Professional Documents

Culture Documents

RPP - Bda18201 - Woksyop 1 Sem 1 1718 Rev01

RPP - Bda18201 - Woksyop 1 Sem 1 1718 Rev01

Uploaded by

Fattihi EkhmalCopyright:

Available Formats

You might also like

- RPP-04-Rekabentuk Kejuruteraan - DAM31903 - SEM1 20172018Document9 pagesRPP-04-Rekabentuk Kejuruteraan - DAM31903 - SEM1 20172018Muhammad HaziqNo ratings yet

- RPP-04 - BBP30103 - Pengurusan Makmal Dan Bengkel - SEM 1 20172018Document7 pagesRPP-04 - BBP30103 - Pengurusan Makmal Dan Bengkel - SEM 1 20172018Syamil ShahulNo ratings yet

- RPH W1Document3 pagesRPH W1eidalinNo ratings yet

- RPP BFC 43033 2013 2014Document7 pagesRPP BFC 43033 2013 2014ewanz89No ratings yet

- Eppa3053 Proforma 20172018 ProformaDocument6 pagesEppa3053 Proforma 20172018 Proformafahmiyyah100% (1)

- 2012 Module BEC10102Document229 pages2012 Module BEC10102Ubaidullah Jaafar IINo ratings yet

- Co Umb2112Document5 pagesCo Umb2112Atiqah Gusu LanNo ratings yet

- Kolej Vokasional Jabatan PerniagaanDocument22 pagesKolej Vokasional Jabatan PerniagaanasteriaaaikoNo ratings yet

- Garis Panduan Pembangunan BPK v1Document45 pagesGaris Panduan Pembangunan BPK v1nb7bxcmbj7No ratings yet

- Co - Dbe 2113 Perakaunan Kewangan 2Document9 pagesCo - Dbe 2113 Perakaunan Kewangan 2m-6165626No ratings yet

- Keprihatinan Guru Terhadap Amalan Pentaksiran PrinDocument24 pagesKeprihatinan Guru Terhadap Amalan Pentaksiran Prinhamidah2No ratings yet

- Pro Forma Kursus - NFNF2722 (Sem 2 2022-2023)Document8 pagesPro Forma Kursus - NFNF2722 (Sem 2 2022-2023)admiraldamian67No ratings yet

- Tugasan Sau 10012 PDFDocument5 pagesTugasan Sau 10012 PDFA05SKR21F006 MUHAMMAD HAZMY BIN MUSTAFARNo ratings yet

- Proforma Audit LanjutanDocument5 pagesProforma Audit LanjutanNORSYAHMIZA BINTI ABDU-LATIFNo ratings yet

- Pma C01 1-2Document7 pagesPma C01 1-2kitomanjaNo ratings yet

- 1 Tugasan Dan Penilaian Markah Ctu552Document4 pages1 Tugasan Dan Penilaian Markah Ctu552AmelieNo ratings yet

- Pembinaan Dan Pengujian Kebolehgunaan Modul Pengajaran Berasaskan Peta Pemikiran Bagi Topik Nisbah, Kadar Dan KadaranDocument257 pagesPembinaan Dan Pengujian Kebolehgunaan Modul Pengajaran Berasaskan Peta Pemikiran Bagi Topik Nisbah, Kadar Dan KadaranNur Ain Syakira100% (1)

- 20 - Proforma Sem 1 20202021 - GGGE6012 - PA1 - OnlineDocument9 pages20 - Proforma Sem 1 20202021 - GGGE6012 - PA1 - OnlineMuhamad Nazrul BoyoteenNo ratings yet

- Proforma EPPA2813 S1 2017-2018Document5 pagesProforma EPPA2813 S1 2017-2018AngelNo ratings yet

- Co - Dbe 1233 Sistem Maklumat PerakaunanDocument7 pagesCo - Dbe 1233 Sistem Maklumat PerakaunanasteriaaaikoNo ratings yet

- Norreza Binti Mohd Taha 24Document43 pagesNorreza Binti Mohd Taha 24Mohd Yazid Mohamad YunusNo ratings yet

- Amali 05Document7 pagesAmali 05Aswaja313No ratings yet

- CONTOH Penyediaan LAPORAN AktivitiDocument6 pagesCONTOH Penyediaan LAPORAN AktivitiShahril Anuar100% (1)

- GBP 8213 Asas Kejuruteraan BioprosesDocument10 pagesGBP 8213 Asas Kejuruteraan BioprosesFaraliza Hassan ShokriNo ratings yet

- Kolej Vokasional Jabatan PerniagaanDocument22 pagesKolej Vokasional Jabatan PerniagaanasteriaaaikoNo ratings yet

- Buku LOG Terkini 12 Sept 2022Document264 pagesBuku LOG Terkini 12 Sept 2022Hafiz HazrinNo ratings yet

- Rps Francais de Base Study CaseDocument17 pagesRps Francais de Base Study CaseNatasha “Nat”No ratings yet

- Faktor-Faktor Yang Mempengaruhi Perkembangan Kerjaya Di Kalangan Profesor Dan Profesor Madya Di Universiti Malaysia SarawakDocument24 pagesFaktor-Faktor Yang Mempengaruhi Perkembangan Kerjaya Di Kalangan Profesor Dan Profesor Madya Di Universiti Malaysia SarawakImzan NazmiNo ratings yet

- K02950 - 20190922054118 - Penilaian KPR 3012 Sem 2 20192020 - 191Document10 pagesK02950 - 20190922054118 - Penilaian KPR 3012 Sem 2 20192020 - 191EZLYEN AZLINNo ratings yet

- K03032 - 20180914001742 - Penilaian KPR 3012 Sem 2 6 SEPT-1Document10 pagesK03032 - 20180914001742 - Penilaian KPR 3012 Sem 2 6 SEPT-1Jam OrenNo ratings yet

- Penilaian KPR 3012Document10 pagesPenilaian KPR 3012John NgooNo ratings yet

- Proforma Audit DalamanDocument4 pagesProforma Audit DalamanNORSYAHMIZA BINTI ABDU-LATIFNo ratings yet

- Manual Pelaksanaan Kerja Kursus Pengajian Am Kertas 4 9004 STPMDocument24 pagesManual Pelaksanaan Kerja Kursus Pengajian Am Kertas 4 9004 STPMFY ChiengNo ratings yet

- Final Proforma Kp1 Gb6013 Sem 2 2018-2019Document6 pagesFinal Proforma Kp1 Gb6013 Sem 2 2018-2019Nur Afifah AhmadNo ratings yet

- Maklumat KursusDocument2 pagesMaklumat KursusMuhammad Syafiq AwaldinNo ratings yet

- Rancangan Pembelajaran Dan Pemudahcaraan (PDPC) Matapelajaran: Penyejukan & Penyamanan UdaraDocument9 pagesRancangan Pembelajaran Dan Pemudahcaraan (PDPC) Matapelajaran: Penyejukan & Penyamanan Udaranasrul2020No ratings yet

- Jurnal TQMDocument128 pagesJurnal TQMAndrew KssNo ratings yet

- Penilaian Kursus Kpr3012 A231Document10 pagesPenilaian Kursus Kpr3012 A231Denny AryanNo ratings yet

- Pembangunan Dan Penilaian Modul Pengajaran Dan Pembelajaran Berasaskan Multimedia Subjek Rekabentuk Dan Teknologi Sekolah Rendah PDFDocument24 pagesPembangunan Dan Penilaian Modul Pengajaran Dan Pembelajaran Berasaskan Multimedia Subjek Rekabentuk Dan Teknologi Sekolah Rendah PDFYaya BatrisyaNo ratings yet

- RI Statistik Gunaan Sem 2 2015 2016Document12 pagesRI Statistik Gunaan Sem 2 2015 2016Suhanthi ManiNo ratings yet

- PIA2008Document2 pagesPIA2008Shamini ShaminiNo ratings yet

- Ri Qku3073 Rehab A172 12 Feb18Document11 pagesRi Qku3073 Rehab A172 12 Feb18FRESILLA MATIUSNo ratings yet

- Perkongsian Pengetahuan Di Dalam Perkhidmatan Pengurusan Fasiliti (Merangkumi Hard Dan Soft Services)Document112 pagesPerkongsian Pengetahuan Di Dalam Perkhidmatan Pengurusan Fasiliti (Merangkumi Hard Dan Soft Services)hafizahNo ratings yet

- Kerja Lapangan Geo 3Document3 pagesKerja Lapangan Geo 3Azlina Mat JamilNo ratings yet

- RPS Teknologi Sediaan SterilDocument19 pagesRPS Teknologi Sediaan Sterilchevyluviana100% (1)

- SAPSP Academic ExerciseDocument9 pagesSAPSP Academic ExercisesarmoneyNo ratings yet

- 6 - PISMP - Senarai Semak Portfolio (Pensyarah)Document4 pages6 - PISMP - Senarai Semak Portfolio (Pensyarah)amirulNo ratings yet

- Kepelbagaian Gaya Pembelajaran Dan Kemahiran BelajarDocument104 pagesKepelbagaian Gaya Pembelajaran Dan Kemahiran BelajarLadyZuely100% (37)

- Lampiran Internship PISMPDocument10 pagesLampiran Internship PISMPjieer tanNo ratings yet

- Course Outline GE6563 SEM 12010Document8 pagesCourse Outline GE6563 SEM 12010Ahmad Fkrudin Mohamed YusoffNo ratings yet

RPP - Bda18201 - Woksyop 1 Sem 1 1718 Rev01

RPP - Bda18201 - Woksyop 1 Sem 1 1718 Rev01

Uploaded by

Fattihi EkhmalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RPP - Bda18201 - Woksyop 1 Sem 1 1718 Rev01

RPP - Bda18201 - Woksyop 1 Sem 1 1718 Rev01

Uploaded by

Fattihi EkhmalCopyright:

Available Formats

Lampiran A

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

FAKULTI KEJURUTERAAN MEKANIKAL DAN PEMBUATAN

PERANCANGAN KULIAH

LECTURE PLAN

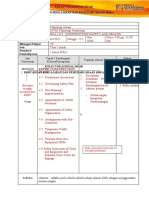

MAKLUMAT KURSUS (COURSE INFORMATION)

SEMESTER / SESI (SEMESTER / SESSION) : 1/2017-2018

KOD KURSUS (COURSE CODE) : BDA 18201

NAMA KURSUS (COURSE TITLE) : BENGKEL KEJURUTERAAN MEKANIKAL I

(MECHANICAL ENGINEERING WORKSHOP I)

BEBAN AKADEMIK PELAJAR (STUDENT ACADEMIC LOAD) :

Kategori Aktiviti Aktiviti Pembelajaran Jumlah Jam/ Semester

(Category of Activities) (Learning Activities) (Total Hours/ Semester)

Kuliah (Lecture) 0

Pembelajaran bersemuka Tutorial / Amali (Tutorial / Practical) 26

(Face-to-face learning) Aktiviti pembelajaran berpusatkan pelajar lain

2

(Other student centered learning activities)

Penyediaan tugasan, projek dan lain-lain

12

(Preparing assignment, project and others)

Pembelajaran kendiri Ulangkaji

0

(Independent study) (Revision)

Persediaan bagi pentaksiran

0

(Preparation for assessment)

Pentaksiran berterusan

0

Pentaksiran rasmi (Continuous assessment)

(Formal assessment) Peperiksaan akhir

0

(Final examination)

JUMLAH JAM BELAJAR PELAJAR (JBP)

40

(TOTAL STUDENT LEARNING TIME (SLT))

Kursus Pra-syarat (Prerequisite Course) :-

Nama Staf Akademik (Name of Academic Staff) :

En. Kamarudin bin Kamdani (Penyelaras) PM Dr. Erween bin Abd Rahim

En. Shazarel bin Shamsudin Dr. Mohd Rasidi bin Ibrahim

En. Suhaimi bin Hassan Dr. Haslina binti Abdullah

En. Noor Hakim bin Rafai Dr. Mohd Sallehuddin bin Yusof

En. Zazuli bin Mohid Dr. Nasuha bin Saude

En. Azriszul bin Mohd Amin Pn. Sulastri binti Sabudin

Disediakan oleh (Prepared by): Disahkan oleh (Approved by):

Tandatangan (Signature): Tandatangan (Signature):

Nama (Name): Kamaruddin bin Kamdani Nama (Name): Dr. Mohd Nasrull bin Abdol Rahman

Tarikh (Date): 4 September 2017 Tarikh (Date): 4 September 2017

RPP-04 / Prosedur Pelaksanaan Kuliah

Edisi: 4 / No. Semakan: 0

Lampiran A

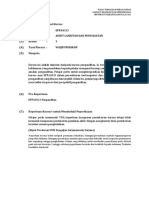

MATLAMAT (GOALS):

This course is designed to give exposure and practice to the use of hand tools, measuring tools and

machine operation and focuses on safety aspects in the workshop.

SINOPSIS (SYNOPSIS):

Safety regulations, fitting, sheet metal forming, turning, grinding, welding and milling.

HASIL PEMBELAJARAN (LEARNING OUTCOMES):

At the end of this course, the students will be able to:

(1) Engineering Knowledge Demonstrate fabrication techniques and processes to produce engineering

products according to the working procedures. (C3, LO1)

(2) Individual and Team Work - Function effectively as an individual, and as a member or leader in

diverse teams in multi-disciplinary in solving problems related fabrication techniques and processes.

(A2, LO5)

(3) Life Long Learning - Comply the fabrication techniques and processes with the current state of the

art technology (A2, LO6)

ISI KANDUNGAN (CONTENT):

MINGGU KANDUNGAN PENTAKSIRAN

(WEEK) (CONTENT) (ASSESSMENT)

1 1.1 BRIEFING

24 2.0 FITTING & METAL SHEETS FORMING Practical, Report, Test

2.1 Safety in fitting workshop.

2.2 Hand tools such as center marker, ruler, tweezers,

vernier caliper, saw and others.

2.3 Procedure of fitting sheets metal.

2.4 Introduction to basic metal plate which covers

marking, folding, cutting and connecting.

58 3.0 WELDING Practical, Report, Test

3.1 Safety in welding workshop.

3.2 Arc welding.

3.3 Gas welding.

3.4 Types of welding operation: Joint, T- joint, overlap

and corner.

6 MID SEMESTER BREAK

9 11 4.0 CONVENTIONAL LATHE Practical, Report, Test

4.1 Introduction to conventional lathe machine.

4.2 Lathe machine operating principle.

4.3 Lathe operations such as facing, taper and etc.

4.4 Thread and manual threading.

12 14 5.0 CONVENTIONAL MILLING Practical, Report, Test

5.1 Introduction to conventional milling machine.

5.2 Milling machine operating principle.

5.3 Cutting tool selection.

5.4 Milling operations: face, angle, groove T.

5.5 Introduction to grinding operation.

5.6 Safety during grinding operation.

5.7 Grinding cutting tool and sizes.

5.8 Selection on cutting tool for grinding operation.

15 6.0 TEST Test

RPP-04 / Prosedur Pelaksanaan Kuliah

Edisi: 4 / No. Semakan: 0

Lampiran A

TUGASAN / PROJEK (ASSIGNMENT / PROJECT):

Students will be given a task (based on drawing given) which consists four hands-on skill that will

complete at end of the semester.

PENTAKSIRAN (ASSESSMENT):

1. Kuiz (Quiz) : 0 %

2. Tugasan (Assignment) : 0 %

3. Ujian (Test) : 20 %

4. Project (Project) : 80 %

5. Lain-lain (Others) : 0 %

6. Peperiksaan Akhir (Final Examination) : 0 %

Jumlah (Total) : 100 %

RUJUKAN (REFERENCES):

1. Richard R. Kibbe, John E. Neely, Roland O. Meyer, Warren T. White. (2010). Machine Tool

Practices. 9th ed. Prentice Hall. Call number: TJ1185.M32 2010

2. Serope Kalpakjian and Steven R. Schmid. (2014). Manufacturing Engineering and Technology. 7 th

ed. Prentice Hall. Call number: TS176.K34 2014

3. Hoffman, Peter J.(2012)." Precision machining technology". Clifton Park, NY: Delmar Cengage

Learning.Call number: TJ1189.P73 2012

4. Sacks, Raymond J. and Bohnart, Edward R. (2012). Welding: Principles and Practices.4th edition.

McGraw-Hill. Call number: TS227.B63 2012

KEHADIRAN / PERATURAN SEMASA KULIAH (ATTENDANCE / REGULATIONS DURING LECTURE)

1. Pelajar mesti hadir tidak kurang dari 80% masa pertemuan yang ditentukan bagi sesuatu kursus termasuk

kursus Hadir Wajib (HW) dan kursus Hadir Sahaja (HS).

Students must attend not less than 80% of the contact hours specified for a course including Compulsory

Attendance (HW) course and Attendance Only (HS) course.

2. Pelajar yang tidak memenuhi perkara 1 di atas tidak dibenarkan menghadiri kuliah dan menduduki

sebarang bentuk pentaksiran selanjutnya. Markah sifar 0 akan diberikan kepada pelajar yang gagal

memenuhi perkara 1. Manakala untuk kursus HW, pelajar yang gagal memenuhi perkara 1 akan diberi

gred Hadir Gagal (HG).

Students who do not fulfill item 1 of the above are not allowed to attend further lecture and sit for any

form of assessment. Zero 0 mark will be given to students who fail to comply with item 1. As for HW

course, students who fail to comply with item 1 will be given Failure Attendance (HG) grade.

3. Pelajar perlu patuh kepada peraturan berpakaian yang berkuatkuasa dan menjaga disiplin diri masing-

masing untuk mengelakkan dari tindakan tatatertib diambil terhadappelajar.

Students should adhere to the dress regulations in effect and must discipline themselves to avoid from

any disciplinary actions.

4. Pelajar perlu mematuhi peraturan keselamatan sepanjang aktiviti pembelajaran dan pengajaran.

Students should adhere to the safety regulations throughout the learning and teaching activities.

RPP-04 / Prosedur Pelaksanaan Kuliah

Edisi: 4 / No. Semakan: 0

Lampiran A

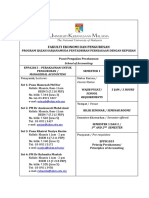

MATRIK HASIL PEMBELAJARAN KURSUS DAN HASIL PEMBELAJARAN PROGRAM

MATRIX OF COURSE LEARNING OUTCOMES AND PROGRAMME LEARNING OUTCOMES

Fakulti (Faculty) : Faculty of Mechanical and Manufacturing Matrikiniperludigunakanbersama:

(This matrix is to be used with)

Program (Programme) : Bachelor of Mechanical Engineering with Honours 1. ObjektifPendidikan Program (PEO)

(Programme Educational Objectives (PEO))

Kod Kursus (Course Code) : BDA 18201 2. HasilPembelajaran Program (PLO)

(Programme Learning Outcomes (PLO))

Nama Kursus (Course Title) : Mechanical Engineering Workshop 1

Pematuhankepada PLO (Compliance to PLO) Kaedah Kaedah

PLO10

PLO11

PLO12

PLO13

Bil. HasilPembelajaranKursus Penyampaian Pentaksiran

PLO1

PLO2

PLO3

PLO4

PLO5

PLO6

PLO7

PLO8

PLO9

KPI

(No.) (Course Learning Outcomes) (Method of (Method of

Delivery) Assessment)

1 Engineering Knowledge Demonstrate fabrication Practical Test, Project 100% of students

techniques and processes to produce engineering Report must get 40% of

products according to the working procedures. (C3, marks and above

LO1)

2 Individual and Team Work - Function effectively as an Practical Report 100% of students

individual, and as a member or leader in diverse teams (Team must get 40% of

in multi-disciplinary in solving problems related Work) marks and above

fabrication techniques and processes (A2, LO5)

3 Life Long Learning - Comply the fabrication techniques Practical Project 100% of students

and processes with the current state of the art Report must get 40% of

technology (A2, LO6) marks and above

Jumlah (Total) 1 1 1

TaksonomiPembelajaran (Learning Taxonomy)

Kognitif(Cognitive) Psikomotor (Psychomotor) Afektif (Affective)

C1 Pengetahuan (Knowledge) P1 Persepsi (Perception) A1 Menerima (Receiving)

C2 Pemahaman (Comprehension) P2 Set (Set) A2 MemberikanMaklumBalas (Responding)

C3 Aplikasi (Application) P3 ResponsBerpandu (Guided Response) A3 Menilai (Valuing)

C4 Analisis (Analysis) P4 Mekanisme (Mechanism) A4 Mengorganisasi (Organising)

C5 Sintesis (Synthesis) P5 ResponsKetaraKompleks (Complex Overt Response) A5 MenghayatiNilai (Internalising)

C6 Penilaian (Evaluation) P6 Adaptasi (Adaptation)

P7 LakuanTulen (Origination)

RPP-04 / Prosedur Pelaksanaan Kuliah

Edisi: 4 / No. Semakan: 0

You might also like

- RPP-04-Rekabentuk Kejuruteraan - DAM31903 - SEM1 20172018Document9 pagesRPP-04-Rekabentuk Kejuruteraan - DAM31903 - SEM1 20172018Muhammad HaziqNo ratings yet

- RPP-04 - BBP30103 - Pengurusan Makmal Dan Bengkel - SEM 1 20172018Document7 pagesRPP-04 - BBP30103 - Pengurusan Makmal Dan Bengkel - SEM 1 20172018Syamil ShahulNo ratings yet

- RPH W1Document3 pagesRPH W1eidalinNo ratings yet

- RPP BFC 43033 2013 2014Document7 pagesRPP BFC 43033 2013 2014ewanz89No ratings yet

- Eppa3053 Proforma 20172018 ProformaDocument6 pagesEppa3053 Proforma 20172018 Proformafahmiyyah100% (1)

- 2012 Module BEC10102Document229 pages2012 Module BEC10102Ubaidullah Jaafar IINo ratings yet

- Co Umb2112Document5 pagesCo Umb2112Atiqah Gusu LanNo ratings yet

- Kolej Vokasional Jabatan PerniagaanDocument22 pagesKolej Vokasional Jabatan PerniagaanasteriaaaikoNo ratings yet

- Garis Panduan Pembangunan BPK v1Document45 pagesGaris Panduan Pembangunan BPK v1nb7bxcmbj7No ratings yet

- Co - Dbe 2113 Perakaunan Kewangan 2Document9 pagesCo - Dbe 2113 Perakaunan Kewangan 2m-6165626No ratings yet

- Keprihatinan Guru Terhadap Amalan Pentaksiran PrinDocument24 pagesKeprihatinan Guru Terhadap Amalan Pentaksiran Prinhamidah2No ratings yet

- Pro Forma Kursus - NFNF2722 (Sem 2 2022-2023)Document8 pagesPro Forma Kursus - NFNF2722 (Sem 2 2022-2023)admiraldamian67No ratings yet

- Tugasan Sau 10012 PDFDocument5 pagesTugasan Sau 10012 PDFA05SKR21F006 MUHAMMAD HAZMY BIN MUSTAFARNo ratings yet

- Proforma Audit LanjutanDocument5 pagesProforma Audit LanjutanNORSYAHMIZA BINTI ABDU-LATIFNo ratings yet

- Pma C01 1-2Document7 pagesPma C01 1-2kitomanjaNo ratings yet

- 1 Tugasan Dan Penilaian Markah Ctu552Document4 pages1 Tugasan Dan Penilaian Markah Ctu552AmelieNo ratings yet

- Pembinaan Dan Pengujian Kebolehgunaan Modul Pengajaran Berasaskan Peta Pemikiran Bagi Topik Nisbah, Kadar Dan KadaranDocument257 pagesPembinaan Dan Pengujian Kebolehgunaan Modul Pengajaran Berasaskan Peta Pemikiran Bagi Topik Nisbah, Kadar Dan KadaranNur Ain Syakira100% (1)

- 20 - Proforma Sem 1 20202021 - GGGE6012 - PA1 - OnlineDocument9 pages20 - Proforma Sem 1 20202021 - GGGE6012 - PA1 - OnlineMuhamad Nazrul BoyoteenNo ratings yet

- Proforma EPPA2813 S1 2017-2018Document5 pagesProforma EPPA2813 S1 2017-2018AngelNo ratings yet

- Co - Dbe 1233 Sistem Maklumat PerakaunanDocument7 pagesCo - Dbe 1233 Sistem Maklumat PerakaunanasteriaaaikoNo ratings yet

- Norreza Binti Mohd Taha 24Document43 pagesNorreza Binti Mohd Taha 24Mohd Yazid Mohamad YunusNo ratings yet

- Amali 05Document7 pagesAmali 05Aswaja313No ratings yet

- CONTOH Penyediaan LAPORAN AktivitiDocument6 pagesCONTOH Penyediaan LAPORAN AktivitiShahril Anuar100% (1)

- GBP 8213 Asas Kejuruteraan BioprosesDocument10 pagesGBP 8213 Asas Kejuruteraan BioprosesFaraliza Hassan ShokriNo ratings yet

- Kolej Vokasional Jabatan PerniagaanDocument22 pagesKolej Vokasional Jabatan PerniagaanasteriaaaikoNo ratings yet

- Buku LOG Terkini 12 Sept 2022Document264 pagesBuku LOG Terkini 12 Sept 2022Hafiz HazrinNo ratings yet

- Rps Francais de Base Study CaseDocument17 pagesRps Francais de Base Study CaseNatasha “Nat”No ratings yet

- Faktor-Faktor Yang Mempengaruhi Perkembangan Kerjaya Di Kalangan Profesor Dan Profesor Madya Di Universiti Malaysia SarawakDocument24 pagesFaktor-Faktor Yang Mempengaruhi Perkembangan Kerjaya Di Kalangan Profesor Dan Profesor Madya Di Universiti Malaysia SarawakImzan NazmiNo ratings yet

- K02950 - 20190922054118 - Penilaian KPR 3012 Sem 2 20192020 - 191Document10 pagesK02950 - 20190922054118 - Penilaian KPR 3012 Sem 2 20192020 - 191EZLYEN AZLINNo ratings yet

- K03032 - 20180914001742 - Penilaian KPR 3012 Sem 2 6 SEPT-1Document10 pagesK03032 - 20180914001742 - Penilaian KPR 3012 Sem 2 6 SEPT-1Jam OrenNo ratings yet

- Penilaian KPR 3012Document10 pagesPenilaian KPR 3012John NgooNo ratings yet

- Proforma Audit DalamanDocument4 pagesProforma Audit DalamanNORSYAHMIZA BINTI ABDU-LATIFNo ratings yet

- Manual Pelaksanaan Kerja Kursus Pengajian Am Kertas 4 9004 STPMDocument24 pagesManual Pelaksanaan Kerja Kursus Pengajian Am Kertas 4 9004 STPMFY ChiengNo ratings yet

- Final Proforma Kp1 Gb6013 Sem 2 2018-2019Document6 pagesFinal Proforma Kp1 Gb6013 Sem 2 2018-2019Nur Afifah AhmadNo ratings yet

- Maklumat KursusDocument2 pagesMaklumat KursusMuhammad Syafiq AwaldinNo ratings yet

- Rancangan Pembelajaran Dan Pemudahcaraan (PDPC) Matapelajaran: Penyejukan & Penyamanan UdaraDocument9 pagesRancangan Pembelajaran Dan Pemudahcaraan (PDPC) Matapelajaran: Penyejukan & Penyamanan Udaranasrul2020No ratings yet

- Jurnal TQMDocument128 pagesJurnal TQMAndrew KssNo ratings yet

- Penilaian Kursus Kpr3012 A231Document10 pagesPenilaian Kursus Kpr3012 A231Denny AryanNo ratings yet

- Pembangunan Dan Penilaian Modul Pengajaran Dan Pembelajaran Berasaskan Multimedia Subjek Rekabentuk Dan Teknologi Sekolah Rendah PDFDocument24 pagesPembangunan Dan Penilaian Modul Pengajaran Dan Pembelajaran Berasaskan Multimedia Subjek Rekabentuk Dan Teknologi Sekolah Rendah PDFYaya BatrisyaNo ratings yet

- RI Statistik Gunaan Sem 2 2015 2016Document12 pagesRI Statistik Gunaan Sem 2 2015 2016Suhanthi ManiNo ratings yet

- PIA2008Document2 pagesPIA2008Shamini ShaminiNo ratings yet

- Ri Qku3073 Rehab A172 12 Feb18Document11 pagesRi Qku3073 Rehab A172 12 Feb18FRESILLA MATIUSNo ratings yet

- Perkongsian Pengetahuan Di Dalam Perkhidmatan Pengurusan Fasiliti (Merangkumi Hard Dan Soft Services)Document112 pagesPerkongsian Pengetahuan Di Dalam Perkhidmatan Pengurusan Fasiliti (Merangkumi Hard Dan Soft Services)hafizahNo ratings yet

- Kerja Lapangan Geo 3Document3 pagesKerja Lapangan Geo 3Azlina Mat JamilNo ratings yet

- RPS Teknologi Sediaan SterilDocument19 pagesRPS Teknologi Sediaan Sterilchevyluviana100% (1)

- SAPSP Academic ExerciseDocument9 pagesSAPSP Academic ExercisesarmoneyNo ratings yet

- 6 - PISMP - Senarai Semak Portfolio (Pensyarah)Document4 pages6 - PISMP - Senarai Semak Portfolio (Pensyarah)amirulNo ratings yet

- Kepelbagaian Gaya Pembelajaran Dan Kemahiran BelajarDocument104 pagesKepelbagaian Gaya Pembelajaran Dan Kemahiran BelajarLadyZuely100% (37)

- Lampiran Internship PISMPDocument10 pagesLampiran Internship PISMPjieer tanNo ratings yet

- Course Outline GE6563 SEM 12010Document8 pagesCourse Outline GE6563 SEM 12010Ahmad Fkrudin Mohamed YusoffNo ratings yet