Professional Documents

Culture Documents

F To G: 1 To 2: Spreadsheets To BS 8110 & EC2

F To G: 1 To 2: Spreadsheets To BS 8110 & EC2

Uploaded by

janithOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F To G: 1 To 2: Spreadsheets To BS 8110 & EC2

F To G: 1 To 2: Spreadsheets To BS 8110 & EC2

Uploaded by

janithCopyright:

Available Formats

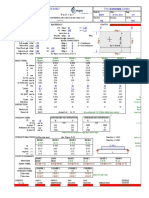

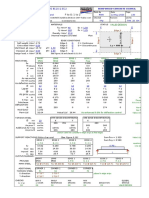

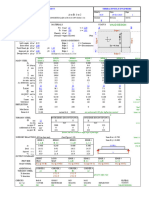

Project Spreadsheets to BS 8110 & EC2 The Concrete Centre

Client Advisory Group Made by Date Page

Location 32nd floor - corner panel F to G: 1 to 2 RMW 01-Oct-2017 174

2-WAY SPANNING INSITU CONCRETE SLABS to BS 8110:2005 (Table 3.14) Checked Revision Job No

Originated from RCC94.xls v4.1 2006 TCC chg - R68

DIMENSIONS MATERIALS STATUS VALID DESIGN

short span, lx m 4.00 fcu N/mm 25 gc = 1.50 F G

long span, ly m 5.20 fy N/mm 500 gs = 1.15 Edge 1

h mm 125 steel class A 1

Top cover mm 20 Density kN/m 25 Plan

Btm cover mm 20 (Normal weight concrete)

Lx = 4 m

Edge 4

Edge 2

LOADING characteristic EDGE CONDITIONS

Self weight kN/m 3.13 Edge 1 C C = Continuous

Extra dead kN/m 5.00 Edge 2 C D = Discontinuous Ly = 5.2 m

Total Dead, gk kN/m 8.13 gf= 1.40 Edge 3 D

Imposed, qk kN/m 5.00 gf= 1.60 Edge 4 C 2

Design load, n kN/m 19.38 See Figure 3.8 and clauses 3.5.3.5-6 Edge 3

SHORT LONG EDGE 1 EDGE 2 EDGE 3 EDGE 4 BS8110

MAIN STEEL SPAN x SPAN y Continuous Continuous Free Continuous Reference

s 0.047 0.028 0.062 0.037 0.000 0.037 Table 3.14

M kNm/m 14.5 8.5 19.4 11.4 0.0 11.4

d mm 100.0 90.0 100.0 91.0 102.0 91.0

k' 0.156 0.156 0.156 0.156 0.156 0.156

k 0.058 0.042 0.077 0.055 0.000 0.055

Z mm 93.1 85.5 90.5 85.1 96.9 85.1 3.4.4.4

As req mm/m 359 229 492 307 0 307

As min mm/m 163 163 163 163 163 163 Table 3.25

As deflection mm/m 604 386 ~ ~ ~ ~

mm 10 10 10 8 6 8

Layer B1 B2 T1 T2 T1 T2

@ mm 125 200 150 150 150 150

As prov mm/m 628 393 524 335 188 335

= % 0.628 0.436 0.524 0.368 0.185 0.368 %

S max mm 310 280 310 281 312 281 Clause

Subclause (a) (a) (a) (a) (a) (a) 3.12.11.2.7

DEFLECTION

fs 190 195 313 306 0 306 Eqn 8

Mod factor 1.565 Base ratio 26.0 Eqn 7

Perm L/d 40.70 Actual L/d 40.00 Asx enhanced 68.3% for deflection control Table 3.10

TORSION STEEL BOTH EDGES DISCONTINUOUS ONE EDGE DISCONTINUOUS

mm 10 X Y X Y

As req mm/m 269 163 3.5.3.5

As prov T mm/m 5000 5000 188 335

Additional As T req mm 0 0 0 0

As prov B mm/m 628 393 628 393

Bottom steel not curtailed in edge strips at free edges

SUPPORT REACTIONS (kN/m char uno) (See Figure 3.10) Sum vx = 0.779 Table 3.15

EDGE 1 EDGE 2 EDGE 3 EDGE 4 Sum vy = 0.720

1, F-G G, 2-1 2, F-G F, 2-1 equations

v 0.468 0.360 0.312 0.360 19 & 20

Dead kN/m 15.20 11.70 10.13 11.70

Imposed kN/m 9.35 7.20 6.24 7.20

Vs kN/m 36.2 27.9 24.2 27.9

OUTPUT/SUMMARY

SHORT LONG EDGE 1 EDGE 2 EDGE 3 EDGE 4

PROVIDE SPAN SPAN 1, F-G G, 2-1 2, F-G F, 2-1

MAIN STEEL H10 @ 125 B1 H10 @ 200 B2 H10 @ 150 T1 H8 @ 150 T2 H6 @ 150 T1 H8 @ 150 T2

ADDITIONAL CORNER 1 CORNER 2 CORNER 3 CORNER 4

TORSION STEEL F1 G1 G2 F2

X direction

placed in edge strips

Y direction

CHECKS BAR SINGLY MIN MAX GLOBAL

Lx > Ly < COVER REINFORCED SPACING SPACING DEFLECTION STATUS

OK OK OK OK OK OK VALID DESIGN

You might also like

- Eastgate Centre, Harare ZimbabweDocument17 pagesEastgate Centre, Harare ZimbabweKIANU STEVE100% (4)

- Installation of Load Bearing (Transverse and Axial) Steel Studs and Related AccessoriesDocument4 pagesInstallation of Load Bearing (Transverse and Axial) Steel Studs and Related Accessoriesmohammed ;arasnehNo ratings yet

- House Building ScheduleDocument39 pagesHouse Building Schedulearshad48586% (14)

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Felicia Ghica100% (1)

- RCC94 Two-Way Slabs (Tables)Document1 pageRCC94 Two-Way Slabs (Tables)curiosity12No ratings yet

- RCC94 Two-Way Slabs (Tables) - RS2Document1 pageRCC94 Two-Way Slabs (Tables) - RS2Arnold TunduliNo ratings yet

- Spreadsheets To BS 8110 & EC2: First Floor-Edge Panel SH 07-Nov-2020 130Document1 pageSpreadsheets To BS 8110 & EC2: First Floor-Edge Panel SH 07-Nov-2020 130buddikalrNo ratings yet

- 2 Way Slab DesignDocument3 pages2 Way Slab DesignAhmedNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2JigarNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document4 pagesRCC94 Two-Way Slabs (Tables)HAFEELNo ratings yet

- Two-Way Solid Slabs - 1Document4 pagesTwo-Way Solid Slabs - 1rizwanjawaid.meenaNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document4 pagesRCC94 Two-Way Slabs (Tables)Jacksizo Mremanyo100% (1)

- 35m Tower CheckDocument68 pages35m Tower CheckHarold Jackson MtyanaNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Ujol PraNo ratings yet

- 2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)Document4 pages2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)alialiNo ratings yet

- Spreadsheets To BS 8110 & EC2 Advisory Group 32nd Floor - Corner Panel RMW 24-Aug-2020 130 CHG R68Document1 pageSpreadsheets To BS 8110 & EC2 Advisory Group 32nd Floor - Corner Panel RMW 24-Aug-2020 130 CHG R68roshan034No ratings yet

- TCC94 Two Way Slabs TablesDocument5 pagesTCC94 Two Way Slabs TablesMihai JNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Yasiri LucNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamNo ratings yet

- CALC SHEET ZOLA - CompressedDocument33 pagesCALC SHEET ZOLA - CompressedSami Abdelgadir MohammedNo ratings yet

- RCC94 Two Way Slabs (Tables) MCY 1f ChillerDocument1 pageRCC94 Two Way Slabs (Tables) MCY 1f ChillerYati ChanNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2மாறன் செங்கேணிNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Cioabla BogdanNo ratings yet

- 5 To 6: A To B: Twin VillaDocument1 page5 To 6: A To B: Twin VillamohammedNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2ery achjariNo ratings yet

- Two-Way Slabs Design To BS 8110Document4 pagesTwo-Way Slabs Design To BS 8110samloo1997No ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)thusiNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2christi SNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)christi SNo ratings yet

- Two-Way Slab V2Document4 pagesTwo-Way Slab V2Eric AbedaniaNo ratings yet

- 4.slab 2Document5 pages4.slab 2ikramNo ratings yet

- PANEL08Document1 pagePANEL08Isaac JosephNo ratings yet

- 5 To 6: A To B: Villa BECDocument1 page5 To 6: A To B: Villa BECmohammedNo ratings yet

- Two-Way Slab DesignDocument4 pagesTwo-Way Slab DesignRaghNo ratings yet

- 2way Slab Output by RCCDocument4 pages2way Slab Output by RCCSherwin PonsNo ratings yet

- 5 To 6: A To B: Aktar BalushiDocument1 page5 To 6: A To B: Aktar BalushimohammedNo ratings yet

- TCC94 Two-Way Slabs (Tables)Document1 pageTCC94 Two-Way Slabs (Tables)Kojo AsareNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC298675No ratings yet

- TCC94 Two-Way Slabs (Tables)Document5 pagesTCC94 Two-Way Slabs (Tables)Mario Sajulga Dela CuadraNo ratings yet

- Two-Way Slabs (Tables)Document5 pagesTwo-Way Slabs (Tables)hala_azhariNo ratings yet

- RCC94 Two Way Slabs (Tables) MCY RF CTDocument1 pageRCC94 Two Way Slabs (Tables) MCY RF CTYati ChanNo ratings yet

- Valid Design: Design of Two Way Slab (S-1)Document1 pageValid Design: Design of Two Way Slab (S-1)Pipoy ReglosNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)adelalwailyNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)Anonymous ELujOV3No ratings yet

- 5 To 6: A To B: VillaDocument1 page5 To 6: A To B: VillamohammedNo ratings yet

- Development On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaDocument12 pagesDevelopment On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaAustin AnindoNo ratings yet

- RCC94 Two-Way Slabs (Tables) - 1Document5 pagesRCC94 Two-Way Slabs (Tables) - 1samueladebo207No ratings yet

- RCC94 Two-Way Slabs (Tables)Document3 pagesRCC94 Two-Way Slabs (Tables)Mohammad Twaha JaumbocusNo ratings yet

- RCC94 Two-Way Slabs TablesDocument3 pagesRCC94 Two-Way Slabs TablesjohnyNo ratings yet

- Dimensions Materials Status: Spreadsheets To Eurocode 2Document1 pageDimensions Materials Status: Spreadsheets To Eurocode 2jasekan.dcNo ratings yet

- Most Critical Interior PanelDocument1 pageMost Critical Interior PanelKagwi MauriceNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Murthy GunaNo ratings yet

- 3.0RCC94 Two-Way Slabs - 2Document5 pages3.0RCC94 Two-Way Slabs - 2ikramNo ratings yet

- Our Critical Slab DesignDocument5 pagesOur Critical Slab DesignIsmail AbdiNo ratings yet

- 1st Floor 2 Way SlabDocument4 pages1st Floor 2 Way SlabOyelade MuyiwaNo ratings yet

- Transformer Slab PDFDocument1 pageTransformer Slab PDFfdfsdfsNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document9 pagesRCC92 Ribbed Slabs (Tables)christi SNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document9 pagesRCC92 Ribbed Slabs (Tables)Murthy GunaNo ratings yet

- RCC95 Continuous Beams (Tables)Document8 pagesRCC95 Continuous Beams (Tables)Felicia GhicaNo ratings yet

- RCC95 Continuous Beams (Tables)Document9 pagesRCC95 Continuous Beams (Tables)christi SNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document7 pagesRCC92 Ribbed Slabs (Tables)Cioabla BogdanNo ratings yet

- My CVDocument3 pagesMy CVjanithNo ratings yet

- HDPE-Pipe InstallationDocument29 pagesHDPE-Pipe InstallationjanithNo ratings yet

- 0 24 Months Offer 2022Document3 pages0 24 Months Offer 2022janithNo ratings yet

- Refund Policy For Cae - 2022Document2 pagesRefund Policy For Cae - 2022janithNo ratings yet

- BC Local Refund FormDocument2 pagesBC Local Refund FormjanithNo ratings yet

- Duty Point Calculation For Pumping Line From Nuwarawewa WTP To Stage Iii TowerDocument18 pagesDuty Point Calculation For Pumping Line From Nuwarawewa WTP To Stage Iii TowerjanithNo ratings yet

- 02.APIT 2223 Table 01Document66 pages02.APIT 2223 Table 01janithNo ratings yet

- 0123 Ac DetDocument3 pages0123 Ac DetjanithNo ratings yet

- Thissawewa AugmentationDocument1 pageThissawewa AugmentationjanithNo ratings yet

- Thank You, Your Payment Was Successfully CompletedDocument1 pageThank You, Your Payment Was Successfully CompletedjanithNo ratings yet

- Evaluation of Modulus of Subgrade Reaction (K) in Gravely Soils Based On Standard Penetration Test (SPT)Document4 pagesEvaluation of Modulus of Subgrade Reaction (K) in Gravely Soils Based On Standard Penetration Test (SPT)janithNo ratings yet

- uPVC Pipes & Fittings PDFDocument20 pagesuPVC Pipes & Fittings PDFjanith100% (1)

- 31 23 23 - Utility Backfill MaterialsDocument9 pages31 23 23 - Utility Backfill MaterialsjanithNo ratings yet

- 2.DI Pipes & Fittings - For Works Doc - 11!10!2017Document4 pages2.DI Pipes & Fittings - For Works Doc - 11!10!2017janithNo ratings yet

- 4.building WorksDocument27 pages4.building WorksjanithNo ratings yet

- 1.civil WorksDocument16 pages1.civil WorksjanithNo ratings yet

- Preamble Notes For Supply and Installation of Pumps / Chlorinators and Chemical Dosing EquipmentDocument4 pagesPreamble Notes For Supply and Installation of Pumps / Chlorinators and Chemical Dosing EquipmentjanithNo ratings yet

- Spreadsheets To BS 8110: A G A GDocument1 pageSpreadsheets To BS 8110: A G A GjanithNo ratings yet

- Spreadsheets To BS 8110: Weight of ReinforcementDocument1 pageSpreadsheets To BS 8110: Weight of ReinforcementjanithNo ratings yet

- Senaka BeamDocument1 pageSenaka BeamjanithNo ratings yet

- Invitation IESL Family Gettogether 2016-2Document1 pageInvitation IESL Family Gettogether 2016-2janithNo ratings yet

- Sail GIDocument40 pagesSail GInitin chaudharyNo ratings yet

- BOQ of Gimbi FenceDocument39 pagesBOQ of Gimbi FenceBekesha100% (1)

- NSCPDocument3 pagesNSCPJulius Christian PerezNo ratings yet

- 2 Design ផ្ទោងមុំ 35Document1 page2 Design ផ្ទោងមុំ 35lavyNo ratings yet

- Railway StudyDocument2 pagesRailway StudyAnonymous UUw70xirblNo ratings yet

- Chapter 1 - Introduction To RCDocument34 pagesChapter 1 - Introduction To RCBeanNo ratings yet

- Aluminium Brochure PDFDocument24 pagesAluminium Brochure PDFHassan Hassan100% (1)

- Panel Schedule (UDH)Document43 pagesPanel Schedule (UDH)Asif SajwaniNo ratings yet

- Project Two Storey Residence Subject BilDocument6 pagesProject Two Storey Residence Subject BilEdgar LavapiezNo ratings yet

- Double SkinDocument15 pagesDouble SkinAnuja JadhavNo ratings yet

- Design Brief On MEP Systems PDFDocument21 pagesDesign Brief On MEP Systems PDFAdhikari ThushanNo ratings yet

- Sectional Elevation-WfDocument1 pageSectional Elevation-Wfsri projectssNo ratings yet

- Bar Bending Schedule: Grade BeamsDocument4 pagesBar Bending Schedule: Grade BeamsTanvir Shahrier MahmudNo ratings yet

- Dedicated Outdoor Air Systems: Models RV and RVEDocument12 pagesDedicated Outdoor Air Systems: Models RV and RVEAndres Aguilar-MatamorosNo ratings yet

- Subfloor - DatasheetsDocument17 pagesSubfloor - DatasheetsLGTNo ratings yet

- Composite Materials 2 Mark Questions 5 UnitsDocument5 pagesComposite Materials 2 Mark Questions 5 UnitsM.Thirunavukkarasu100% (3)

- Feasibility of Using Lightweight Eps Based Partitions For Washrooms of ApartmentsDocument6 pagesFeasibility of Using Lightweight Eps Based Partitions For Washrooms of ApartmentsVishnuNo ratings yet

- WE - Inimetla - GS at CompletedDocument165 pagesWE - Inimetla - GS at Completedgopal krishnaNo ratings yet

- Log Sheet Ylaa 150.72-Mr1Document4 pagesLog Sheet Ylaa 150.72-Mr1dhcastanoNo ratings yet

- Proposed Low-Cost HousingDocument5 pagesProposed Low-Cost Housingmark josephNo ratings yet

- iKW PER TRDocument19 pagesiKW PER TRAsif iqbalNo ratings yet

- For FinolexDocument72 pagesFor FinolexKokila KokilaNo ratings yet

- Chiller ChecklistDocument3 pagesChiller ChecklistMohammed SayeeduddinNo ratings yet

- Gtech SpecificationDocument1 pageGtech Specificationfrengky silabanNo ratings yet

- Bargin Price - OnLY OCT.-5Document4 pagesBargin Price - OnLY OCT.-5Selver SalkicNo ratings yet

- Insulation MaterialsDocument18 pagesInsulation MaterialsChona ManliguisNo ratings yet

- 210.52 (A) (2) Dwelling Unit Receptacle Outlets. Wall SpaceDocument4 pages210.52 (A) (2) Dwelling Unit Receptacle Outlets. Wall SpaceLissett MartinezNo ratings yet