Professional Documents

Culture Documents

Unesco - Eolss Sample Chapters: Food Waste

Unesco - Eolss Sample Chapters: Food Waste

Uploaded by

herikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unesco - Eolss Sample Chapters: Food Waste

Unesco - Eolss Sample Chapters: Food Waste

Uploaded by

herikCopyright:

Available Formats

FOOD ENGINEERING Vol.

IV - Food Waste - Chen, Shulin

FOOD WASTE

Chen, Shulin

Department of Biological Systems Engineering, Washington State University, Pullman,

WA, USA

Keywords: Waste, food waste, wastewater parameters, wastewater characteristics,

environmental regulations, treatment processes, utilization, disposal, land treatment,

lagoons, primary treatment, secondary treatment, tertiary treatment, waste reduction,

sludge.

Contents

1. Introduction

2. Wastewater Parameters

S

TE S

2.1. Temperature

R

AP LS

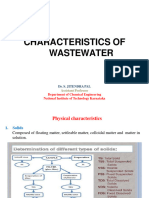

2.2. Solids

2.3. pH

2.4. Dissolved Oxygen

C EO

2.5. Biochemical Oxygen Demand

2.6. Chemical Oxygen Demand

2.7. Oil and Grease

2.8. Nitrogen

2.9. Phosphorous (P)

E

H

2.10. Sulfur

3. Characteristics of Food Processing Wastewater

PL O

3.1. Waste Generation and Waste Load

M SC

4. Regulatory Issues

5. Management and Treatment Processes

5.1. Waste Reduction Strategies

5.2. Utilization

SA NE

5.3. Wastewater Treatment

5.3.1. Pretreatment

5.3.2. Primary Treatment

U

5.3.3. Secondary Treatment

5.4. Treatment and Disposal of Sludge

Glossary

Bibliography

Biographical Sketch

Summary

Food waste management has become a major task in food processing facilities as

environmental regulations worldwide become more stringent. Wastewater from food

processing facilities is often high in strength, as indicated by the major water quality

parameters, and is more difficult to treat than municipal wastewater. The most effective

approach for food waste management is source minimization and by-product recovery.

The major components of food waste contributing to this high strength often have high

Encyclopedia of Life Support Systems (EOLSS)

FOOD ENGINEERING Vol. IV - Food Waste - Chen, Shulin

nutrient values. These substances include proteins, lipids, and carbohydrates that can be

used in livestock feed. Most future efforts in food waste management will largely

replace the production of waste with the production of secondary products. In many

cases, the need to recover by-products provides an opportunity for greater economic

return. Some food waste management problems can be addressed through standard

practices for good manufacturing, and through multi-disciplinary efforts engineering,

economics, food science and technology, soil science, and chemistry. The remaining

waste needs to be treated with proper technologies, which are typically divided into pre-

treatment, secondary treatment and advanced treatment processes. The most suitable

treatment process is often site specific.

1. Introduction

Waste generation is often a natural consequence of food processing operations such as

sugar mill, dairy factories, meat, fish, fruits, and vegetable processing plants. As

S

TE S

environmental regulations become increasingly stringent, appropriate management of

R

AP LS

food wastes has become an essential part of modern food processing management. The

amount of waste generation and the manageability of waste generated by a process have

become criteria for evaluating the applicability of the process.

C EO

There are various types of food waste generated in many steps of production,

processing, distributing, and consumption of food. The discussion of this article focuses

on food waste related to food processing. Waste can be produced in a food processing

plant in different forms, including solid waste, such as shells and residues, and liquid

E

waste, such as wastewater and sludge. This article focuses primarily on wastewater,

H

because wastewater management is more challenging than the management of solids

PL O

waste.

M SC

2. Wastewater Parameters

From a treatment perspective, food waste is characterized by typical parameters that

SA NE

describe the nature of waste and its potential impact on the environment. These

parameters can be divided into physical, chemical and biological, mainly including

temperature, pH, and concentrations of dissolved oxygen, oil and grease, sulfur,

U

nutrients (nitrogen and phosphorous), biochemical oxygen demand, and chemical

oxygen demand. The following discussion briefly explains these parameters.

2.1. Temperature

Temperature of the wastewater determines its thermal impact on the receiving water. In

a receiving water body that supports a biological community, temperature needs to be

maintained within a certain range. For example, direct discharge of cooling water to

streams that support cold water fish species will cause elevated temperature of the

stream and adversely impact the fish. Another important aspect of temperature is its

impact on decay of waste material in the wastewater. The higher the temperature, the

faster the decay rate will be.

Encyclopedia of Life Support Systems (EOLSS)

FOOD ENGINEERING Vol. IV - Food Waste - Chen, Shulin

2.2. Solids

Solids concentration represents the amount of material contained in water, usually

expressed as milligrams of dry weight per liter of water sample. Several terms are

typically used for characterizing solids. For example, the total solids represent the

amount of residue resulting from evaporation of a wastewater sample at 103 to 105oC.

The total solids can be further divided according to particle size into total dissolved

solids (TDS) and total suspended solids (TSS). In wastewater analysis, this separation is

made by using a filter pad with a pore size of about 2 microns. The dry weight of the

residue contained in the water sample that passed through the filter is called TDS,

whereas the dry weight of the solids retained on the filter is called TSS. Another

commonly used term related to solids is settleable solids, which refers to wastewater

solids that settle to the bottom within 1 hour, as measured using a graduated Inhoff

cone.

S

TE S

All the solids portions described above can be further characterized as fixed residue or

R

AP LS

volatile residue. Fixed residue is the ash component produced after the solids material is

burned in a muffle furnace at 550oC for 15 to 30 minutes, where the volatile residue is

the portion of solids that disappeared during the burning process. Thus, volatile residue

C EO

is often interpreted as the organic component of the solids, and fixed residue as the

oxidized inorganic matter.

Solids in wastewater have various environmental impacts. High TDS increases the

salinity of the receiving water. High volatile solids concentration means high organic

loading to the receiving water. High TSS concentration increases the turbidity of the

E

receiving water. Higher turbidity in water reduces light transmittance of the water

H

column. Additionally, discharging the wastewater with a high TSS concentration can

PL O

also alter the habitat of the receiving water due to the deposition of the solids.

M SC

2.3. pH

The pH is related to the hydrogen ion concentration in the wastewater, thus the

SA NE

wastewaters acidity. Most bacterial and biological life can survive only within a certain

pH range. Thus, the wastewater's pH represents its impact on the receiving water's

acidity. Environmental regulations for discharge to the environment typically require

U

that pH of the wastewater be within the range 6 to 9. Extreme wastewater pH also

adversely affects the performance of chemical and biological wastewater treatment

systems, and causes corrosion of equipment as well.

2.4. Dissolved Oxygen

Dissolved oxygen (DO) concentration in wastewater is a measure of oxygen availability

in the wastewater. A variety of aquatic life and many types of aerobic bacteria rely on

DO for proper function. Adequate DO is required in a water body to support aquatic

life. Thus, DO is often the limiting factor in protecting the safety of an aquatic

environment because of the competition for DO between different organisms.

2.5. Biochemical Oxygen Demand

Encyclopedia of Life Support Systems (EOLSS)

FOOD ENGINEERING Vol. IV - Food Waste - Chen, Shulin

Biochemical oxygen demand (BOD) is a parameter that describes the amount of

biological degradable organic matter in wastewater. BOD is determined by measuring

the amount of DO consumed in a wastewater sample for a given time period under a

given temperature. For example, BOD5 is typically used in environmental regulations

for indicating the amount of DO required for the decay of organic constituents in the

wastewater sample within five days at 20oC.

2.6. Chemical Oxygen Demand

Chemical oxygen demand (COD) measures the amount of oxygen needed for chemical

oxidization of organic material contained in the wastewater sample. COD represents the

maximum impact of wastewater on the DO of the receiving water. COD analysis is

conducted using a strong chemical oxidant, which is more rapid than BOD

measurement. For specific wastewater, there may be a correlation between COD and

BOD values.

S

TE S

R

AP LS

2.7. Oil and Grease

Oil and grease are sometimes called fats, oil, and grease. As the names implies, this

C EO

parameter represents the amount of oil and grease in wastewater. The environmental

impact of oil and grease can be noted in several aspects. First, the thin film of oil and

grease on the water surface reduces the interchange of air with water, which reduces

oxygen diffusion to the water. Secondly, these hydrocarbons and related compounds

require more oxygen per unit of weight than other organics to complete their oxidation

E

and thus increase the oxygen demand. Oil and grease are typically less easily

H

biodegradable.

PL O

2.8. Nitrogen

M SC

Nitrogen exists in different forms and is important to all forms of life. Transformation

of nitrogen among different forms is governed by the nitrogen cycle. Most

SA NE

environmentally important nitrogen forms include ammonia, nitrate, nitrogen gas, and

organic nitrogen, such as protein. In most food products, nitrogen exists in the form of

protein. Decomposition of protein in food waste (or animal waste) by bacteria converts

U

the organic nitrogen to ammonia. In an aqueous solution, ammonia has two forms: NH3

and NH4+. The equilibrium between these two species is determined by pH. The

unionized ammonia form (NH3) is toxic to most aquatic life. Under aerobic conditions,

ammonia is converted to nitrite, and then nitrate (NO3-) by a group of bacteria called

nitrifiers. Nitrate can be readily taken up by plants and converted to organic nitrogen.

Nitrate is mobile in soil because of its negative charge. Excessive nitrate leaching to

groundwater can cause health problems. High nitrate concentration in drinking water is

toxic to humans, especially infants, and livestock. Under anaerobic conditions, nitrate is

converted to nitrogen gas biologically through a process called denitrification. Some

bacteria or plants can fix nitrogen from nitrogen gas to protein.

Another often used term in food processing wastewater is Total Kjeldhahl Nitrogen

(TKN), which measures the concentration total of organic nitrogen and ammonia.

Encyclopedia of Life Support Systems (EOLSS)

FOOD ENGINEERING Vol. IV - Food Waste - Chen, Shulin

Organic nitrogen can be determined if ammonia is removed from the TKN analysis. The

protein content of wastewater can be determined by the organic nitrogen content.

2.9. Phosphorous (P)

Phosphorous as phosphate (PO42-) is another essential element in many living

organisms, and is often considered the growth limiting factor in numerous water bodies,

such as rivers and lakes. Excess P input to receiving water can cause eutrophication in

rivers and lakes, characterized by the abundant growth of algae and other aquatic plants,

which during the respiration phase at night can deplete the dissolved oxygen in water

bodies, causing fish kill and other nuisance conditions.

2.10. Sulfur

Sulfur compounds in wastewater are a major problem for some food processors. The use

S

TE S

of sulfur dioxide in pre-treatment of fruits or sodium bisulfide in processing may result

R

AP LS

in sulfur content in wastewater. Sulfur compounds exist in water primarily as sulfide

and sulfate ions or precipitates. Hydrogen sulfide, a product of anaerobic processes, can

cause bad odor problems.

C EO

3. Characteristics of Food Processing Wastewater

3.1. Waste Generation and Waste Load

E

H

The characteristics of wastewater generated by food processing plants can vary

considerably due to the diversity of the food industry and other factors, such as size of

PL O

operation and number of products produced, levels of processing, material conveyance,

cleanup and housekeeping, and process water usage. Table 1 displays typical values for

M SC

water consumption and pollutant contribution in beef, turkey, and broiler processing in

the United States. Additionally, Table 2 gives the characteristics of meat processing

effluent reported from New Zealand. For the purpose of reference, Table 2 also provides

SA NE

typical characteristics of domestic wastewater in the USA.

Animal Type Pollutant Load, kg/1000 animal Water Usage

U

BOD5 TSS Fat and Grease Liters/animal

Beef 3044 3112 200 1325

Turkey 77 118 27 96

Broiler 22 26 3.6 22

Table 1. Water consumption and pollutant contributions for beef, turkey, and broiler

processing.

[From: Ross C.C. and Valentine G.E. (1990). An Overview of Environmental Concerns

in the Meat and Poultry Processing Industry. In Agricultural and Food Processing

Waste, 66-75. Proceedings of the Sixth International Symposium on Agricultural and

Food Processing Wastes, December 17-18, 1990. Chicago, Illinois. ASAE Publication

05-90, American Society of Agricultural Engineers, St. Joseph, Michigan, USA.]

Encyclopedia of Life Support Systems (EOLSS)

FOOD ENGINEERING Vol. IV - Food Waste - Chen, Shulin

Parameter Meat Processing Domestic

(Cooper and Russell, 1992) (Liu, et al., 1997)

BOD5 700-1800 110-400

COD 1000-3000 250-1000

TKN 70-240 20-85

Ammonia-N 5-50 12-50

TSS 200-1200 100-350

Fat 100-900 50-150

TP 5-20 4-15

Table 2. Comparisons of characteristics of meat processing effluent and raw domestic

wastewater (mg/l).

S

TE S

[From: Cooper R.N., and Russell J.M. (1992). The New Zealand Meat Processing

R

Industry, Present Effluent Treatment Practices and Future Directions (eds. L.

AP LS

McElvaney, C.C. Ross, and G.E. Valentine, Jr.), 95-108. Proceedings of the 1992 Food

Industry Environmental Conference, November 9-10, 1992. Atlanta, Georgia: Georgia

Tech Research Institute.]

C EO

Clearly, meat-processing wastewater has a much higher oxygen demand and TSS than

domestic wastewater, and thus has great pollution potential. Such information on

wastewater characteristics, along with data on wastewater volume generation, can be

used to estimate the waste loading, and is essential in selecting wastewater management

E

strategies.

H

PL O

4. Regulatory Issues

M SC

Various nations have passed legislations to limit waste discharge into the environment.

These regulations specify treatment technologies, establish discharge standards, or

specify discharge rates. In the United States, discharge of wastewater from a point

SA NE

source is governed by the National Pollution Discharge Elimination System (NPDES).

The NPDES is administered by the states with EPA oversight. Facilities discharging

directly into the waters of the United States must obtain NPDES permits that place

limits on the quantity and quality of effluents. These limits are based on a case-by-case

U

evaluation of potential environmental impacts. Discharge permits are designed as an

enforcement tool, with the ultimate goal of meeting ambient water quality standards.

Effluent limits are specific control requirements that apply to a specific point-source

discharge. They are based on both national effluent guidelines and state water quality

standards. Effluent limitation determines the NPDES conditions in a specific permit.

The effluent limits and permit requirements specified in a NPDES permit are generally

based on the best available technology (BAT) and the water quality requirement of the

receiving water. The technology standards can be the effluent guidelines, effluent limits,

and definition of BAT. In the United States, the federal effluent guideline governs

specific pollutant discharges from each type of industry regulated. Table 3 lists the

industries and the corresponding regulations that are related to food.

Encyclopedia of Life Support Systems (EOLSS)

FOOD ENGINEERING Vol. IV - Food Waste - Chen, Shulin

40 CFR Part Source

405 Dairy Products

406 Grain Mills

407 Canned and Preserved Fruits and Vegetables

408 Canned and Preserved Seafood

409 Sugar Processing

432 Meat Products

Table 3. Categorical industrial effluent guideline and standards.

Some regulations also specify allowable treatment/disposal methods for a given

industry. For example, in the State of Washington, USA, six treatment/disposal methods

have been authorized for fresh fruit packing: (1) lined evaporative lagoons or ponds

S

TE S

with no discharge of contained material except through evaporation, (2) dust abatement,

R

AP LS

spreading of process wastewater over interior gravel roads, or bin lots, either through a

sprinkler system or by truck/tank hauling, (3) land application, (4) percolation ponds or

ditches, (5) surface water, and (6) POTWs or on-site treatment methods. For discharge

C EO

to a public owned treatment work (POTW), the processor must first obtain written

certification of the acceptance of wastewater discharge. Additional conditions for

discharging to a POTW follow: (1) must comply with all federal, state, and local pre-

treatment standards and ordinances, (2) must not combine any sanitary wastewater with

E

prohibited process water, (3) must not exceed specific numerical limits of discharge as

H

given in permit, and (4) must not discharge toxic chemicals that could upset municipal

wastewater treatment facilities.

PL O

M SC

5. Management and Treatment Processes

5.1. Waste Reduction Strategies

SA NE

The most efficient way of food processing waste management is through waste source

reduction. These include waste minimization, water conservations, and by-product

recovery. These measures are not only environmentally sound, but also economically

U

beneficial.

Waste minimization prevents pollutants from entering the wastewater system and

produces a minimum amount of waste. This includes in-plant modification and

procedural changes in current practice, which could involve new equipment or

techniques. However, the basic method of processing is generally not altered.

Many on-site practices can prevent solid waste from getting into the wastewater steams.

For example, screens and similar solids removal systems should be installed

downstream from processing operations that discharge residues into wastewater.

Spillage should be avoided as much as possible and food residues, such as spoiled or

damaged whole units, seeds, stems peels, etc., should not be allowed to enter the

wastewater stream.

Encyclopedia of Life Support Systems (EOLSS)

FOOD ENGINEERING Vol. IV - Food Waste - Chen, Shulin

Water conservation can reduce the cost directly related to water usage and the cost

related to wastewater treatment. In food processing, water is generally used for washing

incoming material, hydraulic transportation, grading, and inspection, separation of

debris or culls from raw material, incorporation into product, blanching, cleaning up,

heating, and cooling. The first choice of water conservation is water recycling and

reuse. Recycling refers to reusing the water, usually treated, in the same application.

Reuse refers to using processed water, treated or untreated, in other applications where

the quality requirements are usually less critical. For example, there are several

recycling options in canned fruits and vegetable processing: (1) the flume water used for

transporting raw, unpeeled commodities, (2) retorted can cooling water recycled

through a cooling tower, and brine systems used in pickling or curing. In product

transport, dry transport by mechanical or pneumatic conveying systems can be

substituted for some hydraulic transport systems prior to hydraulic washing. Also, raw

incoming fruits and vegetables can be dry cleaned, by using vibrating screens and air

blowers to remove loss dirt, leaves, and twigs.

S

TE S

R

AP LS

Significant amounts of water consumption can be saved through well planned water

recycling and reuse. However, the build up of organic and mineral compounds,

microbial populations, and temperature (increases or decreases) must be considered.

C EO

Each successive contact of water with the product contributes to changing the quality of

water, and measures should be taken to ensure acceptable water quality conditions for

the recycled applications. Typical methods include: (1) treating the recycling water,

using screens, filters or cooling towers (or heaters) to re-establish acceptable quality

conditions of solids content and temperature, (2) disinfecting the microbial populations,

E

to meet the sanitary conditions, and (3) adding make-up water to recycled water stream,

H

to dilute stream and provide acceptable quality conditions or to maintain desired water

PL O

volume. Additionally, any recycling and reuse program must meet the requirements of

federal and state food regulatory agencies.

M SC

-

-

-

SA NE

TO ACCESS ALL THE 21 PAGES OF THIS CHAPTER,

U

Visit: http://www.eolss.net/Eolss-sampleAllChapter.aspx

Bibliography

Berne S. (1998). Pollution solutions. Food Engineering, 6, 113-126. [This paper presents some examples

on how food processors are finding solutions to their environmental challenges.]

Cooper R.N. and Russell J.M. (1992). The New Zealand Meat Processing Industry, Present Effluent

Treatment Practices and Future Directions (eds. L. McElvaney, C.C. Ross, and G.E. Valentine, Jr.), 95-

108. Proceedings of the 1992 Food Industry Environmental Conference, November 9-10, 1992. Atlanta,

Georgia: Georgia Tech Research Institute. [This paper reviews the treatment technologies in use in New

Zealand meat processing industry and typical performance data.]

Encyclopedia of Life Support Systems (EOLSS)

FOOD ENGINEERING Vol. IV - Food Waste - Chen, Shulin

Drennan W.C. (1987). Increasing wastewater treatment. Food Engineering, 8, 97-100, 102. [This article

summarizes concerns about discharging wastewater to public-owned treatment works, and treatment

alternatives.]

Frankel R.J. and Phongsphetraratana A. (1986). Effects of water reuse, recycling and resource recovery

on food processing waste treatment in Thailand. Water Science and Technology 18, 23-33. [This

summarizes the status of pineapple canning and tuna/sardine canning wastewater treatment in Thailand.]

Goldstein N., Glenn J., and Gray K. (1998). Nationwide overview of food residue composting. BiCycle,

8, 50-60. [This paper summarizes a national survey in the USA on food residue composting.]

Green J.H. and Kramer A., Eds. (1979). Food Processing Waste Management. Westport, Connecticut:

AVI Publishing Company, Inc. [This book covers a variety of topics related to food processing

wastewater treatment and waste management.]

Henry J.G. and Heinke G.W. (1996). Environmental Science and Engineering, 2nd Edition. Upper Saddle

River, New Jersey: Prentice Hall. [This is an introductory textbook on a variety of environmental science

and engineering topics.]

S

TE S

Krofta M., Wang L.K., and Pollman C.D. (1989). Treatment of Seafood Processing Wastewater by

R

AP LS

Dissolved Air Floatation, Carbon Adsorption, and Free Chlorination, 535-550. 43rd Purdue Industrial

Waste Concurrence Proceedings. Boca Raton, Florida: Lewis Publishers, Inc. [This paper presents a

literature review and the experimental results using dissolved air flotation and activated carbon for

C EO

treating scallop processing wastewater.]

Marwaha S.S. and Kennedy J.F. (1988). Review: whey-pollution problem and potential utilization.

International Journal of Food Science and Technology 23, 323-336. [This paper summarizes the potential

and limitations in recovering useful products from whey.]

E

Metcaf and Eddy, Inc. (1991). Wastewater Engineering: Treatment, Disposal, and Reuse, 3rd Edition.

H

New York: McGraw-Hill. [This is a textbook on waste and wastewater treatment processes.]

PL O

No H.K. and Meyers S.P. (1989). Recovery of amino acids from seafood processing wastewater with a

M SC

dual chitosan-based ligand-exchange system. Journal of Food Science 54(1), 60-70. [This paper presents

the experimental results using crawfish chitosan as a ligand-exchange material for recovery of amino

acids from seafood processing wastewater.]

SA NE

Ross C.C. and Valentine G.E. (1990). An Overview of Environmental Concerns in the Meat and Poultry

Processing Industry. Agricultural and Food Processing Waste, 66-75. Proceedings of the Sixth

International Symposium on Agricultural and Food Processing Wastes, December 17-18, 1990. Chicago,

Illinois. ASAE Publication 05-90, American Society of Agricultural Engineers, St. Joseph, Michigan,

U

USA. [This paper reviews the major environmental concerns in the meat and poultry processing industry.]

Sebastian F.P. (1997). Treatment Plant Advances. Environmental Engineers Handbook. 2nd Edition (eds.

D.H.F. Liu, B.G. Liptak, and P.A. Bouis), 732-741. Boca Raton, Florida: Lewis Publishers. [This section

in the handbook summarizes advanced or special processes of wastewater treatment.]

Shieh W.K. and Nguyen V.T. (1997a). Activated Sludge Processes. Environmental Engineers

Handbook. 2nd Edition (eds. D.H.F. Liu, B.G. Liptak, and P.A. Bouis), 698-708. Boca Raton, Florida:

Lewis Publishers. [This section in the handbook covers the principles, design, and operation of the

activated sludge process.]

Shieh, W.K., and V.T. Nguyen. (1997b). Trickling Filters. Environmental Engineers Handbook. 2nd

Edition (eds. D.H.F. Liu, B.G. Liptak, and P.A. Bouis), 689-694. Boca Raton, Florida: Lewis Publishers.

[This section in the handbook covers process description and design of trickling filters.]

Shieh W.K. and Nguyen V.T. (1997c). Rotating Biological Contactors. Environmental Engineers

Handbook. 2nd Edition (eds. D.H.F. Liu, B.G. Liptak, and P.A. Bouis), 695-697. Boca Raton, Florida:

Encyclopedia of Life Support Systems (EOLSS)

FOOD ENGINEERING Vol. IV - Food Waste - Chen, Shulin

Lewis Publishers. [This section in the handbook covers description, design and operation of rotating

biological contactors.]

Stratton R.G., Beggs R.A., and Crites R.W. (1990). Groundwater Impacts from Land Application of Food

Processing Wastewater Case Studies, 404-413, in Agricultural and Food Processing Waste, Proceedings

of the Sixth International Symposium on Agricultural and Food Processing Wastes, December 17-18,

1990, Chicago, Illinois. ASAE Publication 05-90, American Society of Agricultural Engineers, St.

Joseph, Michigan, USA. [This paper presents case studies that documented the groundwater impact of

land application of food processing wastewater.]

Zall R.R. (1979). Whey Treatment and Utilization. Food Processing Waste Management (eds. J.H. Green,

and A. Kramer), 175-201. Westport, Connecticut: AVI Publishing Company, Inc. [This chapter of the

book covers various methods for separating different whey components.]

Zegel W.C. (1997). Water Quality Standards. Environmental Engineers Handbook. 2nd Edition (eds.

D.H.F. Liu, B.G. Liptak, and P.A. Bouis), 205-212. Boca Raton, Florida: Lewis Publishers. [This section

in the handbook covers water standards related to environmental regulations in the USA.]

S

TE S

Biographical Sketch

R

AP LS

Shulin Chen is an Associate Professor in the Department of Biological Systems Engineering at

Washington State University. His research and teaching interests are related to wastewater treatment

agricultural waste management, aquacultural engineering, and bioresource utilization. Specific research

C EO

topics include natural systems for wastewater treatment, watershed modeling, decision support system for

animal nutrient management, recirculating aquacultural systems, and conversion of agricultural wastes

and residues to biochemicals.

E

H

PL O

M SC

SA NE

U

Encyclopedia of Life Support Systems (EOLSS)

You might also like

- Chariot PM Checklist SCRUBBERDocument2 pagesChariot PM Checklist SCRUBBERherik0% (1)

- TankCleaning WallWashing November2014Document18 pagesTankCleaning WallWashing November2014Goldy100% (3)

- Proposal For Experiment 7 - Water Quality AnalysisDocument12 pagesProposal For Experiment 7 - Water Quality AnalysisJasmine KangNo ratings yet

- Unesco - Eolss Sample Chapters: Chemistry of WastewaterDocument10 pagesUnesco - Eolss Sample Chapters: Chemistry of WastewaterGustavo Gabriel JimenezNo ratings yet

- (Aquaculture) Monitoring of Soil and Water QualityDocument33 pages(Aquaculture) Monitoring of Soil and Water QualityKristine Hinayon CarpioNo ratings yet

- Cve 517Document56 pagesCve 517Adeleke SamuelNo ratings yet

- Assignment 4Document6 pagesAssignment 4Zeeshan aliNo ratings yet

- Basic Water 1Document21 pagesBasic Water 1Hani ZahraNo ratings yet

- L2-Water Pollutant-Prof. Gourav Dhar BhowmickDocument25 pagesL2-Water Pollutant-Prof. Gourav Dhar BhowmickGourav Dhar BhowmickNo ratings yet

- Physico-Chemical Water Sampling ProtocolDocument5 pagesPhysico-Chemical Water Sampling ProtocolRyan Carlo CondeNo ratings yet

- List and Explain Various Characteristics of Waste Water 2Document7 pagesList and Explain Various Characteristics of Waste Water 2Ranjan GandhiNo ratings yet

- Water Quality CharacteristicsDocument14 pagesWater Quality CharacteristicsNur AqilahNo ratings yet

- Industrial Pollution and Control - OE ME 802D PDFDocument8 pagesIndustrial Pollution and Control - OE ME 802D PDFJoyshree PradhanNo ratings yet

- Water Use in Food IndustryDocument8 pagesWater Use in Food IndustryHisExcellencyNo ratings yet

- 1-The Biological BasisDocument3 pages1-The Biological BasisCatalina RobertoNo ratings yet

- Unit 3Document14 pagesUnit 3Parth TripahiNo ratings yet

- Notes Sem IV Microbiology PII U2Document19 pagesNotes Sem IV Microbiology PII U2nebex12No ratings yet

- Water QualityDocument47 pagesWater QualityRod Palma67% (3)

- Lecture 3 Water (Pollution, Quality, and Conservation)Document24 pagesLecture 3 Water (Pollution, Quality, and Conservation)ShaNto RaHmanNo ratings yet

- Chapter 4Document50 pagesChapter 4MAHMOUD HAMMADNo ratings yet

- 93165-Article Text-237773-1-10-20130827 PDFDocument9 pages93165-Article Text-237773-1-10-20130827 PDFMohamedNo ratings yet

- Wastewater CharacterizationDocument20 pagesWastewater CharacterizationFanilo Razafindralambo67% (3)

- Water PollutionDocument9 pagesWater PollutionDAYA RAM SAHNo ratings yet

- Decomposition of Organic Matter in WaterDocument6 pagesDecomposition of Organic Matter in WaterDivya Reddy100% (1)

- Monitoring Pond Water Quality To Improve Shrimp and Fish ProductionDocument3 pagesMonitoring Pond Water Quality To Improve Shrimp and Fish ProductionInternational Aquafeed magazineNo ratings yet

- Water PollutionDocument21 pagesWater PollutionyekarlNo ratings yet

- Wastewater Disposal.Document266 pagesWastewater Disposal.FarazNo ratings yet

- Chapter 3&4Document36 pagesChapter 3&4Màrwå Rägb ZäkyNo ratings yet

- Topic 3 Wastewater CharacteristicsDocument9 pagesTopic 3 Wastewater CharacteristicsOmar IsaackNo ratings yet

- Biofilter Treatment of Aquaculture Water For Reuse ApplicationsDocument12 pagesBiofilter Treatment of Aquaculture Water For Reuse ApplicationsDavid BorgesNo ratings yet

- Evriomental Engineering PDFDocument9 pagesEvriomental Engineering PDFlyta sinagaNo ratings yet

- Analysis of Wastewater ConstituentsDocument2 pagesAnalysis of Wastewater ConstituentsSheena MeNo ratings yet

- 5508 Et EtDocument12 pages5508 Et Etmadhu guptaNo ratings yet

- CHAPTER 2-Water and Wastewater Analysis (Part 1)Document50 pagesCHAPTER 2-Water and Wastewater Analysis (Part 1)محمد أمير لقمانNo ratings yet

- Basic EnvEng Lecture For Exit ExamDocument279 pagesBasic EnvEng Lecture For Exit Examaduladube0992No ratings yet

- Thermophilic Versus Mesophilic Anaerobic DigestionDocument14 pagesThermophilic Versus Mesophilic Anaerobic DigestionatmanebensaidNo ratings yet

- TOPIC 4 Water Characteristics and Drinking Water QualityDocument17 pagesTOPIC 4 Water Characteristics and Drinking Water QualityJayson Paul BulosanNo ratings yet

- Pengaruh Variasi Biomassa Pistia Stratiotes L. Terhadap Penurunan Kadar Bod, Cod, Dan Tss Limbah Cair Tahu Di Dusun Klero Sleman YogyakartaDocument16 pagesPengaruh Variasi Biomassa Pistia Stratiotes L. Terhadap Penurunan Kadar Bod, Cod, Dan Tss Limbah Cair Tahu Di Dusun Klero Sleman YogyakartaXXAQWEMKLNo ratings yet

- 3) Water Pollution V2 PDFDocument84 pages3) Water Pollution V2 PDFPaanjaisNo ratings yet

- Characteristics of Sewage PDFDocument13 pagesCharacteristics of Sewage PDFUtsav SharmaNo ratings yet

- CEB 30503 CHPTR 2Document42 pagesCEB 30503 CHPTR 2nazirah abdul kareemNo ratings yet

- Chapter One WWTDocument30 pagesChapter One WWTsintayehu sirahbizuNo ratings yet

- Charecteristics of WastewaterDocument12 pagesCharecteristics of WastewaterlnhipulanNo ratings yet

- Waste Water ParametersDocument24 pagesWaste Water ParametersKafue institution Of health sciencesNo ratings yet

- Lecture 0 Introduction To Environmental EngineeringDocument58 pagesLecture 0 Introduction To Environmental EngineeringSilas Nana-Baah MensahNo ratings yet

- O /uv Coupled With Membranes: Oil Industry Wastewater Treatment For ReuseDocument8 pagesO /uv Coupled With Membranes: Oil Industry Wastewater Treatment For ReuseMarcelo Varejão CasarinNo ratings yet

- Unit 11 Water Pollution: StructureDocument16 pagesUnit 11 Water Pollution: Structuretarakesh17No ratings yet

- Environmentalengineering (2)Document27 pagesEnvironmentalengineering (2)Md AshrafNo ratings yet

- Measurement and Processing of Water Quality DataDocument22 pagesMeasurement and Processing of Water Quality DataMatt Julius CorpuzNo ratings yet

- Water Pollution IndicatorsDocument1 pageWater Pollution Indicatorsiamjemah100% (1)

- OBED EnvironmntalDocument6 pagesOBED Environmntalfaith kirwayeNo ratings yet

- Montreal Convension Africa 1) Sudan 2) Chad 3) Kenya 4) Libya 5) EgyptDocument2 pagesMontreal Convension Africa 1) Sudan 2) Chad 3) Kenya 4) Libya 5) Egyptpratik chakrabortyNo ratings yet

- Water Quality ManagementDocument2 pagesWater Quality ManagementDarylNo ratings yet

- Wjarr 2022 0600Document6 pagesWjarr 2022 0600Awomuse JoelNo ratings yet

- Water Quality:: Physical, Chemical and Biological ParametersDocument26 pagesWater Quality:: Physical, Chemical and Biological ParametersGlister DharNo ratings yet

- Water Quality Criteria and Standards For PDFDocument34 pagesWater Quality Criteria and Standards For PDFLorelie BinoyaNo ratings yet

- TITLE: Measurement of WQI Parameters and Volatile Suspended Solids. PreambleDocument4 pagesTITLE: Measurement of WQI Parameters and Volatile Suspended Solids. PreambleAthirah DinataNo ratings yet

- 1-11-2020 Characteristics of WastewaterDocument21 pages1-11-2020 Characteristics of Wastewatervijetakumari.201ch059No ratings yet

- Water Quality ManagementDocument2 pagesWater Quality ManagementDarylNo ratings yet

- Animal Product Processing IndustriesDocument13 pagesAnimal Product Processing IndustriesThirumalaprasad ElishalaNo ratings yet

- A Complete Review On Effluent Testing and Treatment in Pharmaceutical IndustryDocument14 pagesA Complete Review On Effluent Testing and Treatment in Pharmaceutical IndustrysallurajNo ratings yet

- 5014 c2 v2 AP Next RevDocument3 pages5014 c2 v2 AP Next RevherikNo ratings yet

- 10 Famous SpillDocument11 pages10 Famous SpillherikNo ratings yet

- 16 SD F14 SRReportDocument11 pages16 SD F14 SRReportherikNo ratings yet

- Groundwater Aeration Towers, Degasifiers, Air Strippers: Advanced Odor Removal SystemsDocument1 pageGroundwater Aeration Towers, Degasifiers, Air Strippers: Advanced Odor Removal SystemsherikNo ratings yet

- Polystrong Material: Superior Corrosion ProtectionDocument2 pagesPolystrong Material: Superior Corrosion ProtectionherikNo ratings yet

- KCH Wet ScrubbersDocument1 pageKCH Wet ScrubbersherikNo ratings yet

- Scrubber BasicsDocument3 pagesScrubber BasicsherikNo ratings yet

- 980 Behavior Based Safety Program PDFDocument2 pages980 Behavior Based Safety Program PDFherik0% (1)

- Fume ScrubberDocument2 pagesFume ScrubberherikNo ratings yet

- Fume Scrubber Maintenance PDFDocument4 pagesFume Scrubber Maintenance PDFherikNo ratings yet

- Incompatible Chemical GroupsDocument1 pageIncompatible Chemical GroupsherikNo ratings yet

- HAI-HARP Master Amine Scrubber General DesignDocument9 pagesHAI-HARP Master Amine Scrubber General DesignherikNo ratings yet

- Training Needs Analysis ToolDocument3 pagesTraining Needs Analysis ToolherikNo ratings yet

- 2.6 BBS Overview BrochureDocument3 pages2.6 BBS Overview BrochureherikNo ratings yet

- Anaerobic Digestion Fundamentals IIDocument45 pagesAnaerobic Digestion Fundamentals IIscm996No ratings yet

- Environmental EngineeringDocument23 pagesEnvironmental EngineeringshubhamNo ratings yet

- 4 The Treatment of Domestic Wastewater Using Small Scale Vermicompost Filter BedDocument7 pages4 The Treatment of Domestic Wastewater Using Small Scale Vermicompost Filter BedHasan Abdel-FattahNo ratings yet

- Effluent Treatment PlantDocument46 pagesEffluent Treatment PlantVikas Singh67% (3)

- Appendix I Air Quality StandardsDocument21 pagesAppendix I Air Quality StandardsStansilous Tatenda NyagomoNo ratings yet

- Water Quality Analysis of Nairobi DamDocument43 pagesWater Quality Analysis of Nairobi DamOrwe Elly100% (1)

- Biermann's Handbook of Pulp and Paper - Cap 15Document24 pagesBiermann's Handbook of Pulp and Paper - Cap 15chau_riberNo ratings yet

- Environment Development and SustainabilityDocument231 pagesEnvironment Development and SustainabilityDrHitaishi SinghNo ratings yet

- Introduction To Environmental Hydrogeochemistry PDFDocument106 pagesIntroduction To Environmental Hydrogeochemistry PDFJuan-CarlosPeroniZamudioNo ratings yet

- Assessment of Tannery Effluent A Case Study On Dhaleshwari RiverDocument5 pagesAssessment of Tannery Effluent A Case Study On Dhaleshwari Riverসাবিহা মাহমুদ মমিNo ratings yet

- Percobaan 6 (Hydrogen)Document9 pagesPercobaan 6 (Hydrogen)putriNo ratings yet

- Carrosuel 2000Document7 pagesCarrosuel 2000Khang TrầnNo ratings yet

- Determination of Bod of Waste Water: Submitted by Shuva Chandra Bose ID: 161116Document8 pagesDetermination of Bod of Waste Water: Submitted by Shuva Chandra Bose ID: 161116shuvobosu262No ratings yet

- Hasil Pemeriksaan Sampel Bulan Nov 2022 - 230314 - 185401 PDFDocument5 pagesHasil Pemeriksaan Sampel Bulan Nov 2022 - 230314 - 185401 PDFSomali HivantriNo ratings yet

- Pengaruh Pengolahan Multy Stage System (MSS) Terhadap Perbaikan Kualitas Limbah Cair Laundry Di Bantul YogyakartaDocument11 pagesPengaruh Pengolahan Multy Stage System (MSS) Terhadap Perbaikan Kualitas Limbah Cair Laundry Di Bantul YogyakartaEko Setyo BudiNo ratings yet

- Analysis of Various Physical and Chemical Parameters of River Jehlum in Srinagar CityDocument4 pagesAnalysis of Various Physical and Chemical Parameters of River Jehlum in Srinagar CityEr faizu AhangarNo ratings yet

- Ab-221 3 en PDFDocument6 pagesAb-221 3 en PDFmilidarksNo ratings yet

- 04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFDocument8 pages04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFVic KeyNo ratings yet

- Full Thesis PDFDocument83 pagesFull Thesis PDFNewaz KabirNo ratings yet

- PREFACEDocument128 pagesPREFACEAl AminNo ratings yet

- Standard - Methods 5220D Metodología DQODocument2 pagesStandard - Methods 5220D Metodología DQOAndreaFigueroaNo ratings yet

- Handler AxdDocument49 pagesHandler AxdTomás Afonso CavacoNo ratings yet

- 7 Procedures For Estimating The Efficiency of Sludge Reduction TechnologiesDocument19 pages7 Procedures For Estimating The Efficiency of Sludge Reduction Technologiescheras1555No ratings yet

- Report WQI & VSSDocument25 pagesReport WQI & VSSAthirah DinataNo ratings yet

- Performance Comparison of Phenol Removal in Pharmaceutical Wastewater by Activated Sludge and Extended Aeration Augmented With Activated CarbonDocument10 pagesPerformance Comparison of Phenol Removal in Pharmaceutical Wastewater by Activated Sludge and Extended Aeration Augmented With Activated CarbonErickNo ratings yet

- Assessment of Physico-Chemical Characteristics and Microbial Contamination ofDocument28 pagesAssessment of Physico-Chemical Characteristics and Microbial Contamination ofMadhigirubaNo ratings yet

- Ene Lecture 05 Compatibility ModeDocument18 pagesEne Lecture 05 Compatibility ModewaqaskhanNo ratings yet

- DYSTAR Cadira INDIGO Brochure March 2019 - AnsichtDocument2 pagesDYSTAR Cadira INDIGO Brochure March 2019 - AnsichtkwatbNo ratings yet

- Thesis On Water Quality ParametersDocument5 pagesThesis On Water Quality Parametersbsdy1xsd100% (3)