Professional Documents

Culture Documents

Turbine Application Report E PDF

Turbine Application Report E PDF

Uploaded by

Febry AryantoCopyright:

Available Formats

You might also like

- Being Happy - Andrew MatthewsDocument242 pagesBeing Happy - Andrew MatthewsLioe Stanley100% (4)

- FT3000 SKF Compact Speed Monitoring and ProtectionDocument11 pagesFT3000 SKF Compact Speed Monitoring and ProtectionUssamaNo ratings yet

- Vedanta IPP Jharsuguda (4 600MW) Turbine Manual.Document274 pagesVedanta IPP Jharsuguda (4 600MW) Turbine Manual.Ashutosh YadavNo ratings yet

- Epson 3800 3880 SMDocument306 pagesEpson 3800 3880 SMIon IonutNo ratings yet

- Cold Start Up 1Document16 pagesCold Start Up 1Hassan SamiNo ratings yet

- 1-5 Steam Temperature - QuestionnaireDocument3 pages1-5 Steam Temperature - QuestionnairesdiamanNo ratings yet

- Boiler Light-Up PrerequisitesDocument3 pagesBoiler Light-Up PrerequisitesmallavscNo ratings yet

- Filosofia Standard Operacion Caldera ThermaxDocument37 pagesFilosofia Standard Operacion Caldera ThermaxAndújar Báez CésarNo ratings yet

- Schematic Diagram of The New Steam Temperature ControlDocument5 pagesSchematic Diagram of The New Steam Temperature Controladarsh_saxena2627No ratings yet

- 135 MW TGSDocument19 pages135 MW TGSPrudhvi RajNo ratings yet

- Turbine Control PINDocument4 pagesTurbine Control PINAnonymous NwnJNO100% (1)

- CalderaDocument44 pagesCalderaIvan SanchezNo ratings yet

- Jay Giri (Alstom) PDFDocument61 pagesJay Giri (Alstom) PDFPrasanth MKNo ratings yet

- FXCM Traits of Successful Traders GuideDocument43 pagesFXCM Traits of Successful Traders GuidefizzNo ratings yet

- Steam Turbine Governing System 210mwDocument74 pagesSteam Turbine Governing System 210mwRajani Kanta MundaNo ratings yet

- StartupDocument28 pagesStartupAjay Chauhan100% (1)

- How To Improve The VacuumDocument11 pagesHow To Improve The VacuumUdhayakumar VenkataramanNo ratings yet

- Modern ControlDocument16 pagesModern ControlBM100% (1)

- 330mw DEHDocument22 pages330mw DEHkeerthi dayarathna100% (1)

- TCLDocument198 pagesTCLVaisakVenugopal100% (1)

- Truth About TrendsDocument17 pagesTruth About TrendsVladimir UstinovNo ratings yet

- Installation Checklists 1-2MW-xxHz BBCICL EN r01 D PDFDocument39 pagesInstallation Checklists 1-2MW-xxHz BBCICL EN r01 D PDFEduardo Jr.No ratings yet

- Aux Boiler Start UpDocument35 pagesAux Boiler Start UpFauzan KurniaNo ratings yet

- STGDocument12 pagesSTGLiji Brijesh100% (2)

- 500MW-Boiler - Salient FeatureDocument7 pages500MW-Boiler - Salient FeatureAhemadNo ratings yet

- Lecture9 Arm MoocsDocument14 pagesLecture9 Arm MoocsKommaraju BhavanaNo ratings yet

- Instrumentation and Control SystemDocument7 pagesInstrumentation and Control Systemikhsannurrahman100% (1)

- Turbine & Cooling System: Presented by - AVIJEET PRATAP 07ME12 Iet AgraDocument28 pagesTurbine & Cooling System: Presented by - AVIJEET PRATAP 07ME12 Iet AgraAd Man GeTig100% (1)

- Steam Temperature ControlDocument2 pagesSteam Temperature ControlGift Roglands100% (1)

- Boiler-Tuning Basics, Part IIDocument28 pagesBoiler-Tuning Basics, Part IIJhoNo ratings yet

- Super Critical BoilerDocument32 pagesSuper Critical BoilerNardo LlanosNo ratings yet

- Sealoiloperation1 1Document2 pagesSealoiloperation1 1harkiranrandhawa100% (1)

- C&i SystemsDocument116 pagesC&i SystemsbamzNo ratings yet

- Digital Control System of Plant Gyanendra Sharma NPTI DelhiDocument128 pagesDigital Control System of Plant Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Turbine Control and Efficiency ImporovementDocument6 pagesTurbine Control and Efficiency ImporovementUdhayakumar Venkataraman100% (2)

- Thermal Plant Control Instrumentation IDocument41 pagesThermal Plant Control Instrumentation IVishal Khachane100% (2)

- C&I WriteupDocument137 pagesC&I WriteupSayan AichNo ratings yet

- Control Loop PresentationDocument169 pagesControl Loop Presentationrbdubey2020100% (1)

- Better Fuel Distribution To Improve Combustion During Flexible Load OperationDocument12 pagesBetter Fuel Distribution To Improve Combustion During Flexible Load OperationRajeswaranNo ratings yet

- RGMO Frequency Influence SchemeDocument1 pageRGMO Frequency Influence SchemeJitendra SharmaNo ratings yet

- 0704 MCS System Logic Design Instruction PDFDocument28 pages0704 MCS System Logic Design Instruction PDFrahul100% (2)

- Formula For Linear % To Square Root % ConversionDocument2 pagesFormula For Linear % To Square Root % ConversionRaju SkNo ratings yet

- Sadc 1Document4 pagesSadc 1Vikas SuryavanshiNo ratings yet

- Lecture 27 Model Steam Turbine Gov SystemDocument60 pagesLecture 27 Model Steam Turbine Gov Systempk cfctkNo ratings yet

- Turbine Operation SequenceDocument3 pagesTurbine Operation SequenceTitas titasNo ratings yet

- Burner Tilt PDFDocument9 pagesBurner Tilt PDFEE POG-III CSTPSNo ratings yet

- Boiler Instrumentation and ControlsDocument18 pagesBoiler Instrumentation and Controlshayat umar bhat100% (2)

- Maxseal Solenoid Energize To TripDocument1 pageMaxseal Solenoid Energize To TripAmet koko Taro100% (1)

- Pulkit PPT Steam Turbine3Document42 pagesPulkit PPT Steam Turbine3Abhishek Kumar100% (1)

- TSE - Nirav JoshiDocument81 pagesTSE - Nirav JoshiBrahma Dutt100% (1)

- TG Referal DatapediaDocument20 pagesTG Referal Datapediajp mishraNo ratings yet

- Dunkerque Project Sheet (Alstom and Standardkessel)Document2 pagesDunkerque Project Sheet (Alstom and Standardkessel)peter34567100% (1)

- Protection and InterlocksDocument47 pagesProtection and InterlocksRavi kant Ghatoye100% (1)

- Boiler Feed Water SystemDocument80 pagesBoiler Feed Water System1029384765qazwsxNo ratings yet

- 2VAA005093 HR D en Series Control and IO Lo-Res BrochureDocument7 pages2VAA005093 HR D en Series Control and IO Lo-Res BrochureJulioNo ratings yet

- Customer Course CatalogDocument97 pagesCustomer Course Cataloglxd.hepNo ratings yet

- Commissioning Procedure For Governing System - Thermal Power Plant A-ZDocument15 pagesCommissioning Procedure For Governing System - Thermal Power Plant A-ZSukhdev SinghNo ratings yet

- Operation of Condensate and Feed Water System HPDocument8 pagesOperation of Condensate and Feed Water System HPlp mishra100% (1)

- Bhel LP-HP Bypass OrderDocument32 pagesBhel LP-HP Bypass OrderGiriDharanNo ratings yet

- Surge ProtectedDocument42 pagesSurge ProtectedRaul Roque Yujra100% (3)

- Compressor Drive Allison 501-KB Gas TurbineDocument4 pagesCompressor Drive Allison 501-KB Gas Turbineprabu50% (2)

- MTUDocument16 pagesMTUWira Karya Diesel50% (6)

- 7907-Siemens Gas Turbine and Generator PackageDocument6 pages7907-Siemens Gas Turbine and Generator PackagemyegnrNo ratings yet

- Steam EnthalpyDocument14 pagesSteam EnthalpyAshutosh YadavNo ratings yet

- Annexure-I: Fixture & Fitting in Flat NoDocument3 pagesAnnexure-I: Fixture & Fitting in Flat NoAshutosh YadavNo ratings yet

- Automobile GasketsDocument9 pagesAutomobile GasketsAshutosh YadavNo ratings yet

- Saral Prasashnik SabdawaliDocument5 pagesSaral Prasashnik SabdawaliAshutosh YadavNo ratings yet

- 9.turbine Operation Instruction Yx 09 01Document228 pages9.turbine Operation Instruction Yx 09 01Ashutosh YadavNo ratings yet

- Peniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Document3 pagesPeniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Jhocen Grace GanironNo ratings yet

- An Overview of Honey: Its Composition, Nutritional and Functional PropertiesDocument5 pagesAn Overview of Honey: Its Composition, Nutritional and Functional PropertiesSandeep SinghNo ratings yet

- Tax System SriLankaDocument44 pagesTax System SriLankamandarak7146No ratings yet

- 400PNR CDocument3 pages400PNR CmdisicNo ratings yet

- Sewing Skills Checklist PDFDocument44 pagesSewing Skills Checklist PDFyemkem100% (1)

- South Africa Hard Copy Lit 2Document20 pagesSouth Africa Hard Copy Lit 2Jennifer Española BernalNo ratings yet

- 12 2f17 Vegetarian Argumentative EssayDocument7 pages12 2f17 Vegetarian Argumentative Essayapi-413258549No ratings yet

- Hillfoot Data Sheets V5 1Document4 pagesHillfoot Data Sheets V5 1Kristijan IlicNo ratings yet

- Production of Biodegradable Plastics AsDocument6 pagesProduction of Biodegradable Plastics AsEbenezer EffisahNo ratings yet

- Speech Patterns: Christine Martin - Steph Estavillo - Melanie PadillaDocument24 pagesSpeech Patterns: Christine Martin - Steph Estavillo - Melanie PadillaChristineMartinNo ratings yet

- Yuxi CatalogueDocument16 pagesYuxi CatalogueSoltani AliNo ratings yet

- Data Sheet USB5 II 2019 05 ENDocument1 pageData Sheet USB5 II 2019 05 ENJanne LaineNo ratings yet

- Oil & Chemical Tanker Summer 7 - Prepurchase Survey Report - S&a 230098 PpsDocument62 pagesOil & Chemical Tanker Summer 7 - Prepurchase Survey Report - S&a 230098 Ppsp_k_sahuNo ratings yet

- Quarter 3 - Las No. 1 (Week 5-7) Active Recreation (Street and Hip-Hop Dances) (Pe10Pf-Iiia-H-39, Pe10Pf-Lllc-H-45)Document11 pagesQuarter 3 - Las No. 1 (Week 5-7) Active Recreation (Street and Hip-Hop Dances) (Pe10Pf-Iiia-H-39, Pe10Pf-Lllc-H-45)hakkensNo ratings yet

- EQUILIBRIUMDocument1 pageEQUILIBRIUMMohammed IliasNo ratings yet

- Autonomous University of Baja California: Faculty of Engineering Aerospace EngineeringDocument18 pagesAutonomous University of Baja California: Faculty of Engineering Aerospace EngineeringOscar Oreste Salvador CarlosNo ratings yet

- Earth Quake DesignDocument13 pagesEarth Quake DesignRanie boy CabanillaNo ratings yet

- Asme A13.1 - 1996Document27 pagesAsme A13.1 - 1996lohv100% (1)

- Make List SLTD-J-1401-L-6-00003-02Document4 pagesMake List SLTD-J-1401-L-6-00003-02tribhuvan ShankarNo ratings yet

- Is-Cal01 Design Carbon Accounting On Site Rev.02Document6 pagesIs-Cal01 Design Carbon Accounting On Site Rev.02shoba9945No ratings yet

- Gennady Nesis, Leonid Shulman, Malcolm Gesthuysen - Tactics in The King's IndianDocument130 pagesGennady Nesis, Leonid Shulman, Malcolm Gesthuysen - Tactics in The King's Indiancodonauta100% (1)

- Abb Reg615 Ansi Appl 859072 EndDocument124 pagesAbb Reg615 Ansi Appl 859072 EndjppreciadomNo ratings yet

- Bigbang PDFDocument772 pagesBigbang PDFLeanne Haddock100% (1)

- Tutorial-2 - Heterocycles Nomenclature-Part-IIDocument18 pagesTutorial-2 - Heterocycles Nomenclature-Part-IIamirNo ratings yet

- CWAG Rectangular CoordinatesDocument52 pagesCWAG Rectangular CoordinatesRolando MerleNo ratings yet

- UVU Jungle Marathon 2012 BookDocument41 pagesUVU Jungle Marathon 2012 BookGerhard FlatzNo ratings yet

- 11 Chemistry Module 2Document19 pages11 Chemistry Module 2SpongeBob SquarePants Fidget ToysNo ratings yet

- EuropeDocument5 pagesEuropeAmicus CuriaeNo ratings yet

Turbine Application Report E PDF

Turbine Application Report E PDF

Uploaded by

Febry AryantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turbine Application Report E PDF

Turbine Application Report E PDF

Uploaded by

Febry AryantoCopyright:

Available Formats

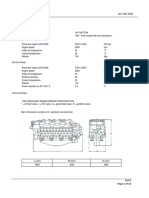

Power Station and Process Control Systems

Turbine Control System

ME 4012

Application Report

Turbine Speed and Power Control

Electronic Turbine Protection

Turbine Auxiliary Systems

Turbine Operating Modes

Process Control System: Features

Turbine Control System ME 4012

Application Report

Turbine Operation Monitoring

All rights reserved Contents Page

No part of this publication may be reproduced, stored in a retrieval Measuring Equipment Used in Turbine Operation 21

system, or transmitted in any form or any means electronic or Turbine Speed Measurement 21

mechanical, without the written permission of Helmut Mauell

Shaft Vibration Measurement 21

GmbH.

Bearing Vibration Measurement 21

Relative Expansion Measurement (Rotor/Bearing Housing) 22

Shaft Position Measurement

(Measurement of Wear and Tear on Block Bearing) 22

Introduction to Digital Turbine Control with ME 4012

Absolute Expansion Measurement 22

Contents Page

Future-Oriented Digital Turbine Control 5 Axial Thrust Measurement (if provided) 22

The Turbine Controller 6

Electronic Turbine Protection

Turbine Temperature and Power Reference Unit (TPR Unit) 6

Contents Page

Turbine Auxiliaries Control 6 Tasks of the Turbine Protection 23

Turbine Operation Monitoring 6 Possible Protection Tripping Criteria and Tripping Values

Electronic Turbine Protection 7 for Turbine Protection (acc. to VGB R-103-M)VGB R-103-M) 23

Operator Control and Plant Monitoring 7 Types of Turbine Protection 24

Turbine Protection Replacing an Existing Hydraulic Overspeed

Protection (Typical for Retrofit Projects) 24

Control Task and Control Strategy

Failsafe Protection (FS) 24

Contents Page

Speed Monitoring Modules (DW Modules) 24

The Control Strategy 8

Protection Block for Central Hydraulics 25

Turbine Controller 10 Open-Circuit Protection System (OC Turbine Protection) 26

Design of the Turbine Controller 10 Monitoring of the OC Protection System 26

Firmware with Function Blocks 11 Logic and Permutation Operations on the Turbine Trip

Digital Measurement of the Turbine Speed 12 Criteria 26

The IE2F2 Pulse Input Module 12 Trip Criteria 26

Load Shedding 13 Test Programs for the Turbine Protection System 26

Testing the DW Modules (Turbine Overspeed Monitoring) 27

Power / Pressure Controller 13

Changeover from Full-Arc to Partial-Arc Admission 13 Testing the Hydraulic Protection Block 27

In-Situ Test of the Emergency Stop and Control Valve 27

HP/IP Coordinator 14

Overspeed Test 27

HP /IP Balancing Controller 14

Electronic 2oo3 Turbine Protection with

HP Limiting Controller 14 Distributed Hydraulic 1oo2 Trip 28

Servo Drive and Control Valve 15 ANS MV Modules for Solenoid Valve Control 28

Availability and Redundancy 15 Manual Release of the Emergency Stop Function 28

ME 4012 System Cubicle Test Programs 28

Typical Layout of Functional Areas 16 Test Program "Electrical Trip Device 28

Electrohydraulic Power Actuators (E/H Transducers) 16 Test Program "Steam Valves 28

Servo Drive and Group Operation of the

Steam Admission Control Valves 16 Control Equipment of the Turbine Auxiliary Plant

Valve Position Controller 17 Contents Page

Servo Drive Turbine Auxiliary Installations 30

Principle of Operation and Hydraulic Interaction 17 Gland Steam Pressure Control 31

Gland Steam Temperature Control 31

Turbine Temperature and Power Reference Unit (TPR Unit) Controlling the Bearing Oil Temperature by means of

Contents Page Oil Flow Control 31

Controlling the Bearing Oil Temperature by means of

How the TPR Unit Influences the Turbine Controller 18

Coolant Flow Contro 31

Thermal Stresses in the Turbine 18 Control Fluid Temperature Control 32

Arithmetic Models: Thermodynamics, Shaft Temperature Condensate Level Control 32

and Stress 18

Condensate Minimum Flow Control 32

Temperature and Power Transients during On-Load Operation Modes of the HP Bypass Station (HPBS) 33

Operation 19

Start-Up Operation 33

Hardware of the TPR Unit 19 Start and Operating Connection of an HP Bypass Station 33

Signal Exchange through the SUB-NET Process Bus 20 Normal Operation with Turbine Connected 33

2 ME 4012 Turbine Control System Application Report

Example of a HP Bypass Station Pressure Characteristic 34 System Hardware of the Digital ME 4012 Turbine Control

Pilot Control of the HPBS Injection 34 System

Shutdown 34 Contents Page

Standstill 34 The AE 4012 Programmable Controller 44

Boiler Cool-Down 34 Criterion Transmitter Signal Conditioning 45

Emergency Situation 34

Analog Signal Conditioning 45

Turbine Emergency Trip 34

Interface Module AEAA8 00AF for Continuous Servo Drives 45

Overpressure Conditions 34

Isolated Operation 34 Drive Control 47

Enthalpy Control of the HPBS Outlet Temperature 34 Protection and Interlocking Logic 47

Operation of the IP/LP Bypass Stations (IPBS) 35 Signal Scan Monitoring 47

Normal Operation with the Turbine Connected 35 Process Control 48

Pressure Adjustment of the Intermediate Superheater (IS) 35 Visual/Acoustic Alarms 48

Emergency Situation 35

SUB-NET Interface 48

Pressure Stability 36

Interfacing to Third-Party Systems 48

Overpressure Conditions 36

Temperature After the IP Bypass Station (IPBS) 36 Power Controllers for Continuous Servo Drives 48

Control of the Water Shut-off Valve 36 Power Controllers for Step-Action Servo Drives 49

IP Bypass Control 36 Electro-Hydraulic Power Controller (E/H Converter) 49

HPBS/IPBS Overpressure Protection with Failsafe Control 37 Control Valves and Servo Drives 49

Principal of Operation 37 Cabling 49

Test Circuit 38 System Cubicle Layout 50

Generator Auxiliary Servo Loops 38

I/O Connections 50

Function Groups 39

Availability 39 Power Supply and Cubicle Mains Infeed 50

Plant Sections 39 Cubicle Signalling System 52

Function Groups: Principle of Operation 39 Auxiliary Supply L 52

Function Group: Condensate Extraction 39 Auxiliary Supply L- 52

Function Group: Oil Circulation and Turn Drive 40 Power Dissipation 52

Function Group: Sealing Steam Supply and Air Exhaustion 40 Ambient Conditions for System Cubicles without

Function Group: Turbine Control 40 Internal Ventilation and Forced Ventilation 52

Peripheral Interface Signal Level 52

Start-Up, Shut-Down and Load Variation of a Turbine

with Reheat Binary Signal Definition (with respect to M-potential)) 52

Contents Page Analog Signal Definition (with respect to measuring earth MZ) 52

Start-Up of the Turbo Generator Set 41 Cubicle Characteristics 52

Preparations 41 Electromagnetic Compatibility Test 53

Heating of the Turbine Housings 41 Interference Test 53

Drainage of Casings and Piping 41 Noise Emission Test 53

Sealing Steam Supply 41

EC Conformity Declaration with CE Label 53

Activation Criteria for the Emergency Trip System 41

Planning and Documentation 53

Warm-Up of Live Steam Piping and HP Valve Housings 41

Warm-Up of the Inlet Lines 42 Coherent Computer-Aided Design and Configuration

Run-Up to Nominal Speed 42 (ME-DRP) 53

Turbine Speed Acceleration 42 Factory Test 53

Load Variation 42 Installation 54

Minimum Load Connection 42 Device Designation and Labelling 54

Load Increase and Bypass Shut-Down 42 Commissioning 54

Loading after Bypass Shut-Down 43 Service and Diagnosis 54

Load Rejection 43

Minimum Permissible IS Temperatures 43

Turbo Generator Set Shut-Down 43

Load Rejection up to Control Valve Closure 43

Disconnection from the Network 43

Turbine Tripping and Deceleration 43

Turbine Cool-Down 43

Turbine Shut-Down 43

ME 4012 Turbine Control System Application Report 3

Introduction to Digital Turbine Control with ME 4012

ME-DRP project design,

documentation and diagnosis

Gateway to

plant management system

Events

Messages

ME-AIS ME-DRP

server ME-AIS server Client 1 Client n

Video printer client 1

Project

Printer server Workstation Workstation Workstation AIS-LAN database

PD-LAN computer computer computer DRP-LAN

Bridge

PD-LAN

Radio

Master computer 1 Master computer 2 clock

SUB-NET Process bus SUB-NET

Channel 1 Channel 2 Channel 3

Binary/Analog Binary

Block Turbine Turbine Turbine temp. Automated Limit values Limit values Limit values Single test Turbine Serial

Analog Drive

power speed load pressure and power function Closed-loop Analog Analog Analog Quick-action NC current link to third-

input control

coordinator controller controller controller groups control input input input stop valve test party system

Block control system

& & &

P

FD

N

_1

> _1

> _1

>

& & &

- +

f L L

2v3 2s 0 2v3 2s 0 2v3 2s 0

& & &

+

+ - + LS 01 LS 01 LS 01

F

DE n

G

K X HP MP LP G SS Turbine SS Turbine SS Turbine

HP MP/

LP ~

S

#

S #

#

~

Turbine-

M F

Hydraulic protection block shaft

2v3

G

M

TR

Quick-action stop valve Control valve

Steam generator Turbine controllers Turbine auxiliary plants Turbine monitoring Turbine no-load current protection

- Coaling, pulverization - Speed and speed master controller 1v2 Closed-loop control - Shaft oscillation - Overspeed

- Air / flue gas - Power and power master controller - Gland steam pressure control - Bearing housing oscillation - Condenser pressure Sensor and

- Coaling ( fail-safe ) -Live steam prepressure and - Gland steam temperature control - Relative expansion - Bearing oil pressure processing

- Feed -water limit pressure contol - Bearing oil temperature control - Shaft position - Tank protection 2v3,

- Superheater - Hot reheater accumulation control - Condenser level control - Absolute expansion - Generator protection

- Condensed steam - Condenser minimum quantity control - Axial thrust - Tail blade protection trip NC current

- Heat extraction control

- Long-range energy branch - HP / MP coordinator - Generator auxiliary control circuits - Shaft position 1v2

- House service - Valve positioner HP, MP/LP - HP outlet temperature

- MP bypass control with Function groups Turbine load current protection

Auxiliary plants pressure and injection control - Function group Cooling water - Dual-channel

- Flue gas desulfurization - FG Condensed steam transport - Dual-channel processing Protection monitoring No-load current

Turbine temperature and

- DeNOx, NH 3 tankage - FG Bearing oil, actuating fluid and rotary mech. - Trip criterion 1v2 - Electronic protection system

power controller (TLFG)

- Water treatment - TFD ,TZ and turbine power - FG Evacuation - Hydraulic 2v3 protection block

- Condensed steam treatment - Transient limiting - FG Blocking steam - Single test Quick-action stop valve

- Coal, lime supply - Logging and reporting - FG Bleeding Single test Quick-action stop valve - Single test Control valve

- Ashes, gypsum disposal - FG Water extraction

Block power coordinator - FG Turbine control

- Setpoint control Steam generator

- Setpoint control Turbine

Uniform and coherent digitale turbine control with ME 4012

ME 4012 system cubicle with digital turbine controller and digital

turbine protection

4 ME 4012 Turbine Control System Application Report

Power station technology has - just like all other engineering Systems development

branches - undergone an enormous technical change over the last Project planning and design

two decades. Especially in the field of steam turbines, new

developments based on the latest findings on the strength and Components and systems manufacturing

long-term behaviour of materials, on flow dynamics and on Systems assembly and on-site erection and installation

mechanical design have turned the relatively simple turbine of the

Commissioning and technical training

past into a high-tech unit. This advanced complexity in power

station technology puts an even greater demand on operational This focus on the total integration of individual ME 4012 control

safety, plant availability and the service life of the turbine. functions into a complete power station control system has yielded

an efficient and consistent control philosophy that can be applied to

With our ME 4012 process control system, we offer a digital turbine all sections of power station unit and turbine generator control.

controller that meets these strict requirements. The ME 4012

turbine controller is capable of observing each single aspect of the ME 4012 process controls are particularly suited for applications

complex turbine process, and controlling it with very high accuracy with extremely high demands on turbine control criteria, such as:

within specified ranges. Our technology is in line with the stringent Controller cycle time (e.g., for turbine speed control)

requirements laid down by the DVG guidelines, the former National

Accuracy of measurement (e.g., for frequency and speed

Association of German Electricity Network Operators, now known

measurement)

as VDN. (See http://www.vdn-berlin.de). Supervisory automated

function groups ensure optimum interaction of the individual control Safe signal and information processing for electronic turbine

processes and smoothly integrate them into the overall power protection

station scheme. This means that the turbine plant - which is after Essential parts of the ME 4012 turbine control system are:

all an installation of huge capital expenditure-, can be operated

safely and economically far into the future. Turbine controller (speed, power and live steam pressure)

Turbine Temperature and Power Reference Control Unit (TPR

For safe, reliable and efficient operation and control of the power

unit) for the calculation of temperature and power transients

stations turbogenerator set, the ME 4012 process control system

has to meet very specific requirements for its five principal Open circuit turbine protection (material vibration, expansion,

operating states: temperatures)

Start-up and synchronization Failsafe turbine protection (overspeed, generator and boiler

protection, emergency shut-off)

Loading and power generation, taking into account network

regulator and frequency influencing quantities Turbine auxiliaries (measurement, drives, HP/IP bypass station

control, function groups)

Controlled deceleration and securing station services at load

Failsafe protection for HP and IP bypass stations

shedding

Continuous self-test of open-circuit and failsafe protection

Load ramp operation systems

Shut-down Turbine control room (monitoring, operator control, message and

During turbine control, the ME 4012 process control system alarm logging)

continuously monitors the actual status of the plant so that changes Fault diagnosis, configuration and documentation at one central

can be detected. This provides information from which conclusions point

about optimum plant operation can be drawn so that necessary

Interfacing to station unit equipment via SUB-NET process bus,

adjustments can be made.

serial connection to third-party systems

The employment of leading edge turbine control technology ME 4012 provides the power station industry with a turbine control

ensures: philosophy that offers uniformity and coherence in all parts of the

Highest possible plant and operational safety control system, namely in:

Highest possible plant availability System hardware

Firmware

Minimum wear and tear on equipment

Documentation

Maximum service life of the turbine

User interfaces

Complete integration of turbine control in the supervisory plant

control system and easy operator control Consistent and efficient automation, reliable process monitoring

and convenient operator control these are characteristic ME 4012

Maximum depth of fault diagnostics and easy system features in all phases of the power station process including:

maintenance

Steam generation

Longer service intervals Turbine generator set

Auxiliary installations for plant operation and pollution control

Future-Oriented Digital Turbine Control

The concept of integrating all control aspects into one consistent

With the development of a digital turbine controller, the automation control strategy for the entire turbine plant can be applied to

and process control experts at Mauell GmbH have truly created a retrofitting projects as well as to new turbine plant developments of

first. Their creation was the result of many years experience any size and power capacity. Existing plant operation strategies

accumulated in the field of process control and the related subjects and control schemes can be transposed to new technologies and

of enhanced with new control algorithms.

ME 4012 Turbine Control System - Application Report 5

Introduction to Digital Turbine Control with ME 4012

Digital Turbine Control Concepts The Temperature and Power Reference Unit comprises:

for Retrofitting or Modernization Projects

Industrial computer

SUB-NET process bus connection through the serial interface to

Conditions Recommendations the turbine controller CPU; this connection handles all process

for future operation for future operation data acquisition and control command output

Hard disk

Life expectancy Monitor and keyboard connection (for system administration and

DVG guide lines for Availability / Reliability

plant safety Extended safety

parameter setting only)

Operation monitoring Turbine Auxiliaries Control

In addition to the automatic control of turbine speed and power, the

Primary control Turbine temperature and turbine auxiliary equipment plays an important role in ensuring

(frequency stability) power reference control unit

Secondary control (TPR unit) efficient and safe turbine operation. These auxiliaries are basically

(system characteristic control) Load limit device in charge of the following tasks:

Unit control reserve HP/IP balancing control

Overspeed protection Protection monitoring Gland steam pressure control

Fundamental protection Turbine operation monitoring

Extended protection Turbine auxiliary plant Gland steam temperature control

Control of high pressure (HP) and intermediate pressure (IP)

bypass stations

Control System Overall Concept These separate control and automation tasks are solved by stan-

dard modules of the ME 4012 process control system. They are

smoothly incorporated into the overall turbine control scheme to

provide a fully integrated control solution.

The Turbine Controller

The auxiliary system comprises the following modules and facilities:

The turbine controller is a task-oriented configuration using standard

Field units for process data acquisition

software function blocks of the ME 4012 process control system. Its

modular design allows single-channel structures for the control of Field installations and cabling

industrial turbines as well as dual-channel structures with bumpless Measured value conditioning

changeover for power station turbines. Binary signal conditioning

Functions of the turbine controller Drive control

Measured data conditioning

Closed-loop control and power actuators

Speed control

Pressure control Failsafe modules with type approval

Power control Message generation and alarm annunciation

Coordination of the HP and IP turbines

Automated function groups

Valve positioning control

Control logics Operator control, logging and reporting facilities

Message generation and alarm annunciation These control components and modules fulfil the following principal

Operator guidance tasks:

Special features of the turbine controller Closed-loop control of the turbine auxiliary servo loops

Controller cycle time 2 ms, typical Control of the auxiliary drives

Controller response time 5 ms, typical

Failsafe protection for the HP and IP bypass system

Speed signal resolution 0.5 mHz

Speed measurement accuracy 2 mHz absolute, at 50 Hz Automatic function groups to ensure controlled operation

Operator guidance

Turbine Temperature and Power Reference Unit (TPR Unit)

Operator control and plant monitoring in a central control station

The Temperature and Power Reference Unit (TPR unit) reads a

number of process quantities, such as steam pressure, steam Turbine Operation Monitoring

temperature, turbine valve positions and turbine speed, and cal- Turbine operation is monitored by the following functions:

culates thermal stress values on the basis of these input quantities. Measured value conditioning

It then compares the results with the admissible stress parameters

defined for the high pressure and temperature components of the Signal evaluation and limit value generation

turbine which are subjected to the highest strain (i.e., the turbine Display of measured values, message generation, alarm

shafts). The TPR unit controls the rate of change of the steam annunciation

temperatures (i.e., of the live steam and intermediate superheater Amongst others, the following process parameters are monitored:

steam) and the rate of change of the turbine power such that the

Shaft vibration (eddy current measurement in x and y directions)

limit strain values are never exceeded. This ensures optimized

turbine operation while at the same time taking into account Bearing vibration (seismic sensors)

thermal stress limitations associated with the turbine with the aim to Relative/absolute expansion (expansion and distance sensors)

avoid thermal stress-related fatigue and achieve the envisaged Shaft position (distance and eddy current sensors)

service life of the turbine.

As the hardware of the TPR unit is installed in the turbine controller Axial thrust (evaluation of strain gauges)

cubicle and directly connected to the process bus, it is optimally

integrated in the overall control strategy of turbine operation.

6 ME 4012 Turbine Control System - Application Report

Electronic Turbine Protection

The electronic turbine protection system monitors all process Emergency Stop, HP outlet temperature

criteria that may cause damage to human life or plant equipment. Extended protection

Turbine operation is interrupted as soon as one of the critical Shaft vibration, relative expansion, bearing temperatures, exhaust

values is found to be out of the permissible range. For best steam temperatures, temperature differences between HP and IP

meeting the stringent demands on turbine reliability and availability, turbine casings

the protection criteria are grouped according to the guidelines

All signal processing is protected by a safe and available 2oo3-type

issued by the German VGB PowerTech Association (Guidelines

protection scheme (i.e., 2-out-of-3 reliability). In this scheme, the

VGB-R103-M "Supervision, Limiting and Protection Devices in

trip criteria of the basic protection level and those of the extended

Steam Turbine Units, see http://www.vgb.org). Protective tripping

protection level (i.e., the signals generated by the failsafe

acts onto all shut-off and control valves as well as onto all

overspeed protection module) are logically linked with the trip

controlled stop valves (i.e. non-return valves).

signals generated by the overspeed relays. In retrofitting or

Electronic turbine protection is structured into the following modernization projects, a 2oo3-type hydraulic block is installed. It

protection groups: has the purpose of converting the electronic signals into a hydraulic

Overspeed protection, 3 channels control signal which controls the spring-powered shut-off and

Limit value generation and signal logics control valves. In newly built installations, it is more economical to

use 2oo3-type power electronics to directly control the bypass

Failsafe trip signal generation (i.e., the trip relay is energized

solenoid valves (2 channels for each shut-off and control valve). A

under normal conditions and de-energizes upon alarm or upon

test program allows channel-by-channel online testing of the entire

loss of power)

failsafe protection scheme, inclusive of the trip action for the shut-

Online test facilities for all protection components off and control valves. The test covers both the electrical and

These facilities fulfil the following tasks: hydraulic operation and can be carried out at any time without

Overspeed protection affecting running turbine operation.

Basic protection Operator Control and Plant Monitoring

Bearing oil and condensate pressure, shaft position, LP end blade One of two different approaches can be adopted for operating and

protection, boiler protection, generator protection, monitoring the digital turbine control system:

1. Use of the Mauell-T-LT

system, employed as an

autonomous ME 4012 process

control system with serial

connections to the third-party

supervisory unit control system.

2. Use of the Mauell-T-LT

ME-VIEW Diagnosis system, employed as an

ME-DRP integral part of the supervisory

server Client unit control system.

Project

database The integrated approach offers

DRP-LAN a number of advantages over

Bridge

the autonomous ME 4012

control system such as:

SUB-NET

Identical configuration methods

and tools throughout the

system

Steam generator

Unit control Turbine protect. Automated Process data Identical plant documentation

control system function groups acqu. monitoring

T-control

Consistent alarm and

Turbine protect. Closed-loop Process data message processing, alarm

HP/IP bypass control acqu. monitoring

control logging and reporting

TPR HP/IP Drive Process data Identical graphical user

bypass control acqu. monitoring

protection interface and operator control

Turbine protect. Signal Process data concept

Power section conditioning acqu. monitoring

System configuration and fault

Monitoring Monitoring Monitoring Monitoring Monitoring diagnosis at a central point

Infeed Infeed Infeed Infeed Infeed The use of a local ME-VIEW

operator station is a cost-

effective solution for on-site

operator control and plant

monitoring.

Overview of the hardware of the ME 4012 control system for steam turbogenerators

ME 4012 Turbine Control System - Application Report 7

Control Task and Control Strategy

The success of digital control of steam turbines in the 9 to 600 MW In our example, the steam generator is controlled by a power

range is based upon standard components of the ME 4012 controller which is capable of providing the required transfer power

process control system. The automatic controller of the ME 4012 of the unit at a sufficient precision. U.S. technical literature refers to

system can be installed in new turbine installations as well as in this type of control for power station units as "turbine follow mode.

retrofit projects. To date, for the control of drum-type boilers, turbine follow mode is

Principally, the turbine is controlled by the quantity of live steam fed applied much more frequently than the better known "boiler follow

to the HP turbine. If the turbine is of the intermediate superheating mode usually applied in the control of forced flow-through boilers

type, then control also considers the quantity of the superheated (also known as Benson boilers).

steam fed to the intermediate and low-pressure parts. Servo- Today, digital process control systems such as ME 4012 allow us

hydraulic actuator drives implement the control action. to implement the simulations of fairly complex controlled systems

The closed-loop control strategy described in this application report and elaborate control algorithms. This method yields the required

has been applied to a condensing turbine with superheating. It maximum dynamic response while at the same time reducing the

runs on the ME 4012 process control system and uses ME 4012 strain on the high-pressure power station components. Such

standard function blocks as well as function blocks specifically implementations could for instance be the import and export

developed for highly dynamic processes. The completed processes that may be caused by fluctuations in the grid frequency,

configuration of the software controller and the turbine controller or that may even be desirable in the event of scheduled load

hardware can be tested on a unit simulation device. The ME 4012 changes. In addition, digital control allows selective intervention

controller also allows automatic control of other turbine types, such and adjustment of turbine valves in the event of fuel problems in

as back-pressure turbines, bleeding turbines, tapped back-pressure order to restore process stability.

turbines, condensing turbines and tapped condensing turbines. During the start-up phase of the steam generator and turbine units

The multi-variable control rule is always designed according to the -which is the initial non-coordinated operating phase- a start-up

German VDI/VDE guidelines,

no. 3521, sheet 3. Power setpoint

DE/Turbine E PTx PTx

+ X

DE -

The Control Strategy TLFG

Load capability

"FFD "

Of course we cannot look at the Unit KL Turbine PTx

gradient

[MWE /min] IP/LP

turbine as an isolated self- MIN

content

p +

contained entity. On the SWF E -

X

[MW ]

contrary, a turbine set must be E Unit PTx

Frequency stability: model + +

considered as only one Primary control

component of the technological D Condensate build-up + [MWE ]

control + -

process of a power station and + + + -

+

as such it forms an integral part [MWE ] p

Tu

C X

of the overall dynamic process [MW]

consisting of the steam n

generator and the steam +

+

-+

turbine, each with their auxiliary PSWF Speed/

"PFD SW"

"M "

HPBS power control

plant. [MW] PTx

BrnSt

PTx

[bar]

Turbine

+ + +

[t/h] -

Now, let us have a closer look X

DE model "F " [t/h]

at a control strategy that FD

produces optimum dynamic Load control

Steam generator

results of the entire process, - -

H E

both at sliding and constant PFD

-

P G

-

H

G

-

-

E

pressure operation. The

approach described in the G

following also allows the n

optional change to pre-pressure

control which is required when Reference: BAG, KW Pleinting Block 1, 300MW

the pressure must be kept

constant at a precise value.

Valve position control offers the Unit load and power control with modelling for steam generator and turbine

additional benefit of allowing regulator controls fuelling in order to run the steam generator up to

selection of specific valve points, which is required particularly for the required start-up power. At the same time, the turbine set is

turbines with stage valves or for constant-pressure controlled warmed up and run up to its nominal speed, and the start-up

turbines equipped with a regulating wheel. Reduced wear and tear control of the HP/IP bypass system ensures the superheater

and improved heat consumption are the main advantages of this through-flow required for boiler start-up.

control method. However, if this way of setting the valve points

goes hand in hand with the admission of a pre-pressure or power

controller, then this would inevitably lead to instabilities.

8 ME 4012 Turbine Control System - Application Report

After grid synchronization, the Short designations/symbols:

generator is started under load From/to unit control EHU - Electro-hydraulic converter

f - Frequency

N - Correction

pV / p GV - Pre-pressure/pre-pressure limit diff. value

by applying a target power 4 3 1 PG Soll 2 PFD Soll h - Position

n - Speed

PG - Generator active power

PG Soll - Generator setpoint power

n - Overspeed differential value

value to the setpoint transmitter - Control loop/signal generation,

- Transducer - processing

of the unit coordinator. As a PV

+

- Setpoint

+

result, the base power value in f PG

-

-

+

-

the coordinator changes in line PGV

+

+

MAX

with a permissible transient PG2 PG1

value generated at the transient n

selection point until finally the N N

+

+

n

predefined target power is PG

#

PG/V N

+ 0 n M I N

# 2

reached. -

MAX

n

1 +

W

- -

+

This transient selection restricts Start/

n - -

Stop # dn/dt

the preselected power transient Operation

-

+ +

-

by applying external influencing +

h h

quantities, such as the

permissible steam generator

and turbine transients. The M I N p

- - EHU FD

turbine transient is calculated by +

+

h

- f

the Temperature and Power PG2

Reference Unit (TPR unit) on +

- EHU

n1 n2

PG1

the basis of the stresses - +

-

h

HP IP/LP G

measured in the HP and IP

turbine rotors. If the power

setpoint of the unit exceeds the

volume of the start-up fire during Turbine speed and power control

start-up under load, then the HP

At the same time, the dynamic part of the setpoint power derived

bypass unit closes and the power between steam generator and

from the frequency deviation is fed through a steam generation

turbine continues to rise in a coordinated manner. Now, this has

model and added to the output of the steam generator observer

the effect of changing the power setpoint for the turbine on the

whose only purpose is to process the changes of the base power

basis of an observer model in line with the dynamical behaviour of

value of the unit. In this way, the pressure setpoint necessary for

the steam generation process in the steam generator.

the current operational status is calculated.

The load controller responsible for fuel control receives the

In the event of fluctuations in the grid frequency, the turbogenerator

controlled variable _p. The control valve of the HP turbine and the

set contributes to the restoration of frequency stability by means of

power controller of the turbine (using two transducers for the

primary control. The frequency deviation is fed to the turbine

generator power) compare the actual power derived from the

controller such that there is a linear relationship between the actual

steam generator observer with the generator power. For load

power and the frequency. If the grid frequency and, as a result, the

ramps that are in line with the schedule there is no deviation,

turbine speed increase, the controller throttles the valve and

unless the comparison of a boiler model with a boiler observer has

consequently reduces the generator power. Should the grid

produced a difference. Such a difference could lead to the

frequency fall, the generator reacts by producing a higher output

conclusion that there is a deviation in the calorific value of the fuel.

value than is set by the normal setpoint. The amount of

In this case the power controller follows up.

contribution to frequency stability provided by the turbogenerator

If the accumulated steam of the live steam system is to be utilized

set depends on the slope of the frequency-power characteristics

for scheduled load ramps, the turbine governor valves can be pilot

which can be set as proportional gradient.

controlled accordingly. However, a live steam accumulation model

placed at the comparator of the boiler load controller compensates This control strategy is thus based on the principle that the load

for the excess power that is dynamically generated by the live controller which affects fuelling will only take action upon an actual

steam released from the live steam accumulator. The result is change in the calorific value of the fuel, whereas changes due to

merely an offset of the power release; later -at steady state dynamic processes in the network do not cause any change in the

operation- there will be no need for larger quantities of fuel. error signal of the power controller. To avoid the so-called "wrong

control effect it is therefore not necessary to replace the electrical

The behaviour of the frequency influence required for maintaining

power and instead calculate, say, the mechanical power of the

network stability is similar. Therefore, the frequency influence which

turbogenerator set which must typically be obtained as wheel

can be suppressed in some load situations (e.g., low load), is

chamber pressure for constant pressure machines with wheel

added to the unit setpoint and fed to the boiler and turbine units,

regulator, or by means of complex algorithms that compute the

directly and without delay. In this process, the utilization of

thermo-dynamical parameters.

accumulated live steam is desirable and enhances network

stability. However, in those phases in which steam production has

not yet reached the new power setpoint (derived from unit setpoint

and frequency influence) due to the slower dynamic response of

the steam generator, the effect of the frequency influence upon the

deviation of the live steam pressure can be limited such that no

unwanted operational states occur.

ME 4012 Turbine Control System - Application Report 9

Design of the Turbine Controller

Turbine Controller Design of the Turbine Controller

The digital turbine controller is an integral part of the overall power The turbine controller comprises the following components:

station process. It complies with the DVG regulations Power supply (decentralized arrangement; installed on each

(DVG=German Association of the Transmission System Operators) processor module)

for feedforward control with bumpless changeover involving the

output signals of the power, speed and limit power controllers. Speed controller and speed master controller

Due to its high processing speed for analog process values, the Power controller and power master controller (if not part of the unit

multifunctional processor is used in turbine control for the control system)

implementation of complex control loop structures and arithmetic Pre-pressure controller

functions. Limit pressure controller

The extensive ME 4012 firmware library assists the process Accelerometer for RPM measurement (with two speed

engineer in configuring the structures of the control tasks and measurement channels and maximum value selection)

transferring the configuration to the controller module. Dedicated

function blocks, specifically developed for the control of power Pulse preamplifier for every RPM sensor at the turbine, with 3

station processes, execute the complex control and arithmetic decoupled output channels each

functions required for turbine control at extremely high speeds. HP/IP preset potentiometer

Integrated analog and binary functions allow the logical

Load limit device (HP turbine)

interconnection of the turbine controller with the sequential control

programs for turbine start-up, running up under load and shut- Bumpless changeover from full-arc to partial-arc admission

down. The controller is part of the redundant SUB-NET process Valve position controller for the HP and IP control valves with

bus system and fully integrated in the functional structures of the cascaded voter circuit for the construction of redundant turbine

steam generator. controllers with bumpless changeover (1v2 configuration) to the

The turbine controller is of modular design and made up of other functioning I/O channel

standard modules of the ME 4012 process control system. Test device for turbine controller (option)

Principally, it consists of a subprocessor module for information

The turbine controller is capable of driving each valve separately.

processing and of interface modules that handle the process

This means, it can control the HP valves sequentially or in parallel

signals coming from the plant I/O equipment. In addition, special

mode, and in any random combination. The controllers highly

control modules drive subordinated highly dynamic servo valves.

sensitive position control for the admission valves ensures an

The control strategy is based on the principle that each admission

extremely efficient and accurate transfer of the control dynamics to

valve has its own servo drive. This concept allows easy controller

the actuating units.

adjustment to different configurations of the plant I/O equipment.

The turbine controller is divided into two function sections:

The turbine controller can be employed in a single-channel or dual-

channel master/slave arrangement with bumpless changeover. Speed control with integrated valve position control

Its typical cycle time of less than 2 ms, its speed measurement Power control / pre-pressure control

accuracy of +/- 2 mHz (which corresponds to 0.004% approx.) at

nominal speed, and its high signal resolution of 0.5 mHz make it

Additional functions can be implemented, such as:

the ideal controller for the following tasks:

Unit power control

Maintaining frequency stability

Speed / bleed pressure control

Attenuation of phase swinging and grid instabilities

Speed / back pressure control

Logical combination (summation) of the power limiting controller

and the speed controller Speed / pre-pressure control

Safe turbogenerator recovery maintaining unit service load in the Bleed pressure / back pressure control

event of disconnection from the grid Bleed pressure / pre-pressure control

Safe turbogenerator recovery at a selectable part load above the Back pressure / pre-pressure control

service load criterion

Safe response to grid faults of any kind

Deviation control and stabilization after jerky load changes of up

to 10 % approx. of rated power during isolated operation keeping

frequency deviations below 1 Hz.

High sensibility of the speed governor for fast response to the

slightest frequency changes during isolated operation

10 ME 4012 Turbine Control System - Application Report

One part of the controller is reserved for time-critical functions. It is The base speed controller has a special operating system which

configured as a speed controller and fulfils the following tasks: ensures a typical arithmetic cycle time of less than 2 milliseconds

Speed measurement for all functions required for speed control.

Speed setpoint master The electrohydraulic transducers with integrated jitter voltage

generation ensure highest precision in the control of servo control

Acceleration measurement valves. Their power amplifiers are driven by standard 4 to 20 mA

Feedforwarding of additive and multiplicative correction signals to signals.

the controller output YDR All other functional sections of the turbine controller are in charge of

Acquisition and processing of binary signals which are required as the following tasks:

starting condition for the speed setpoint master controller. Power control, taking into account frequency influences

Manual/automatic sequence control logics Pre-pressure control

Alarm acquisition and signalling Limit pressure control

Limit value processing and event time stamping HP/IP balancing

Setpoint transfer to the integrated HP and IP valve position The turbine controller is available in redundant master/slave

actuators (also referred to as valve positioners) for the following configuration with hot standby for high availability.

tasks:

Reliable I/O signal processing is a particularly important factor for

Actuator control for each servo drive without steady state error the availability of the overall turbine controller system. Special

Position feedback with load independent current and normalization emphasis has therefore been placed on the development of I/O

of rising or falling characteristics modules with robust electronic characteristics that meet the high

requirements in power station operation. For detailed specifications

Selection of setpoint position by means of selectable max/min

of the modules employed in the described turbine control project,

selection

please refer to chapter "System Hardware of the Digital ME 4012

Linearization of the valve characteristics Turbine Control System at the end of this application report.

Bumpless change of the operating mode of several parallel-driven However, the acquisition and processing of speed values will be

servo drives (full-arc/partial-arc admission) explained in more detail on the next pages as speed control in

particular puts a fairly high demand on input signal processing.

Valve check with selectable closing speed

Control of electrohydraulic transducers with load independent Firmware with Function Blocks

current ( 4 to 20 mA)

The configuration that implements the turbine control system was

High-speed closing via cascaded intrinsically controlled cartridge programmed with the aid of function macros offered by the ME

valves 4012 firmware library.

Position measurement monitoring The process control engineer responsible for the turbine control

Alarm signalling and annunciation strategy may decide to divide the controller into a slow and a fast

acting function.

Functional section for time-critical tasks (faster than 5 ms).

This functional section is

Turbine controller (B)

Slave (option)

reserved for the control

Turbine controller (A) algorithms of the turbine speed

Master control and of the individual

Non-time critical valve positioners.

function areas

<20ms Functional section for

Automated function groups Option

Power control

standard tasks.

Power controller This functional section

Frequency influence

Closed-loop control

HP/IP balancing controller contains all the other control

Pressure controller Turbine protection

- Steam generator HP outlet load limit device N/C current

tasks, including the turbine

- Network Turbine protection system (TS) (2 oo 3) protection system.

Operating current 2 oo 3

TS test units

2 oo 3

All configuration work and

parameter setting can be done

Time-critical

function areas during online operation.

< 5 ms Developing and expanding the

Speed control Pulse

Speed controller pre-amplifier configuration has no noticeable

Acceleration measurement and

Valve position controller decoupling

effect upon the cycle time of the

fast-acting controller section.

Voter

Master / Slave The possibility of carrying out all

E / H converter E / H converter G configuration work and

Servomotor Servomotor parameter setting during online

operation is of considerable

importance for the different

Shut-off valve Control valve

phases of commissioning, test

Master/slave turbine speed and power controller with functional sections for time-critical and slow runs and process optimization.

control tasks

ME 4012 Turbine Control System - Application Report 11

Design of the Turbine Controller

Digital Measurement of the

Turbine Speed Pulse pre-amplifier Turbine

overspeed

The turbine is equipped with a protection 2oo3

trigger wheel for speed Channel 1

2oo3

measurement. The trigger &

Turbine

wheels teeth are scanned by Channel 2

three separate magnetic pulse shaft

DW channel 1

generators. The resulting Channel 3 DW channel 2 Shut-

off valve

DW channel 3

signals are amplified directly at

Reserve

the point of scanning and then detector IE2 FZ

transmitted in the form of 24V Turbine

square pulses to the turbine speed measurement

1oo2

controller via screened cables.

The frequency at nominal speed Digital speed measurement : I/O bus

is approximately 10 kHz.

Accuracy : 0.004 % = +/- 2mHz at 50Hz netw. frequency

Supply, protection and

SUB-NET

Signal resolution : 0.5 mHz Speed and

monitoring of the ISV3 power controller

preamplifiers installed in the Signal scan cycle : 5 ms

vicinity of the machine are Measuring range : 3 min-1

provided by the protected power Long-term and temperature stability due to digital acquisition and processing

supply of the turbine controller

cubicle. The three pulse

generator signal trains are Pulse signal acquisition with sensor /pulse pre-amplifier (three-channel, decoupled outputs) and signal

decoupled and sent to the conditioning for the areas turbine protection and turbine speed control

turbine controller, to the turbine

protection facilities and to the independent turbine speed

measurement facility, respectively..

To ensure safe pulse signals, every pulse generator is monitored

for device faults and wire-break in the signal lines. The pulse

The IE2F2 Pulse Input Module inputs are electrically isolated to prevent potential carry-over.

To obtain the turbine speed, the pulse trains produced by the three

The pulse input module is supplied by two separate d.c. voltage

magnetic pulse generators are processed by a module that has

transducers which ensure an electrically isolated power supply for

special redundant pulse input channels. Should one of the speed

the two independent input channels. Due to the high measuring

transmitters fail, a MAX selection logic in the turbine controller

accuracy of the pulse input modules, the turbine speed controller

ensures that the maximum value of each pulse signal train is read

can also be used for frequency stability operation.

and passed on for further processing.

Efficient turbine speed control requires high-precision acquisition of To ensure fast and accurate conversion of the pulse signals into

the turbine RPM value. To ensure that the signals of the pulse speed signals, the pulse input module is connected to the speed

generators reach the IE2F2 input module safely and free of noise, controller module through the I/O bus.

the signals are transmitted by screened cables at a signal level of

The speed controller compares the input signals of the pulse

24V +/- 20%. The input channels of the IE2F2 module are

transmitters with the specified setpoint and calculates the

designed for pulse frequencies in the range from 2 Hz to 500 kHz.

command signal for the actuators of the HP and IP control valves.

At nominal turbine speed the frequency is about 10 kHz. The

The control of the cascaded servo drives is based on the principle

pulses are evaluated by a gating circuit which adjusts to the RPM

that the servo valve modulates the differential pressure at a follow-

value. Thus, if for instance the turbine speed is low, the speed is

up piston unit (which is the main slide valve of the servo drive)

not measured by counting the scanned trigger wheel teeth in a

according to the control error of the actuator. The proportional

specified period, but by letting a quartz-stabilised oscillator obtain

gradient which is typically set to 8% is continuously adjustable in

the time between two leading tooth edges. To compensate for

the wide range from 2% to 11%.

possible mechanical inaccuracies, this procedure is carried out

over several tooth edges depending on the RPM value. For low The start-up unit of the speed controller controls turbine

turbine speeds, but particularly for very high turbine speeds, this acceleration from slewing gear mode to nominal speed. A speed

procedure ensures a digital and very accurate speed measurement master controller modifies the speed setpoint in line with a set fixed

on the basis of the number of teeth of the trigger wheel. transient value until finally the selectable target speed is reached.

The absolute accuracy of this type of speed measurement is +/- The speed controller obtains the difference between the speed

4 which corresponds to 2.0 mHz at 50 Hz nominal frequency. setpoint value and the speed actual value and provides at its output

The accuracy of the quartz-stabilised time base is 15 . The the command signal to the HP and IP control valves.

resolution of the speed measurement is as high as 0.5 mHz.

12 ME 4012 Turbine Control System - Application Report

Load Shedding Maximum turbine and unit power values can be defined by

During load shedding it is desirable to keep speed overshooting as specifying a power limit value. For efficient power limiting, the

low as possible. To maintain a sufficient distance to the emergency power limit value is integrated in the load capability unit and thus

shut-off speed even at full-load turbine stop, an accelerometer acts as the upper limit for both the steam generator and the turbine.

monitors the dh/dt ratio of the turbine shaft. If the dh/dt ratio The limit pressure controller throttles the turbine admission valves

exceeds a selectable limit value, a signal is generated that as soon as the live steam pressure has dropped below its setpoint

intervenes in the position control loop of the servo drives such that by a specified amount. Should the live steam pressure continue to

the control valves are closed quickly. fall, the limit pressure controller demands a power reduction that is

The steady state control error xw depends on the specified proportional to the pressure drop.

proportional-action control component, as follows: A live steam pressure controller is provided for the case that the

turbine is put in charge of live steam pressure control, i.e. the

xp 4 to 6% approximately. "turbine follows boiler mode is applied. The live steam pressure

xw max. depends on various influencing quantities, such as: controller is a PID controller. It must be provided with the required

Specified proportional-action range live steam pressure signal from an external source. A changeover

from power control (provided that this is part of the turbine control

Live steam pressure

scheme) to live steam pressure control can be done during running

Residual load at isolated operation turbine operation. When power control is enabled, the actuating

Response of the control valves (100% seating stroke < 200 msec) variable of the live steam pressure controller is feedforwarded.

and of enclosed steam volumes which is +5% to 8% max. (This Vice versa, when live steam pressure control is enabled, it is the

corresponds to +150 to +240 min-1). actuating variable of the power controller that is feedforwarded.

This method ensures a smooth changeover from one control mode

to the other.

Power / Pressure Controller

A power master controller reads the target power value issued by Changeover from Full-Arc to Partial-Arc Admission

the unit control and converts it to a power base value to which the A turbine equipped with a regulating wheel must be warmed up

frequency influence (which can also be disabled) is added. The and run up to speed with as little wear and strain as possible. For

power controller applies a PI control algorithm to the control this purpose, a changeover sequence control can be activated that

deviation, calculated from the frequency-dependent power setpoint controls the order in which the control valves are opened. At any

and the actual power value. The actuating variable of the speed point of turbine operation, this changeover sequence control allows

controller is then added to the control output of the power controller. a smooth change from full-arc admission (i.e., parallel opening of

This control principle complies with the recommendations of the valves) to partial-arc admission (i.e. sequential opening of valves),

DVG, the National Association of the German Electricity Network and vice versa. The changeover logic ensures that the sum of all

Operators. The role of the power controller within the turbine steam volumes going through the control valves remains constant

control system depends on the unit control strategy selected. The during the changeover process irrespective of the changeover

base control loops of the system are enhanced by feedforwarding signal, and thus prevents additional thermal rotor voltages.

additional control quantities.

Turbine behaviour at start-up and load operation and load shedding

1

min

Overspeed protection triggering (emergency tripping)

3300 dn

= 300 U/s =Turbine running time constant

dt

3240

3150

Load connection, Dxd

Target speed load operation on network Max. = 5-7% Dxw

3000

10 rpm 350-500 ms Steady-state deviation

2990 10s dn Synchronization phase w.r.t. depending on load and

dt power frequency proportional band

(Xp = 4-6%, V = 16-25)

Load shedding

600 rpm

dn

1 min dt

Turndrive operation

40

5 min 10s

(PI control response) (P control response) t

min

Turbine behaviour at load shedding

ME 4012 Turbine Control System - Application Report 13

Design of the Turbine Controller

Turbine controller B

Turbine controller A

Power control

Power controller Pre-pressure controller Limit pressure controller

SUB-NET

(Opening setpoint)

Speed

control

n1 (n2) IS

Acceleration HP/IP HP limiting

Speed limit pressure

n2 (n3) meter balancing controller

controller controller

controller

HP/IP coordinator

HP valve IP valve

position controller position controller

IS

n 1 n 2 n3

HP IP G

IS = Intermediate superheater

HP/IP Coordinator During turbine reloading, following such no-load or low-load

The actuating variables (i.e., the outputs) of the turbine controller phases, the HP limiting controller controls the opening of the control

correspond to the mass flow required by the HP and IP turbine valves and, as a result, the power input to the HP turbine, always

units. However, the final distribution of this mass is coordinated by keeping an eye on the flange temperature at the HP outlet, in order

the HP/ID coordinator module. It coordinates the opening strokes to prevent thermal overloads at this point of the turbogenerator.

of the valves for two purposes: to prevent overstepping thermal The aim is to keep the difference between the steam temperature

limit values, and to achieve the fastest possible turbo generator and the flange temperature, measured at the centre line, below

start-up and loading by shifting the steam mass flows as needed. 60 K.

HP /IP Balancing Controller Therefore, the HP limiting controller redirects the steam flows from

During start-up and no-load turbine operation, two contradicting the HP turbine to the IP/LP turbines in order to ensure that the

tasks must be accomplished: First, there must be sufficient cooling specified cooling transient of the HP outlet is not exceeded. This is

steam for the end blades of the LP turbine. Yet, at the same time, to prevent the worst case from happening which would be the

the outlet temperature of the HP turbine must not exceed the distortion of the joint. Should during this control process the

permissible value. A balancing controller solves this problem. It pressure of the intermediate superheater (IS) drop below its

increases the steam flow allocated to the HP turbine as soon as the minimum limit, the IS limit pressure controller sees to it that the IP

outlet temperature exceeds a specific value which is a function of valves are not opened any further.

the live steam temperature. At cold start-up, when the turbine The allocation of the two valve groups for the HP and the IP turbine

casing temperature is below 100 C, and after grid synchronization, section can be adjusted. In normal situations, the static charac-

the steam flow to the IP turbine is increased at a slow transient teristics show that the actuating variable for the mass flow of the IP

value to about 10% of the nominal steam volume. valves changes proportionally with the actuating variable for the

HP Limiting Controller mass flow of the HP valves. Dividing these actuating variables by

the live steam setpoint (or by the intermediate superheater

In high-capacity steam turbines, the problems that arise at no-load pressure setpoint) produces a constant operational controller gain

and off-peak operation are due to the fact that in those situations in all operating states. The actuating variable obtained by this

the HP turbine requires only very low volumetric flow rates. This calculation then passes through a linearization circuit, of which

may lead to blading windage in the turbine end stages and, as a there is one for every control valve and its associated servo drive.

result, to power losses in form of heat given off to the outside. This circuit linearizes the heavily non-linear flow rate response of

The HP limiting controller has the task of counteracting these the control valves. After having been smoothed out, the actuating

effects. It is active in the following situations: signals reach the valve position controllers where they are

Turbine loading after a longer stretch of no-load operation converted into hydraulic signals by the E/H transducers of the

Turbine reloading after load disconnection hydraulic servo drives.

Turbine reloading after off-peak operation and isolated operation

14 ME 4012 Turbine Control System - Application Report

Rapid closing in the event of turbine tripping is driven by a

FD HDA

cartridge-type valve. It connects the control valve servo drive with

Speed Power Pre-pressure HDA central protection pulse hydraulic fluid (Pi) and ensures controlled

controller controller controller f(x) NI

rapid valve closing.

p Z

Balancing However, safety is principally ensured by the turbine shut-off valves

controller

C

specifically installed for this purpose.

Intermediate For rapid closing operations due to load shedding (also referred to

superheater as load rejection) or turbine tripping, the servo drive piston and the

+ + limit pressure

controller connected control valve jackscrew reach maximum closing speed.

To prevent the valve plug from hitting the valve seat at high speed

+- - + ++

C

at the end of the closing movement, the piston enters a damping

C C chamber containing hydraulic fluid, which softens the impact. The

p FD pZ impact speed can be adjusted by means of a throttle. The control

fluid line to the servo drive is connected to bottom part of the servo

+ drive. As the servo drive is mounted horizontally, feeding the

-

control fluid from below ensures that no hydraulic fluid lines run in

the vicinity of turbine admission components and hence near hot

steam pipes. For additional safety, the pressure oil lines that run

IP valve through free spaces are embedded in guarded pipes to prevent oil

HP valve leakages to the outside which could cause oil fires. Flexible tubing

position controller position controller

for the feeder lines to the servo drives ensures sufficient flexibility

inside the valve unit.

nnn

1 2 3

Availability and Redundancy

HP IP G

To achieve the highest possible degree of availability of the turbine

controller modules, the overall control concept was given a

distributed redundant structure. The following design features were

put in place to meet these requirements:

Servo Drive and Control Valve Redundant inputs for speed measurement for every controller, i.e.

for master and for slave (1v4)

The admission control valves are single-seat valves with a pilot

plug for pressure relief when opening. They regulate the steam Independent hardware inputs for analog signal conditioning with

flow to the turbine by reducing and increasing the free space single fusing (1v2)

between the valve plug and the valve seat. Electronic modules, system cabling and control cubicles of high-

Every control valve has its own servo drive. This servo drive quality design and construction

receives its control commands through a servo valve which is Supply voltage rating for switchgear according to highest safety