Professional Documents

Culture Documents

Production of Methanol From Synthesis Gas

Production of Methanol From Synthesis Gas

Uploaded by

AdibHelmiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Production of Methanol From Synthesis Gas

Production of Methanol From Synthesis Gas

Uploaded by

AdibHelmiCopyright:

Available Formats

Production of Methanol from synthesis gas

Carbon monoxide and hydrogen react over a catalyst to produce methanol. Today, the most

widely used catalyst is a mixture of copper and zinc oxides, supported on alumina, as first used

by ICI in 1966. At 510 MPa (50100 atm) and 250 C (482 F), the reaction is characterized by

high selectivity (>99.8%):

CO + 2 H2 CH3OH

Since the production of synthesis gas from methane produces three moles of hydrogen for

every mole of carbon monoxide, whereas the synthesis consumes only two moles of hydrogen

gas per mole of carbon monoxide. One way of dealing with the excess hydrogen is to

inject carbon dioxide into the methanol synthesis reactor, where it, too, reacts to form methanol

according to the equation:

CO2 + 3 H2 CH3OH + H2O

In terms of mechanism, the process occurs via initial conversion of CO into CO2, which is

then hydrogenated:[39]

CO2 + 3 H2 CH3OH + H2O

where the H2O byproduct is recycled via the water-gas shift reaction

CO + H2O CO2 + H2,

This gives an overall reaction, which is the same as listed above.

CO + 2 H2 CH3OH

Other

The catalytic conversion of methane to methanol has long been sought as a route to methanol.

This route is effected by enzymes such as methane monooxygenases but commercial routes

remain elusive because of the tendency for over-oxidation, i.e., methanol is more readily

oxidized than methane.[40][41]

You might also like

- Project Group 9 CC01 PDFDocument24 pagesProject Group 9 CC01 PDFHuy NinhNo ratings yet

- EtbeDocument11 pagesEtbeSebastian Pala100% (1)

- Acetone BDocument9 pagesAcetone BIrdani IdrisNo ratings yet

- Production of Acetaldehyde Via Oxidation of Ethylene: LegendDocument1 pageProduction of Acetaldehyde Via Oxidation of Ethylene: LegendCarissa TejioNo ratings yet

- Converting Waste Plastics Into Liquid Fuel by Pyrolysis Developments in China - Yuan XingzhongDocument27 pagesConverting Waste Plastics Into Liquid Fuel by Pyrolysis Developments in China - Yuan Xingzhongvuongcoi102No ratings yet

- The Dehydrogenation of Isopropanol To Form Hydrogen GasDocument31 pagesThe Dehydrogenation of Isopropanol To Form Hydrogen GasEdidiong AsuquoNo ratings yet

- Acrylonitrile by The Ammoxidation of PropaneDocument10 pagesAcrylonitrile by The Ammoxidation of PropaneVincet Vega100% (1)

- ButadineDocument68 pagesButadineraihonaNo ratings yet

- Chapter V Regional Market Analysis PDFDocument222 pagesChapter V Regional Market Analysis PDFester dNo ratings yet

- Lab 1: Food SpoilageDocument15 pagesLab 1: Food SpoilageAdibHelmi100% (2)

- Methanol Synthesis From SyngasDocument3 pagesMethanol Synthesis From SyngasSylvia SimonNo ratings yet

- Manufacturing Methods: 1. Methanol Carbonylation 2. Acetaldehyde Oxidation 3. Ethylene Oxidation 4. Anerobic FermentationDocument39 pagesManufacturing Methods: 1. Methanol Carbonylation 2. Acetaldehyde Oxidation 3. Ethylene Oxidation 4. Anerobic Fermentationkumari svgNo ratings yet

- Direct Dimethyl Ether Synthesis: Takashi Ogawa, Norio Inoue, Tutomu Shikada, Yotaro OhnoDocument9 pagesDirect Dimethyl Ether Synthesis: Takashi Ogawa, Norio Inoue, Tutomu Shikada, Yotaro OhnoM Alim Ur RahmanNo ratings yet

- Review Methyl Chloride ProcessesDocument13 pagesReview Methyl Chloride ProcessesAlfredo PeñaNo ratings yet

- Mthanol ProductionDocument61 pagesMthanol Productionvv vvNo ratings yet

- Dme Report Word Own LATESTDocument73 pagesDme Report Word Own LATESTvyas reddyNo ratings yet

- PFD PDFDocument1 pagePFD PDFFajar AgumNo ratings yet

- Rozovskii Et Al. (2003) - Fundamentals of Methanol Synthesis and DecompositionDocument14 pagesRozovskii Et Al. (2003) - Fundamentals of Methanol Synthesis and DecompositionbltzkrigNo ratings yet

- Material and Energy BalanceDocument9 pagesMaterial and Energy BalanceSana100% (1)

- Plant Design For Methanol Distillation Unit: February 2021Document51 pagesPlant Design For Methanol Distillation Unit: February 2021maged1998100% (1)

- Final Report BiomassDocument114 pagesFinal Report BiomassJan100% (4)

- A01 031Document17 pagesA01 031jaimeNo ratings yet

- MTBE Unit Expansion-ConversionDocument13 pagesMTBE Unit Expansion-Conversiontunganh1110100% (1)

- Vinyl Chloride Monomer (VCM) Production ProcessDocument11 pagesVinyl Chloride Monomer (VCM) Production ProcessKubra ĖdrisNo ratings yet

- Project Report On HexamineDocument48 pagesProject Report On HexamineHimatushNo ratings yet

- Dimethyl Ether SDS E4589Document7 pagesDimethyl Ether SDS E4589Daniil GhilescuNo ratings yet

- Viewcontent11 PDFDocument54 pagesViewcontent11 PDFEr Mayur PatilNo ratings yet

- From Synthesis Gas Production To Methanol Synthesi 2015 Journal of Natural GDocument14 pagesFrom Synthesis Gas Production To Methanol Synthesi 2015 Journal of Natural GRafael DamarNo ratings yet

- Nhóm (Đ.Anh+ Hiếu + Ý) Syngas to MethanolDocument40 pagesNhóm (Đ.Anh+ Hiếu + Ý) Syngas to MethanolStrong NguyenNo ratings yet

- Vapor-Liquid Equilibria. Ethylene Oxide - Acetaldehyde and Ethylene Oxide - Water SystemsDocument5 pagesVapor-Liquid Equilibria. Ethylene Oxide - Acetaldehyde and Ethylene Oxide - Water SystemsGie0% (1)

- Ass. 5Document14 pagesAss. 5Saumya SelvarajiNo ratings yet

- Optimal Design of Intensified Processes For DME SynthesisDocument30 pagesOptimal Design of Intensified Processes For DME SynthesisNorma JenarezNo ratings yet

- Butene-1: Trans-2-Butene, Isobutylene, and ButadieneDocument1 pageButene-1: Trans-2-Butene, Isobutylene, and ButadieneYESIKBMARTIN100% (1)

- Methanol - Material BalanceDocument3 pagesMethanol - Material BalanceAnonymous Ksq1dyPRhNo ratings yet

- Production of MTBE (Methyl Tert-Butyl Ether)Document2 pagesProduction of MTBE (Methyl Tert-Butyl Ether)Aaron SinghNo ratings yet

- Simulation of Methanol Production From Biomass Gasification in Interconnected Fluidized BedsDocument9 pagesSimulation of Methanol Production From Biomass Gasification in Interconnected Fluidized BedsKelly TorresNo ratings yet

- Energy Saving of A Methyl Methacrylate Separation Process PDFDocument11 pagesEnergy Saving of A Methyl Methacrylate Separation Process PDFClaudia CelestinoNo ratings yet

- Turton AppBDocument114 pagesTurton AppBAdesuwa O'sae0% (1)

- Process Calculation Py Qs by Dev SirDocument97 pagesProcess Calculation Py Qs by Dev SirVIKAS SINGHNo ratings yet

- DME UlmannDocument4 pagesDME UlmannLeonard SaftaNo ratings yet

- Mitsui Chemicals - MeOH From Flue GasDocument2 pagesMitsui Chemicals - MeOH From Flue GasrajarshisoftNo ratings yet

- Acetaldehyde Production by Ethanol DehydrogenationDocument9 pagesAcetaldehyde Production by Ethanol DehydrogenationHugo Gerdulli AlbertinNo ratings yet

- Chapter 2Document48 pagesChapter 2hazmi_omarNo ratings yet

- N-Butanol Plant Design BriefDocument5 pagesN-Butanol Plant Design BriefTom Hart100% (1)

- Final Project2Document135 pagesFinal Project2Mr NU KHANNo ratings yet

- University of Lagos: Process Description For The Production of Mtbe A Presentation by Group 10 ConsistingDocument7 pagesUniversity of Lagos: Process Description For The Production of Mtbe A Presentation by Group 10 ConsistingJide Williams100% (1)

- Steam Methane Reforming Reaction Process Intensification by Using A ReactorDocument14 pagesSteam Methane Reforming Reaction Process Intensification by Using A ReactorserchNo ratings yet

- Production of Vinyl Chloride Monomer Via Thermal Cracking of Ethylene DichlorideDocument138 pagesProduction of Vinyl Chloride Monomer Via Thermal Cracking of Ethylene DichlorideAmber UsmanNo ratings yet

- AlkylationDocument8 pagesAlkylationMohammad AlMousaNo ratings yet

- Mtbe PDFDocument47 pagesMtbe PDFYayee LalainheavenNo ratings yet

- Direct Dimethyl Ether SynthesisDocument9 pagesDirect Dimethyl Ether SynthesissltnrmnNo ratings yet

- File1 - Laporan 5Document48 pagesFile1 - Laporan 5Bhaskoro AbdillahNo ratings yet

- CHAPTER 3 (v3) - ETHYLENE BASED PRODUCTIONDocument46 pagesCHAPTER 3 (v3) - ETHYLENE BASED PRODUCTIONAleeya KamalNo ratings yet

- Reactor Types Characteristics/usages Benefits in A DME Plant CautionsDocument4 pagesReactor Types Characteristics/usages Benefits in A DME Plant CautionsNeha MadanNo ratings yet

- CHAPTER 3 Shreve Chemical Process Industries 5th Ed. OCRpdfDocument25 pagesCHAPTER 3 Shreve Chemical Process Industries 5th Ed. OCRpdfFellippe AmorNo ratings yet

- Multiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsFrom EverandMultiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsYi ChengNo ratings yet

- Obtencion de MetanolDocument2 pagesObtencion de MetanolPedro BarbosaNo ratings yet

- Ammonia Production From Natural GasDocument3 pagesAmmonia Production From Natural GasnakeyahxoNo ratings yet

- Methanol SynthesisDocument21 pagesMethanol SynthesisAnonymous cenxRyKU5No ratings yet

- Production Process of MethanolMETANOLDocument2 pagesProduction Process of MethanolMETANOLFlávia MonteiroNo ratings yet

- Publication 12 18639 6095Document4 pagesPublication 12 18639 6095Naliana LupascuNo ratings yet

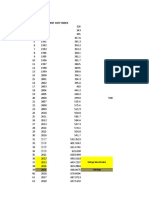

- Land CostDocument1 pageLand CostAdibHelmiNo ratings yet

- Exercise Chapter 7Document9 pagesExercise Chapter 7AdibHelmiNo ratings yet

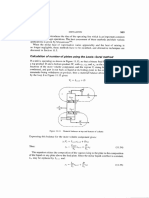

- Lewis Sorel MethodDocument4 pagesLewis Sorel MethodIbnu HamidNo ratings yet