Professional Documents

Culture Documents

Motores Anillos Rozantes WEG

Motores Anillos Rozantes WEG

Uploaded by

Ismael Borrego BelmarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Motores Anillos Rozantes WEG

Motores Anillos Rozantes WEG

Uploaded by

Ismael Borrego BelmarCopyright:

Available Formats

Line

60Hz

Three-Phase Induction Motors

TEFC - Slip-ring Rotor

General Characteristics:

Output: 2,2 up to 550kW

Voltages: up to 440V

Frequency: 60Hz

Frames: 132 up to 450 (IEC)

Degree of protection: IP54/55

Mounting: Horizontal or vertical

FOR INTERMITTENT DUTY

Three-phase Slip Ring Motors - F Line

APLICATIONS Double shaft end

Taconite labyrinth

This line of slip ring motors has been designed in Class B temperature rise (80 C)

compliance with IEC Standard for use on Special secondary voltages and current

intermittent duty equipment with high number of Terminal box on top (up to frame 450)

starting and braking by counter-current, reversible Special thread in terminal box entries

rotation systems or speed control systems through Terminal block

rotor circuit such as: Terminal board

Rolling bridges

Hoists and cranes

Jib cranes

Steel-works

And other applications with high inertia loads.

ADVANTAGES

In view of the applications they are suitable for,

these motors are built with the most advanced

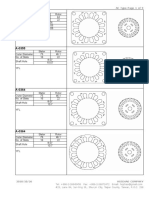

technology available, featuring a vast range of ABNT DIMENSINS OF FF FLANGE N of

advantages: Frame Flange C LA M N P T S

holes

132M FF265 89 12 265 230 300 4 15

Rugged construction 160L 108

FF300 300 250 350

Low maintenance 180L 121 45 4

200M

Long life and safe operation FF350 133 350 300 400

200L

Extra strong rotor assembly to withstand high 225S

FF400 149 18 400 350 450 5 19

225M

torques 250S

168

Adequate insulating materials to withstand 250M

FF500 500 450 550

280S

overvoltages during accelerations and braking 190 22

280M 30 8

Eletromagnetic circuit designed to ensure high 315S

FF600 216 22 600 550 660

breakdown torques 315M

355M 6 24

Double rotation direction FF740 254 22 740 680 800

355L

Symmetric frame, allowing change of mounting 400L FF940 280 28 940 880 1000 28

from B3R to B3L and vice-versa

On request motors can be supplied with following

features:

Degree of protection IPW55 and IPW65

Cable gland in terminal box

Class H insulation (180 C)

Four voltage supply (220 /380/ 440 /760V)

Epoxy painting

ABNT DIMENSIONS OF C FLANGE N of

Space heaters Frame holes

Flange C M

N P S T

Bimetallic thermostats 132M

FC 184

89

184.2 215.9 225

160L 108 13

Thermistors (PTC or NTC) 4

180L 121 UNC

FC 228 228.6 266.7 280

Resistance temperature detectors (PT 100) 200L 133

Witnessed or unwitnessed tests 225S

FC 279 149 279.4 317.5 395

225M

Double-sealed bearings (2RS) 6.3

250S

168 5/8

Special tapered shaft end 250M

FC 355 355.6 406.4 455 11 8

280S UNC

Built-in electromagnetic brake (up to frame 280M

190

200) 315S

FC 368 216 368.3 419.1 455

315M

Mounting configuration B5 or B35 until frame

200

This sheet is part of catalog n 269 Revision: 01/10/01

2

Three-phase Slip Ring Motors - F Line

FAF (Frames 132 to 450)

Protection: IP54/55 Cooling: IC 411

Ball/Roller Bearings Voltage: 220, 380 or 440V

Wound rotor Insulation: Class F (155 C)

- The values shown are subject to change prior notice.

- Rotor terminal box since frame 355 (S2).

- Accessories terminal box since frame 400 (3xRWG3/4).

- Optional double shaft end.

This sheet is part of catalog n 269 Revision: 01/10/01

3

Three-phase Slip Ring Motors - F Line

Output and Torque Reduction in Function of the Speed

Reduction with Continuous Duty

Rated speed (%) 100 90 80 70 60 50 40 <40

Torque available (%) 100 96 91 85 80 72 62 On request

Output (%) 100 86 73 60 48 36 25 On request

When an application requires the motor to run

permanently or under continuous at reduced

speed (fan efficiency decreases with speed

reduction), motor outputs and torques available

must be limited as per table aside.

For these cases, where speed reduction is

required permanently or continuous duty, motors

can be oversized in order to deliver output and

torque required.

NOTE: When there are other special

requirements which can not be determined by the

table aside, please contact the nearest WEG sale

office.

This sheet is part of catalog n 269 Revision: 01/10/01

4

Three-phase Slip Ring - Line F

4 POLE - 60Hz

SERVICE DUTY S3 6 START/H

ED = 25% ED = 40% ED = 60 % ED = 100%

Inertia Power Approx.

ABNT Rotor

RPM Moment Factor Effici- Weight Stator Inertia Stator Inertia Stator Inertia Stator Inertia

Frame Voltage ency Tb/ Rotor Moment Tb/ Rotor Moment Tb/ Rotor Moment Tb/ Rotor Moment

(kgm2) Cos (kg) kW HP Amps kW HP Amps kW HP amps kW HP amps at

Tn Amps Trac. Tn Amps Trac. Tn Amps Trac. Tn Amps Trac.

at 440V at 440V at 440V 440V

(kgm2) (kgm2) (kgm2) (kgm2)

132 M 1730 155 0.07 0.83 82.0 85 6.6 9.0 12.7 1.9 28 4.1 5.9 8.0 11.4 2.1 25 6.6 5.2 7.0 10.0 2.4 22 9.95 4.5 6.1 8.7 2.8 19 16.6

132 M 1740 230 0.08 0.86 83.0 100 9.9 13.5 18.2 1.9 28 6.0 8.8 12.0 16.2 2.1 25 9.6 7.4 10.0 13.6 2.5 21 14.4 6.7 9.1 12.3 2.8 19 24.0

160 L 1750 190 0.11 0.82 86.0 140 11.8 16.0 22.0 2.2 41 9.7 10.7 14.5 19.9 2.4 37 15.6 9.2 12.5 17.1 2.8 32 23.4 8.0 10.9 14.9 3.2 27 39.0

160 L 1750 295 0.13 0.82 87.0 150 18.4 25.0 33.8 2.2 41 13.4 16.2 22.0 29.8 2.5 36 21.5 14.0 19.0 25.8 2.9 31 32.4 12.5 17.0 23.0 3.2 27 54.1

180 L 1750 305 0.25 0.85 87.0 200 25.0 34.0 44.4 2.2 83 19.6 22.0 30.0 39.0 2.5 47 31.4 19.0 26.0 33.7 2.8 41 47.2 17.0 23.0 30.0 3.2 35 79.0

200 L 1755 250 0.42 0.84 87.5 280 30.0 41.0 54.0 2.1 77 27.0 26.0 35.0 46.0 2.5 66 43.0 22.0 30.0 39.0 2.9 57 65 20.0 27.2 35.7 3.2 50 108.0

200 L 1760 315 0.45 0.84 88.0 300 37.5 51.0 67.0 2.1 77 30.0 32.0 43.0 57.0 2.5 65 48.0 28.0 38.0 50.0 2.9 57 72 25.0 34.0 44.4 3.2 49 120.0

225 S/M 1760 325 1.10 0.88 87.0 400 44.0 60.0 75.0 2.1 90 44.0 38.0 52.0 65.0 2.5 78 71.0 33.0 45.0 57.0 2.8 67 107 30.0 40.8 51.4 3.2 57 179.0

250 S/M 1770 210 1.25 0.88 90.0 500 60.0 82.0 99.0 2.1 186 59.0 52.0 71.0 86.0 2.5 161 88.0 46.0 62.0 76.0 2.8 141 144 40.0 54.3 66.3 3.2 118 241.0

250 S/M 1770 270 1.40 0.89 91.0 510 76.0 104.0 123.0 2.2 180 67.0 66.0 90.0 107.0 2.5 158 107.0 58.0 79.0 94.0 2.8 137 161 52.0 70.7 84.2 3.2 119 270.0

280 S/M* 1775 270 3.00 0.85 91.0 700 93.0 127.0 158.0 2.1 220 92.0 81.0 110.0 137.0 2.5 190 148.0 74.0 100.0 126.0 2.7 173 223 62.0 84.2 105.0 3.2 139 374.0

280 S/M* 1775 350 3.40 0.86 92.0 800 121.0 165.0 201.0 2.1 220 102.0 105.0 143.0 174.0 2.5 191 164.0 95.0 129.0 158.0 2.7 172 246 80.0 108.0 132.0 3.2 139 413.0

280 S/M* 1780 410 3.60 0.87 92.0 830 144.0 195.0 236.0 2.1 222 123.0 124.0 169.0 203.0 2.5 192 199.0 110.0 150.0 180.0 2.8 170 300 95.0 129.0 155.0 3.2 140 502.0

315S/M* 1780 435 3.80 0.88 93.0 1000 202.0 275.0 324.0 2.2 290 154.0 176.0 240.0 282.0 2.5 253 248.0 158.0 215.0 253.0 2.8 227 374 137.0 186.0 219.0 3.3 191 626.0

315 S/M* 1780 525 4.00 0.89 93.5 1050 220.0 300.0 347.0 2.3 262 168.0 191.0 260.0 301.0 2.7 228 271.0 173.0 235.0 273.0 3.0 205 409 147.0 199.0 231.0 3.5 170 685.0

355M/L* 1785 430 9.00 0.89 93.0 1500 242.0 330.0 384.0 2.3 355 290.0 210.0 285.0 333.0 2.6 308 467.0 184.0 250.0 292.0 3.0 270 704 160.0 217.0 253.0 3.4 221 1170.0

355M/L* 1785 430 10.50 0.89 93.5 1700 272.0 370.0 429.0 2.3 400 330.0 235.0 320.0 371.0 2.7 346 530.0 210.0 285.0 331.0 3.0 308 800 184.0 250.0 290.0 3.4 254 1340.0

355M/L* 1785 515 11.50 0.89 94.0 1800 330.0 450.0 518.0 2.5 402 380.0 267.0 390.0 450.0 2.9 348 610.0 250.0 340.0 392.0 3.4 304 920 220.0 298.0 345.0 3.8 254 1540.0

355M/L* 1785 570 12.50 0.89 94.0 1900 385.0 525.0 604.0 2.3 423 445.0 335.0 455.0 525.0 2.7 366 720.0 295.0 400.0 463.0 3.1 322 1090 258.0 350.0 404.0 3.5 269 1820.0

400M/L* 1785 500 15.00 0.90 94.5 2500 485.0 660.0 748.0 1.9 588 770.0 422.0 574.0 651.0 2.1 511 1200.0 372.0 505.0 574.0 2.4 450 1800 325.0 441.0 501.0 2.8 387 3000.0

400M/L* 1785 600 18.00 0.90 95.0 2800 582.0 790.0 893.0 1.9 588 900.0 506.0 687.0 777.0 2.1 511 1500.0 446.0 606.0 684.0 2.4 450 2100 390.0 529.0 598.0 2.8 387 3700.0

450 A/B* 1785 600 25.00 0.91 94.0 3800 700.0 950.0 1074.0 1.7 707 1200.0 610.0 830.0 936.0 1.9 616 2000.0 537.0 730.0 824.0 2.2 542 3000 470.0 638.0 720.0 2.6 466 5000.0

450 A/B* 1785 600 30.00 0.91 94.5 4100 820.0 1110.0 1251.0 1.7 828 1500.0 714.0 970.0 1089.0 1.9 720 2500.0 630.0 855.0 961.0 2.2 635 3700 550.0 747.0 839.0 2.6 545 6200.0

For Continuous Duty S1 - use the characteristics of the column 6 start/h ED 100%.

Note: The above indicated Power Factor and efficiency can only be considered as correct for duties equivalent to continuous duty, that is duty S3 6 start/h - ED 100%

and S4 or S5 150 start/h ED 60%.

For others duties to consider as estimated.

This sheet is part of catalog n 269 Revision: 01/10/01

5

Three-phase Slip Ring - Line F

4 POLE - 60Hz

SERVICE DUTY S4 OR S5 150 START/h Output equivalent

ED = 25% ED = 40% ED = 60% continuous duty S1

Inertia Power Approx.

ABNT Rotor Efficiency Weight Inertia

RPM Moment Factor Stator Inertia Stator Inertia Stator

Frame Voltage (%) Tb/ Rotor Tb/ Rotor Tb/ Rotor Moment

(kgm2) Cos (kg) kW HP Amps Moment kW HP amps Moment kW HP Amps kW HP

Tn amps Tn amps Tn amps Trac.

at 440V Trac.(kgm2) at 440V Trac. (kgm2) at 440V

(kgm2)

132 M 1730 155 0.07 0.83 82.0 85 5.5 7.5 10.6 2.3 24 0.12 5.2 7 10.0 2.4 22 0.22 4.5 6 8.7 2.8 19 0.35 4.5 6.1

132 M 1740 230 0.08 0.86 83.0 100 8.5 11.5 15.6 2.2 24 0.17 7.4 10 13.6 2.5 21 0.32 6.7 9 12.3 2.8 18.5 0.51 6.7 9.1

160 L 1750 190 0.11 0.82 86.0 140 10.3 14 19.2 2.5 36 0.28 9.2 12.5 17.1 2.8 32 0.52 8.0 11 14.9 3.2 28 0.83 8.0 10.9

160 L 1750 295 0.13 0.82 87.0 150 15.5 21 28.5 2.6 35 0.39 14 19 25.8 2.9 31 0.72 12.5 17 23.0 3.2 28 1.15 12.5 17.0

180 L 1750 305 0.25 0.85 87.0 200 21.3 29 37.8 2.5 45 0.54 19 26 33.7 2.8 41 1.02 17 23 30 3.2 36 1.65 17.0 23.0

200 L 1755 250 0.42 0.84 87.5 280 25 34 45 2.5 64 0.68 22 30 39 2.9 57 1.33 20 27 36 3.2 51 2.20 20.0 27.2

200 L 1760 315 0.45 0.84 88.0 300 31 42 55 2.6 63 0.78 28 38 50 2.9 57 1.50 25 34 44 3.2 51 2.46 25.0 34.0

225 S/M 1760 325 1.10 0.88 87.0 400 36 49 62 2.6 73 1.04 32.4 44 56 2.9 66 2.12 30 40 51 3.2 60 3.55 30.0 40.8

250 S/M 1770 210 1.25 0.88 90.0 500 50 68 83 2.6 155 1.32 45 61 75 2.9 139 2.77 40 55 66 3.2 125 4.70 40.0 54.3

250 S/M 1770 270 1.40 0.89 91.0 510 64 87 104 2.6 150 1.46 57 78 92 2.9 135 3.10 52 70 84 3.2 121 5.25 52.0 70.7

280 S/M* 1775 270 3.00 0.85 91.0 700 78 106 132 2.6 183 1.95 70 95 119 2.9 164 4.20 62 85 105 3.2 147 7.20 62.0 84.2

280 S/M* 1775 350 3.40 0.86 92.0 800 100 137 166 2.6 183 2.14 90 123 149 2.9 164 4.63 80 110 133 3.2 147 7.94 80 108

280 S/M* 1780 410 3.60 0.87 92.0 830 119 162 195 2.6 184 2.53 107 145 175 2.9 165 5.56 95 130 156 3.2 148 9.60 95 129

315S/M* 1780 435 3.80 0.88 93.0 1000 169 230 271 2.7 242 3.18 151 205 242 3.0 216 7.0 137 185 220 3.3 195 12.0 137 186

315S/M* 1780 525 4.00 0.89 93.5 1050 184 250 290 2.8 219 3.47 162 220 255 3.2 192 7.59 147 200 232 3.5 175 13.1 147 199

355M/L* 1785 430 9.00 0.89 93.0 1500 202 275 320 2.7 297 6.03 180 245 285 3.1 264 13.1 160 220 254 3.4 237 22.6 160 217

355M/L* 1785 430 10.50 0.89 93.5 1700 228 310 360 2.7 335 6.80 206 280 325 3.0 302 14.9 184 250 290 3.4 270 25.7 184 250

355M/L* 1785 515 11.50 0.89 94.0 1800 275 375 431 3.0 335 7.90 246 335 386 3.4 299 17.2 220 300 345 3.8 268 29.6 220 298

355M/L* 1785 570 12.50 0.89 94.0 1900 320 435 502 2.8 350 9.30 287 390 450 3.1 314 20.3 258 350 405 3.5 282 35.0 258 350

400M/L* 1785 500 15.00 0.90 94.5 2500 403 547 622 2.2 488 16 360 490 555 2.5 437 35 325 440 501 2.8 394 60 325 441

400M/L* 1785 600 18.00 0.90 95.0 2800 484 658 743 2.2 488 20 434 590 666 2.5 437 42 390 530 599 2.8 394 72 390 529

450 A/B* 1785 600 25.00 0.91 94.0 3800 583 792 894 2.0 589 27 523 710 802 2.3 528 58 470 640 721 2.6 475 100 470 638

450 A/B* 1785 600 30.00 0.91 94.5 4100 682 927 1041 2.0 689 32 612 830 934 2.3 618 70 550 750 839 2.6 555 120 550 747

For Continuous Duty S1 - use the characteristics of the column 6 start/h ED 100%.

Note: The above indicated Power Factor and efficiency can only be considered as correct for duties equivalent to continuous duty, that is duty S3 6 start/h - ED 100%

and S4 or S5 150 start/h ED 60%.

For others duties to consider as estimated.

This sheet is part of catalog n 269 Revision: 01/10/01

6

Three-phase Slip Ring - Line F

4 POLE - 60Hz

SERVICE DUTY S4 OR S5 300 START/h SERVICE DUTY S4 OR S5 - 600 START/h Output equivalent

Inertia Power Effici- Approx. ED = 40% ED = 60% ED = 60% Continuous duty S1

ABNT Rotor

RPM Moment Factor ency Weight Stator Inertia Stator Inertia Stator Inertia

Frame Voltage Tb/ Rotor Tb/ Rotor Tb/ Rotor

(kgm2) Cos (%) (kg) kW HP Amps Moment kW HP Amps Moment kW HP amps Moment kW HP

Tn amps Tn amps Tn amps

at 440V Trac. (kgm2) at 440V Trac.(kgm2) at 440V Trac.(kgm2)

132 M 1730 155 0.07 0.83 82.0 85 4.4 6 8.5 2.8 19 0.083 3.7 5 7.1 3.4 16 0.15 2.9 4 5.6 4.2 13 0.050 4.5 6.1

132 M 1740 230 0.08 0.86 83.0 100 6.3 8.5 11.6 3.0 17.5 0.12 5.5 7.5 10.1 3.4 15.5 0.22 4.0 5.5 7.4 4.6 11.5 0.075 6.7 9.1

160 L 1750 190 0.11 0.82 86.0 140 8.0 11 14.9 3.2 28 0.20 7.0 9.5 13.0 3.7 24 0.36 5.5 7.5 10.2 4.7 19 0.125 8.0 10.9

160 L 1750 295 0.13 0.82 87.0 150 11.8 16 21.7 3.4 26 0.28 10.7 14.5 19.7 3.8 24 0.50 7.7 10.5 14.2 5.2 17 0.175 12.5 17.0

180 L 1750 305 0.25 0.85 87.0 200 16.2 22 29 3.3 34 0.38 14.7 20 26 3.7 31 0.70 11 15 20 4.9 23 0.225 17.0 23.0

200 L 1755 250 0.42 0.84 87.5 280 19 26 34 3.3 49 0.47 17 23 30 3.8 43 0.90 13 17.5 23 4.9 33 0.250 20.0 27.2

200 L 1760 315 0.45 0.84 88.0 300 23.5 32 42 3.4 48 0.54 21.3 29 38 3.8 44 1.02 16 22 28 4.9 33 0.300 25.0 34.0

225 S/M 1760 325 1.10 0.88 87.0 400 27 37 46 3.5 55 0.68 24.3 33 42 3.9 49 1.40 18.4 25 32 5.1 37 0.325 30.0 40.8

250 S/M 1770 210 1.25 0.88 90.0 500 38 52 63 3.4 118 0.83 34 46 56 3.8 105 1.80 25.8 35 43 * 5.0 80 0.35 40.0 54.3

250 S/M 1770 270 1.40 0.89 91.0 510 48 65 78 3.4 112 0.92 43 59 70 3.8 102 2.0 33 45 53 5.0 78 0.375 52.0 70.7

280 S/M* 1775 270 3.00 0.85 91.0 700 58 79 98 3.4 137 1.20 53 72 90 3.8 125 2.70 41 56 70 4.9 97 0.45 62.0 84.2

280 S/M* 1775 350 3.40 0.86 92.0 800 75 102 124 3.5 136 1.31 68 93 113 3.8 124 2.97 53 72 88 4.9 96 0.485 80 108

280 S/M* 1780 410 3.60 0.87 92.0 830 88 120 144 3.5 137 1.53 81 110 133 3.8 125 3.54 62.5 85 102 4.9 97 0.52 95 129

315S/M* 1780 435 3.80 0.88 93.0 1000 126 172 202 3.5 181 1.93 115 157 184 3.9 165 4.44 90 122 144 5.0 129 0.67 137 186

315S/M* 1780 525 4.00 0.89 93.5 1050 136 185 214 3.8 162 2.10 125 170 197 4.1 149 4.84 96 130 151 5.4 114 0.72 147 199

355M/L* 1785 430 9.00 0.89 93.0 1500 150 204 238 3.7 220 3.67 136 185 216 4.0 200 8.40 106 145 168 5.2 156 1.30 160 217

355M/L* 1785 430 10.50 0.89 93.5 1700 170 230 268 3.7 248 4.10 155 210 244 4.0 227 9.50 120 165 189 5.2 178 1.40 184 250

355M/L* 1785 515 11.50 0.89 94.0 1800 202 275 317 4.1 246 4.80 187 255 293 4.5 228 11.0 143 195 224 5.8 174 1.70 220 298

355M/L* 1785 570 12.50 0.89 94.0 1900 240 325 376 3.8 262 5.67 217 295 340 4.2 238 13.0 170 230 267 5.3 185 2.00 258 350

400M/L* 1785 500 15.00 0.90 94.5 2500 302 410 466 3.0 366 10 273 370 421 3.3 330 22 214 290 330 4.2 259 4.0 325 441

400M/L* 1785 600 18.00 0.90 95.0 2800 363 493 557 3.0 366 12 328 445 503 3.3 330 27 257 350 394 4.2 259 5.0 390 529

450 A/B* 1785 600 25.00 0.91 94.0 3800 437 594 670 2.8 440 17 395 537 606 3.0 400 38 309 420 474 3.9 312 6.8 470 638

450 A/B* 1785 600 30.00 0.91 94.5 4100 511 694 780 2.8 516 20 462 628 705 3.0 466 45 362 492 552 3.9 365 8.0 550 747

For Continuous Duty S1 - use the characteristics of the column 6 start/h ED 100%.

Note: The above indicated Power Factor and efficiency can only be considered as correct for duties equivalent to continuous duty, that is duty S3 6 start/h - ED 100%

and S4 or S5 150 start/h ED 60%.

For others duties to consider as estimated.

This sheet is part of catalog n 269 Revision: 01/10/01

7

Three-phase Slip Ring - Line F

6 POLE - 60Hz

SERVICE DUTY S3 6 START/h

Inertia Power Effici- Approx. ED = 25% ED = 40% ED = 60 % ED = 100%

ABNT Rotor Inertia Inertia Inertia

RPM Moment Factor ency Weight Stator Stator Stator Stator Inertia

Frame Voltage Tb/ Rotor Moment Tb/ Rotor Moment kW HP Tb/ Rotor Moment Tb/ Rotor

(kgm2) Cos (%) (kg) kW HP Amps kW HP Amps amps kW HP amps Moment

Tn amps Trac. Tn amps Trac. Tn amps Trac. Tn amps

at 440V at 440V at 440V at 440V Trac. (kgm2)

(kgm2) (kgm2) (kgm2)

132 M 1145 105 0.06 0.65 80.0 85 4.4 6 11.1 1.9 28 9.30 4 5.5 10.1 2.0 26 14.9 3.3 4.5 9.3 2.5 21 22.4 3.0 4.1 7.6 2.8 19 37.5

132 M 1145 155 0.08 0.68 81.0 100 6.6 9 15.7 1.9 28 11.5 5.9 8 14.1 2.1 25 18.5 5.2 7 13.1 2.4 22 27.9 4.5 6.1 10.7 2.8 19 46.6

160 L 1150 230 0.16 0.70 83.0 140 9.5 13 21.5 1.9 27 17.1 8.5 11.5 19.2 2.2 24 27.5 7.4 10 19.2 2.5 21 41.3 6.7 9.1 15.1 2.8 19 69

160 L 1160 280 0.17 0.77 83.0 150 12.5 17 25.7 1.8 29 22.5 10.7 14.5 22.0 2.1 25 36 9.2 12.5 21.1 2.5 22 54 8.0 10.9 16.5 2.8 18 90

180 L 1170 260 0.40 0.83 86.0 200 18.4 25 33.8 1.8 47 35 16.2 22 29.8 2.2 41 57 14.4 19.5 29.8 2.4 36.5 86 12.5 17.0 23.0 2.8 31 144

200 L 1170 290 0.60 0.82 87.0 300 26.7 35 49 1.8 58 49 22.8 31 43 2.1 51 79 20 27 41 2.4 45 119 17.0 23.1 31.2 2.8 36.5 199

225 S/M 1175 260 1.17 0.85 89.0 370 30 41 52 1.8 74 67 26.5 36 46 2.1 65 109 23.5 32 43 2.4 58 164 20.0 27.2 34.7 2.8 48 274

225 S/M 1175 330 1.50 0.86 89.0 400 39 53 67 1.8 76 77 34 46 58 2.1 66 124 29.4 40 54 2.4 58 186 25.0 34.0 42.9 2.8 47 312

250 S/M 1180 150 1.70 0.82 89.0 500 46 62 83 2.1 195 92 40 55 72 2.3 173 148 34.6 47 67 2.7 148 223 30.0 40.8 53.9 3.2 124 374

250 S/M 1180 210 1.90 0.84 90.0 530 62 84 108 2.1 188 115 54 73 94 2.4 163 185 46.4 63 89 2.8 141 278 40.0 54.3 69.4 3.2 118 466

280 S/M* 1180 220 3.80 0.81 91.0 750 80 108 136 2.1 230 164 68 93 116 2.4 198 264 60 81 111 2.8 172 397 52.0 70.7 88.7 3.2 143 665

280 S/M* 1180 270 4.80 0.85 91.0 800 96 131 163 2.1 227 200 85 116 144 2.3 201 323 73 99 136 2.7 171 486 62.0 84.2 105 3.2 139 810

315 S/M* 1185 280 5.00 0.83 90.0 950 124 168 218 2.1 280 243 107 146 188 2.4 243 392 93 127 179 2.8 211 590 80 108 140 3.2 173 980

315S/M* 1185 355 5.70 0.84 91.0 1000 160 218 275 2.1 285 288 137 186 235 2.4 243 464 120 163 223 2.7 213 690 104 141 178 3.2 178 1170

355S/M* 1185 265 13.00 0.82 91.0 1650 204 277 359 2.1 490 420 177 240 311 2.5 424 675 158 215 299 2.8 380 1020 137 186 240 3.2 307 1700

355M/L* 1185 285 13.70 0.83 92.0 1700 220 300 378 2.1 490 465 191 260 328 2.4 425 750 169 230 316 2.7 376 1130 147 199 252 3.1 307 1890

355M/L* 1185 345 14.50 0.82 92.0 1750 242 330 421 1.9 442 480 210 285 365 2.2 382 775 188 255 351 2.4 342 1170 160 217 278 2.8 276 1960

355M/L* 1185 380 15.00 0.82 92.5 1800 276 375 477 1.8 457 540 239 325 413 2.1 396 870 213 290 394 2.3 354 1310 185 251 320 2.7 290 2200

355M/L* 1185 430 16.00 0.81 93.0 2000 331 450 577 1.9 485 620 267 390 465 2.2 420 1000 254 345 481 2.4 371 1500 220 298 383 2.8 304 2500

400M/L* 1185 510 31.00 0.82 93.5 2600 409 556 700 1.7 487 1000 355 480 608 2.0 422 1600 314 426 582 2.2 374 2400 272 369 465 2.6 317 4000

400M/L* 1185 600 35.00 0.83 94.0 3000 480 650 807 1.6 487 1200 417 566 701 1.9 422 1900 370 503 673 2.1 374 2900 320 434 538 2.5 317 4900

450 A/B* 1185 510 39.00 0.84 94.0 4000 587 797 975 1.6 699 2000 508 690 844 1.9 605 3200 450 610 814 2.1 536 4800 390 529 648 2.5 455 8000

450 A/B* 1185 600 46.00 0.85 95.0 4300 690 937 1121 1.6 699 2300 600 815 975 1.9 605 3800 530 720 938 2.1 536 5700 460 625 747 2.5 456 9500

For Continuous Duty S1 - use the characteristics of the column 6 start/h ED 100%.

Note: The above indicated Power Factor and efficiency can only be considered as correct for duties equivalent to continuous duty, that is duty S3 6 start/h - ED 100%

and S4 or S5 150 start/h ED 60%.

For others duties to consider as estimated.

This sheet is part of catalog n 269 Revision: 01/10/01

8

Three-phase Slip Ring - Line F

6 POLE - 60Hz

SERVICE S4 OR S5 150 START/h Output equivalent to

ED = 25% ED = 40% ED = 60% continuous Duty S1

Inertia Power Effici- Approx.

ABNT Rotor Inertia

RPM Moment Factor ency Weight Stator Inertia Stator Inertia Stator

Frame Voltage Tb/ Rotor Tb/ Rotor Tb/ Rotor Moment

(kgm2) Cos (%) (kg) kW HP Amps Moment kW HP Amps Moment kW HP amps kW HP

Tn amps Tn amps Tn amps Trac.

at 440V Trac. (kgm2) at 440V Trac. (kgm2) at 440V

(kgm2)

132 M 1145 105 0.06 0.65 80.0 85 3.7 5 9.3 2.2 24 0.33 3.3 4.5 8.3 2.5 21 0.55 3 4 7.6 2.8 19 0.85 3.0 4.1

132 M 1145 155 0.08 0.68 81.0 100 5.5 7.5 13.1 2.2 24 0.39 5.2 7 12.4 2.4 22 0.67 4.5 6 10.7 2.8 19 1.04 4.5 6.1

160 L 1150 230 0.16 0.70 83.0 140 8.5 11.5 19.2 2.2 24 0.55 7.4 10 16.7 2.5 21 0.97 6.7 9 15.1 2.8 19 1.52 6.7 9.1

160 L 1160 280 0.17 0.77 83.0 150 10.3 14 21.1 2.2 24 0.74 9.2 12.5 18.9 2.5 22 1.28 8 11 16.4 2.8 19 2.01 8.0 10.9

180 L 1170 260 0.40 0.83 86.0 200 16.2 22 29.8 2.2 41 1.13 14.4 19.5 26.5 2.4 36.5 2.0 12.5 17 23.0 2.8 32 3.16 12.5 17.0

200 L 1170 290 0.60 0.80 86.0 300 21.3 29 41 2.2 48 1.50 19.1 26 36 2.5 43 2.70 17 23 32 2.8 38 4.30 17.0 23.1

225 S/M 1175 260 1.17 0.85 89.0 370 25 34 43 2.2 62 1.85 22.8 31 40 2.4 56 3.50 20 27 35 2.8 49 5.70 20.0 27.2

225 S/M 1175 330 1.50 0.86 89.0 400 31.6 43 54 2.2 62 2.18 28.7 39 49 2.4 56 4.06 25 34 43 2.8 49 6.55 25.0 34.0

250 S/M 1180 150 1.70 0.82 89.0 500 37 50 67 2.6 158 2.50 32 44 58 2.9 139 4.75 30 40 54 3.2 126 7.75 30.0 40.8

250 S/M 1180 210 1.90 0.84 90.0 530 51 69 89 2.6 154 3.12 45 61 78 2.9 136 5.91 40 55 69 3.2 123 9.65 40.0 54.3

280 S/M 1180 220 4.60 0.85 90.5 750 65 88 111 2.5 187 3.97 57 78 97 2.9 166 7.97 52 70 89 3.2 149 13.3 52.0 70.7

280 S/M 1180 270 4.80 0.85 91.0 800 80 108 136 2.5 187 4.67 70 96 119 2.8 166 9.57 62 85 105 3.2 147 16.1 62.0 84.2

315S/M 1185 280 5.00 0.83 90.0 950 102 139 179 2.5 231 5.42 91 123 160 2.9 205 11.4 80 110 141 3.2 183 19.3 80 108

315S/M 1185 355 5.70 0.84 91.0 1000 130 176 223 2.5 230 6.25 114 155 196 2.9 203 13.3 104 140 179 3.2 183 22.7 104 141

355M/L* 1185 265 13.00 0.82 91.0 1650 170 230 299 2.6 406 8.67 150 205 264 2.9 363 19.0 137 185 241 3.2 327 32.7 137 186

355M/L* 1785 285 13.70 0.83 92.0 1700 184 250 316 2.5 409 9.50 162 220 278 2.8 360 20.9 147 200 253 3.1 327 36.1 147 199

355M/L* 1785 345 14.50 0.82 92.0 1750 202 275 351 2.2 369 9.87 180 245 313 2.5 329 21.7 160 220 278 2.8 295 37.4 160 217

355M/L* 1785 380 15.00 0.82 92.5 1800 228 310 394 2.2 378 11.2 206 280 356 2.4 342 24.5 185 250 320 2.7 305 42.2 185 251

355M/L* 1785 430 16.00 0.81 93.0 2000 276 375 481 2.2 404 12.8 247 335 430 2.5 361 28.0 220 300 383 2.8 323 48.3 220 298

400M/L* 1785 510 31.00 0.82 93.5 2600 340 462 582 2.1 405 22 305 414 522 2.3 363 45 272 370 466 2.6 324 80 272 369

400M/L* 1785 600 35.00 0.83 94.0 3000 400 544 673 2.0 405 27 360 489 605 2.2 363 55 320 435 538 2.5 324 95 320 434

450 A/B* 1785 510 39.00 0.84 94.0 4000 490 666 814 2.0 583 42 438 595 728 2.2 520 90 390 530 648 2.5 464 155 390 529

450 A/B* 1785 600 46.00 0.85 95.0 4300 577 784 938 2.0 583 50 516 700 838 2.2 520 106 460 625 747 2.5 464 185 460 625

For Continuous Duty S1 - use the characteristics of the column 6 start/h ED 100%.

Note: The above indicated Power Factor and efficiency can only be considered as correct for duties equivalent to continuous duty, that is duty S3 6 start/h - ED 100%

and S4 or S5 150 start/h ED 60%.

For others duties to consider as estimated.

This sheet is part of catalog n 269 Revision: 01/10/01

9

Three-phase Slip Ring - Line F

6 POLE - 60Hz

SERVICE DUTY S4 OR S5 300 START/h SERVICE DUTY S4 OR S5 600 START/h Output equivalent to

Inertia Power Effici- Approx. ED = 40% ED = 60% ED = 60% continuous Duty S1

ABNT Rotor

RPM Moment Factor ency Weight Stator Inertia Stator Inertia Stator Inertia

Frame Voltage Tb/ Rotor Tb/ Rotor Tb/ Rotor

(kgm2) Cos (%) (kg) kW HP Amps Moment kW HP Amps Moment kW HP amps Moment kW HP

Tn amps Tn amps Tn amps

at 440V Trac. (kgm2) at 440V Trac. (kgm2) at 440V Trac. (kgm2)

132 M 1145 105 0.06 0.65 80.0 85 2.6 3.5 6.6 3.2 17 0.25 2.6 3.5 6.6 3.2 17 0.40 2.2 3 5.6 3.7 14 0.175 3.0 4.1

132 M 1145 155 0.08 0.68 81.0 100 4 5.5 9.5 3.1 17 0.29 3.7 5 8.8 3.4 16 0.48 3.3 4.5 7.9 3.7 14 0.20 4.5 6.1

160 L 1150 230 0.16 0.70 83.0 140 6.6 9 14.9 2.8 19 0.41 5.9 8 13.3 3.2 17 0.69 4.8 6.5 10.8 3.9 14 0.275 6.7 9.1

160 L 1160 280 0.17 0.77 83.0 150 7.7 10.5 15.8 2.9 18 0.56 7 9.5 14.4 3.2 16 0.92 5.9 8 12.1 3.9 14 0.375 8.0 10.9

180 L 1170 260 0.40 0.83 86.0 200 11.8 16 21.7 3.0 30 0.84 10.7 14.5 19.7 3.3 27 1.42 8.5 11.5 15.6 4.1 21.5 0.55 12.5 17.0

200 L 1170 290 0.60 0.80 86.0 300 15.5 21 30 3.1 35 1.10 14.7 20 28 3.2 33 1.90 11.4 15.5 22 4.2 26 0.70 17.0 23.1

225 S/M 1175 260 1.17 0.85 89.0 370 19.1 26 33 2.9 47 1.30 17 23 29 3.3 42 2.40 13.2 18 23 4.2 33 0.75 20.0 27.2

225 S/M 1175 330 1.50 0.86 89.0 400 23.5 32 40 3.0 46 1.55 21.3 29 37 3.3 42 2.80 17 23 29 4.1 33 0.925 25.0 34.0

250 S/M 1180 150 1.70 0.82 89.0 500 28 38 50 3.4 120 1.75 25 34 45 3.8 107 3.25 20 27 36 4.7 85 1.00 30.0 40.8

250 S/M 1180 210 1.90 0.84 90.0 530 38 52 66 3.4 116 2.18 34.5 47 60 3.7 105 4.05 27 37 47 4.8 83 1.25 40.0 54.3

280 S/M* 1180 220 4.60 0.85 90.5 750 49 67 84 3.3 143 2.63 43 59 73 3.8 126 5.30 34 46 58 4.9 98 1.30 52.0 70.7

280 S/M* 1180 270 4.80 0.85 91.0 800 59 80 100 3.4 138 3.03 53 72 90 3.8 125 6.30 42 57 71 4.8 99 1.40 62.0 84.2

315S/M* 1185 280 5.00 0.83 90.0 950 77 105 135 3.4 175 3.43 69 94 121 3.7 156 7.40 54 73 95 4.8 121 1.45 80 108

315S/M 1185 355 5.70 0.84 91.0 1000 97 132 167 3.4 173 3.90 88 120 151 3.7 157 8.60 68 93 117 4.8 122 1.55 104 141

355M/L 1185 265 13.00 0.82 91.0 1650 127 172 223 3.4 304 5.23 115 157 202 3.8 277 21.1 90 122 158 4.9 216 1.80 137 186

355M/L 1185 285 13.70 0.83 92.0 1700 136 185 234 3.4 302 5.70 125 170 215 3.6 278 13.3 97 132 167 4.7 216 1.90 147 199

355M/L 1185 345 14.50 0.82 92.0 1750 150 205 261 3.0 275 5.93 138 187 240 3.3 251 13.8 107 145 186 4.2 194 2.0 160 217

355M/L 1185 380 15.00 0.82 92.5 1800 170 232 294 2.9 283 6.73 156 212 270 3.2 259 15.6 121 165 209 4.1 201 2.30 185 251

355M/L 1185 430 16.00 0.81 93.0 2000 206 280 359 3.0 301 7.77 188 255 327 3.3 275 17.9 145 198 253 4.2 213 2.70 220 298

400M/L 1185 510 31.00 0.82 93.5 2600 255 346 436 2.8 303 14 232 315 397 3.0 276 31 179 243 306 3.9 213 6.0 272 369

400M/L* 1185 600 35.00 0.83 94.0 3000 300 408 505 2.7 303 17 273 370 459 2.9 276 37 210 285 353 3.8 213 7.0 320 434

450 A/B* 1185 510 39.00 0.84 94.0 4000 365 496 607 2.7 434 26 333 452 553 2.9 396 59 257 349 427 3.8 306 10 390 529

450 A/B* 1185 600 46.00 0.85 95.0 4300 430 584 699 2.7 434 31 393 534 639 2.9 396 70 303 411 492 3.9 306 12 460 625

For Continuous Duty S1 - use the characteristics of the column 6 start/h ED 100%.

Note: The above indicated Power Factor and efficiency can only be considered as correct for duties equivalent to continuous duty, that is duty S3 6 start/h - ED 100%

and S4 or S5 150 start/h ED 60%.

For others duties to consider as estimated.

This sheet is part of catalog n 269 Revision: 01/10/01

10

Three-phase Slip Ring - Line F

8 POLE - 60Hz

SERVICE DUTY S3 6 START/h

Inertia Power Effici- Approx. ED = 25% ED = 40% ED = 60 % ED = 100%

ABNT Rotor Inertia

RPM Moment Factor ency Weight Stator Inertia Stator Inertia Stator Inertia Stator

Frame Voltage Tb/ Rotor Tb/ Rotor Tb/ Rotor Tb/ Rotor Moment

(kgm2) Cos (%) (kg) kW HP Amps Moment kW HP Amps Moment kW HP amps Moment kW HP amps

Tn amps Tn amps Trac. (kgm2) Tn amps Trac. (kgm2) Tn amps Trac.

at 440V Trac. (kgm2) at 440V at 440V at 440V

(kgm2)

132 M* 845 125 0.09 0.60 80.0 100 4.4 6 12.0 1.3 25 12.5 3.8 5.2 10.4 1.5 22 20 3.3 4.5 9.0 1.8 19 30 3.0 4.1 8.2 2.0 16 50

160 L* 845 120 0.10 0.59 80.0 140 6.6 9 18.3 1.5 38 20 5.9 8 16.4 1.7 33 32 5.1 7 14.2 1.9 29 49 4.5 6.1 12.5 2.2 24 82

160 L* 845 150 0.13 0.62 81.0 150 8.8 12 23.0 1.5 40 27 7.7 10.5 20.1 1.7 35 44 6.6 9 17.2 2.0 30 65 6.0 8.2 15.8 2.2 26 110

180 L 845 225 0.30 0.71 80.0 200 12.5 17 28.9 1.8 37 44 10.7 14.5 24.7 2.1 32 71 9.2 12.5 21.3 2.5 27 106 8.0 10.9 18.5 2.8 23 178

200 L 870 265 0.55 0.71 86.0 300 18.4 25 39.5 1.9 43 72 16.2 22 34.8 2.2 38 116 14 19 30.1 2.5 32 174 12.5 17.0 26.9 2.8 29 290

225 S/M 870 250 1.10 0.77 87.0 370 26 35 50.9 1.8 67 101 22 30 43.1 2.1 57 162 19 26 37.2 2.5 50 244 17.0 23.1 33.3 2.8 42 408

225 S/M 870 290 1.35 0.78 88.0 400 30 41 57 1.8 67 128 26.5 36 51 2.1 59 205 23.5 32 45 2.4 52 308 20.0 27.2 38.2 2.8 43 515

250 S/M 875 180 1.70 0.73 88.0 500 38 52 78 2.1 138 154 34 46 69 2.4 122 248 29.4 40 60 2.7 106 373 25.0 34.0 51.1 3.2 86 620

250 S/M 880 210 2.00 0.74 89.0 530 46 62 92 2.1 140 173 40 54 80 2.4 122 278 34.6 47 69 2.7 106 418 30.0 40.8 59.8 3.2 88 690

280 S/M 880 215 3.80 0.70 90.0 750 62 85 129 2.1 185 253 54 74 112 2.4 161 407 48 65 100 2.7 142 610 40.0 54.3 83.3 3.2 113 1020

280 S/M 885 275 4.80 0.72 91.0 800 80 109 160 2.1 187 320 69 94 138 2.4 161 510 60 82 120 2.7 141 770 52.0 70.7 104 3.2 115 1290

315 S/M 890 300 6.30 0.66 91.5 960 97 132 211 2.1 205 380 83 113 180 2.4 175 610 73 99 159 2.7 154 920 62.0 84.2 134 3.2 125 1540

315 S/M 890 390 6.80 0.68 92.0 1100 124 168 260 2.1 200 470 107 146 224 2.4 174 760 95 129 199 2.7 154 1140 80 108 167 3.2 124 1910

355 M/L 890 405 13.00 0.72 92.0 1550 157 213 311 2.1 246 670 135 184 267 2.4 213 1090 119 162 236 2.8 187 1640 104 141 206 3.2 153 2740

355 M/L 890 535 17.00 0.75 92.0 1700 210 285 399 2.1 250 820 181 246 344 2.4 215 1320 158 215 300 2.8 188 1990 137 186 260 3.2 152 3300

355 M/L 890 550 20.00 0.76 93.0 1900 243 330 451 1.7 281 980 213 290 395 2.0 248 1580 188 255 349 2.2 218 2380 160 217 297 2.6 173 3900

400 M/L* 890 460 24.00 0.76 93.0 2900 290 394 538 1.7 373 1150 253 344 470 1.9 325 1800 223 303 414 2.2 287 2800 190 258 352 2.6 246 4500

400 M/L* 890 540 26.00 0.77 93.5 3100 335 455 611 1.7 367 1350 293 398 534 1.9 321 2300 260 353 474 2.2 285 3500 220 298 400 2.6 242 5500

450 A/B* 890 525 53.00 0.77 94.0 4100 450 611 816 1.6 507 2600 393 534 712 1.8 443 4000 347 471 629 2.1 391 6000 295 400 534 2.5 334 10500

450 A/B 890 600 65.00 0.77 95.0 4500 546 742 979 1.6 538 3000 480 652 861 1.8 473 5000 423 575 759 2.1 417 7500 360 489 645 2.5 357 13000

For Continuous Duty S1 - use the characteristics of the column 6 start/h ED 100%.

Note: The above indicated Power Factor and efficiency can only be considered as correct for duties equivalent to continuous duty, that is duty S3 6 start/h - ED 100%

and S4 or S5 150 start/h ED 60%.

For others duties to consider as estimated.

This sheet is part of catalog n 269 Revision: 01/10/01

11

Three-phase Slip Ring - Line F

8 POLE - 60Hz

SERVICE DUTY S4 OR S5 150 START/h Output equivalent to

Inertia Power Effici- Approx. ED = 25% ED = 40% ED = 60% continuous Duty S1

ABNT Rotor

RPM Moment Factor ency Weight Stator Inertia Stator Inertia Stator Inertia

Frame Voltage Tb/ Rotor Tb/ Rotor Tb/ Rotor

(kgm2) Cos (%) (kg) kW HP Amps Moment kW HP Amps Moment kW HP amps Moment kW HP

Tn amps Tn amps Tn amps

at 440V Trac. (kgm2) at 440V Trac. (kgm2) at 440V Trac. (kgm2)

132 M* 845 125 0.09 0.60 80.0 100 3.7 5 10.1 1.6 21 0.45 3.3 4.5 9 1.8 19 0.75 3 4 8.2 2.0 17 1.16 3.0 4.1

160 L* 845 120 0.10 0.59 80.0 140 5.5 7.5 15.3 1.8 31 0.73 5 6.7 14 2.0 28 1.20 4.5 6 12.5 2.2 25 1.88 4.5 6.1

160 L* 845 150 0.13 0.62 81.0 150 7.4 10 19.3 1.8 34 0.95 6.6 9 17 2.0 30 1.65 6 8 15.7 2.2 27 2.50 6.0 8.2

180 L 845 225 0.30 0.71 80.0 200 10.3 14 24 2.2 31 1.46 9.2 12.5 21.3 2.5 27 2.53 8 11 18.5 2.8 24 3.96 8.0 10.9

200 L 870 265 0.55 0.71 86.0 300 15.5 21 33 2.3 36 2.42 13.6 18.5 29.2 2.6 32 4.17 12.5 17 26.9 2.8 29 6.50 12.5 17.0

225 S/M 870 250 1.10 0.77 87.0 370 20.6 28 40 2.3 54 3.13 18.4 25 36 2.6 48 5.58 17 23 33.3 2.8 44 8.85 17.0 23.1

225 S/M 870 290 1.35 0.78 88.0 400 25 34 48 2.2 55 3.95 21.3 29 41 2.6 47 7.16 20 27 38 2.8 44 11.3 20.0 27.2

250 S/M 875 180 1.70 0.73 88.0 500 31.6 43 65 2.5 114 4.75 27.2 37 56 2.9 98 8.50 25 34 51 3.2 90 13.5 25.0 34.0

250 S/M 880 210 2.00 0.74 89.0 530 36.8 50 73 2.6 113 5.30 32.4 44 65 2.9 99 9.50 30 40 60 3.2 90 15.1 30.0 40.8

280 S/M 880 215 3.80 0.70 90.0 750 51 69 106 2.6 151 7.35 45 61 94 2.9 133 13.5 40 55 83 3.2 120 21.7 40.0 54.3

280 S/M 885 275 4.80 0.72 91.0 800 65. 89 130 2.5 153 9.41 57 77 114 2.9 132 17.1 52 70 104 3.2 120 27.5 52.0 70.7

315 S/M 890 300 6.30 0.66 91.5 960 78 106 169 2.6 165 10.7 68 93 148 2.9 144 20.0 62 85 135 3.2 132 32.4 62.0 84.2

315 S/M 890 390 6.80 0.68 92.0 1100 102 139 214 2.5 166 13.1 89 121 187 2.9 144 24.6 80 110 168 3.2 131 40.0 80 108

355 M/L 890 405 13.00 0.72 92.0 1550 130 176 258 2.5 204 18.0 113 154 224 2.9 178 34.5 104 140 206 3.2 162 56.5 104 141

355 M/L 890 535 17.00 0.75 92.0 1700 170 231 323 2.6 202 22.1 149 203 283 2.9 178 42.1 137 185 261 3.2 162 68.9 137 186

355 M/L 890 550 20.00 0.76 93.0 1900 202 275 375 2.2 235 25.0 177 240 329 2.4 205 46.0 160 220 297 2.6 185 80.0 160 217

400 M/L* 890 460 24.00 0.76 93.0 2900 240 326 446 2.0 308 32 210 285 390 2.3 270 60 190 260 353 2.6 244 95 190 258

400 M/L* 890 540 26.00 0.77 93.5 3100 278 378 507 2.0 304 37 243 330 443 2.3 266 70 220 300 401 2.6 241 115 220 298

450 A/B* 890 525 53.00 0.77 94.0 4100 373 507 676 1.9 420 60 326 443 591 2.2 367 120 295 400 535 2.5 332 200 295 400

450 A/B 890 600 65.00 0.77 95.0 4500 455 618 816 1.9 449 70 398 540 714 2.2 392 150 360 490 646 2.5 355 260 360 489

For Continuous Duty S1 - use the characteristics of the column 6 start/h ED 100%.

Note: The above indicated Power Factor and efficiency can only be considered as correct for duties equivalent to continuous duty, that is duty S3 6 start/h - ED 100%

and S4 or S5 150 start/h ED 60%.

For others duties to consider as estimated.

This sheet is part of catalog n 269 Revision: 01/10/01

12

Three-phase Slip Ring - Line F

8 POLE - 60 Hz

SERVICE DUTY S4 OR S5 300 START/h SERVICE DUTY S4 OR S5 600 START/h Output equivalent to

Inertia Power Effici- Approx. ED = 40% ED = 60% ED = 60% continuous Duty S1

ABNT Rotor

RPM Moment Factor ency Weight Stator Inertia Stator Inertia Stator Inertia

Frame Voltage Tb/ Rotor Tb/ Rotor Tb/ Rotor

(kgm2) Cos (%) (kg) kW HP Amps Moment kW HP Amps Moment kW HP amps Moment kW HP

Tn amps Tn amps Tn amps

at 440V Trac. (kgm2) at 440V Trac. (kgm2) at 440V Trac. (kgm2)

132 M* 845 125 0.09 0.60 80.0 100 2.7 3.7 7.4 2.2 15.7 0.35 2.5 3.4 6.8 2.4 14.4 0.55 1.9 2.6 5.2 3.1 11 0.25 3.0 4.1

160 L* 845 120 0.10 0.59 80.0 140 4 5.5 11.1 2.4 23 0.56 3.8 5.1 10.6 2.6 21 0.89 3 4 8.3 3.3 17 0.40 4.5 6.1

160 L* 845 150 0.13 0.62 81.0 150 5.5 7.5 14.4 2.3 25 0.75 5.2 7 13.6 2.5 24 1.20 3.9 5.3 10.2 3.3 18 0.55 6.0 8.2

180 L 845 225 0.30 0.71 80.0 200 7.4 10 17.1 3.1 22 1.11 7 9.5 16.2 3.2 21 1.82 5.2 7 12 4.4 15.3 0.75 8.0 10.9

200 L 870 265 0.55 0.71 86.0 300 11.8 16 25.4 3.0 27 1.83 10.7 14.5 23 3.3 25 3.0 8.5 11.5 18.3 4.1 20 1.25 12.5 17.0

225 S/M 870 250 1.10 0.77 87.0 370 16 22 31.3 2.9 42 2.31 14.7 20 28.8 3.2 38 3.95 11 15 21.5 4.3 29 1.50 17.0 23.1

225 S/M 870 290 1.35 0.78 88.0 400 19 26 36. 2.9 42 3.03 17 23 32 3.3 37 5.10 13.2 18 25 4.2 29 2.0 20.0 27.2

250 S/M 875 180 1.70 0.73 88.0 500 23.6 32 48 3.4 85 3.50 21.3 29 44 3.8 77 6.0 17 23 35 4.7 61 2.25 25.0 34.0

250 S/M 880 210 2.00 0.74 89.0 530 28 38 56 3.4 86 3.90 25.8 35 51 3.7 79 6.70 19.1 26 38 4.9 59 2.50 30.0 40.8

280 S/M 880 215 3.80 0.70 90.0 750 38 52 79 3.4 113 5.30 34.5 47 72 3.7 103 9.40 27 37 56 4.8 81 3.25 40.0 54.3

280 S/M 885 275 4.80 0.72 91.0 800 49 67 98 3.3 115 6.83 45 61 90 3.7 105 12.0 34.5 47 69 4.8 81 4.25 52.0 70.7

315 S/M 890 300 6.30 0.66 91.5 960 59 80 128 3.4 124 7.60 54 73 117 3.7 113 13.8 41 56 89 4.9 87 4.50 62.0 84.2

315 S/M 890 390 6.80 0.68 92.0 1100 77 105 162 3.4 125 9.33 70 90 147 3.7 113 17.0 54 73 113 4.8 87 5.50 80 108

355 M/L 890 405 13.00 0.72 92.0 1550 97 132 192 3.4 153 12.5 88 120 174 3.7 139 23.5 70 95 139 4.7 110 7.0 104 141

355 M/L 890 535 17.00 0.75 92.0 1700 130 177 247 3.3 155 15.4 118 161 224 3.7 141 28.8 90 123 171 4.8 108 8.75 137 186

355 M/L 890 550 20.00 0.76 93.0 1900 150 205 278 2.8 175 17.0 138 187 256 3.1 160 30 107 145 199 3.9 123 10.0 160 217

400 M/L* 890 460 24.00 0.76 93.0 2900 178 242 330 2.7 229 22 164 223 304 3.0 211 40 127 172 236 3.8 163 12 190 258

400 M/L* 890 540 26.00 0.77 93.5 3100 206 280 375 2.7 226 24 190 258 346 3.0 208 50 147 200 268 3.8 161 13 220 298

450 A/B* 890 525 53.00 0.77 94.0 4100 276 375 500 2.6 311 36 255 346 462 2.9 287 80 197 268 357 3.7 222 15 295 400

450 A/B 890 600 65.00 0.77 95.0 4500 337 358 605 2.6 332 44 310 421 556 2.9 306 100 241 327 432 3.7 238 18 360 489

For Continuous Duty S1 - use the characteristics of the column 6 start/h ED 100%.

Note: The above indicated Power Factor and efficiency can only be considered as correct for duties equivalent to continuous duty, that is duty S3 6 start/h - ED 100%

and S4 or S5 150 start/h ED 60%.

For others duties to consider as estimated.

This sheet is part of catalog n 269 Revision: 01/10/01

13

Three-phase Slip Ring - Line F

10 POLE - 60Hz

SERVICE DUTY S3 6 START/h

Inertia Power Effici- Approx. ED = 25% ED = 40% ED = 60 % ED = 100%

ABNT Rotor Inertia Inertia Inertia Inertia

RPM Moment Factor ency Weight Stator Stator Stator Stator

Frame Voltage Tb/ Rotor Moment Tb/ Rotor Moment Tb/ Rotor Moment kW HP Tb/ Rotor Moment

(kgm2) Cos (%) (kg) kW HP Amps kW HP Amps kW HP amps amps

Tn amps Trac. Tn amps Trac. Tn amps Trac. Tn amps Trac.

at 440V at 440V at 440V at 440V

(kgm2) (kgm2) (kgm2) (kgm2)

160L* 685 160 0.18 0.52 75.0 140 6.6 9 22 1.5 28.5 30 5.9 8 20 1.7 25 48 5.2 7 17 1.9 22 72 4.5 6.1 15.1 2.2 18 120

180L* 685 210 0.35 0.60 79.0 200 8.8 12 24 1.5 28.5 49 7.4 10 20 1.8 24 79 6.6 9 18 2.0 21 119 6.0 8.2 16.7 2.2 18 200

200L* 690 210 0.65 0.61 84.0 300 14.7 20 38 1.4 46 70 12.5 17 32 1.7 39 112 11 15 28 1.9 35 189 9.5 12.9 24.3 2.2 28 280

225 S/M* 690 270 1.60 0.57 81.0 450 18.4 25 52 1.5 44 117 16.2 22 46 1.7 39 189 14.7 20 42 1.9 35 280 12.5 17.0 35.6 2.2 29 470

225 S/M* 690 315 1.80 0.60 84.0 500 22 30 57 1.5 45 138 19 26 49 1.7 39 220 17 23 44 1.9 35 330 14.7 20.0 38.3 2.2 29 550

250 S/M 695 150 2.00 0.65 84.0 550 31 42 74 1.8 132 169 28 38 67 2.0 120 270 23.5 32 56 2.4 101 400 20.0 27.2 48.1 2.8 82 670

250 S/M 695 190 2.50 0.69 85.0 620 40 54 89 1.8 135 198 35 47 78 2.0 118 315 30 41 67 2.3 102 470 25.0 34.0 55.9 2.8 81 790

280 S/M 700 165 3.90 0.62 89.0 750 48 62 109 1.8 177 280 40 55 95 2.0 157 450 35 47 83 2.4 134 680 30.0 40.8 71.3 2.8 110 1140

280 S/M 705 225 4.80 0.64 90.0 850 63 86 144 1.8 180 360 55 75 125 2.1 157 580 49 66 112 2.3 138 870 40.0 54.3 91.1 2.8 108 1450

315 S/M 705 270 5.50 0.62 88.0 1000 82 111 197 1.8 192 450 70 95 168 2.1 164 720 61 83 147 2.4 143 1090 52.0 70.7 125 2.8 117 1830

315 S/M 705 325 6.30 0.63 90.0 1100 99 134 229 1.8 192 540 85 116 197 2.1 166 870 74 100 171 2.4 144 1300 62.0 84.2 143 2.8 116 2200

355 M/L 710 325 16.50 0.65 91.0 1700 127 173 282 1.8 247 770 111 151 246 2.0 216 1240 95 130 211 2.4 186 1860 80 108 177 2.8 146 3100

355 M/L 710 415 18.00 0.66 92.0 2000 162 220 350 1.8 246 960 140 190 303 2.1 212 1540 120 164 259 2.4 183 2300 104 141 224 2.8 149 3850

400 M/L 710 430 29.00 0.58 92.5 2700 212 289 519 1.8 312 1220 189 257 462 2.0 278 1950 160 217 391 2.4 235 2900 137 186 335 2.8 189 4900

400 M/L 710 510 33.0 0.60 93.0 2900 256 349 602 1.8 317 1490 223 303 524 2.0 275 2400 190 258 447 2.4 235 3600 160 217 376 2.8 187 6000

450 A/B* 710 335 68.00 0.65 93.0 4000 336 457 729 1.8 608 2800 392 398 851 2.0 528 4500 250 340 543 2.4 452 6500 210 285 455 2.8 373 11000

450 A/B* 710 420 80.00 0.73 93.5 4500 424 576 815 1.8 611 3400 369 502 709 2.0 532 5600 315 428 606 2.4 455 8000 265 360 509 2.8 375 14000

For Continuous Duty S1 - use the characteristics of the column 6 start/h ED 100%.

Note: The above indicated Power Factor and efficiency can only be considered as correct for duties equivalent to continuous duty, that is duty S3 6 start/h - ED 100%

and S4 or S5 150 start/h ED 60%.

For others duties to consider as estimated.

This sheet is part of catalog n 269 Revision: 01/10/01

14

Three-phase Slip Ring - Line F

10 POLE - 60Hz

SERVICE DUTY S4 OR S5 150 START/h Output equivalent to

Inertia Power Effici- Approx. ED = 25% ED = 40% ED = 60% continuous Duty S1

ABNT Rotor

RPM Moment Factor ency Weight Stator Inertia Stator Inertia Stator Inertia

Frame Voltage Tb/ Rotor Tb/ Rotor Tb/ Rotor

(kgm2) Cos (%) (kg) kW HP Amps Moment kW HP Amps Moment kW HP amps Moment kW HP

Tn amps Tn amps Tn amps

at 440V Trac. (kgm2) at 440V Trac.(kgm2) at 440V Trac. (kgm2)

160L* 685 160 0.18 0.52 75.0 140 5.5 7.5 18.5 1.8 24 1.08 4.9 6.7 16.5 2.0 21 1.82 4.5 6 15.1 2.2 19 2.79 4.5 6.1

180L* 685 210 0.35 0.60 79.0 200 7.4 10 20 1.8 24 1.70 6.6 9 18.3 2.0 21 2.90 6 8 16.6 2.2 19 4.50 6.0 8.2

200L* 690 210 0.65 0.61 84.0 300 12 16 31 1.8 37 2.43 10.7 14.5 27.4 2.0 33 4.13 9.5 13 24.3 2.2 30 6.40 9.5 12.9

225 S/M* 690 270 1.60 0.57 81.0 450 15.5 21 44 1.8 37 3.85 14 19 39.8 2.0 34 6.70 12.5 17 35.5 2.2 30 10.5 12.5 17.0

225 S/M* 690 315 1.80 0.60 84.0 500 18.4 25 48 1.8 38 4.48 16.2 22 42.2 2.0 33 7.83 14.7 20 38.3 2.2 30 12.3 14.7 20.0

250 S/M 695 150 2.00 0.65 84.0 550 25 34 60 2.2 107 5.23 22 30 52.9 2.5 94 9.33 20 27 48.1 2.8 85 14.8 20.0 27.2

250 S/M 695 190 2.50 0.69 85.0 620 31 42 69 2.3 105 6.20 27 37 60.4 2.6 93 11.0 25 34 55.9 2.8 85 17.4 25.0 34.0

280S/M 700 165 3.90 0.62 89.0 750 37 50 88 2.2 143 8.60 32 44 76 2.5 125 15.5 30 40 71 2.8 114 24.7 30.0 40.8

280 S/M 705 225 4.80 0.64 90.0 850 52 71 118 2.2 148 11.0 46 63 105 2.4 132 19.8 40 55 91 2.8 115 31.5 40.0 54.3

315 S/M 705 270 5.50 0.62 88.0 1000 65 89 156 2.2 154 13.3 59 80 142 2.4 138 24.3 52 70 125 2.8 121 39.0 52.0 70.7

315 S/M 705 325 6.30 0.63 90.0 1100 80 108 185 2.2 155 16.0 70 96 162 2.5 138 29.3 62 85 143 2.8 122 47.0 62.0 84.2

355 M/L 710 325 16.50 0.65 91.0 1700 103 140 228 2.2 200 21.7 92 125 204 2.5 178 40.5 80 110 177 2.8 157 65.5 80 108

355 M/L 710 415 18.00 0.66 92.0 2000 131 178 283 2.2 198 27.5 118 160 255 2.4 178 50.0 104 140 225 2.8 156 80.0 104 141

400 M/L 710 430 29.00 0.58 92.5 2700 173 235 423 2.2 254 34.3 154 209 377 2.5 226 64.1 137 185 335 2.8 200 104 137 186

400 M/L 710 510 33.0 0.60 93.0 2900 206 280 484 2.2 255 41.7 184 250 433 2.5 227 78.0 160 220 376 2.8 200 126 160 217

450 A/B* 710 335 68.00 0.65 93.0 4000 270 367 586 2.2 438 65 241 328 523 2.5 436 134 210 286 456 2.8 380 220 210 285

450 A/B* 710 420 80.00 0.73 93.5 4500 341 464 656 2.2 492 75 305 415 586 2.5 440 163 265 360 509 2.8 382 270 265 360

For Continuous Duty S1 - use the characteristics of the column 6 start/h ED 100%.

Note: The above indicated Power Factor and efficiency can only be considered as correct for duties equivalent to continuous duty, that is duty S3 6 start/h - ED 100%

and S4 or S5 150 start/h ED 60%.

For others duties to consider as estimated.

This sheet is part of catalog n 269 Revision: 01/10/01

15

Three-phase Slip Ring - Line F

10 POLE - 60Hz

SERVICE DUTY S4 OR S5 300 START/h SERVICE DUTY S4 OR S5 600 START/h Output equivalent to

Inertia Power Effici- Approx. ED = 40% ED = 60% ED = 60% continuous Duty S1

ABNT Rotor

RPM Moment Factor ency Weight Stator Inertia Stator Inertia Stator Inertia

Frame Voltage Tb/ Rotor Tb/ Rotor Tb/ Rotor

(kgm2) Cos (%) (kg) kW HP Amps Moment kW HP Amps Moment kW HP amps Moment kW HP

Tn amps Tn amps Tn amps

at 440V Trac. (kgm2) at 440V Trac. (kgm2) at 440V Trac. (kgm2)

160L* 685 160 0.18 0.52 75.0 140 5.5 7.5 18.5 1.8 24 1.08 4.9 6.7 16.5 2.0 21 1.82 4.5 6 15.1 2.2 19 2.79 4.5 6.1

180L* 685 210 0.35 0.60 79.0 200 7.4 10 20 1.8 24 1.70 6.6 9 18.3 2.0 21 2.90 6 8 16.6 2.2 19 4.50 6.0 8.2

200L* 690 210 0.65 0.61 84.0 300 12 16 31 1.8 37 2.43 10.7 14.5 27.4 2.0 33 4.13 9.5 13 24.3 2.2 30 6.40 9.5 12.9

225 S/M* 690 270 1.60 0.57 81.0 450 15.5 21 44 1.8 37 3.85 14 19 39.8 2.0 34 6.70 12.5 17 35.5 2.2 30 10.5 12.5 17.0

225 S/M* 690 315 1.80 0.60 84.0 500 18.4 25 48 1.8 38 4.48 16.2 22 42.2 2.0 33 7.83 14.7 20 38.3 2.2 30 12.3 14.7 20.0

250 S/M 695 150 2.00 0.65 84.0 550 25 34 60 2.2 107 5.23 22 30 52.9 2.5 94 9.33 20 27 48.1 2.8 85 14.8 20.0 27.2

250 S/M 695 190 2.50 0.69 85.0 620 31 42 69 2.3 105 6.20 27 37 60.4 2.6 93 11.0 25 34 55.9 2.8 85 17.4 25.0 34.0

280S/M 700 165 3.90 0.62 89.0 750 37 50 88 2.2 143 8.60 32 44 76 2.5 125 15.5 30 40 71 2.8 114 24.7 30.0 40.8

280 S/M 705 225 4.80 0.64 90.0 850 52 71 118 2.2 148 11.0 46 63 105 2.4 132 19.8 40 55 91 2.8 115 31.5 40.0 54.3

315 S/M 705 270 5.50 0.62 88.0 1000 65 89 156 2.2 154 13.3 59 80 142 2.4 138 24.3 52 70 125 2.8 121 39.0 52.0 70.7

315 S/M 705 325 6.30 0.63 90.0 1100 80 108 185 2.2 155 16.0 70 96 162 2.5 138 29.3 62 85 143 2.8 122 47.0 62.0 84.2

355 M/L 710 325 16.50 0.65 91.0 1700 103 140 228 2.2 200 21.7 92 125 204 2.5 178 40.5 80 110 177 2.8 157 65.5 80 108

355 M/L 710 415 18.00 0.66 92.0 2000 131 178 283 2.2 198 27.5 118 160 255 2.4 178 50.0 104 140 225 2.8 156 80.0 104 141

400 M/L 710 430 29.00 0.58 92.5 2700 173 235 423 2.2 254 34.3 154 209 377 2.5 226 64.1 137 185 335 2.8 200 104 137 186

400 M/L 710 510 33.0 0.60 93.0 2900 206 280 484 2.2 255 41.7 184 250 433 2.5 227 78.0 160 220 376 2.8 200 126 160 217

450 A/B* 710 335 68.00 0.65 93.0 4000 270 367 586 2.2 438 65 241 328 523 2.5 436 134 210 286 456 2.8 380 220 210 285

450 A/B* 710 420 80.00 0.73 93.5 4500 341 464 656 2.2 492 75 305 415 586 2.5 440 163 265 360 509 2.8 382 270 265 360

For Continuous Duty S1 - use the characteristics of the column 6 start/h ED 100%.

Note: The above indicated Power Factor and efficiency can only be considered as correct for duties equivalent to continuous duty, that is duty S3 6 start/h - ED 100%

and S4 or S5 150 start/h ED 60%.

For others duties to consider as estimated.

This sheet is part of catalog n 269 Revision: 01/10/01

16

WEG INDSTRIAS S.A. - EXPORTADORA

Av. Pref. Waldemar Grubba, 3000 89256-900 Jaragu do Sul/SC

Phone: 55 (047) 372-4000 Fax: 55 (047) 372-4030

So Paulo/SP: Phone: 55 (011) 5053-2300 Fax: 55 (011) 5052-4202

http://www.weg.com.br

You might also like

- Final Exam Spring 2020Document7 pagesFinal Exam Spring 2020Irum SabaNo ratings yet

- Equipments For Oil and Gas Drilling RigsDocument4 pagesEquipments For Oil and Gas Drilling RigsAlexandru StănculescuNo ratings yet

- Boomer S 1D PDFDocument4 pagesBoomer S 1D PDFlorenzo henerNo ratings yet

- Perforadora-Boomer 282-Atlas Copco PDFDocument4 pagesPerforadora-Boomer 282-Atlas Copco PDFBraulio Araya100% (1)

- WEG Fire Pump Motor Usa375 Brochure EnglishDocument12 pagesWEG Fire Pump Motor Usa375 Brochure EnglishZet LaimeNo ratings yet

- WEG Motor - ODP-60HP 230-460VAC - Información TécnicaDocument6 pagesWEG Motor - ODP-60HP 230-460VAC - Información TécnicaFranklin Gustavo Zagaceta BautistaNo ratings yet

- NOLH NT ENG 50HzDocument54 pagesNOLH NT ENG 50Hzrudi 01No ratings yet

- Single-Stage Centrifugal Pumps To Standards EN 733 (NFE 44111) and ISO 5199Document54 pagesSingle-Stage Centrifugal Pumps To Standards EN 733 (NFE 44111) and ISO 5199leejoNo ratings yet

- Lehe1126 01Document2 pagesLehe1126 01Matías MocilnikarNo ratings yet

- Lehe1126 01Document2 pagesLehe1126 01Matías MocilnikarNo ratings yet

- CEMP Electric Motors Size 355Document6 pagesCEMP Electric Motors Size 355Сергій ТарасенкоNo ratings yet

- Catalogue MF SulzerDocument4 pagesCatalogue MF SulzerRaymond GanNo ratings yet

- Catalogo VHS Leroy SomerDocument2 pagesCatalogo VHS Leroy SomerThe_RainmakerNo ratings yet

- Liebherr - FMF MotorsDocument4 pagesLiebherr - FMF MotorsCarlos Andrés CuelloNo ratings yet

- Kub T120 - en PDFDocument6 pagesKub T120 - en PDFoelbergluisNo ratings yet

- Equipments For Oil and Gas Drilling Rigs PDFDocument4 pagesEquipments For Oil and Gas Drilling Rigs PDFAlexandru StanculescuNo ratings yet

- Technical Specifications - Atlas Copco Underground Jumbo Face Drilling Rig - Boomer S1 D PDFDocument4 pagesTechnical Specifications - Atlas Copco Underground Jumbo Face Drilling Rig - Boomer S1 D PDFsegomezp100% (1)

- WEG Medium Voltage Stock Motors Tefc Severe Duty Mvstockcatalog Brochure EnglishDocument16 pagesWEG Medium Voltage Stock Motors Tefc Severe Duty Mvstockcatalog Brochure EnglishMiguel ChavezNo ratings yet

- Submersible Pumps: For Dewatering, Sewage, Marine and Rental MarketsDocument20 pagesSubmersible Pumps: For Dewatering, Sewage, Marine and Rental MarketsDebora MaryantiNo ratings yet

- BOX BD 1010 M4 059kWDocument4 pagesBOX BD 1010 M4 059kWAiman AliNo ratings yet

- Timken Commercial Vehicle Wheel End Accessories Brochure 10933Document4 pagesTimken Commercial Vehicle Wheel End Accessories Brochure 10933tampa2008No ratings yet

- Catalogo de Calentadores Imc700Document52 pagesCatalogo de Calentadores Imc700PieroNo ratings yet

- BA DirectDocument17 pagesBA DirectRam RajyaNo ratings yet

- Big Red 600 Lincoln ElectricDocument6 pagesBig Red 600 Lincoln Electricamerica1591No ratings yet

- Easy Servomotor: HPB Technology Co., LTDDocument14 pagesEasy Servomotor: HPB Technology Co., LTDLIDER YOEL CASTILLO LABANNo ratings yet

- Motor Perforacion General ElectricDocument1 pageMotor Perforacion General ElectricJesus SanchezNo ratings yet

- Convectoare de Pardoseala Isan Practic - Carte TehnicaDocument25 pagesConvectoare de Pardoseala Isan Practic - Carte TehnicaDaniel MihaiNo ratings yet

- Hibon - SN Ingersoll Rand BlowerDocument7 pagesHibon - SN Ingersoll Rand BlowermarquezsiemNo ratings yet

- Bomba Goulds 3888 D3Document4 pagesBomba Goulds 3888 D3Juanpablo OXNo ratings yet

- Technical Specification Boomer 282Document4 pagesTechnical Specification Boomer 282Emrah MertyürekNo ratings yet

- LV Motor EQP Global IEC Brochure Rev 190301Document4 pagesLV Motor EQP Global IEC Brochure Rev 190301Victor LinaresNo ratings yet

- Vsa Eko - enDocument4 pagesVsa Eko - enEmanuel LucaNo ratings yet

- Hydraulic Oil Coolers Product CatalogueDocument24 pagesHydraulic Oil Coolers Product Cataloguethiagorep17No ratings yet

- ABS Submersible Mixer RW 200, 50HzDocument2 pagesABS Submersible Mixer RW 200, 50Hzalisya.blwsNo ratings yet

- Cable Chains in Bright Zinc Plated Steel: Inner Height (D) 32 MMDocument2 pagesCable Chains in Bright Zinc Plated Steel: Inner Height (D) 32 MMboba78No ratings yet

- Datasheet MFHDocument3 pagesDatasheet MFHwan haffizNo ratings yet

- Scania Engine Range BrochureDocument17 pagesScania Engine Range BrochureLiora Vanessa DopacioNo ratings yet

- Pole Sheets: Cold-Rolled Steel StripDocument2 pagesPole Sheets: Cold-Rolled Steel StripL Mahender ReddyNo ratings yet

- Circulator Pumps: Hot & Cold Water CirculatorsDocument4 pagesCirculator Pumps: Hot & Cold Water Circulatorstvshow zeeNo ratings yet

- ACFrOgBm3SfXP8Zq091EfTagnMbEVShjdleqDRPPVdEohcOqJ3Ail1mCJF3DHUexwomxidEXraSOjH xK3Qnb0ynKnNkJkdAYiWdgQWT7PdupqFtfHnaQzu4z7uoDgMDocument11 pagesACFrOgBm3SfXP8Zq091EfTagnMbEVShjdleqDRPPVdEohcOqJ3Ail1mCJF3DHUexwomxidEXraSOjH xK3Qnb0ynKnNkJkdAYiWdgQWT7PdupqFtfHnaQzu4z7uoDgMMERHAWIT NEGATUNo ratings yet

- Extruder Brochure - Old SeriesDocument4 pagesExtruder Brochure - Old SeriesAmirmasoudNo ratings yet

- MOVA CN BW EngDocument1 pageMOVA CN BW Engfopoku2k2No ratings yet

- BOOMERL1DDocument3 pagesBOOMERL1DOsscar HerreraNo ratings yet

- 200706-PD-Overview-for Distributor TrainingDocument96 pages200706-PD-Overview-for Distributor TrainingChester Dalitso MwanzaNo ratings yet

- DONGFENG 220-460 kVA: Technical SpecificationsDocument2 pagesDONGFENG 220-460 kVA: Technical SpecificationsHector Sepulveda OrellanaNo ratings yet

- WEG NemapremiumDocument11 pagesWEG NemapremiumGualaNo ratings yet

- CHT CVTDocument4 pagesCHT CVTMîrza MateiNo ratings yet

- Boomer M2 C SP - 9851 2578 01aDocument4 pagesBoomer M2 C SP - 9851 2578 01aPablo Luis Pérez PostigoNo ratings yet

- Generator EdcDocument77 pagesGenerator EdcAJAY KUMAR100% (2)

- Feed Beams Technical Specifications - Atlas Copco Underground Jumbo Face Drilling RigDocument5 pagesFeed Beams Technical Specifications - Atlas Copco Underground Jumbo Face Drilling RigZhang JieNo ratings yet

- HOTSTART IMC 800 Standard Product CatalogDocument52 pagesHOTSTART IMC 800 Standard Product CatalogRUBENNo ratings yet

- Gearless Machines For Elevators: Lift Range 2014Document8 pagesGearless Machines For Elevators: Lift Range 2014Khaled ZakariaNo ratings yet

- WEG Weg Tefc Odp Motors With Aegis Ring Inside Aegisinsidebrochure Brochure EnglishDocument20 pagesWEG Weg Tefc Odp Motors With Aegis Ring Inside Aegisinsidebrochure Brochure Englishpaulo da silva dutraNo ratings yet

- IMC-800-catalog HOTSTART PDFDocument52 pagesIMC-800-catalog HOTSTART PDFEfrain MarceloNo ratings yet

- Motor Mass Iveco Uni Sabana 01.402.01spen.03 - Specification - Sheet - If07 - A-B-C - Tih-FDocument2 pagesMotor Mass Iveco Uni Sabana 01.402.01spen.03 - Specification - Sheet - If07 - A-B-C - Tih-Fjose mauricio lucuaraNo ratings yet

- EuroblocVM Essential GBDocument6 pagesEuroblocVM Essential GBMAHMOUD YOUNISNo ratings yet

- SFC-B: Chilled Water Fan Coil UnitsDocument6 pagesSFC-B: Chilled Water Fan Coil UnitsRyan Au YongNo ratings yet

- Pneumatic Actuators CatalogueDocument42 pagesPneumatic Actuators CataloguerserraNo ratings yet

- Cranes Cargo PDFDocument4 pagesCranes Cargo PDFpangestu100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- D Cosp369 WW Eng Tx6a10gigutpcopcable WDocument2 pagesD Cosp369 WW Eng Tx6a10gigutpcopcable WIsmael Borrego BelmarNo ratings yet

- D Cosp397 WW Eng Tx7000shieldedsftp WDocument2 pagesD Cosp397 WW Eng Tx7000shieldedsftp WIsmael Borrego BelmarNo ratings yet

- Grounding Kit: Installation Instructions PN176CDocument1 pageGrounding Kit: Installation Instructions PN176CIsmael Borrego BelmarNo ratings yet

- 8-Port Industrialnet Din Rail Mount Copper Patch Panel: Installation Instructions Pn557Document2 pages8-Port Industrialnet Din Rail Mount Copper Patch Panel: Installation Instructions Pn557Ismael Borrego BelmarNo ratings yet

- D NCCB64 WW ENG EnterPrefPartsMEX WEB PDFDocument12 pagesD NCCB64 WW ENG EnterPrefPartsMEX WEB PDFIsmael Borrego BelmarNo ratings yet

- Minicom Shielded Jack ModulesDocument3 pagesMinicom Shielded Jack ModulesIsmael Borrego BelmarNo ratings yet

- D Cosp339 WW Eng Indnetcat6 5erj45ftrmDocument2 pagesD Cosp339 WW Eng Indnetcat6 5erj45ftrmIsmael Borrego BelmarNo ratings yet

- D Cosp309 WW Eng Indnet8 Portdinrailmnt WDocument2 pagesD Cosp309 WW Eng Indnet8 Portdinrailmnt WIsmael Borrego BelmarNo ratings yet

- C Cocjsgk Xy EngDocument1 pageC Cocjsgk Xy EngIsmael Borrego BelmarNo ratings yet

- Home Office CCTV Control Room Ergonomics 14 98Document25 pagesHome Office CCTV Control Room Ergonomics 14 98Ismael Borrego BelmarNo ratings yet

- Tvss 450 Series Pulsar 1197 r2Document2 pagesTvss 450 Series Pulsar 1197 r2Ismael Borrego BelmarNo ratings yet

- Structural Steel Savings With CoSPECDocument41 pagesStructural Steel Savings With CoSPECIsmael Borrego BelmarNo ratings yet

- PCS 3140 (1) 27JN05Document46 pagesPCS 3140 (1) 27JN05Ismael Borrego BelmarNo ratings yet

- Gek 113494 PDFDocument76 pagesGek 113494 PDFBraiton EcheverryNo ratings yet

- Induction MotorDocument20 pagesInduction MotorC V VIJAY KUMASRNo ratings yet

- EWS Motor Details - Sent To MSSDocument11 pagesEWS Motor Details - Sent To MSSMani KandanNo ratings yet

- Unit - I Dynamics of Electric Drives: Electrical Power Transmission SystemsDocument4 pagesUnit - I Dynamics of Electric Drives: Electrical Power Transmission Systemsyemane gebremichalNo ratings yet

- Test2see3433 QuestionDocument2 pagesTest2see3433 QuestionFizah Abdul RahmanNo ratings yet

- USPCASE UET Departmental Test 2017Document6 pagesUSPCASE UET Departmental Test 2017Farhan KhanNo ratings yet

- Pages From Switched Reluctance Motor PDFDocument10 pagesPages From Switched Reluctance Motor PDFHAMID SULIAMANNo ratings yet

- AC Motor - (En - wikipedia.org/wiki/AC - Motor)Document10 pagesAC Motor - (En - wikipedia.org/wiki/AC - Motor)Lila CareyNo ratings yet

- PCB MotorDocument4 pagesPCB MotorKhush PatelNo ratings yet

- Synchronous MotorDocument4 pagesSynchronous MotorvanathisamyNo ratings yet

- Electric Motors Reference GuideDocument166 pagesElectric Motors Reference GuideYashveer100% (2)

- Application On Three Phase Induction Motor: ObjectivesDocument5 pagesApplication On Three Phase Induction Motor: ObjectivesAdnan AltafNo ratings yet

- 16n28 Brushed DC Motor DatasheetDocument1 page16n28 Brushed DC Motor DatasheetPaweł DoboszNo ratings yet

- BLDC MotorsDocument45 pagesBLDC Motorswicked_not_meNo ratings yet

- Solving DC Motors Simple Torque Problems PDFDocument8 pagesSolving DC Motors Simple Torque Problems PDFRv EstebanNo ratings yet

- Questions & Answers On Synchronous MachinesDocument80 pagesQuestions & Answers On Synchronous Machineskibrom atsbha100% (2)

- Construction and Working Principle of BLDC MotorDocument5 pagesConstruction and Working Principle of BLDC Motormuralajaswini.21.cseNo ratings yet

- 15 - ISSN - 1392-1215 - Investigation of Effects of Rotor Pole Geometry and Permanent Magnet To Line Start Permanent Magnet Synchronous Motors EfficiencyDocument6 pages15 - ISSN - 1392-1215 - Investigation of Effects of Rotor Pole Geometry and Permanent Magnet To Line Start Permanent Magnet Synchronous Motors EfficiencykfaliNo ratings yet

- HSJCHAO AC Catalogue 20181026Document9 pagesHSJCHAO AC Catalogue 20181026omkarnadkarniNo ratings yet

- Dokumen - Tips Cataloge-MotordcDocument29 pagesDokumen - Tips Cataloge-MotordcKHOLIFAH NURHASANAHNo ratings yet

- 1-Phase IM-2Document8 pages1-Phase IM-2abcdNo ratings yet

- Synchronous Generator Tcioe 1Document8 pagesSynchronous Generator Tcioe 1Rohit Newar100% (1)

- Speed Control of Induction MotorsDocument6 pagesSpeed Control of Induction Motorsthamilmaran alwarNo ratings yet

- Special Electrical MachinesDocument5 pagesSpecial Electrical MachinesEswaran0% (1)

- AC Machines Alternators 1Document16 pagesAC Machines Alternators 1Vanvan BitonNo ratings yet

- EEN 350 Spring 2019 Formula Sheet Last PartDocument2 pagesEEN 350 Spring 2019 Formula Sheet Last PartMario ArjaNo ratings yet

- Discovery of BLDC Motor: Brushless vs. Brushed DC MotorDocument9 pagesDiscovery of BLDC Motor: Brushless vs. Brushed DC MotorNoni MaheshwariNo ratings yet

- Crawling and CoggingDocument4 pagesCrawling and Coggingpramana_gmrit100% (1)

- ED Assignment 2Document2 pagesED Assignment 2sushant.sahayee20No ratings yet

- Ward Leonard Method of Speed ControlDocument6 pagesWard Leonard Method of Speed ControlSunil Kumar ThakurNo ratings yet