Professional Documents

Culture Documents

ODEC Ventilation Layout UK

ODEC Ventilation Layout UK

Uploaded by

sondeepyadav4873Copyright:

Available Formats

You might also like

- 87th (A) FSM Coursework - GRP 7Document90 pages87th (A) FSM Coursework - GRP 7Mohammad ZaidNo ratings yet

- AMT StandardsDocument31 pagesAMT StandardsAdrian GarciaNo ratings yet

- GDL Louvre CalculatorDocument1 pageGDL Louvre CalculatorVictor ValenciaNo ratings yet

- Product CatalogueDocument95 pagesProduct CatalogueMido AbdoNo ratings yet

- HVAC Course 2015Document107 pagesHVAC Course 2015MohamedAhmedFawzy100% (1)

- Resume of Dhien MohammadDocument6 pagesResume of Dhien MohammadMittuNo ratings yet

- 1,644 L2-596kg 424 L1-94kg 3,082: G+2P+8TYP+GYM-1185DXB FahuDocument2 pages1,644 L2-596kg 424 L1-94kg 3,082: G+2P+8TYP+GYM-1185DXB FahuBalaji JenarthananNo ratings yet

- Fpe Cwsi Wireless Fire Alarm SystemsDocument43 pagesFpe Cwsi Wireless Fire Alarm SystemsRandy BjorensenNo ratings yet

- D14114-0100D-MBR-TD-MH-LPG-102 Rev2Document1 pageD14114-0100D-MBR-TD-MH-LPG-102 Rev2zfrlNo ratings yet

- Linear DiffuserDocument52 pagesLinear Diffusermohamed adelNo ratings yet

- IRR On Proper Sewage HandlingDocument51 pagesIRR On Proper Sewage HandlingDexter G. BatalaoNo ratings yet

- GDL Louvre CalculatorDocument1 pageGDL Louvre CalculatorVictor ValenciaNo ratings yet

- Fuel System Schematic DiagramDocument1 pageFuel System Schematic DiagramAbhilash100% (1)

- Air Diffuser Architecture PDFDocument28 pagesAir Diffuser Architecture PDFBranislavPetrovicNo ratings yet

- Foam Suppression SystemDocument19 pagesFoam Suppression Systemansar thowfeekNo ratings yet

- K-84-11 Addressable Pull Station 3300Document2 pagesK-84-11 Addressable Pull Station 3300Dani Setia RamdaniNo ratings yet

- Effective Fire Protection For Transformers PDFDocument43 pagesEffective Fire Protection For Transformers PDFANDRESNo ratings yet

- Kaiflex MasterSpecificationDocument8 pagesKaiflex MasterSpecificationnaseema1No ratings yet

- Duct Engineering D752 PDFDocument3 pagesDuct Engineering D752 PDFIvan BriscoeNo ratings yet

- F - Ceiling DiffusersDocument25 pagesF - Ceiling Diffuserssiva_nagesh_2No ratings yet

- SAT Schedule From SAFID 16-11-2016Document1 pageSAT Schedule From SAFID 16-11-2016Rama Lakshmi SaradhiNo ratings yet

- Sand Oil Interceptor Sizing Calculations 90 SubmittalDocument4 pagesSand Oil Interceptor Sizing Calculations 90 SubmittalBRANDONNo ratings yet

- GAPS Guidelines: Ventilation of Fire Pump RoomsDocument3 pagesGAPS Guidelines: Ventilation of Fire Pump RoomsViswanathanNo ratings yet

- AHU-02 Submittal Saivar Rev-02Document49 pagesAHU-02 Submittal Saivar Rev-02Hossam AttefNo ratings yet

- Ashghal Cad Standards ManualDocument173 pagesAshghal Cad Standards ManualJohn CartelNo ratings yet

- 6 Fire Protection SystemDocument1,320 pages6 Fire Protection SystemedmondevangelistacorpuzNo ratings yet

- Hydraulic Calculations For Small RoomsDocument4 pagesHydraulic Calculations For Small RoomsAnonymous qrSsYuxyoYNo ratings yet

- U Value CalculationDocument51 pagesU Value CalculationRalphNkdNo ratings yet

- Wise CatalogDocument177 pagesWise CatalogHatim IshakNo ratings yet

- Fire Extinguisher Placement and Design ProcedureDocument16 pagesFire Extinguisher Placement and Design ProcedureDIEGOZaf100% (1)

- Piping Guide b03Document8 pagesPiping Guide b03Jeferson Binay-anNo ratings yet

- Revised 200CMD PULSAR HOTEL-Mar25-2019Document5 pagesRevised 200CMD PULSAR HOTEL-Mar25-2019Jonathan Quilang Obiena100% (1)

- MIFAB Control Flo Roof DrainsDocument5 pagesMIFAB Control Flo Roof DrainsjavedwestNo ratings yet

- Smoke Control by Pressurization in Stairwells and Elevator Shafts 080808Document12 pagesSmoke Control by Pressurization in Stairwells and Elevator Shafts 080808Neša P MarojevićNo ratings yet

- Thermal Load SummaryDocument1 pageThermal Load SummaryMohammad Altaf HussainNo ratings yet

- BreatheDocument9 pagesBreatheMohammad Arshad KamarNo ratings yet

- Asd 640Document2 pagesAsd 640RICHI100% (1)

- NBC Part 7Document72 pagesNBC Part 7Shubham AggarwalNo ratings yet

- Cla-Val: Fire Protection Pressure Relief ValveDocument2 pagesCla-Val: Fire Protection Pressure Relief ValveShoaib AhmedNo ratings yet

- Hap Calculation Guide Lines: Weather DataDocument12 pagesHap Calculation Guide Lines: Weather DataCraig MubaiwaNo ratings yet

- Diffuser SelectionDocument145 pagesDiffuser SelectionManojNo ratings yet

- Fire ProtectionDocument15 pagesFire Protectionrimi7alNo ratings yet

- Sealant - 1st Acrylic A-700 MSDSDocument6 pagesSealant - 1st Acrylic A-700 MSDSBozow BongNo ratings yet

- Fire Damper and Fire Smoke Damper PDFDocument26 pagesFire Damper and Fire Smoke Damper PDFRiaz ahmedNo ratings yet

- Liquefied Petroleum Tank CalculationsDocument2 pagesLiquefied Petroleum Tank CalculationsMd EtNo ratings yet

- Dasco 19-26Document8 pagesDasco 19-26Ahmed AzadNo ratings yet

- Safid FlexibleDocument23 pagesSafid FlexiblesalimNo ratings yet

- ULSZ.S4011 - Audible-Signal AppliancesDocument3 pagesULSZ.S4011 - Audible-Signal AppliancesOmar Alfredo Del Castillo QuispeNo ratings yet

- SLXBobinwoundfiltersDocument1 pageSLXBobinwoundfiltersKAMALNo ratings yet

- FMDS0803Document20 pagesFMDS0803hhNo ratings yet

- Water Mist Layout - PlanDocument1 pageWater Mist Layout - PlanPrivate PersonNo ratings yet

- Cat Dcs Sis ControllerDocument2 pagesCat Dcs Sis ControllerЮрий Шариков100% (5)

- Saudi Arabian Oil Company: 965 A SM-255564 002 BDocument1 pageSaudi Arabian Oil Company: 965 A SM-255564 002 Bahmad.suliman.saeedNo ratings yet

- G3306 Generator Set Electrical System: Control Panel (Emcpii+)Document2 pagesG3306 Generator Set Electrical System: Control Panel (Emcpii+)Mr.Thawatchai hansuwanNo ratings yet

- Saudi Arabian Oil Company: DA-727887 001 P 0D2 K07 RestrictedDocument1 pageSaudi Arabian Oil Company: DA-727887 001 P 0D2 K07 RestrictedWaqarNo ratings yet

- Revised Utandi Estate 2Document1 pageRevised Utandi Estate 2Bessie SiyadoNo ratings yet

- mcc2 PDFDocument1 pagemcc2 PDFSravyaSree100% (2)

- Pump Foundation Plan Pump Foundation Plan: NotesDocument1 pagePump Foundation Plan Pump Foundation Plan: NotesamitNo ratings yet

- Sequence of Operation: Typical Ahu DDC Control Diagram - (Cav) System - 1Document1 pageSequence of Operation: Typical Ahu DDC Control Diagram - (Cav) System - 1JYOTHEESWARA NAIDU100% (1)

- Trusses A3 S18Document1 pageTrusses A3 S18Irish CañalesNo ratings yet

- Instrumentation: Method Statement ForDocument8 pagesInstrumentation: Method Statement ForWalid MarhabaNo ratings yet

- Panelboard EatonDocument104 pagesPanelboard Eatonlduong4100% (1)

- Class Notes Course Code: EEE 237 Course Title: Electrical Properties of Materials Text: Principles of Electronic Materials and Devices (S. O. Kasap)Document5 pagesClass Notes Course Code: EEE 237 Course Title: Electrical Properties of Materials Text: Principles of Electronic Materials and Devices (S. O. Kasap)Md. Rana BabuNo ratings yet

- Philips Oxygen ConcentrationDocument2 pagesPhilips Oxygen ConcentrationRafikul RahemanNo ratings yet

- DGMS - Tech - Circular No 03. 2009 Qualitative and Quantitative Assessment of Fire FightingDocument3 pagesDGMS - Tech - Circular No 03. 2009 Qualitative and Quantitative Assessment of Fire FightingminingnovaNo ratings yet

- KIA KIA KIA: 1.descriptionDocument5 pagesKIA KIA KIA: 1.descriptionhugos31No ratings yet

- Kaivac 1700 Series: Operator & Parts ManualDocument34 pagesKaivac 1700 Series: Operator & Parts ManualNestor Marquez-DiazNo ratings yet

- Dairy Land OVPDocument2 pagesDairy Land OVPkisan singhNo ratings yet

- 11-17 April 2009Document16 pages11-17 April 2009pratidin100% (9)

- 38-Hydraulic Design of Reservoir Outlet WorksDocument201 pages38-Hydraulic Design of Reservoir Outlet WorksAbdi RahimianNo ratings yet

- Presentation of GOFADocument13 pagesPresentation of GOFAKnigh RiderNo ratings yet

- Injection Cream: Technical Information Sheet Article No. 0709Document2 pagesInjection Cream: Technical Information Sheet Article No. 0709wassimmahfouzNo ratings yet

- University of Energy and Natural Resources SunyaniDocument12 pagesUniversity of Energy and Natural Resources SunyaniAnggieGarcésNo ratings yet

- wps63 PDFDocument4 pageswps63 PDFErick HoganNo ratings yet

- Tyrolit (SB - SB E) CatalogueDocument2 pagesTyrolit (SB - SB E) Cataloguejromero_rpgNo ratings yet

- Inductive Sensor NJ2-12GM-N-V1: DimensionsDocument5 pagesInductive Sensor NJ2-12GM-N-V1: DimensionsMushfiqur RahmanNo ratings yet

- Aurora - Yarn MercerizingDocument4 pagesAurora - Yarn Mercerizinglieven.verraest6369No ratings yet

- QW 5110Document9 pagesQW 5110AminNo ratings yet

- India and Sustainable Development Goals SDGsDocument2 pagesIndia and Sustainable Development Goals SDGsPritish MohanNo ratings yet

- Final PHYS1410 Winter2022 Formula SheetDocument26 pagesFinal PHYS1410 Winter2022 Formula Sheetcameron.king1202No ratings yet

- Kl25z SchematicDocument5 pagesKl25z SchematicMenandro AmbanlocNo ratings yet

- 2015-TPC-0930 Reel-Lay Method To Allow For Direct Tie-In of Pipelines - DRAFTLDocument11 pages2015-TPC-0930 Reel-Lay Method To Allow For Direct Tie-In of Pipelines - DRAFTLnicholas_j_vaughanNo ratings yet

- WWW - Sem: Anti-Lock Braking SystemDocument25 pagesWWW - Sem: Anti-Lock Braking SystemSHAIK AKBARNo ratings yet

- Einstein in A NutshellDocument70 pagesEinstein in A NutshellguignanNo ratings yet

- Thermodynamics MineDocument12 pagesThermodynamics MineSyd MalaxosNo ratings yet

- 噴射發動機原理Theory of Jet EngineDocument6 pages噴射發動機原理Theory of Jet Engineeric1961lkNo ratings yet

- 9701 Chemistry Data Booklet 2016 (Revised)Document23 pages9701 Chemistry Data Booklet 2016 (Revised)historic.dude3.14No ratings yet

- How To Build A Bomb Shelter-1Document9 pagesHow To Build A Bomb Shelter-1dmac27100% (2)

- Jot CompositeDocument12 pagesJot CompositeabdulsmithNo ratings yet

- Climaeco: Intelligent Hvac Solutions With Abb I-Bus® KNXDocument16 pagesClimaeco: Intelligent Hvac Solutions With Abb I-Bus® KNXAyoub DjemaciNo ratings yet

ODEC Ventilation Layout UK

ODEC Ventilation Layout UK

Uploaded by

sondeepyadav4873Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ODEC Ventilation Layout UK

ODEC Ventilation Layout UK

Uploaded by

sondeepyadav4873Copyright:

Available Formats

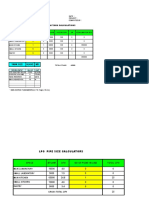

GRILLE / PLENUM / LOUVER SCHEDULE VENTILATION NOTES:

FLOW MODEL / 1. THE MECHANICAL SERVICES CONTRACTOR SHALL COORDINATE THE

REF NECK SIZE FACE SIZE PLENUM

(lps) INSTALLATION WITH REFERENCE BEING MADE TO ALL ARCHITECTURAL,

MANUFACTURER CIVIL, STRUCTURAL AND ELECTRICAL DRAWINGS.

S1 295x295 16-35 KRC-150/SYSTEMAIRE 125,250MM

125 P5ER 125-160 2. FIRE DAMPERS TO BE INSTALLED ON ALL DUCTWORK PASSING

E1 SYSTEMAIRE THROUGH FIRE PARTITIONS.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 S2

370x370

40-65 KRC-225/SYSTEMAIRE 150,350MM

PER 200-250 3. VENTILATION INSTALLATION TO BE IN ACCORDANCE WITH RELEVANT

150 EUROPEAN STANDARDS, CODES OF PRACTICE, DW143 AND DW144.

E2 SYSTEMAIRE

4. ALL DUCTWORK TO BE SHEET METAL TYPE AS DETAILED IN

S3 250,450MM SPECIFICATION.

L4 313 520x520 85-130 KRC-375/SYSTEMAIRE PER 250-315

E3 SYSTEMAIRE 5. ALL DUCTWORK TO BE PROPERLY SEALED TO GIVE ABSOLUTE AIR

C C 200x200 200x200 60 -

TIGHTNESS AT ALL JOINTS

TG1

6. ALL FANS, DUCTWORK AND ACCESSORIES TO BE NEATLY SUPPORTED

FROM THE BUILDING STRUCTURE.

Group Staff Work

7. SYSTEM TO BE TESTED AND COMMISSIONED IN ACCORDANCE WITH

Space Room CIBSE STANDARDS. FIGURES TO BE GIVEN TO ENGINEER FOR APPROVAL.

8. SUPPLY AND EXTRACT DUCTWORK TO BE INSULATED IN ACCORDANCE

F.04 F.06

HRU SCHEDULE WITH THE SPECIFICATION.

8.89 m 8.87 m

CO2

9. THE CONTRACTOR SHALL INCLUDE FOR ALL OFFSETS WHERE DUCTS

REF MODEL MANUFACTURER SFP CAPACITY COMMENT CROSS OVER AND WHERE DUCTWORK HAS TO RISE TO HIGHER LEVEL OR

Year 1 (w/l/s) (lps)

Classroom Year 1 DROP BELOW STRUCTURAL BEAMS ON ALL FLOORS.

125

Year 2 Year 2 Classroom

F.07 HRU-01 XBC25-H NUAIRE 1.3 256@100 Pa

Classroom Stair Lobby Classroom Stair Lobby 10. VOLUME CONTROL DAMPERS TO BE FITTED ON ALL MAIN DUCTWORK

F.08

F.01 F.02 F.03 62.85 m F.09 BRANCHES.

63.75 m HRU-02 XBC15-H NUAIRE 1.3 120@100 Pa

64.82 m 24.53 m 68.95 m 24.53 m

T

11. FINAL LOCATION OF ALL GRILLES AND EXTERNAL WALL TERMINALS TO

Platform

Lift

BE AGREED WITH ARCHITECT.

Library

F.21 FAN SCHEDULE 12. VENTILATION DUCTWORK SHALL BE MANUFACTURED AND ASSEMBLED

Space

2.46 m F.05 IN ACCORDANCE WITH THE HEATING AND VENTILATION CONTRACTORS

REF TYPE SFP FLOW MODEL / ASSOCIATION (HVAC) DW/144 "SPECIFICATION FOR SHEET METAL

18.82 m (w/l/s) (lps) DUCTWORK".

MANUFACTURER

T T FD

B B Ceiling

C

40

r2D

w

yA

B

p

n

.oih

gt C

r2

4 D

w

yA

B

p

n

.o

0 ih

gt .4DA

B

2

ih

t0 C

w

o

n

yp

rg D

t0

.4 A

B

2

ih C

w

o

n

yp

rg D

t0

.4 A

B

rg

2

ih C

w

o

n

yp DA

B

rg

2

ih

t0

.4 C

w

o

n

yp

C

w

p

ih

o

n

g D

yA

rtB.4

0

2 C

w

p

ih

o

n

g D

yA

rtB.4

0

2

EF-01 0.1 18@20Pa OPUS40S-ES/NUAIRE 13. HEATING & DOMESTIC PIPEWORK & ASSOCIATED STORAGE VESSELS,

Mounted REFRIGERANT PIPEWORK AND VENTILATION DUCTWORK SHALL BE

Bulk head over Ceiling

EF-02 0.1 12@20Pa OPUS40S-ES/NUAIRE INSULATED IN ACCORDANCE WITH THE RECOMMENDATIONS GIVEN IN

Circulation Mounted DCLG PUBLICATION " NON-DOMESTIC HEATING, COOLING AND

F.10 VENTILATION COMPLIANCE GUIDE" PART L.

Group EF-03 Ceiling 0.2 AM41ES/NUAIRE

Space 2 93.91 m Suspended 200@40Pa

14. ALL FIXED BUILDING SERVICES TO BE COMMISSIONED IN

F.20 FD Ceiling

EF-04 0.3 35@15Pa OPUS60S-ES/NUAIRE ACCORDANCE WITH CIBSE COMMISSIONING CODE M "COMMISSIONING

18.89 m T

C

4

r2

0

.o

w

D

n

p

B

yA

g

ih

t C

4

r2

0

.o

w

D

n

p

B

yA

g

ih

t

Group Mounted MANAGEMENT" AND PROCEDURES OUTLINE FOR AIR LEAKAGE TESTING

EF

rw A

n

C

o

p g

th 4

y B

riD 2

.0

Space 1

o

p

n g

C th

rw D B

yriA 4

2

.0

n

p

o

rw

C

th

g

yriA

D B

.0

2

4

Comms. / Acc. WC EF-05 Ceiling 0.2 90@30Pa AM41ES/NUAIRE OF DUCTWORK IN TECHNICAL BOOKLET PART L.

04 Elec. SF F.12 Suspended

rw A

n

C

o

p g

th y B

riD 2

.0

4

F.14

F.17 Infant WC's n

p

o

rw

C

th

g

yriA

D B

.0

2

4

rw

o

p

n D B

yriA

g

C th 4

2

.0

15. TOILET AND CLEANERS STORE EXTRACT FANS TO BE CONTROLLED VIA

01 10.2 m Ceiling 0.2 AM41ES/NUAIRE

F.15 4.16 m EF-06 125@30Pa PIR ON THE LOCAL LIGHTING CIRCUIT

4.12 m E1 Suspended

43.51 m FD VCD Ceiling

S1 SF-01 0.1 35@25Pa AM41ES/NUAIRE

FD

125

Suspended

VCD Ceiling

VCD KH-01 Mounted XXX 60@40Pa KITCHEN HOOD/NUAIRE

T

E1

150

125

LEGEND

E1

Year 2 Year 2 ATTENUATOR SCHEDULE

Classroom Year 1 Year 1 DENOTES VOLUME CONTROL DAMPER FITTED

T

Classroom

VCD Classroom Classroom

F.19 F.18 175 VCD TO DUCTWORK

F.13 F.11 REF SIZE LENGTH PRESSURE SERVICE

175

64.94 m 66.06 m DROP DENOTES FIRE DAMPER IN AN INTERNAL WALL

E1 VCD E1

63.15 m 62.86 m

Supply & FD

ATT 1 350X250 600mm 10Pa

125

Exhaust

T THERMOSTAT

VCD Supply &

ATT 2 200 600mm 10Pa

Exhaust CO2 TRAFFIC LIGHT CO2 CONTROL PANEL

VCD

CO2 CO2 E1 CO2 CO2

400X250 600mm 10Pa Exhaust

A EF

E1

A ATT 3

L4 L6 L6 EF 250 600mm 10Pa Exhaust

05 ATT 4

06

ATT 5 300 600mm 10Pa Supply

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

LOUVER SCHEDULE

REF FLOW CONNECTION FACE SIZE MODEL COMMENT

(lps)

Vent Level 1 L1 256 300 600x450 GILBERTS

2 1 : 100 L2 200 250 450x450

SERIES WG

GILBERTS

SERIES WG

18 125 150 IGC-125/

L3

SYSTEMAIRE

35 200 225 IGC-200/

L4

SYSTEMAIRE

60 250 275 IGC-250/

L5

SYSTEMAIRE

125 315 350 IGC-315/

L6

SYSTEMAIRE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

L3 L5 L3 EF L2 L2

L1 L2 L1 L1 L1 L1

C L1

03

C

300 E1 ATT 1 300 ATT 1 300

350x250

E1 E2 Plant

125 ATT 1 ATT 1

ATT 1 G.15 E3 E3 E3

VCD

200

5.23 m VCD

.4

t0

D

ih

B

A

2

rg

yp

w

C

n

o

E3 VCD VCD

VCD

175

HRU VCD

100

100

S3

t0

.4DA

B

2

ih C

w

o

n

yp

rg

.4

HRU

t0

D

ih

B

A

2

rg

yp

w

C

n

o

200

150

E3 - Staff Work FD Sensory HRU

250

E1

250

01 Hyg. VCD VCD

Base Room 01

--- 125 250 Room/Access. 01

G.13 G.14 WC VCD

15.78

E1 E1 Infant WC's Reception Reception

S1m 20.85

S2m

250

G.16

175

.4

t0

D

ih

B

A

2

rg

yp

w

C

n

o

G.19 Classroom Classroom

9.13 m ATT 1 ATT 1 250

125 G.20 G.21 Staircase

VCD 20.96 m 250

Staircase VCD 250 350x250

t0

.4DA

B

2

ih C

w

o

n

yp

rg

.4

t0

D

ih

B

A

2

rg

yp

w

C

n

o

VCD VCD FD FD ATT 1 G.26

VCD FD 69.25 m 350x25069.12 m

250

Staff WC G.12

125 ATT 1

125

ATT 1 FD FD FD FD Platform S3 S3 S3 24.47 m

G.02 22.31 m S3

Lift VCD

ATT 3 250

T

2.06 m EF Store G.17 Store

Cl. Store

01 G.11 E1 G.18

G.10 2.45 m

FD VCD VCD

350x250

150

350x250 250 350x250 250

1.17 m 1.24 m ATT 2 4.13 m

T

T

FD CO2 CO2

B KITCHEN EXTRACT

EF ATT 4 VCD VCD

B

CO2

E3 S3 DUCT WITH FIRE WRAP 02 Circulation

G.09

200

VCD KH 33.26 m ATT 2

VCD ATT 5

Sleep 01

E2 S2

VCD Room Kitchen E3 E3

Nursery 150 HRU S3 S3

400x250

G.03 G.05 250

Classroom350x250 02

VCD 17.98 m 6.73 m TG1

G.01 TG1

169.29 m 125 Comms/Elec VCD

FD VCD ATT 1 350x250 VCD VCD

G.08 250

T

T

125 4.24 m 250 ATT 1 ATT 1 Plant Room

250

Infant Infant G.28

Classroom ATT 1 Classroom 250

w

C

rn h

yig

p

o D

A

tB

.4

0

2

rn

o

C

p

w

yig

h

tB

A

D

2

0

.4

E1 250 350x250 350x250 14.44 m

125 G.23 G.22

FD FD FD

VCD 100.11 m 116.05 m

VCD HRU

300x250

E1 VCD HRU

250

VCD 01 VCD

E3 01

S3 Nursery VCD VCD

E1 Infant WC's S3 VCD E3 E3

w

C

rn h

yig

p

o D

A

tB

.4

0

2

rn

o

C

p

w

yig

h

tB

A

D

2

0

.4

WC's General Lobby

S1

Office

E1 G.25

G.04 VCD E1 G.07 VCD

Reception Desk

G.06 22.82 m

14.31 m 8.27 m S3

15.16 m ATT 1

300x250 ATT 1

VCD E1 E1 ATT 1

125

ATT 1

VCD

CO2 CO2

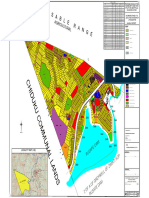

A A Layout Name: Ventilation Installation (GF

L1 L1 L1 L1

& 1st FL)

Drawn By: Checked By: Date:

Project No. Originator Zone Level Type Role Number

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Vent Level 0 Revision Revision Description :

Scale(s) @ A1

1 1 : 100 Status Status Description : 1 : 100

You might also like

- 87th (A) FSM Coursework - GRP 7Document90 pages87th (A) FSM Coursework - GRP 7Mohammad ZaidNo ratings yet

- AMT StandardsDocument31 pagesAMT StandardsAdrian GarciaNo ratings yet

- GDL Louvre CalculatorDocument1 pageGDL Louvre CalculatorVictor ValenciaNo ratings yet

- Product CatalogueDocument95 pagesProduct CatalogueMido AbdoNo ratings yet

- HVAC Course 2015Document107 pagesHVAC Course 2015MohamedAhmedFawzy100% (1)

- Resume of Dhien MohammadDocument6 pagesResume of Dhien MohammadMittuNo ratings yet

- 1,644 L2-596kg 424 L1-94kg 3,082: G+2P+8TYP+GYM-1185DXB FahuDocument2 pages1,644 L2-596kg 424 L1-94kg 3,082: G+2P+8TYP+GYM-1185DXB FahuBalaji JenarthananNo ratings yet

- Fpe Cwsi Wireless Fire Alarm SystemsDocument43 pagesFpe Cwsi Wireless Fire Alarm SystemsRandy BjorensenNo ratings yet

- D14114-0100D-MBR-TD-MH-LPG-102 Rev2Document1 pageD14114-0100D-MBR-TD-MH-LPG-102 Rev2zfrlNo ratings yet

- Linear DiffuserDocument52 pagesLinear Diffusermohamed adelNo ratings yet

- IRR On Proper Sewage HandlingDocument51 pagesIRR On Proper Sewage HandlingDexter G. BatalaoNo ratings yet

- GDL Louvre CalculatorDocument1 pageGDL Louvre CalculatorVictor ValenciaNo ratings yet

- Fuel System Schematic DiagramDocument1 pageFuel System Schematic DiagramAbhilash100% (1)

- Air Diffuser Architecture PDFDocument28 pagesAir Diffuser Architecture PDFBranislavPetrovicNo ratings yet

- Foam Suppression SystemDocument19 pagesFoam Suppression Systemansar thowfeekNo ratings yet

- K-84-11 Addressable Pull Station 3300Document2 pagesK-84-11 Addressable Pull Station 3300Dani Setia RamdaniNo ratings yet

- Effective Fire Protection For Transformers PDFDocument43 pagesEffective Fire Protection For Transformers PDFANDRESNo ratings yet

- Kaiflex MasterSpecificationDocument8 pagesKaiflex MasterSpecificationnaseema1No ratings yet

- Duct Engineering D752 PDFDocument3 pagesDuct Engineering D752 PDFIvan BriscoeNo ratings yet

- F - Ceiling DiffusersDocument25 pagesF - Ceiling Diffuserssiva_nagesh_2No ratings yet

- SAT Schedule From SAFID 16-11-2016Document1 pageSAT Schedule From SAFID 16-11-2016Rama Lakshmi SaradhiNo ratings yet

- Sand Oil Interceptor Sizing Calculations 90 SubmittalDocument4 pagesSand Oil Interceptor Sizing Calculations 90 SubmittalBRANDONNo ratings yet

- GAPS Guidelines: Ventilation of Fire Pump RoomsDocument3 pagesGAPS Guidelines: Ventilation of Fire Pump RoomsViswanathanNo ratings yet

- AHU-02 Submittal Saivar Rev-02Document49 pagesAHU-02 Submittal Saivar Rev-02Hossam AttefNo ratings yet

- Ashghal Cad Standards ManualDocument173 pagesAshghal Cad Standards ManualJohn CartelNo ratings yet

- 6 Fire Protection SystemDocument1,320 pages6 Fire Protection SystemedmondevangelistacorpuzNo ratings yet

- Hydraulic Calculations For Small RoomsDocument4 pagesHydraulic Calculations For Small RoomsAnonymous qrSsYuxyoYNo ratings yet

- U Value CalculationDocument51 pagesU Value CalculationRalphNkdNo ratings yet

- Wise CatalogDocument177 pagesWise CatalogHatim IshakNo ratings yet

- Fire Extinguisher Placement and Design ProcedureDocument16 pagesFire Extinguisher Placement and Design ProcedureDIEGOZaf100% (1)

- Piping Guide b03Document8 pagesPiping Guide b03Jeferson Binay-anNo ratings yet

- Revised 200CMD PULSAR HOTEL-Mar25-2019Document5 pagesRevised 200CMD PULSAR HOTEL-Mar25-2019Jonathan Quilang Obiena100% (1)

- MIFAB Control Flo Roof DrainsDocument5 pagesMIFAB Control Flo Roof DrainsjavedwestNo ratings yet

- Smoke Control by Pressurization in Stairwells and Elevator Shafts 080808Document12 pagesSmoke Control by Pressurization in Stairwells and Elevator Shafts 080808Neša P MarojevićNo ratings yet

- Thermal Load SummaryDocument1 pageThermal Load SummaryMohammad Altaf HussainNo ratings yet

- BreatheDocument9 pagesBreatheMohammad Arshad KamarNo ratings yet

- Asd 640Document2 pagesAsd 640RICHI100% (1)

- NBC Part 7Document72 pagesNBC Part 7Shubham AggarwalNo ratings yet

- Cla-Val: Fire Protection Pressure Relief ValveDocument2 pagesCla-Val: Fire Protection Pressure Relief ValveShoaib AhmedNo ratings yet

- Hap Calculation Guide Lines: Weather DataDocument12 pagesHap Calculation Guide Lines: Weather DataCraig MubaiwaNo ratings yet

- Diffuser SelectionDocument145 pagesDiffuser SelectionManojNo ratings yet

- Fire ProtectionDocument15 pagesFire Protectionrimi7alNo ratings yet

- Sealant - 1st Acrylic A-700 MSDSDocument6 pagesSealant - 1st Acrylic A-700 MSDSBozow BongNo ratings yet

- Fire Damper and Fire Smoke Damper PDFDocument26 pagesFire Damper and Fire Smoke Damper PDFRiaz ahmedNo ratings yet

- Liquefied Petroleum Tank CalculationsDocument2 pagesLiquefied Petroleum Tank CalculationsMd EtNo ratings yet

- Dasco 19-26Document8 pagesDasco 19-26Ahmed AzadNo ratings yet

- Safid FlexibleDocument23 pagesSafid FlexiblesalimNo ratings yet

- ULSZ.S4011 - Audible-Signal AppliancesDocument3 pagesULSZ.S4011 - Audible-Signal AppliancesOmar Alfredo Del Castillo QuispeNo ratings yet

- SLXBobinwoundfiltersDocument1 pageSLXBobinwoundfiltersKAMALNo ratings yet

- FMDS0803Document20 pagesFMDS0803hhNo ratings yet

- Water Mist Layout - PlanDocument1 pageWater Mist Layout - PlanPrivate PersonNo ratings yet

- Cat Dcs Sis ControllerDocument2 pagesCat Dcs Sis ControllerЮрий Шариков100% (5)

- Saudi Arabian Oil Company: 965 A SM-255564 002 BDocument1 pageSaudi Arabian Oil Company: 965 A SM-255564 002 Bahmad.suliman.saeedNo ratings yet

- G3306 Generator Set Electrical System: Control Panel (Emcpii+)Document2 pagesG3306 Generator Set Electrical System: Control Panel (Emcpii+)Mr.Thawatchai hansuwanNo ratings yet

- Saudi Arabian Oil Company: DA-727887 001 P 0D2 K07 RestrictedDocument1 pageSaudi Arabian Oil Company: DA-727887 001 P 0D2 K07 RestrictedWaqarNo ratings yet

- Revised Utandi Estate 2Document1 pageRevised Utandi Estate 2Bessie SiyadoNo ratings yet

- mcc2 PDFDocument1 pagemcc2 PDFSravyaSree100% (2)

- Pump Foundation Plan Pump Foundation Plan: NotesDocument1 pagePump Foundation Plan Pump Foundation Plan: NotesamitNo ratings yet

- Sequence of Operation: Typical Ahu DDC Control Diagram - (Cav) System - 1Document1 pageSequence of Operation: Typical Ahu DDC Control Diagram - (Cav) System - 1JYOTHEESWARA NAIDU100% (1)

- Trusses A3 S18Document1 pageTrusses A3 S18Irish CañalesNo ratings yet

- Instrumentation: Method Statement ForDocument8 pagesInstrumentation: Method Statement ForWalid MarhabaNo ratings yet

- Panelboard EatonDocument104 pagesPanelboard Eatonlduong4100% (1)

- Class Notes Course Code: EEE 237 Course Title: Electrical Properties of Materials Text: Principles of Electronic Materials and Devices (S. O. Kasap)Document5 pagesClass Notes Course Code: EEE 237 Course Title: Electrical Properties of Materials Text: Principles of Electronic Materials and Devices (S. O. Kasap)Md. Rana BabuNo ratings yet

- Philips Oxygen ConcentrationDocument2 pagesPhilips Oxygen ConcentrationRafikul RahemanNo ratings yet

- DGMS - Tech - Circular No 03. 2009 Qualitative and Quantitative Assessment of Fire FightingDocument3 pagesDGMS - Tech - Circular No 03. 2009 Qualitative and Quantitative Assessment of Fire FightingminingnovaNo ratings yet

- KIA KIA KIA: 1.descriptionDocument5 pagesKIA KIA KIA: 1.descriptionhugos31No ratings yet

- Kaivac 1700 Series: Operator & Parts ManualDocument34 pagesKaivac 1700 Series: Operator & Parts ManualNestor Marquez-DiazNo ratings yet

- Dairy Land OVPDocument2 pagesDairy Land OVPkisan singhNo ratings yet

- 11-17 April 2009Document16 pages11-17 April 2009pratidin100% (9)

- 38-Hydraulic Design of Reservoir Outlet WorksDocument201 pages38-Hydraulic Design of Reservoir Outlet WorksAbdi RahimianNo ratings yet

- Presentation of GOFADocument13 pagesPresentation of GOFAKnigh RiderNo ratings yet

- Injection Cream: Technical Information Sheet Article No. 0709Document2 pagesInjection Cream: Technical Information Sheet Article No. 0709wassimmahfouzNo ratings yet

- University of Energy and Natural Resources SunyaniDocument12 pagesUniversity of Energy and Natural Resources SunyaniAnggieGarcésNo ratings yet

- wps63 PDFDocument4 pageswps63 PDFErick HoganNo ratings yet

- Tyrolit (SB - SB E) CatalogueDocument2 pagesTyrolit (SB - SB E) Cataloguejromero_rpgNo ratings yet

- Inductive Sensor NJ2-12GM-N-V1: DimensionsDocument5 pagesInductive Sensor NJ2-12GM-N-V1: DimensionsMushfiqur RahmanNo ratings yet

- Aurora - Yarn MercerizingDocument4 pagesAurora - Yarn Mercerizinglieven.verraest6369No ratings yet

- QW 5110Document9 pagesQW 5110AminNo ratings yet

- India and Sustainable Development Goals SDGsDocument2 pagesIndia and Sustainable Development Goals SDGsPritish MohanNo ratings yet

- Final PHYS1410 Winter2022 Formula SheetDocument26 pagesFinal PHYS1410 Winter2022 Formula Sheetcameron.king1202No ratings yet

- Kl25z SchematicDocument5 pagesKl25z SchematicMenandro AmbanlocNo ratings yet

- 2015-TPC-0930 Reel-Lay Method To Allow For Direct Tie-In of Pipelines - DRAFTLDocument11 pages2015-TPC-0930 Reel-Lay Method To Allow For Direct Tie-In of Pipelines - DRAFTLnicholas_j_vaughanNo ratings yet

- WWW - Sem: Anti-Lock Braking SystemDocument25 pagesWWW - Sem: Anti-Lock Braking SystemSHAIK AKBARNo ratings yet

- Einstein in A NutshellDocument70 pagesEinstein in A NutshellguignanNo ratings yet

- Thermodynamics MineDocument12 pagesThermodynamics MineSyd MalaxosNo ratings yet

- 噴射發動機原理Theory of Jet EngineDocument6 pages噴射發動機原理Theory of Jet Engineeric1961lkNo ratings yet

- 9701 Chemistry Data Booklet 2016 (Revised)Document23 pages9701 Chemistry Data Booklet 2016 (Revised)historic.dude3.14No ratings yet

- How To Build A Bomb Shelter-1Document9 pagesHow To Build A Bomb Shelter-1dmac27100% (2)

- Jot CompositeDocument12 pagesJot CompositeabdulsmithNo ratings yet

- Climaeco: Intelligent Hvac Solutions With Abb I-Bus® KNXDocument16 pagesClimaeco: Intelligent Hvac Solutions With Abb I-Bus® KNXAyoub DjemaciNo ratings yet