Professional Documents

Culture Documents

Revolving Screen Separator Fdsa

Revolving Screen Separator Fdsa

Uploaded by

Pauk GyiiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Revolving Screen Separator Fdsa

Revolving Screen Separator Fdsa

Uploaded by

Pauk GyiiCopyright:

Available Formats

REVOLVING SCREEN SEPARATOR FDSA

The Satake Revolving Screen

Separator FDSA has been specifically

designed for the separation of large

impurities from free flowing materials

at very high capacities.

The most common uses for the

machine are grain pre-cleaning, high

capacity screening of powdery material

and the screening of animal feed

products.

Used at the intake of grain silos, flour mills, feed mill and other processing utilities, it is

ideally suited for the separation of material such as straw, string, paper, wood, maize

cobs, stones etc. from the main product.

The Satake Drum Separator thus reduces the amount of wear and tear on the

subsequent machinery in the processing plant while improving their efficiency and also

ensures more hygienic bulk storage conditions for the product.

FDSA Features:

1. High capacity with excellent cleaning efficiency

2. Rugged, maintenance free design

3. Low space and power requirements

4. Easy installation

5. Rapid and simple screen replacement

6. Two piece drum for optimal performance size selection

Operational Principle

Material is fed through a curved inlet chute to the inside of a revolving perforated sheet metal drum. Here the product

falls through the perforations whereas the coarse impurities are retained in the drum. Debris lifting paddles fixed to

the inner part of the rotating drum ensure that impurities are unable to concentrate on the surface of the drum to

prevent passage of product through the apertures. An extraction spiral inside the drum causes coarse impurities to be

conveyed to the large overtails outlet that is situated beneath the inlet at the head of the machine.

The spiral as the secondary function of ensuring that good grain cannot simply be carried over the impurities outlet

with the coarse material, but is retained in the drum long enough to fall through the screen.

The sieve drum is sub-divided into a feed section and a discharge section to ensure that optimal performance

dimensions may be chosen for each particular application. A full length brush cleaner ensures that the sieving

efficiency is maximized at all times.

Construction

Sturdy, long lasting and hygienic construction. Simple in design. All metal fabrication with side inspection door. Two

piece perforated metal drum with extraction spiral. Strong nylon bristled full length brush cleaner. Machine

incorporates feed inlet spout, throughs and tailing hoppers and general exhaust connection. Direct coupled geared

motor drive with robust trouble-free bearing assembly.

Optional Features

A variable speed drive can be supplied for absolute selection of rotational speed for multi-purpose application.

All Satake products are the subject of continuous development and, as a result, their specification may change and differ in detail from that outlined in this leaflet.

SATAKE AUSTRALIA Pty Ltd Telephone: +61 (0) 2 4725 2600

15 Leland Street Facsimile: +61 (0) 2 4725 2601

Penrith E-mail: info@satake.com.au

NSW 2750 Website: www.satake.com.au

Australia

REVOLVING SCREEN SEPARATOR GDIA

Machine Type FDSA Product Cleaning capacity t/h

(dependent on perforation size)

Dimensions (mm) Wheat 200

A 2280 Rye 200

B 1200 Cargo Rice 200

C 1445 Soya 120

D 1072 Maize 100

E 1600 Paddy 70

F 1040 Oats 60

G 355 Barley 60

H 190 Cocoa 60

J 1150 Pellets 550 kg/m3 35

Motor Rating kW 0.37 Dense Feed Meals 650 kg/m3 60

Exhaust Requirement m3/min 12 Light Feed Meals 500 kg/m3 25

Approximate Shipping Data

Weight kg Nett 515

Gross 778

3

Volume m Unpacked 4.49

Packed 6.23

All Satake products are the subject of continuous development and, as a result, their specification may change and differ in detail from that outlined in this leaflet.

SATAKE AUSTRALIA Pty Ltd Telephone: +61 (0) 2 4725 2600

15 Leland Street Facsimile: +61 (0) 2 4725 2601

Penrith E-mail: info@satake.com.au

NSW 2750 Website: www.satake.com.au

Australia

You might also like

- 1st Grade Envision Math 2Document7 pages1st Grade Envision Math 2api-51171643550% (2)

- F5.301a Reviewed2 PDFDocument29 pagesF5.301a Reviewed2 PDFTomasz BNo ratings yet

- IB Prepared PsychologyDocument29 pagesIB Prepared PsychologyAlina Kubra100% (2)

- Wirtgen W150Document8 pagesWirtgen W150Ashraf m aliNo ratings yet

- Underground Gravity Sewers Specification CVS02700 PDFDocument12 pagesUnderground Gravity Sewers Specification CVS02700 PDFNassim Sabri0% (1)

- EDocument2 pagesEanon-542240100% (2)

- Matlab TutorialDocument31 pagesMatlab TutorialShiyeng CharmaineNo ratings yet

- Laka / Rcda.: Drum SieveDocument4 pagesLaka / Rcda.: Drum SieveMauricio Viola CastellaNo ratings yet

- WWW Buhlergroup Com Docs 34421PTDocument6 pagesWWW Buhlergroup Com Docs 34421PTapi-26913433No ratings yet

- GQ Flyer Ladb 4-Seiter en LQDocument4 pagesGQ Flyer Ladb 4-Seiter en LQahmed shomanNo ratings yet

- Dewatering Screens: Single-Deck Twin VibratorDocument8 pagesDewatering Screens: Single-Deck Twin Vibratorekrem0867No ratings yet

- Rice Mill-WebDocument2 pagesRice Mill-WebceleNo ratings yet

- Waferline Equipment List: Polysilicon To WafersDocument6 pagesWaferline Equipment List: Polysilicon To Wafersindian21rNo ratings yet

- DYNO-MILL KD - Tomášová Lea, S.R.ODocument3 pagesDYNO-MILL KD - Tomášová Lea, S.R.OBhavin SolankiNo ratings yet

- Milling Separator: SFI1000A / SFI1500ADocument2 pagesMilling Separator: SFI1000A / SFI1500AHighlifeNo ratings yet

- Industrial Cleaner Mega 168 1 Datasheet ENDocument1 pageIndustrial Cleaner Mega 168 1 Datasheet ENshakar azizNo ratings yet

- Agricultural Eq Ipments Incl Ding Food R Ce& S D Rocessina Lab Qu PmentsDocument1 pageAgricultural Eq Ipments Incl Ding Food R Ce& S D Rocessina Lab Qu PmentssamNo ratings yet

- AB Double Flow Drier WebDocument2 pagesAB Double Flow Drier WebHalit Baris SertbakanNo ratings yet

- Ginning Investment Machine Lay OutDocument14 pagesGinning Investment Machine Lay OutGizachew ZelekeNo ratings yet

- InstaPro CornExtruderDocument2 pagesInstaPro CornExtruderMaría Eugenia PérezNo ratings yet

- Industrial Flour Mill MachineDocument24 pagesIndustrial Flour Mill MachineRonin SainiNo ratings yet

- Pembangunan Pabrik Pembuatan Agregat Perkerasan JalanDocument12 pagesPembangunan Pabrik Pembuatan Agregat Perkerasan JalanRiston BelMan SidabutarNo ratings yet

- Wendel Mixer W - and WV-seriesDocument6 pagesWendel Mixer W - and WV-seriesFerry KurniaNo ratings yet

- Terratop: The Perfect Share For Every ApplicationDocument2 pagesTerratop: The Perfect Share For Every ApplicationTündeNo ratings yet

- Mining Hose - Hard Wall Range (808) : Excellent Minerals SolutionsDocument2 pagesMining Hose - Hard Wall Range (808) : Excellent Minerals Solutionshiram89No ratings yet

- Impact Hammer Crushers Okd enDocument1 pageImpact Hammer Crushers Okd enMartin ŠimurdaNo ratings yet

- Chapter 16 Rice MillingDocument85 pagesChapter 16 Rice MillingRyza MartizanoNo ratings yet

- Eco-Friendly: Ruian Zhenjing Machinery. PVT - LTDDocument8 pagesEco-Friendly: Ruian Zhenjing Machinery. PVT - LTDBikash NayakNo ratings yet

- Rice Mill Brochure 1Document4 pagesRice Mill Brochure 1nurizdihar9No ratings yet

- Inteded CylinderDocument1 pageInteded CylinderAzlan RamliNo ratings yet

- Large Feed Opening For Large Volumes: Strength in WasteDocument1 pageLarge Feed Opening For Large Volumes: Strength in WasteRoberto Velarde AlvaradoNo ratings yet

- MODEL Mesin BriketDocument9 pagesMODEL Mesin BriketIbrahim SyaharuddinNo ratings yet

- Satake (Thailand) Co., LTDDocument3 pagesSatake (Thailand) Co., LTDjuan vargasNo ratings yet

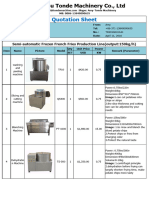

- Basic Investment Overview French FriesDocument2 pagesBasic Investment Overview French FriesSKNo ratings yet

- Otsukatec Super Cubical BrochureDocument11 pagesOtsukatec Super Cubical BrochureMostar NNo ratings yet

- Development of Small Millet Processing Technology by TNAU DR VaradharajuDocument38 pagesDevelopment of Small Millet Processing Technology by TNAU DR VaradharajuBabu CNo ratings yet

- 10 Ton Per Day Wheat Flour Mill Plant Details For CustomersDocument20 pages10 Ton Per Day Wheat Flour Mill Plant Details For CustomersMD. NAHIDUZZAMANNo ratings yet

- Scan File - 0000Document1 pageScan File - 0000HasanNo ratings yet

- Model 2 CatalogueDocument8 pagesModel 2 CataloguebalajicaptainNo ratings yet

- Fully Automatic Cashew Cutting MachineDocument11 pagesFully Automatic Cashew Cutting MachineLadrilleraNo ratings yet

- Zzb0955a WWD Filters Mar2022Document2 pagesZzb0955a WWD Filters Mar2022Raffless SadissNo ratings yet

- VT TubeBundleDryer PDFDocument2 pagesVT TubeBundleDryer PDFDouglas TondelloNo ratings yet

- ARI FOUNDRY PDFDocument13 pagesARI FOUNDRY PDFabdallah batainehNo ratings yet

- Sand Washing Plants For Sale LZZGDocument11 pagesSand Washing Plants For Sale LZZGFirdaus MangawingNo ratings yet

- Thickness Grader: High Capacity in A Compact BodyDocument2 pagesThickness Grader: High Capacity in A Compact BodyNheanvatnak AukNo ratings yet

- Firewood Logs Firewood Logs: Charcoal Briquettes Charcoal BriquettesDocument6 pagesFirewood Logs Firewood Logs: Charcoal Briquettes Charcoal BriquettesJosephine ChirwaNo ratings yet

- Product LiteratureDocument2 pagesProduct Literatureaura maria ubeda gadeaNo ratings yet

- Waste Sorting SolutionDocument8 pagesWaste Sorting SolutionLi GaryNo ratings yet

- 06 Cleaning PDFDocument40 pages06 Cleaning PDFpambudi 24No ratings yet

- TUME-CK ENG EsiteDocument2 pagesTUME-CK ENG EsiteAnonymous 1XBCMXNo ratings yet

- Asphalt Batch Mix PlantDocument8 pagesAsphalt Batch Mix PlantحسامNo ratings yet

- High Density CycloneDocument2 pagesHigh Density CycloneEdson CastelliNo ratings yet

- DB WR Baureihe en 1112 LoDocument8 pagesDB WR Baureihe en 1112 Lolmn_grss0% (1)

- FB Hammermill en DataDocument8 pagesFB Hammermill en DataAditya Whisnu Heryudhanto100% (1)

- Inplant Training ReportDocument79 pagesInplant Training ReportAnand HariNo ratings yet

- Crusher + MixerDocument9 pagesCrusher + MixerBORU Mud Pump Parts100% (1)

- 150kgh Output Frozen French Fries Production LineDocument7 pages150kgh Output Frozen French Fries Production LineAdvantica ServicesNo ratings yet

- DL AI20-1015 SpecSheet CabinetHardmountWasher-Extractor-BC40 en-APDocument2 pagesDL AI20-1015 SpecSheet CabinetHardmountWasher-Extractor-BC40 en-APBrunoNo ratings yet

- ShredderDocument2 pagesShreddershanthimam38100% (1)

- Brochure Rotostar Small Plansifter MPAR en LowDocument4 pagesBrochure Rotostar Small Plansifter MPAR en LowGonzalo MuleroNo ratings yet

- Combo EbroDocument5 pagesCombo Ebroamolsinha1No ratings yet

- Ficha Técnica 42090Document2 pagesFicha Técnica 42090pipo_jackassNo ratings yet

- Jaw Crusher For Primary Crushing - Fote Heavy MachineryDocument18 pagesJaw Crusher For Primary Crushing - Fote Heavy MachineryIvy100% (1)

- Maize Baler Wrapper: Model Tsw2021Document4 pagesMaize Baler Wrapper: Model Tsw2021SandeepNairNo ratings yet

- Rice&wheat Combine HarvesterDocument4 pagesRice&wheat Combine HarvesterHardeep Singh KangNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Ea800 6kva-30kva UpsDocument1 pageEa800 6kva-30kva UpsPauk GyiiNo ratings yet

- Catolog Jaguar Screw CompressorDocument20 pagesCatolog Jaguar Screw CompressorPauk GyiiNo ratings yet

- Bucket ElevatorsDocument913 pagesBucket ElevatorsPauk GyiiNo ratings yet

- Arkansas Rice Research Study 2015Document471 pagesArkansas Rice Research Study 2015Pauk GyiiNo ratings yet

- Bridge Rectifier KBPC35××Document2 pagesBridge Rectifier KBPC35××Pauk GyiiNo ratings yet

- Schneider Compact Catlouge 2018Document156 pagesSchneider Compact Catlouge 2018Pauk GyiiNo ratings yet

- Bridge Rectifier KBPC35××Document2 pagesBridge Rectifier KBPC35××Pauk GyiiNo ratings yet

- In Productivity Your Partner: Since 1883Document2 pagesIn Productivity Your Partner: Since 1883Pauk GyiiNo ratings yet

- Scania CatalogDocument68 pagesScania Catalogj_hernandez_ch80% (5)

- How To Produce Your Book With Scribus.: Make The Front MatterDocument3 pagesHow To Produce Your Book With Scribus.: Make The Front MattersudyNo ratings yet

- Maruti 110306013819 Phpapp02Document148 pagesMaruti 110306013819 Phpapp02NishantShah0% (1)

- Correctional AdministrationDocument9 pagesCorrectional AdministrationEmmanuel BuanNo ratings yet

- Jayanta Bhattacharya Former Professor of Medicine Stanford (41-1 PDF) Chaplains Class ActionDocument64 pagesJayanta Bhattacharya Former Professor of Medicine Stanford (41-1 PDF) Chaplains Class ActionUncoverDC100% (1)

- Ecclesiastes 7.1-14 QuestionsDocument2 pagesEcclesiastes 7.1-14 QuestionsSamuel XiaoNo ratings yet

- ITECH - 1103 - Mid - Sem - TestDocument3 pagesITECH - 1103 - Mid - Sem - TestharryNo ratings yet

- The Ideas That Made America A Brief History Ratner Rosenhagen Full ChapterDocument67 pagesThe Ideas That Made America A Brief History Ratner Rosenhagen Full Chapterkurtis.mosley227100% (19)

- Maton Neck Adjustments Rev1Document11 pagesMaton Neck Adjustments Rev1golf12345No ratings yet

- Kamma and Rebirth Lectured by Venerable PaññajotaDocument2 pagesKamma and Rebirth Lectured by Venerable PaññajotatinNo ratings yet

- Matiltan HPP (Vol-II A) Specs NTDCDocument258 pagesMatiltan HPP (Vol-II A) Specs NTDCsami ul haqNo ratings yet

- Teaching Reading Lesson Plan 1Document2 pagesTeaching Reading Lesson Plan 1api-301343173No ratings yet

- Banking Assessment 10Document10 pagesBanking Assessment 10AMARJEET SINGHNo ratings yet

- Product - Guide - Bizhub 164 - vs1.0Document20 pagesProduct - Guide - Bizhub 164 - vs1.0vladimir2426No ratings yet

- Feritin TestDocument9 pagesFeritin TestCharles SibagariangNo ratings yet

- Electrical Circuit 2 - Updated Dec 8Document24 pagesElectrical Circuit 2 - Updated Dec 8hadil hawillaNo ratings yet

- Kathrin Seidl Gomez - The Creativity of DisplacementDocument390 pagesKathrin Seidl Gomez - The Creativity of DisplacementSantiago Ospina CelisNo ratings yet

- Pemeriksaan Nervus FasialisDocument25 pagesPemeriksaan Nervus FasialisAldy BimaNo ratings yet

- Installation and User's Guide: IBM Tivoli Storage Manager For Windows Backup-Archive ClientsDocument800 pagesInstallation and User's Guide: IBM Tivoli Storage Manager For Windows Backup-Archive ClientsJavier GonzalezNo ratings yet

- Iqac - Report 2011 12Document91 pagesIqac - Report 2011 12Prashant SinghNo ratings yet

- Accessories Andrew PDFDocument64 pagesAccessories Andrew PDFaralsoNo ratings yet

- Service Manual: Outdoor Unit Series Trane TVR™ II DC Inverter VRF SystemDocument343 pagesService Manual: Outdoor Unit Series Trane TVR™ II DC Inverter VRF SystemUNNI VENUGOPAL67% (3)

- Accenture Bringing Science To SellingDocument16 pagesAccenture Bringing Science To SellingManmeet SinglaNo ratings yet

- PHD On Al Hakim Al TirmidhiDocument468 pagesPHD On Al Hakim Al TirmidhischolarlypurposeNo ratings yet

- Invoice 2 PDFDocument4 pagesInvoice 2 PDFjeevanNo ratings yet