Professional Documents

Culture Documents

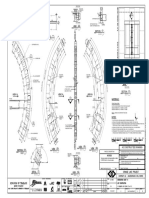

(STD 003) Grating Layout ClearancesF284E094CF1D

(STD 003) Grating Layout ClearancesF284E094CF1D

Uploaded by

Jeffrey WalkerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(STD 003) Grating Layout ClearancesF284E094CF1D

(STD 003) Grating Layout ClearancesF284E094CF1D

Uploaded by

Jeffrey WalkerCopyright:

Available Formats

10

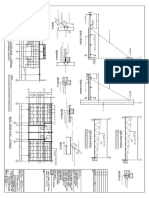

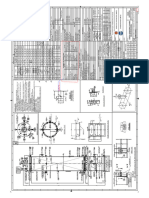

MIN. CLEARANCE 15 10 10 10 20 x 5FLx100LG KEEPER BAR

10 10 10 FOR REMOVABLE PANELS.

EQUAL TO REBATE

ANGLE THICKNESS

1 USE WHERE NOTED.

10

10

50 x 50 x 5L

WELD 50/100

TOP & BTM.

TO SUPPORT

STEEL BY

OTHERS.

TYPICAL CLEARANCES

NOTE: CLEAT SPACING MUST BE NOMIATED BY CUSTOMER

100

T.O.G. A B C BELOW TABEL IS FOR REFERANCE ONLY

3500 3000

SECTION THRU' 850 1800 850 1700 1300

KICK PLATES

AS1657 Cl 5.3.3

6626

SPACING OF CLEATS ON

63 1750 1750 2759 241 WALKWAYS STEEPER THAN 10deg

241 358 63

243

63

63

RECOMMENDED CLEAT SPACING, MM

1 SLOPE OF

243

243

WALKWAY

335

1053

Spacing

900

1000

1000

1000

63 237

175

175 338 300

200 100

A

DI

00

>10 <=15 450

*

10

15

= = = = =

1000

1250

700 300 700 >15 <=18 400

1707

10 SQ. BAR

1000

2020

350

4500

4626

4626

750 250 63 750 63 >18

287 T.O.G.

1250

750

400 405 300 338 175

REMOVABLE CLEAT WELDING:

=

PANEL

1086

1066

1000

100

200

1205 10 WELD EACH END 5MM FILLET.

500

500

=

1250

ON SLOPING WALKWAYS WHERE CLEATS ARE REQ'D.

TACK WELD EVERY 100MM STAGGERED ON SIDES OF CLEAT.

* *

200

ALL STANDARD PANELS SHOULD BE IDENTICAL

1000

175

900

707

800

243

243

2 CLEAT DETAILS BANDING WELDING:

63

73

241 1566 356 80 TYP WELD ONE SIDE OF EVERY 5th LOAD BAR FOR

A & B GRATING

63 957 1586 957 300 300 500 300 300 1122 356 922 63 WELD ONE SIDE OF EVERY 4th LOAD BAR FOR

C & D GRATING

7726 LOAD BAR LOAD BAR WELD ONE SIDE OF EVERY 3th LOAD BAR FOR

NOTES:

1. ALL GRATING TO BE WEBFORGE A325MPG. E & F GRATING

1000 1500 1000 1700 1300 1100 WELD ONE SIDE OF EVERY LOAD BAR FOR

2. ALL PANELS & CUT-OUTS TO BE FULLY BANDED.

3. INDICATES LOAD BAR DIRECTION. DRAINAGE GRATING

ALL BEAMS 250UB31 CROSSROD

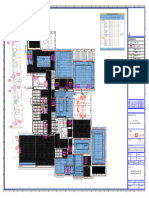

4. INDICATES ABRASIVE NOSING. PLAN ON RL 27.340 T.O.S. ALL CHANNELS 150X75PFC

5. INDICATES 130 x 6FL KICK PLATE.

6. GRATING TO BE SECURED BY STANDARD WEBFORGE FASTENERS.

7. SPLICE GRATING AROUND CUT-OUTS DENOTED

*

TYPICAL OUTLINE DETAIL DRAWING GRATING SYMBOLS

SIDES OF PANELS

ARE NOT REQ'D TO INDICATES ALL PANELS FULLY BANDED

LAND ON SUPPORT KICK PLATE

INDICATES PANELS CUT TO SIZE ONLY (ie. UNBANDED)

STEEL BANDING BAR BANDING BAR

100 MIN

INDICATES DIRECTION OF LOAD BARS

KICK PL. TYP. KICK PL. TYP.

3 25(325) INDICATES ABRASIVE NOSING

ALL BANDING BARS TO BE 5mm INDICATES FLOOR PLATE NOSING

CROSSROD

VARIES

ALL KICK PLATE TO BE 6mm INDICATES PERFORATED PLATE NOSING

WELD ONE SIDE OF EVERY ALL PENETRATIIONS/CUT-OUTS WILL BE TAKEN TO THE NEAREST LOAD

LOAD BAR WHERE GRATING INDICATES SIDE JOIN

BAR IF PENETRATIONS/CUT-OUTS FALL WITHIN 40mm OF A LOAD BAR INDICATES 10mm SQUARE BAR CLEATS

IS NOT SUPPORTED

PENETRATIONS INDICATED THUS * TO BE SPLIT ST INDICATES CUTTING START

PENETRATIONS/CUT-OUTS LESS THAN 100 TO BE FABRICATED SQUARE INDICATES KICK PLATE

LOAD BAR SUPPORT LUG

3 25(325)

KICKPLATE NOT WELDED DIRECTLY ONTO LOADBAR.

AS E

WELDS TO BE STAGGERED

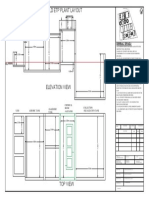

TYPICAL KICK PLATE SECTION

GRATING PENETRATIONS/CUT-OUTS

E L E

TYPICAL LOAD BAR DIRECTION

RA LR

NOSING LINE NOSING LINE

NOSING LINE

EN E

G

FOR

T.O.G.

5 40

15

2 Cleats changed, Banding welding added JN 19/3/14

GOING

NO

1 SIDE CLEARANCE CLARIFIED TW 27/4/07

SI

NG

0 RE-NUMBERED FROM STD-016r2 TW 19/5/05

LIN

STRINGER STRINGER REV PARTICULARS BY DATE

E

RISE

10 MIN ALL STAIR TREADS TO BE WEBFORGE (WA)

WEBFORGE T5/C255MPG 24 TENNANT STREET, WELSHPOOL

WESTERN AUSTRALIA

A.C.N. 009 419 756

T.O.G. T.O.G. Phone (08) 9361 8933 Fax (08) 9361 7057

ALL STAIR TREADS TO BE CLIENT:

WEBFORGE T6/C255MPG

TREAD 50 x 50 x 5L SUPPORT 50 x 50 x 5L SUPPORT

TYPICAL TREAD DETAILS JOB:

DETAIL:

STANDARD GRATING

LAYOUT & CLEARANCES

WIDTH

WEBFORGE SURFACE

GRID TYPE TREATMENT REQ'N No.

DRAWN CHK DRAWING No. REV.

TAW CUST. O/N.

DATE 30/1/03 JOB No.

STD - 003 2

STATIONARY DATE: 27/10/04

You might also like

- A Design Manual For Water WheelsDocument82 pagesA Design Manual For Water WheelsNicolas InfanteNo ratings yet

- 4700 Ofs - 6610239659Document2 pages4700 Ofs - 6610239659ALEJO100% (1)

- Structural Dynamics & Earthquake EngineeringDocument8 pagesStructural Dynamics & Earthquake EngineeringHema Chandra Reddy KarimireddyNo ratings yet

- 150 AI LOM C003 Layout2Document1 page150 AI LOM C003 Layout2hikmah rekardiNo ratings yet

- 155 FANSHAWE - SD - RevO - 179Document1 page155 FANSHAWE - SD - RevO - 179Kuraba KvoRdzNo ratings yet

- Detail Atap2Document1 pageDetail Atap2Anwar DhaniNo ratings yet

- Fort Polk MapDocument1 pageFort Polk Maplukev2007No ratings yet

- Standby Sru & Additional Tanks: General NotesDocument1 pageStandby Sru & Additional Tanks: General NotesPRASHANT SOODNo ratings yet

- Detail Atap1Document1 pageDetail Atap1muhammad.dhani11No ratings yet

- 01 F2110 TGT Dra 0502 ADocument1 page01 F2110 TGT Dra 0502 AsunyiNo ratings yet

- First Floor Working DrawingDocument1 pageFirst Floor Working DrawingmahalexmiNo ratings yet

- 4 - Light Plot - Deck - Billy Elliot - C01 PDFDocument1 page4 - Light Plot - Deck - Billy Elliot - C01 PDFMike WoodNo ratings yet

- Section Detail 19: Stair Footing 17Document1 pageSection Detail 19: Stair Footing 17Jhon SabinoNo ratings yet

- 203-I-118 - Hvac Layout FF R1Document1 page203-I-118 - Hvac Layout FF R1waleed.snovacNo ratings yet

- Basic Structuraaal-20x30.3Document1 pageBasic Structuraaal-20x30.3Jom Asagra100% (1)

- 028 RCP PDFDocument1 page028 RCP PDFOcokoljic SrdjanNo ratings yet

- Bureau of Design: Spot Detail (Media Agua)Document1 pageBureau of Design: Spot Detail (Media Agua)Marcjun Colmo AlegradoNo ratings yet

- T2 Truss Detail 14Document1 pageT2 Truss Detail 14Jhon SabinoNo ratings yet

- 10-05-2023 - Banquet HallDocument1 page10-05-2023 - Banquet Hallds18.albertcastroNo ratings yet

- 10-5-2023 - Banquet Hall..Document1 page10-5-2023 - Banquet Hall..ds18.albertcastroNo ratings yet

- Canopy&Roof TrussDocument1 pageCanopy&Roof TrussKamaleshsan GanesanNo ratings yet

- Water and Sewer Line Lay-Out: Foundation PlanDocument1 pageWater and Sewer Line Lay-Out: Foundation PlanAYSON N. DELA CRUZNo ratings yet

- Side View Top View Front View: Ihc Holland Beaver Dredgers B.VDocument1 pageSide View Top View Front View: Ihc Holland Beaver Dredgers B.VSélcio PaulinaNo ratings yet

- Ven - GF-FF-RF R.00-GFDocument1 pageVen - GF-FF-RF R.00-GFAnsinNo ratings yet

- Concrete Pile PlanDocument1 pageConcrete Pile PlanRODEL YUNTINGNo ratings yet

- RC Pile Detail PlanDocument1 pageRC Pile Detail PlanRODEL YUNTINGNo ratings yet

- Texas Congressional Maps, Present and ProposedDocument2 pagesTexas Congressional Maps, Present and ProposedbeaumontenterpriseNo ratings yet

- 01 - Etp Layout Part - 1Document1 page01 - Etp Layout Part - 1Rajkumar DhanavelNo ratings yet

- Pula, DA - No Concurr-4Document1 pagePula, DA - No Concurr-4Scott WayneNo ratings yet

- MBPP-Pondok Bas-ModelDocument1 pageMBPP-Pondok Bas-ModelFendy RoynNo ratings yet

- 6.D&B - P&S01 - 6TH Sty - PlumbingDocument1 page6.D&B - P&S01 - 6TH Sty - Plumbingtao zhouNo ratings yet

- Amc Rfa Mepfs 2017 014Document1 pageAmc Rfa Mepfs 2017 014arjay22xNo ratings yet

- S48505 Sen 000 PCD Pid 1144 - 00Document1 pageS48505 Sen 000 PCD Pid 1144 - 00Mohamed BahloulNo ratings yet

- 6 ST Ar MH Es Det 001Document1 page6 ST Ar MH Es Det 001Jacob FryeNo ratings yet

- Cop 28 Map Blue Zone v5Document1 pageCop 28 Map Blue Zone v5vechannel2005No ratings yet

- Cop 28 Map Blue Zone V5Document1 pageCop 28 Map Blue Zone V5Ezequiel CancliniNo ratings yet

- Ce 5 1Document1 pageCe 5 1abdullah mangatongNo ratings yet

- Crif Door Window Detail-601Document1 pageCrif Door Window Detail-601surbhi aggarwalNo ratings yet

- 1.vie-Pc01-Stn-Bht-Fp-1001 (R1) Foundation LVL Plan-1001Document1 page1.vie-Pc01-Stn-Bht-Fp-1001 (R1) Foundation LVL Plan-1001Ashish BhartiNo ratings yet

- East SideDocument1 pageEast SideVarun KanwarNo ratings yet

- Offsite-1 Electrical SchemesDocument1 pageOffsite-1 Electrical SchemesvijaykrishnatennetiNo ratings yet

- Standby Sru & Additional Tanks: Drawing LimitDocument1 pageStandby Sru & Additional Tanks: Drawing LimitPRASHANT SOODNo ratings yet

- Esquema - MCF Global PartsDocument1 pageEsquema - MCF Global PartswillianNo ratings yet

- Opteva 560 Cash Dispenser Through The Wall 4 HIGH WITH 40mm (1 9/16 ") SAFEDocument4 pagesOpteva 560 Cash Dispenser Through The Wall 4 HIGH WITH 40mm (1 9/16 ") SAFEDNSXNo ratings yet

- 1-ModelDocument1 page1-Modeljoselito navarroNo ratings yet

- Gad 1013Document1 pageGad 1013RAJESHWARNo ratings yet

- Teknık Resım Odev 1Document1 pageTeknık Resım Odev 1tarıkNo ratings yet

- 76Document1 page76john cartagenaNo ratings yet

- OCT3-CCT-PTE-ST9-INF-008-R01 - Plan Armare Culee C1 Si C2-900x297Document1 pageOCT3-CCT-PTE-ST9-INF-008-R01 - Plan Armare Culee C1 Si C2-900x297Maitintojo PuikusNo ratings yet

- Manual Secador CD 550+Document1 pageManual Secador CD 550+Paulo GarciaNo ratings yet

- Zone A Zone B: 3Rd Floor PlanDocument6 pagesZone A Zone B: 3Rd Floor PlanArif ZamzamiNo ratings yet

- Province of Quezon Construction of 3-Storey Science Laboratory BuildingDocument1 pageProvince of Quezon Construction of 3-Storey Science Laboratory BuildingVenus PunzalanNo ratings yet

- Province of Quezon Construction of 3-Storey Science Laboratory BuildingDocument1 pageProvince of Quezon Construction of 3-Storey Science Laboratory BuildingVenus PunzalanNo ratings yet

- General Layout Plan For Madanpatti Weir On River Sugarway: Section of U/S & D/S River Afflux & Guide BundDocument1 pageGeneral Layout Plan For Madanpatti Weir On River Sugarway: Section of U/S & D/S River Afflux & Guide Bundविवेक कुमारNo ratings yet

- Project SU RigDocument1 pageProject SU RigBrett SmithNo ratings yet

- Civile-Plan Fundatii PDFDocument1 pageCivile-Plan Fundatii PDFMircea CarageaNo ratings yet

- As Constructed Drawing: AgreedDocument4 pagesAs Constructed Drawing: AgreedRaymond CiaoNo ratings yet

- Detail 2Document1 pageDetail 2KangBaharNo ratings yet

- Storm Drain Layout: Construction of 2-Storey Residential Duplex BuildingDocument1 pageStorm Drain Layout: Construction of 2-Storey Residential Duplex Buildingcharles yansonNo ratings yet

- Platinum 9 BrochureDocument18 pagesPlatinum 9 Brochureharshkalantri46545No ratings yet

- J12530-01-C-910-P-3 Detail Layout Bulk EarthworksDocument1 pageJ12530-01-C-910-P-3 Detail Layout Bulk Earthworksvarity butheleziNo ratings yet

- SL PlanDocument1 pageSL Planjohn cartagenaNo ratings yet

- 1500pts Chaos Army ListDocument2 pages1500pts Chaos Army ListJeffrey WalkerNo ratings yet

- Programming in Emacs Lisp - ConsDocument1 pageProgramming in Emacs Lisp - ConsJeffrey WalkerNo ratings yet

- Body Count Reference 2Document2 pagesBody Count Reference 2Jeffrey WalkerNo ratings yet

- Programming in Emacs Lisp - SetcarDocument1 pageProgramming in Emacs Lisp - SetcarJeffrey WalkerNo ratings yet

- Programming in Emacs Lisp - NTHDocument1 pageProgramming in Emacs Lisp - NTHJeffrey WalkerNo ratings yet

- Micromark Catalogue Wargames Army Lists Organisation Charts ForDocument16 pagesMicromark Catalogue Wargames Army Lists Organisation Charts ForJeffrey Walker100% (1)

- Combat Based On Space Crusade 260920Document2 pagesCombat Based On Space Crusade 260920Jeffrey WalkerNo ratings yet

- Enware Product Guide PDFDocument38 pagesEnware Product Guide PDFJeffrey WalkerNo ratings yet

- Guerre-Froide Conferences IssuuDocument8 pagesGuerre-Froide Conferences IssuuJeffrey WalkerNo ratings yet

- Pipe Thread SizeDocument1 pagePipe Thread SizeJeffrey WalkerNo ratings yet

- Shear Capacity: Michael TerkDocument1 pageShear Capacity: Michael TerkJeffrey WalkerNo ratings yet

- Culkin Darnell Miller T Echos Programmer ManualDocument7 pagesCulkin Darnell Miller T Echos Programmer ManualBenjamin CulkinNo ratings yet

- Twin Screw PumpsDocument56 pagesTwin Screw PumpsAyman MedaneyNo ratings yet

- Three-Phase Asynchronous Motor Series 1R.5/1S.5: Operating Instructions Edition 03.2011Document284 pagesThree-Phase Asynchronous Motor Series 1R.5/1S.5: Operating Instructions Edition 03.2011Mamadou NdongoNo ratings yet

- Ganpat University U.V. Patel College of Engineering Mechatronics Engineering Department Experiment: - 4Document5 pagesGanpat University U.V. Patel College of Engineering Mechatronics Engineering Department Experiment: - 4Jaygopal SharmaNo ratings yet

- Control-Valve-Handbook-En-3661206 Pages 21-30Document10 pagesControl-Valve-Handbook-En-3661206 Pages 21-30trevNo ratings yet

- Module 1 Fundamentals of Auditing and Assurance ServicesDocument28 pagesModule 1 Fundamentals of Auditing and Assurance ServicesMary Grace Dela CruzNo ratings yet

- EC100Document2 pagesEC100Esfan GaripNo ratings yet

- Homo LumoDocument12 pagesHomo LumoShivam KansaraNo ratings yet

- Area Studies, Transnational Ism, and The Feminist ProductionDocument2 pagesArea Studies, Transnational Ism, and The Feminist Productiondonnakishot100% (1)

- Siti Norzuani - M03 - T5Document4 pagesSiti Norzuani - M03 - T5SITI NORZUANI BINTI BAHARUDDIN MoeNo ratings yet

- Wndw3 PrintDocument520 pagesWndw3 Printx7No ratings yet

- Wendt SummaryDocument2 pagesWendt SummaryMohammad Zandi ZiaraniNo ratings yet

- IGCSE Computer by Inqilab Patel-Paper 2 PDFDocument208 pagesIGCSE Computer by Inqilab Patel-Paper 2 PDFJawad hossainNo ratings yet

- Classified2019 2 3564799 PDFDocument9 pagesClassified2019 2 3564799 PDFaarianNo ratings yet

- Insight Release NotesDocument28 pagesInsight Release NotesChris FavreNo ratings yet

- Znote Analyzer 1931427Document12 pagesZnote Analyzer 1931427nalini KNo ratings yet

- Very Basic GSADocument46 pagesVery Basic GSATim ChongNo ratings yet

- Improvement Effect of Vacuum Consolidation and Prefabricated Vertical Drain in Peat GroundDocument10 pagesImprovement Effect of Vacuum Consolidation and Prefabricated Vertical Drain in Peat GroundMark MengNo ratings yet

- 印尼演讲稿1Document36 pages印尼演讲稿1ekounidhaNo ratings yet

- Roll No. ...................... Total Pages: 3: GSM/D-21Document3 pagesRoll No. ...................... Total Pages: 3: GSM/D-21Pankaj KaushikNo ratings yet

- Detailed Reading Recovery PlansDocument9 pagesDetailed Reading Recovery PlansOmairah bantasanNo ratings yet

- ActivityDocument2 pagesActivityTunWin NaingNo ratings yet

- Statistics Is The Science of Using Information Discovered From Studying NumbersDocument3 pagesStatistics Is The Science of Using Information Discovered From Studying NumbersAMIN BUHARI ABDUL KHADERNo ratings yet

- Resume - Structural LabDocument5 pagesResume - Structural Labali bin sefuNo ratings yet

- Mri AssignmentDocument3 pagesMri AssignmentaparjotNo ratings yet

- Arikamedu: Chaitanya .V. Parte T.Y.B.A-285 Semester V Paper V - Introduction of ArchaeologyDocument22 pagesArikamedu: Chaitanya .V. Parte T.Y.B.A-285 Semester V Paper V - Introduction of ArchaeologyCRAZY GAMING100% (1)

- Homework: Name DateDocument24 pagesHomework: Name DateboysNo ratings yet