Professional Documents

Culture Documents

Pipe Fitting Tolerancces

Pipe Fitting Tolerancces

Uploaded by

Varun PatelOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Fitting Tolerancces

Pipe Fitting Tolerancces

Uploaded by

Varun PatelCopyright:

Available Formats

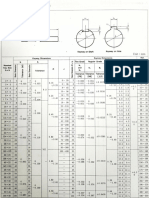

Tolerances of BW Fittings to ASME B16.

9

These drawings are for illustration purposes. Please also refer to the drawings with each dimensional chart.

Nominal Pipe

All Fittings Elbows and Tees 180 Deg Return Ben

Size

Centre-to-End

O.D. at Bevel (1), I.D. at End (1), Wall Thickness Centre-to

NPS Dimension

(2) (3), (4) (3) -Centre O

A,B,C,M

+0.06

1/2 to 21/2 0.03 0.06 0.25

-0.03

3 to 31/2 0.06 0.06 0.06 0.25

4 0.06 0.06 0.06 0.25

+0.09 Not less than

5 to 8 0.06 0.06 0.25

-0.06 87.5% of

+0.16 nominal

10 to 18 0.12 thickness 0.09 0.38

-0.12

+0.25

20 to 24 0.19 0.09 0.38

-0.19

+0.25

26 to 30 0.19 0.12

-0.19

+0.25

32 to 48 0.19 0.19

-0.19

Notes:

All dimensions are given in inches. Tolerances are equal plus and minus except as noted.

Angularity Tolerances

Nominal Pipe Size

NPS Off Angle Off Plane

Q P

1/2 to 4 0.03 0.06

5 to 8 0.06 0.12

10 to 12 0.09 0.19

14 to 16 0.09 0.25

18 to 24 0.12 0.38

26 to 30 0.19 0.38

32 to 42 0.19 0.50

44 to 48 0.18 0.75

(1) Out-of-round is the sum of absolute values of plus and minus tolerance.

(2) This tolerance may not apply in localized areas of formed fittings where increased wall thickness is required to meet design requirements of ASME B16.9.

(3) The inside diameter and the nominal wall thicknesses at ends are to be specified by the purchaser.

(4) Unless otherwise specified by the purchaser, these tolerances apply to the nominal inside diameter, which equals the difference between the nominal outsid

and twice the nominal wall thickness.

180 Deg Return Bends Reducers Caps

Alignment of

Back-to Overall Length Overall Length

Ends

-Face K H E

U

0.25 0.03 0.06 0.12

0.25 0.03 0.06 0.12

0.25 0.03 0.06 0.12

0.25 0.03 0.06 0.25

0.25 0.06 0.09 0.25

0.25 0.06 0.09 0.25

0.19 0.38

0.19 0.38

sign requirements of ASME B16.9.

ifference between the nominal outside diameter

You might also like

- CSCMP Academic Case Study Series: BP's Procurement and Supply Chain Management Teaching NotesDocument11 pagesCSCMP Academic Case Study Series: BP's Procurement and Supply Chain Management Teaching NotesMansi GuptaNo ratings yet

- Customer List With Product DetailsDocument25 pagesCustomer List With Product Detailsprashant100% (1)

- Structural Plate Astm A36: Plates, Shapes, and Sheet PilingDocument4 pagesStructural Plate Astm A36: Plates, Shapes, and Sheet Pilingeko kusumoNo ratings yet

- The EMPI Sportster Was A Sheet Metal Buggy Built On A Modified VW Beetle FloorpanDocument23 pagesThe EMPI Sportster Was A Sheet Metal Buggy Built On A Modified VW Beetle Floorpansoldatbr4183No ratings yet

- Camisea Opt 2005 25-02-05Document4 pagesCamisea Opt 2005 25-02-05davidmars100% (1)

- Tolerances B 169Document1 pageTolerances B 169Onur oskay SaatçiNo ratings yet

- Ring Design Chapter010Document1 pageRing Design Chapter010ismail güleçNo ratings yet

- B16.9-2018 TolerancesDocument2 pagesB16.9-2018 TolerancesJack FanucNo ratings yet

- 2 - Die Design 2Document78 pages2 - Die Design 2May FadlNo ratings yet

- RuberGuide - 2017 ENGLISHDocument8 pagesRuberGuide - 2017 ENGLISHAndres Byke SepulvedaNo ratings yet

- IncertidumbreDocument3 pagesIncertidumbreJuan SantiagoNo ratings yet

- Calculation of A Box Culvert: Data Ǿ (Ton/m )Document5 pagesCalculation of A Box Culvert: Data Ǿ (Ton/m )sidiq7No ratings yet

- Lab 2Document8 pagesLab 2Cristel Choquehuayta EspinozaNo ratings yet

- Plate A36 (2016)Document4 pagesPlate A36 (2016)eko kusumoNo ratings yet

- Bend Allowance K-Factor CalculatorDocument17 pagesBend Allowance K-Factor Calculatorchaitanya kulkarniNo ratings yet

- Api 6a FLG Slide Rule SizeDocument9 pagesApi 6a FLG Slide Rule SizeRamzi BEN AHMEDNo ratings yet

- Ejercicio 1 - AnalisisDocument3 pagesEjercicio 1 - AnalisisSheiler Alvarado SanchezNo ratings yet

- Ejercicio 1 - AnalisisDocument3 pagesEjercicio 1 - AnalisisSheiler Alvarado SanchezNo ratings yet

- Jis 3193Document3 pagesJis 3193Angga KurniawanNo ratings yet

- Jis 3193 PDFDocument3 pagesJis 3193 PDFAngga KurniawanNo ratings yet

- Calculo de Caida de Tension: 440/220 Voltios 600.00 W/loteDocument3 pagesCalculo de Caida de Tension: 440/220 Voltios 600.00 W/lotejuan leoncio piedras ramiresNo ratings yet

- Results:: A) Experimental Shear CentreDocument4 pagesResults:: A) Experimental Shear Centrekaram bawadiNo ratings yet

- Crca CRM Diversion '22-23Document5 pagesCrca CRM Diversion '22-23ram kum,arNo ratings yet

- Interpreting Fits and Tolerances:: - by William B MoringDocument14 pagesInterpreting Fits and Tolerances:: - by William B Moringwillmors31No ratings yet

- Fastener Tols PDFDocument1 pageFastener Tols PDFbcsf01No ratings yet

- 10 1034 PDFDocument1 page10 1034 PDFbcsf01No ratings yet

- Carbon - EquivalentsDocument3 pagesCarbon - EquivalentsAliAkarNo ratings yet

- MOC DetailsDocument2 pagesMOC DetailsrammaheNo ratings yet

- BeamsDocument199 pagesBeamsSigue Ramel HinayasNo ratings yet

- SlabDocument279 pagesSlabSigue Ramel HinayasNo ratings yet

- Pregunta 5Document16 pagesPregunta 5JHOAN YAMIL TRUJILLO GARCIANo ratings yet

- EN Standards For Rolled Aluminium: Alloy Group I 1080A, 1070A, 1050A, 1200Document6 pagesEN Standards For Rolled Aluminium: Alloy Group I 1080A, 1070A, 1050A, 1200Sanjay MehtaNo ratings yet

- Standar Acuan Gambar Untuk AutocadDocument20 pagesStandar Acuan Gambar Untuk AutocadSarif DamuhuNo ratings yet

- Copper Nickel Pipe Din86089 Eemua145Document1 pageCopper Nickel Pipe Din86089 Eemua145Araby GamalNo ratings yet

- W Wenzhou O Outebao P Pipe F Fitting C Co.,Ltd: Mill Test Certificates Acc. EN 10204 - 3.1Document1 pageW Wenzhou O Outebao P Pipe F Fitting C Co.,Ltd: Mill Test Certificates Acc. EN 10204 - 3.1Josivaldo Andres Montero EscalanteNo ratings yet

- Answer Key Quizactivity - MansciDocument10 pagesAnswer Key Quizactivity - MansciKyla MendozaNo ratings yet

- Experiment-2: Shear Centre of Open SectionsDocument7 pagesExperiment-2: Shear Centre of Open SectionsRahul RoyNo ratings yet

- Debt Betas by Credit RatingDocument2 pagesDebt Betas by Credit Ratingxxx85828No ratings yet

- Brush and Brush-Holder Tolerances On "T" and "A" Dimensions: Technical Note Sta Be 16-4 GBDocument2 pagesBrush and Brush-Holder Tolerances On "T" and "A" Dimensions: Technical Note Sta Be 16-4 GBloulou_beNo ratings yet

- Excel Help HQ Waterfall Chart TemplateDocument6 pagesExcel Help HQ Waterfall Chart TemplateMauricio MatusNo ratings yet

- Lincoln (Data Sheet) Murex E7024Document2 pagesLincoln (Data Sheet) Murex E7024PubcrawlNo ratings yet

- Table of Contents Will Be Inserted Here On UpdateDocument11 pagesTable of Contents Will Be Inserted Here On Updatehuo lenghakNo ratings yet

- Tabella Seno, Coseno e Tangente Dati Angoli Da 0 A 90Document4 pagesTabella Seno, Coseno e Tangente Dati Angoli Da 0 A 90perty92No ratings yet

- Flat Keys and KeywaysDocument1 pageFlat Keys and KeywaysBarNo ratings yet

- Beamshield UvaluesDocument1 pageBeamshield UvaluesJoe SmithNo ratings yet

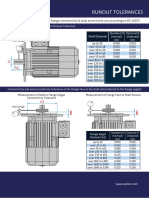

- Runout TollerancesDocument1 pageRunout Tollerancesbiranchi satapathyNo ratings yet

- A/t A1/t1+ (A/l-A1/l1) / (A2/l2-A1/l1) (A2/t2-A1/t1) (Linear Interpolation Formula)Document6 pagesA/t A1/t1+ (A/l-A1/l1) / (A2/l2-A1/l1) (A2/t2-A1/t1) (Linear Interpolation Formula)phan hoang diepNo ratings yet

- How To Evaluate For PAUTDocument6 pagesHow To Evaluate For PAUTphan hoang diep100% (1)

- Chemical Compositiopn of FCAW ElectrodesDocument1 pageChemical Compositiopn of FCAW ElectrodeskapsarcNo ratings yet

- CVG5312 - Assignment 1.pdf Filename "CVG5312 - Assignment 1Document2 pagesCVG5312 - Assignment 1.pdf Filename "CVG5312 - Assignment 1Habeeb FarooqNo ratings yet

- Analisa BS @shift-3Document4 pagesAnalisa BS @shift-3mita septiNo ratings yet

- UnsDocument7 pagesUnsWalton Science Research LabNo ratings yet

- BAP 130 Juni 2020Document4 pagesBAP 130 Juni 2020masawi719No ratings yet

- Concrete Proportion Cement and Sand For CHB Mortar Per Square MeterDocument4 pagesConcrete Proportion Cement and Sand For CHB Mortar Per Square MeterHorhe LacanilaoNo ratings yet

- Vulcan Smart+ Calibration Datasheets (Dec 2020)Document5 pagesVulcan Smart+ Calibration Datasheets (Dec 2020)Paula InesNo ratings yet

- Acceptance Standards For RTDocument2 pagesAcceptance Standards For RTf4CHNo ratings yet

- Plates Steel MetalDocument12 pagesPlates Steel MetalAnonymous aWpx7nENo ratings yet

- Calculo de Caida de Tension: 440/220 Voltios 600.00 W/loteDocument3 pagesCalculo de Caida de Tension: 440/220 Voltios 600.00 W/lotejuan leoncio piedras ramiresNo ratings yet

- Specification HbeamsDocument4 pagesSpecification HbeamsPankaj RaulNo ratings yet

- Sample, Boq of Steel Columns, Platform, Roof, Staircase (Proj-Transmittal, P.d.laboratory)Document11 pagesSample, Boq of Steel Columns, Platform, Roof, Staircase (Proj-Transmittal, P.d.laboratory)Rohan JaiswalNo ratings yet

- Calculate The 3 Control Limits For X-Bar and R Charts Based On The First 12 Samples ReflectingDocument6 pagesCalculate The 3 Control Limits For X-Bar and R Charts Based On The First 12 Samples ReflectingRamzi SaeedNo ratings yet

- Prepared By: Soh Kim FaiDocument12 pagesPrepared By: Soh Kim Faisohkimfai6340No ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- What Is MAWP? Difference Between MAWP, Design Pressure and Operating PressureDocument7 pagesWhat Is MAWP? Difference Between MAWP, Design Pressure and Operating Pressurevarun1567100% (1)

- Psl1 Vs Psl2Document10 pagesPsl1 Vs Psl2Varun PatelNo ratings yet

- P&ID Symbols For EngineerDocument2 pagesP&ID Symbols For EngineerVarun PatelNo ratings yet

- Fundamental of Pipes For Oil & Gas EngineerDocument19 pagesFundamental of Pipes For Oil & Gas EngineerVarun PatelNo ratings yet

- Piping ComponentsDocument26 pagesPiping ComponentsVarun Patel100% (1)

- Pipe Handbook Cum Guide (A-Z of Pipe For Oil & Gas Engineer)Document15 pagesPipe Handbook Cum Guide (A-Z of Pipe For Oil & Gas Engineer)Varun PatelNo ratings yet

- JFE Connections Field Service Handbook Rev0 20210902104108Document56 pagesJFE Connections Field Service Handbook Rev0 20210902104108Nasser JNo ratings yet

- PVDF CompleteDocument33 pagesPVDF CompleteIbram GunarsaNo ratings yet

- MLCDocument34 pagesMLCEmad JamshidiNo ratings yet

- Bq-Differential Pressure GaugeDocument2 pagesBq-Differential Pressure Gaugepankaj doshiNo ratings yet

- Plumbing Presentation SlideDocument76 pagesPlumbing Presentation SlideSopheareak ChhanNo ratings yet

- Fly p7Document112 pagesFly p7Samuel Millan BorgesNo ratings yet

- Plumbing Practical Handouts PDFDocument288 pagesPlumbing Practical Handouts PDFfaye yanzon100% (1)

- Hindustan Urvarak and Rasayan Limited Barauni & Sindri: Job Specification For Supply Pipe and Piping ComponentsDocument38 pagesHindustan Urvarak and Rasayan Limited Barauni & Sindri: Job Specification For Supply Pipe and Piping ComponentsAmit SharmaNo ratings yet

- Strema Act 2Document42 pagesStrema Act 2James Ryu ZagalaNo ratings yet

- Catalogue CPVCDocument4 pagesCatalogue CPVCmedo.k016No ratings yet

- Brochure Weld InspectionDocument40 pagesBrochure Weld InspectionAdam OthmanNo ratings yet

- Corrosion RingsDocument1 pageCorrosion RingsRichard More LeonNo ratings yet

- General SpecificationsDocument9 pagesGeneral SpecificationsLiz MontianoNo ratings yet

- Multiple Meter Cabinet DetailsDocument1 pageMultiple Meter Cabinet DetailsMohammed sabatinNo ratings yet

- List of Contents For Gs-15Document13 pagesList of Contents For Gs-15Kalai SelvanNo ratings yet

- Operating Manual: Edition: 01 / 2016Document91 pagesOperating Manual: Edition: 01 / 2016Juan Manuel Llorente VaraNo ratings yet

- API Company Profile 2018Document16 pagesAPI Company Profile 2018nurfareesya zabidiNo ratings yet

- Product Catalogue: Redefining Racing SolutionsDocument22 pagesProduct Catalogue: Redefining Racing SolutionsVaibhav AnandNo ratings yet

- Smap3D Piping enDocument8 pagesSmap3D Piping enpatel_devendraaNo ratings yet

- Ch-38 Plinth Area RateDocument7 pagesCh-38 Plinth Area RateAchinta_b11No ratings yet

- Lapp Main Catalogue - 1819 - EN - 1file PDFDocument1,190 pagesLapp Main Catalogue - 1819 - EN - 1file PDFAndrew LowNo ratings yet

- General Installation Practices: Section EDocument26 pagesGeneral Installation Practices: Section EMohsen ArabifardNo ratings yet

- F 46133 0 PDFDocument2 pagesF 46133 0 PDFTamás KósaNo ratings yet

- API Standard 653, Tank Inspection, Repair, Alteration, and ReconstructionDocument14 pagesAPI Standard 653, Tank Inspection, Repair, Alteration, and ReconstructionSaqib KhanNo ratings yet

- Steam Distribution and Condensate Collection Manifolds Usdm / UccmDocument2 pagesSteam Distribution and Condensate Collection Manifolds Usdm / UccmsiddheshNo ratings yet

- Buried Pipe Calculation Report: Title Name Date Report NameDocument3 pagesBuried Pipe Calculation Report: Title Name Date Report NameDenis OhwofadaNo ratings yet