Professional Documents

Culture Documents

Material For Helical Springs

Material For Helical Springs

Uploaded by

jayadevakodiCopyright:

Available Formats

You might also like

- Transformer Basics (Excellent For Practical Purpose)Document40 pagesTransformer Basics (Excellent For Practical Purpose)Sandeep Kumar100% (3)

- Transformer BasicsPDFDocument64 pagesTransformer BasicsPDFShrikant Kajale100% (1)

- Interpretation of The Microstructure of SteelsDocument61 pagesInterpretation of The Microstructure of SteelsCiresica Sanda Cocindau100% (1)

- Spring MaterialsDocument4 pagesSpring MaterialssohamkoliNo ratings yet

- 6.7 DGCA +EASADocument61 pages6.7 DGCA +EASAlaurielleNo ratings yet

- 4 MaterialsDocument5 pages4 MaterialsAzaher ShaikhNo ratings yet

- SpringsDocument28 pagesSpringsmaheshNo ratings yet

- Classification of Carbon and Low Alloy SteelsDocument4 pagesClassification of Carbon and Low Alloy SteelsmomoitachiNo ratings yet

- Think About SpringsDocument28 pagesThink About SpringsKavi ArasuNo ratings yet

- Transformer Installation, Commissioning, Operation and MaintenanceDocument40 pagesTransformer Installation, Commissioning, Operation and MaintenancejunclarcNo ratings yet

- Gland Packing Vs Mech Seals PDFDocument9 pagesGland Packing Vs Mech Seals PDFbratishkaityNo ratings yet

- Gland Packing Vs Mech SealsDocument9 pagesGland Packing Vs Mech SealsbratishkaityNo ratings yet

- RTRTRTRTRDocument2 pagesRTRTRTRTRjanarthananNo ratings yet

- Materials and HardwareDocument364 pagesMaterials and Hardwarekls070376100% (10)

- Present G.M.Document6 pagesPresent G.M.10march1965No ratings yet

- Piping Material - GuidanceDocument17 pagesPiping Material - GuidanceAlfon50% (2)

- The Impact of Component Material Selection On Pump ReliabilityDocument7 pagesThe Impact of Component Material Selection On Pump ReliabilityAhmed Ibrahim Ahmed EissaNo ratings yet

- A330 PylonsDocument21 pagesA330 Pylonsosamoz100% (2)

- Amt 4201 Final Module 1Document20 pagesAmt 4201 Final Module 1Mae EspinosaNo ratings yet

- Metallurgy, Properties, and Uses of FerrousDocument37 pagesMetallurgy, Properties, and Uses of FerrousAl DrinNo ratings yet

- PipesDocument7 pagesPipesmohamedNo ratings yet

- Engine Parts MaterialsDocument4 pagesEngine Parts Materialsmy generalNo ratings yet

- Alloy Steel and Cast IronDocument16 pagesAlloy Steel and Cast IronDennis AlvarezNo ratings yet

- Steam Turbines Blades Blades Blading Steam Turbines Steam Turbine Blades Steam Blades BladesDocument1 pageSteam Turbines Blades Blades Blading Steam Turbines Steam Turbine Blades Steam Blades BladesصصNo ratings yet

- High Speed SteelDocument14 pagesHigh Speed SteelKushan Gajjar100% (1)

- Corbon Content Steel 1Document75 pagesCorbon Content Steel 1Aditya GadhaviNo ratings yet

- Best Practices For TIG Welding 1Document6 pagesBest Practices For TIG Welding 1Orlando1949No ratings yet

- Dme Unit V (17.11.22)Document16 pagesDme Unit V (17.11.22)sathiaNo ratings yet

- Machining Titanium AlloysDocument22 pagesMachining Titanium AlloysSarswati SuryawanshiNo ratings yet

- Metallurgy of MaterialsDocument15 pagesMetallurgy of Materialscal2_uniNo ratings yet

- AdditionalNotesonMaterialScience Tech 3Document27 pagesAdditionalNotesonMaterialScience Tech 3Sumit JainNo ratings yet

- About Welding Process 43Document1 pageAbout Welding Process 43XerexNo ratings yet

- Aalco MaterialsDocument20 pagesAalco MaterialsMohamed FaragNo ratings yet

- Steel Fasteners: Materials - Carbon & Alloy SteelsDocument1 pageSteel Fasteners: Materials - Carbon & Alloy SteelsNegro PretoNo ratings yet

- Guide To Aluminium WeldingDocument3 pagesGuide To Aluminium WeldingManish SharmaNo ratings yet

- SpringsDocument7 pagesSpringssreeramNo ratings yet

- A Guide To Aluminum Welding - Lincoln ElectricDocument2 pagesA Guide To Aluminum Welding - Lincoln ElectriccvjdjmNo ratings yet

- Construction of TransformerDocument33 pagesConstruction of TransformervurumuuNo ratings yet

- Steel: 1) Carbon SteelsDocument2 pagesSteel: 1) Carbon SteelsPriyanathan ThayalanNo ratings yet

- Engineering Materials NewDocument11 pagesEngineering Materials Newnihar0008No ratings yet

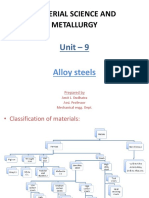

- Material Science and Metallurgy: Unit - 9Document24 pagesMaterial Science and Metallurgy: Unit - 9Vivek BajpaiNo ratings yet

- Alloy SteelsDocument23 pagesAlloy Steelssk.bashaNo ratings yet

- Alloy SteelDocument26 pagesAlloy Steelthesis ruetNo ratings yet

- Hss Tools and AppilcationDocument17 pagesHss Tools and AppilcationMeena SivasubramanianNo ratings yet

- Carbon SteelDocument9 pagesCarbon SteelArfanAliNo ratings yet

- 1 SpringDocument69 pages1 SpringAJ Bantay100% (1)

- AISI Designation: Stainless Tool Steels Killed Carbon SteelsDocument14 pagesAISI Designation: Stainless Tool Steels Killed Carbon SteelsShankar JhaNo ratings yet

- Heat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingFrom EverandHeat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingRating: 1 out of 5 stars1/5 (1)

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithFrom EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithNo ratings yet

- Tool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforFrom EverandTool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforNo ratings yet

- Standard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsFrom EverandStandard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsNo ratings yet

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicFrom EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNo ratings yet

- Forging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingFrom EverandForging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingRating: 5 out of 5 stars5/5 (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- Vane Motor: Limited Rotation ActuatorsDocument1 pageVane Motor: Limited Rotation ActuatorsjayadevakodiNo ratings yet

- Test/Date and Time Semester/year Course/Course Code Max MarksDocument1 pageTest/Date and Time Semester/year Course/Course Code Max MarksjayadevakodiNo ratings yet

- Chafter-1 Introduction To Machine DesignDocument2 pagesChafter-1 Introduction To Machine DesignjayadevakodiNo ratings yet

- Petrol EngineDocument3 pagesPetrol EnginejayadevakodiNo ratings yet

- 15ME65P Practice Core (Practice) : Course Outcome CLDocument6 pages15ME65P Practice Core (Practice) : Course Outcome CLjayadevakodiNo ratings yet

- Test2 H&PDocument1 pageTest2 H&PjayadevakodiNo ratings yet

- Venturi Meter ProblemsDocument5 pagesVenturi Meter ProblemsjayadevakodiNo ratings yet

- Explain The Relationship Between Functional Requirement and External Appearance of The ProductDocument1 pageExplain The Relationship Between Functional Requirement and External Appearance of The ProductjayadevakodiNo ratings yet

- Petrol EngineDocument3 pagesPetrol EnginejayadevakodiNo ratings yet

- Assignments HydraulicsDocument3 pagesAssignments Hydraulicsjayadevakodi100% (1)

- Communication Skills in EnglishDocument19 pagesCommunication Skills in EnglishjayadevakodiNo ratings yet

- Petrol EngineDocument3 pagesPetrol EnginejayadevakodiNo ratings yet

- Dmet 1Document1 pageDmet 1jayadevakodiNo ratings yet

- Design of Machine ElementsDocument5 pagesDesign of Machine ElementsjayadevakodiNo ratings yet

- 5.basic Computer Skills LABDocument8 pages5.basic Computer Skills LABjayadevakodiNo ratings yet

- Types of Forging MachinesDocument5 pagesTypes of Forging Machinesjayadevakodi100% (2)

- Iron Carbon Phase DiagramDocument5 pagesIron Carbon Phase DiagramjayadevakodiNo ratings yet

- Powder MetallurgyDocument6 pagesPowder MetallurgyjayadevakodiNo ratings yet

Material For Helical Springs

Material For Helical Springs

Uploaded by

jayadevakodiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material For Helical Springs

Material For Helical Springs

Uploaded by

jayadevakodiCopyright:

Available Formats

Material for Helical Springs

The material of the spring should have high fatigue strength, high ductility, high resilience

and it should be creep resistant. It largely depends upon the service for which they are used

i.e. severe service, average service or light service.

Severe service means rapid continuous loading where the ratio of minimum to

maximum load (or stress) is one-half or less, as in automotive valve springs.

Average service includes the same stress range as in severe service but with only

intermittent operation, as in engine governor springs and automobile suspension springs.

Light service includes springs subjected to loads that are static or very infrequently varied,

as in safety valve springs.

The springs are mostly made from oil-tempered carbon steel wires containing 0.60 to 0.70

per cent carbon and 0.60 to 1.0 per cent manganese. Music wire is used for small springs. Non-

ferrous materials like phosphor bronze, beryllium copper, monel metal, brass etc., may be used

in special cases to increase fatigue resistance, temperature resistance and corrosion resistance.

The helical springs are either cold formed or hot formed depending upon the size of the wire.

Wires of small sizes (less than 10 mm diameter) are usually wound cold whereas larger size wires

are wound hot. The strength of the wires varies with size, smaller size wires have greater

You might also like

- Transformer Basics (Excellent For Practical Purpose)Document40 pagesTransformer Basics (Excellent For Practical Purpose)Sandeep Kumar100% (3)

- Transformer BasicsPDFDocument64 pagesTransformer BasicsPDFShrikant Kajale100% (1)

- Interpretation of The Microstructure of SteelsDocument61 pagesInterpretation of The Microstructure of SteelsCiresica Sanda Cocindau100% (1)

- Spring MaterialsDocument4 pagesSpring MaterialssohamkoliNo ratings yet

- 6.7 DGCA +EASADocument61 pages6.7 DGCA +EASAlaurielleNo ratings yet

- 4 MaterialsDocument5 pages4 MaterialsAzaher ShaikhNo ratings yet

- SpringsDocument28 pagesSpringsmaheshNo ratings yet

- Classification of Carbon and Low Alloy SteelsDocument4 pagesClassification of Carbon and Low Alloy SteelsmomoitachiNo ratings yet

- Think About SpringsDocument28 pagesThink About SpringsKavi ArasuNo ratings yet

- Transformer Installation, Commissioning, Operation and MaintenanceDocument40 pagesTransformer Installation, Commissioning, Operation and MaintenancejunclarcNo ratings yet

- Gland Packing Vs Mech Seals PDFDocument9 pagesGland Packing Vs Mech Seals PDFbratishkaityNo ratings yet

- Gland Packing Vs Mech SealsDocument9 pagesGland Packing Vs Mech SealsbratishkaityNo ratings yet

- RTRTRTRTRDocument2 pagesRTRTRTRTRjanarthananNo ratings yet

- Materials and HardwareDocument364 pagesMaterials and Hardwarekls070376100% (10)

- Present G.M.Document6 pagesPresent G.M.10march1965No ratings yet

- Piping Material - GuidanceDocument17 pagesPiping Material - GuidanceAlfon50% (2)

- The Impact of Component Material Selection On Pump ReliabilityDocument7 pagesThe Impact of Component Material Selection On Pump ReliabilityAhmed Ibrahim Ahmed EissaNo ratings yet

- A330 PylonsDocument21 pagesA330 Pylonsosamoz100% (2)

- Amt 4201 Final Module 1Document20 pagesAmt 4201 Final Module 1Mae EspinosaNo ratings yet

- Metallurgy, Properties, and Uses of FerrousDocument37 pagesMetallurgy, Properties, and Uses of FerrousAl DrinNo ratings yet

- PipesDocument7 pagesPipesmohamedNo ratings yet

- Engine Parts MaterialsDocument4 pagesEngine Parts Materialsmy generalNo ratings yet

- Alloy Steel and Cast IronDocument16 pagesAlloy Steel and Cast IronDennis AlvarezNo ratings yet

- Steam Turbines Blades Blades Blading Steam Turbines Steam Turbine Blades Steam Blades BladesDocument1 pageSteam Turbines Blades Blades Blading Steam Turbines Steam Turbine Blades Steam Blades BladesصصNo ratings yet

- High Speed SteelDocument14 pagesHigh Speed SteelKushan Gajjar100% (1)

- Corbon Content Steel 1Document75 pagesCorbon Content Steel 1Aditya GadhaviNo ratings yet

- Best Practices For TIG Welding 1Document6 pagesBest Practices For TIG Welding 1Orlando1949No ratings yet

- Dme Unit V (17.11.22)Document16 pagesDme Unit V (17.11.22)sathiaNo ratings yet

- Machining Titanium AlloysDocument22 pagesMachining Titanium AlloysSarswati SuryawanshiNo ratings yet

- Metallurgy of MaterialsDocument15 pagesMetallurgy of Materialscal2_uniNo ratings yet

- AdditionalNotesonMaterialScience Tech 3Document27 pagesAdditionalNotesonMaterialScience Tech 3Sumit JainNo ratings yet

- About Welding Process 43Document1 pageAbout Welding Process 43XerexNo ratings yet

- Aalco MaterialsDocument20 pagesAalco MaterialsMohamed FaragNo ratings yet

- Steel Fasteners: Materials - Carbon & Alloy SteelsDocument1 pageSteel Fasteners: Materials - Carbon & Alloy SteelsNegro PretoNo ratings yet

- Guide To Aluminium WeldingDocument3 pagesGuide To Aluminium WeldingManish SharmaNo ratings yet

- SpringsDocument7 pagesSpringssreeramNo ratings yet

- A Guide To Aluminum Welding - Lincoln ElectricDocument2 pagesA Guide To Aluminum Welding - Lincoln ElectriccvjdjmNo ratings yet

- Construction of TransformerDocument33 pagesConstruction of TransformervurumuuNo ratings yet

- Steel: 1) Carbon SteelsDocument2 pagesSteel: 1) Carbon SteelsPriyanathan ThayalanNo ratings yet

- Engineering Materials NewDocument11 pagesEngineering Materials Newnihar0008No ratings yet

- Material Science and Metallurgy: Unit - 9Document24 pagesMaterial Science and Metallurgy: Unit - 9Vivek BajpaiNo ratings yet

- Alloy SteelsDocument23 pagesAlloy Steelssk.bashaNo ratings yet

- Alloy SteelDocument26 pagesAlloy Steelthesis ruetNo ratings yet

- Hss Tools and AppilcationDocument17 pagesHss Tools and AppilcationMeena SivasubramanianNo ratings yet

- Carbon SteelDocument9 pagesCarbon SteelArfanAliNo ratings yet

- 1 SpringDocument69 pages1 SpringAJ Bantay100% (1)

- AISI Designation: Stainless Tool Steels Killed Carbon SteelsDocument14 pagesAISI Designation: Stainless Tool Steels Killed Carbon SteelsShankar JhaNo ratings yet

- Heat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingFrom EverandHeat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingRating: 1 out of 5 stars1/5 (1)

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithFrom EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithNo ratings yet

- Tool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforFrom EverandTool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforNo ratings yet

- Standard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsFrom EverandStandard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsNo ratings yet

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicFrom EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNo ratings yet

- Forging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingFrom EverandForging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingRating: 5 out of 5 stars5/5 (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- Vane Motor: Limited Rotation ActuatorsDocument1 pageVane Motor: Limited Rotation ActuatorsjayadevakodiNo ratings yet

- Test/Date and Time Semester/year Course/Course Code Max MarksDocument1 pageTest/Date and Time Semester/year Course/Course Code Max MarksjayadevakodiNo ratings yet

- Chafter-1 Introduction To Machine DesignDocument2 pagesChafter-1 Introduction To Machine DesignjayadevakodiNo ratings yet

- Petrol EngineDocument3 pagesPetrol EnginejayadevakodiNo ratings yet

- 15ME65P Practice Core (Practice) : Course Outcome CLDocument6 pages15ME65P Practice Core (Practice) : Course Outcome CLjayadevakodiNo ratings yet

- Test2 H&PDocument1 pageTest2 H&PjayadevakodiNo ratings yet

- Venturi Meter ProblemsDocument5 pagesVenturi Meter ProblemsjayadevakodiNo ratings yet

- Explain The Relationship Between Functional Requirement and External Appearance of The ProductDocument1 pageExplain The Relationship Between Functional Requirement and External Appearance of The ProductjayadevakodiNo ratings yet

- Petrol EngineDocument3 pagesPetrol EnginejayadevakodiNo ratings yet

- Assignments HydraulicsDocument3 pagesAssignments Hydraulicsjayadevakodi100% (1)

- Communication Skills in EnglishDocument19 pagesCommunication Skills in EnglishjayadevakodiNo ratings yet

- Petrol EngineDocument3 pagesPetrol EnginejayadevakodiNo ratings yet

- Dmet 1Document1 pageDmet 1jayadevakodiNo ratings yet

- Design of Machine ElementsDocument5 pagesDesign of Machine ElementsjayadevakodiNo ratings yet

- 5.basic Computer Skills LABDocument8 pages5.basic Computer Skills LABjayadevakodiNo ratings yet

- Types of Forging MachinesDocument5 pagesTypes of Forging Machinesjayadevakodi100% (2)

- Iron Carbon Phase DiagramDocument5 pagesIron Carbon Phase DiagramjayadevakodiNo ratings yet

- Powder MetallurgyDocument6 pagesPowder MetallurgyjayadevakodiNo ratings yet