDocument3 pagesDevlopment and Analysis of Natural Banana Fiber CompositeEditor IJRITCCNo ratings yet

- Materials Today Communications: SciencedirectDocument12 pagesMaterials Today Communications: Sciencedirectsook mun100% (2)

- CH 02.09.04 Pliant MediaDocument5 pagesCH 02.09.04 Pliant MediaRinush Fedrikdo Bushido OdaNo ratings yet

- Instructions On RE-FLAMEDocument5 pagesInstructions On RE-FLAMEDIEGONo ratings yet

- Green HVACR 04 HeresiteDocument1 pageGreen HVACR 04 HeresiteAdeel NaseerNo ratings yet

- Icietet 83Document8 pagesIcietet 83Shashikanth MohrirNo ratings yet

- Experimental Performance and Neural NetwDocument6 pagesExperimental Performance and Neural Netw21UME116 Geetha ObhinniNo ratings yet

- IGC2Document20 pagesIGC2tharwatNo ratings yet

- Investigation of The Physical Properties of Meltblown Nonwovens For Air FiltrationDocument7 pagesInvestigation of The Physical Properties of Meltblown Nonwovens For Air FiltrationalbertoNo ratings yet

- (Done Read Half) Lamination and CoatingDocument11 pages(Done Read Half) Lamination and CoatingIbranesa NissreyasaNo ratings yet

- SHED-000 SHED Process (During Construction Work) 09.08.2021 (Pratusda) .....Document50 pagesSHED-000 SHED Process (During Construction Work) 09.08.2021 (Pratusda) .....Debraj SenNo ratings yet

- Environmental Product Declaration: Frescasa EcoDocument17 pagesEnvironmental Product Declaration: Frescasa EcoJairo EstebanNo ratings yet

- Buildings Department Practice Note For Authorized Persons and Registered Structural Engineers 144Document8 pagesBuildings Department Practice Note For Authorized Persons and Registered Structural Engineers 144Kaiser EdwardNo ratings yet

- Particle Filtration: Solutions For The Filtration of Oil Mist, Fumes, Aerosols, Electro-Erosion Smoke, EtcDocument2 pagesParticle Filtration: Solutions For The Filtration of Oil Mist, Fumes, Aerosols, Electro-Erosion Smoke, EtczakariaNo ratings yet

- Cao SuDocument47 pagesCao SuAnonymous 4MUYbZdx5TNo ratings yet

- Painting DalamDocument4 pagesPainting DalamAgung Juni KurniawanNo ratings yet

- C. Waste Management: 15. Waste Volume Reduction - Solid WasteDocument2 pagesC. Waste Management: 15. Waste Volume Reduction - Solid WasteJayniel AlcantaraNo ratings yet

- EnergyDocument10 pagesEnergyDennis Paul Paz LopezNo ratings yet

- JHA CoatingDocument9 pagesJHA Coatingبسام كريم100% (1)

- Importing With SAMSON Eco Hoppers: Dry Bulk MaterialsDocument3 pagesImporting With SAMSON Eco Hoppers: Dry Bulk MaterialsAtul HingnekarNo ratings yet

- Economics of Abrasive SelectionDocument4 pagesEconomics of Abrasive SelectionahmerkhateebNo ratings yet

- Safety Risk Managment Plan (Lahor Project)Document14 pagesSafety Risk Managment Plan (Lahor Project)rao sajjad0% (1)

- Environmental Inspection ChecklistDocument6 pagesEnvironmental Inspection ChecklistAhmed Salah El DinNo ratings yet

- Work Written Particulas Pm-2.5Document4 pagesWork Written Particulas Pm-2.5Pedro Daniel Mendoza OropezaNo ratings yet

- Introduction of FWTS, F W T S: Ujikin Aste Water Reatment YstemDocument12 pagesIntroduction of FWTS, F W T S: Ujikin Aste Water Reatment YstemdeddyNo ratings yet

- Risk Assessment and Management For A Ceramics IndustryDocument50 pagesRisk Assessment and Management For A Ceramics IndustryScribdTranslationsNo ratings yet

- Chapter 4 - Layout StrategyDocument8 pagesChapter 4 - Layout Strategyson15072003No ratings yet

- A Review of Processing Strategies For Producing Micro Nano Fibres For High Efficiency FiltrationDocument44 pagesA Review of Processing Strategies For Producing Micro Nano Fibres For High Efficiency Filtrationvinod kumarNo ratings yet

- Worksheet Project Barrier Final Nov 2020 ADocument1 pageWorksheet Project Barrier Final Nov 2020 AmcgonzalezNo ratings yet

- Fateh Ullah Mazhar, 00566534Document19 pagesFateh Ullah Mazhar, 00566534vivek vjNo ratings yet

- 5 Things Surface Prep 1Document40 pages5 Things Surface Prep 1Jesus De la RosaNo ratings yet

- Brochure Dechets-Solides EN PDFDocument4 pagesBrochure Dechets-Solides EN PDFishfaq.hamidNo ratings yet

- What Is A Cleanroom1Document55 pagesWhat Is A Cleanroom1XUAN CUONG PHANNo ratings yet

- 8.0 Floors: 8.1 Floor FinishesDocument3 pages8.0 Floors: 8.1 Floor FinishesLimar Al-QabbaniNo ratings yet

- FLEX B10087 00 7600 WS Atex 8S ENDocument2 pagesFLEX B10087 00 7600 WS Atex 8S ENShruthi RavichandranNo ratings yet

- Fabrication and Testing of Dry Waste Sor PDFDocument4 pagesFabrication and Testing of Dry Waste Sor PDFEmer JayNo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- 04-204 FLSKrebs gMAX Cyclones 10-26-16 WebDocument4 pages04-204 FLSKrebs gMAX Cyclones 10-26-16 WebrodrigoalcainoNo ratings yet

- Isou TC/SCDocument8 pagesIsou TC/SCSuperlucidoNo ratings yet

- Report 1 (Jack)Document9 pagesReport 1 (Jack)Mark SelvanNo ratings yet

- To Pull or Not To PullDocument17 pagesTo Pull or Not To PullJabri JuhininNo ratings yet

- TPM Training MaterialDocument87 pagesTPM Training MaterialNsidibe Michael Etim100% (1)

- Kisweld CatalogDocument76 pagesKisweld Cataloglara_rajkumar667No ratings yet

- Experiment No. 8 DoneDocument25 pagesExperiment No. 8 DoneshahNo ratings yet

- Summer Training ReportDocument60 pagesSummer Training ReportSanjay ChoudharyNo ratings yet

- BS1881 110 Method For Making Test Cylinders From Fresh ConcreteDocument12 pagesBS1881 110 Method For Making Test Cylinders From Fresh ConcretekhairulhakamNo ratings yet

- Logistic ProjectDocument94 pagesLogistic ProjectAdil Aslam100% (1)

- 12 PressroomDocument58 pages12 PressroomilliteratewhinoNo ratings yet

- Elvax Extrusion GuideDocument19 pagesElvax Extrusion GuideEsteban Ibarra RuizNo ratings yet

- Name Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentDocument12 pagesName Netid Group Number: Website Link: Tutorial Details Time Spent On Assignmentoliver_rose12345No ratings yet

- Lean ManufacturingDocument34 pagesLean ManufacturingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Operations Management 2nd Sem Mba at Bec DomsDocument164 pagesOperations Management 2nd Sem Mba at Bec DomsBabasab Patil (Karrisatte)No ratings yet

- Sika User Manual Pro RetailDocument20 pagesSika User Manual Pro RetailSeno HadiyantoNo ratings yet

- SpandexDocument35 pagesSpandexNift MfmNo ratings yet

- Piping FundamentalsDocument12 pagesPiping FundamentalsKurian Jose100% (1)

- Aluminum Alloy DatabaseDocument5 pagesAluminum Alloy Databaserizviabbas2012100% (1)

- Astm A53Document23 pagesAstm A53hermes willian santiago floresNo ratings yet

- Comparative AdvantageDocument7 pagesComparative AdvantageDhrs nnNo ratings yet

- PDFDocument4 pagesPDFInkanata SacNo ratings yet

- Toyota Production SystemDocument26 pagesToyota Production SystemVignesh HegdeNo ratings yet

- Master Kure 181Document2 pagesMaster Kure 181aahtagoNo ratings yet

- Boring OperationDocument9 pagesBoring Operation3pherNo ratings yet

- Annexure-II-List of Codes & StandardsDocument25 pagesAnnexure-II-List of Codes & StandardsMochamad BhadawiNo ratings yet