Professional Documents

Culture Documents

Dimecote 9 Inorganic Zinc Silicate Coating

Dimecote 9 Inorganic Zinc Silicate Coating

Uploaded by

abdulgafoor54Copyright:

Available Formats

You might also like

- Cen-Tr 16999-2019Document75 pagesCen-Tr 16999-2019Muhammed Hasan GüçlüNo ratings yet

- Bus. Fin. WEEk 5-6Document14 pagesBus. Fin. WEEk 5-6Jessa Gallardo100% (1)

- Carboline Carboguard 890 PDSDocument2 pagesCarboline Carboguard 890 PDSSamNo ratings yet

- SSPC - Paint 41 PDFDocument5 pagesSSPC - Paint 41 PDFIvanSanchez100% (1)

- Amercoat 68hs - Ingles 2015Document6 pagesAmercoat 68hs - Ingles 2015Peter CallánNo ratings yet

- The Industrial Coatings MarketDocument5 pagesThe Industrial Coatings MarketjagrititanuNo ratings yet

- Amercoat 56E Polyamide Epoxy High Solids Tank LiningDocument4 pagesAmercoat 56E Polyamide Epoxy High Solids Tank LiningMuhammad MustahsinNo ratings yet

- Painting Inspection Report Final CoatDocument3 pagesPainting Inspection Report Final Coatabdulgafoor54100% (1)

- A Quantum Explanation of Sheldrakes Morphic Resonance by A GoswamiRupert SheldrakeDocument13 pagesA Quantum Explanation of Sheldrakes Morphic Resonance by A GoswamiRupert SheldrakeDavid Jaramillo KlinkertNo ratings yet

- SES Amercoat Dimetcote 9Document4 pagesSES Amercoat Dimetcote 9kamalkashNo ratings yet

- AI Hempel's Galvosil 15700 EnglishDocument7 pagesAI Hempel's Galvosil 15700 EnglishvitharvanNo ratings yet

- Sigmaprime 700Document7 pagesSigmaprime 700Trịnh Minh KhoaNo ratings yet

- Interseal 670HS BR Eng PDFDocument2 pagesInterseal 670HS BR Eng PDFandreaju2013No ratings yet

- 7570 SigmaZinc 170 Sigmazinc 9 (January 2014)Document6 pages7570 SigmaZinc 170 Sigmazinc 9 (January 2014)Akhtar AnsariNo ratings yet

- AAA Passivation MethodsDocument7 pagesAAA Passivation Methodsdianita nurnandaNo ratings yet

- Hempadur Avantguard 750 1736g - Product DatasheetDocument2 pagesHempadur Avantguard 750 1736g - Product DatasheetWisnu Wardhana0% (1)

- Surface Prep StandardsDocument2 pagesSurface Prep StandardsAnonymous 5mN1tLMNo ratings yet

- ASTM D 1186 Pelicula SecaDocument3 pagesASTM D 1186 Pelicula SecaFelipe montana100% (1)

- Requisitos de PinturaDocument4 pagesRequisitos de PinturaPablo Hidalgo ValenzuelaNo ratings yet

- 1411 - Explanation To Product Data SheetsDocument0 pages1411 - Explanation To Product Data SheetseraswastaNo ratings yet

- Schedule For Sand BlastingDocument2 pagesSchedule For Sand BlastingPratik GurungNo ratings yet

- Ventilation and Dehumidification of Ship Ballast Tanks For Blasting and Coating WorkDocument10 pagesVentilation and Dehumidification of Ship Ballast Tanks For Blasting and Coating WorkMehman Nasibov100% (1)

- SSPC SP-16 (2010) - Brush-Off Blast CleaningDocument13 pagesSSPC SP-16 (2010) - Brush-Off Blast CleaningPubcrawlNo ratings yet

- Flash Rust Formed After WaterjettingDocument12 pagesFlash Rust Formed After WaterjettingPedro Michell Rodriguez PerezNo ratings yet

- Sae Spec For Steel Shot & GritDocument3 pagesSae Spec For Steel Shot & Gritsanoopvk100% (1)

- Apcodur CF 699: Product DescriptionDocument4 pagesApcodur CF 699: Product DescriptionShravana PrasadNo ratings yet

- Coatings Bro PDFDocument8 pagesCoatings Bro PDFMBastawyNo ratings yet

- API 6A Licensing Information Form 20190510Document1 pageAPI 6A Licensing Information Form 20190510Guillermo Aponte RiañoNo ratings yet

- 1.2.4 HDG - Painting Issues PDFDocument2 pages1.2.4 HDG - Painting Issues PDFAnonymous 1AAjd0No ratings yet

- Paint Specification No.: SSPC: The Society For Protective CoatingsDocument5 pagesPaint Specification No.: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- SSPC Qp1 Application, Instructions, and Program RulesDocument21 pagesSSPC Qp1 Application, Instructions, and Program RulesRejoy BabyNo ratings yet

- Hempel Product Data SheetDocument6 pagesHempel Product Data SheetHendri Arief SetyawanNo ratings yet

- Control of The Mat Gloss BalanceDocument3 pagesControl of The Mat Gloss Balancejulio100% (1)

- Sigmacover 380Document18 pagesSigmacover 380eitan-dalia4971No ratings yet

- The Challenges of Designing and Complying With Paint ICorr AberdeenDocument60 pagesThe Challenges of Designing and Complying With Paint ICorr Aberdeenzaxader100% (1)

- SSPC Guide 3 - Paint Safety PDFDocument19 pagesSSPC Guide 3 - Paint Safety PDFAlexander SaulNo ratings yet

- Salt TestDocument16 pagesSalt Testم.ذكى فضل ذكى100% (1)

- Dry Coating Thickness Lab ReportDocument9 pagesDry Coating Thickness Lab Reportwidad100% (2)

- Dichtol ThermalSpraying SealantDocument2 pagesDichtol ThermalSpraying SealantLuis Aguilar GNo ratings yet

- Astm D6132-22Document5 pagesAstm D6132-22jesus.cwiengineerNo ratings yet

- Metco 34F 10-046Document8 pagesMetco 34F 10-046JSH100No ratings yet

- Immersion Testing of Industrial Protective Coatings: Standard Practice ForDocument6 pagesImmersion Testing of Industrial Protective Coatings: Standard Practice ForJhon Jeiwer SantosNo ratings yet

- Rust TestDocument16 pagesRust TestManolo CastilloNo ratings yet

- Blastline Institute of Surface Preparation & PaintingDocument12 pagesBlastline Institute of Surface Preparation & PaintingKawish TamourNo ratings yet

- Visual Comparative Guide Degrees of CleanlinessDocument1 pageVisual Comparative Guide Degrees of CleanlinessAhmad GhafouriNo ratings yet

- Dichtol Sealer Broschure ENDocument12 pagesDichtol Sealer Broschure ENgersom100% (1)

- FBE Testleri - DeFelskoDocument54 pagesFBE Testleri - DeFelskoÖzgür TuştaşNo ratings yet

- SSPC Paint 22 Nov 2004 PDFDocument6 pagesSSPC Paint 22 Nov 2004 PDFMuhammad PervaizNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 6Document6 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 6anony8103No ratings yet

- Intershield 163 Inerta 160 - Underwater Hull AntiabrasionDocument20 pagesIntershield 163 Inerta 160 - Underwater Hull AntiabrasionrbmtavNo ratings yet

- Painting STDSDocument4 pagesPainting STDSAshok KsNo ratings yet

- Hard Chrome ReplacementDocument7 pagesHard Chrome ReplacementPhu, Le HuuNo ratings yet

- Aga CourseDocument40 pagesAga CourseTarek YehiaNo ratings yet

- Data Sheet Proguard CN 200 A.SDocument3 pagesData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieNo ratings yet

- Amine Blush (Rubor de Amina)Document2 pagesAmine Blush (Rubor de Amina)Melissa Edith Vega Reynoso100% (1)

- Iso12944 Technical PaperDocument10 pagesIso12944 Technical PaperGuillermo Arnulfo Villa Garay100% (1)

- 05500Document6 pages05500khalid764No ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data Sheetajuhaseen100% (1)

- Visco-Elastic Coating MaterialDocument17 pagesVisco-Elastic Coating Materialosmanmop100% (1)

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- Dimetcote 6: Inorganic Zinc Silicate Coating Product Data/ Application InstructionsDocument4 pagesDimetcote 6: Inorganic Zinc Silicate Coating Product Data/ Application InstructionsYokesh Anand RNo ratings yet

- Amercoat 68 BSDocument4 pagesAmercoat 68 BSStephen Francis BothelloNo ratings yet

- PN78HBCDocument4 pagesPN78HBCLassadNo ratings yet

- Amercoat 253Document4 pagesAmercoat 253Sherif AbdelhameedNo ratings yet

- Flat Bed Reactor Loading& UnloadingDocument12 pagesFlat Bed Reactor Loading& Unloadingabdulgafoor54No ratings yet

- Gerard B. Hawkins Managing DirectorDocument37 pagesGerard B. Hawkins Managing Directorabdulgafoor54No ratings yet

- Purchase Request Form: Position: Delevery Instruction (Place) : Purpose: SN. Item Description With SpecificationDocument6 pagesPurchase Request Form: Position: Delevery Instruction (Place) : Purpose: SN. Item Description With Specificationabdulgafoor54No ratings yet

- Weld Matrix - PAGE 1&2Document20 pagesWeld Matrix - PAGE 1&2abdulgafoor54No ratings yet

- Straight Tees Inches / Pounds: Schedule 160Document1 pageStraight Tees Inches / Pounds: Schedule 160abdulgafoor54No ratings yet

- Weld Matrix - PAGE 1&2Document20 pagesWeld Matrix - PAGE 1&2abdulgafoor54No ratings yet

- Datasheet Penguard TopcoatDocument5 pagesDatasheet Penguard Topcoatabdulgafoor54No ratings yet

- Quality Management System (Qms Iso 9001:2008) Department Log of FilesDocument2 pagesQuality Management System (Qms Iso 9001:2008) Department Log of Filesabdulgafoor54No ratings yet

- Industrial Cadre For Operation and Maintenance: 15-Jan-18 25-Feb-18Document2 pagesIndustrial Cadre For Operation and Maintenance: 15-Jan-18 25-Feb-18abdulgafoor54No ratings yet

- Industrial Cadre For Operation and Maintenance: Date: 1/3/2018Document1 pageIndustrial Cadre For Operation and Maintenance: Date: 1/3/2018abdulgafoor54No ratings yet

- Chemanol-PRJ-17096: 18-Dec-17 25-Dec-17Document762 pagesChemanol-PRJ-17096: 18-Dec-17 25-Dec-17abdulgafoor54No ratings yet

- Ik MFC T CJ DJ CM 2174 PDFDocument1 pageIk MFC T CJ DJ CM 2174 PDFabdulgafoor54No ratings yet

- SN5 Cutting PlanDocument1 pageSN5 Cutting Planabdulgafoor54No ratings yet

- Job Safety Analysis Identifying Hazards Checklist: SN Hazards YES NO N/A 1 2 3 4 5 6 7Document3 pagesJob Safety Analysis Identifying Hazards Checklist: SN Hazards YES NO N/A 1 2 3 4 5 6 7abdulgafoor54No ratings yet

- No. Vehicle Plate Vehicle Name Vehicle Company Vehicle Color Driver Name Vehicle ModelDocument2 pagesNo. Vehicle Plate Vehicle Name Vehicle Company Vehicle Color Driver Name Vehicle Modelabdulgafoor54No ratings yet

- G M Fluidtech PVT LTD: Forged Gate Valve GM160-F11-SWDocument3 pagesG M Fluidtech PVT LTD: Forged Gate Valve GM160-F11-SWabdulgafoor54No ratings yet

- Purchase Request Form: Position: Delevery Instruction (Place) : Purpose: SN. Item Description With SpecificationDocument6 pagesPurchase Request Form: Position: Delevery Instruction (Place) : Purpose: SN. Item Description With Specificationabdulgafoor54No ratings yet

- Saudi Aramco Inspection ChecklistDocument22 pagesSaudi Aramco Inspection Checklistabdulgafoor54100% (2)

- Product DataDocument2 pagesProduct Dataabdulgafoor54No ratings yet

- Industrial Cadre For Operation and MaintenanceDocument1 pageIndustrial Cadre For Operation and Maintenanceabdulgafoor54No ratings yet

- Product DataDocument2 pagesProduct Dataabdulgafoor54No ratings yet

- Key Features Designed For Limited Access Boiler Tube BevelingDocument1 pageKey Features Designed For Limited Access Boiler Tube Bevelingabdulgafoor54No ratings yet

- 1cutting PlanDocument1 page1cutting Planabdulgafoor54No ratings yet

- Liner Installation in Sump S 8416 Liner Installation in Sump S 8416Document2 pagesLiner Installation in Sump S 8416 Liner Installation in Sump S 8416abdulgafoor54No ratings yet

- Qa/Qc Department Welding Inspection ReportDocument3 pagesQa/Qc Department Welding Inspection Reportabdulgafoor54No ratings yet

- SN4 Orthographic ViewsDocument1 pageSN4 Orthographic Viewsabdulgafoor54No ratings yet

- Cutting PlanDocument1 pageCutting Planabdulgafoor54No ratings yet

- DN670 Ductile Iron Manhole Cover D400 EN124Document11 pagesDN670 Ductile Iron Manhole Cover D400 EN124munisipalcastings100% (1)

- Piping Material Specification - Tsmto 99fu M 99 Pt0 001 Rev0!3!65Document64 pagesPiping Material Specification - Tsmto 99fu M 99 Pt0 001 Rev0!3!65epbamdad100% (1)

- Creating A Trading RoutineDocument8 pagesCreating A Trading Routinekumarcuk4143No ratings yet

- PDF File Rites of The Lock-Picking With Surgat Lapaca by AftahhDocument7 pagesPDF File Rites of The Lock-Picking With Surgat Lapaca by AftahhvrsNo ratings yet

- ProxxonDocument32 pagesProxxonZoran LazicNo ratings yet

- Water Proofing CompoundDocument17 pagesWater Proofing CompoundDharmendra KumarNo ratings yet

- Effective Learning StrategiesDocument5 pagesEffective Learning StrategiesRossy Milena JarabaNo ratings yet

- Epta Pilot Set 22Document13 pagesEpta Pilot Set 22Max ChanNo ratings yet

- UnivibeDocument1 pageUnivibePablo EspinosaNo ratings yet

- K-2 Ela-1Document219 pagesK-2 Ela-1Julie SuteraNo ratings yet

- Rift Valley University: Department: - Weekend Computer ScienceDocument13 pagesRift Valley University: Department: - Weekend Computer ScienceAyele MitkuNo ratings yet

- Fire Awareness PresentationDocument37 pagesFire Awareness Presentationshailu178No ratings yet

- M.najib CV 2023 Foto ScaffDocument12 pagesM.najib CV 2023 Foto Scaffamad copyitamNo ratings yet

- Widiastini, P.M.F and Et Al. (2023) - Prima Wiyata Health. 4 (2) : 47-56pDocument10 pagesWidiastini, P.M.F and Et Al. (2023) - Prima Wiyata Health. 4 (2) : 47-56pnayla nadrahNo ratings yet

- 4 Lista Teme Disertatie 2020-2021 BSCMC EnglezaDocument3 pages4 Lista Teme Disertatie 2020-2021 BSCMC EnglezaqawsfawsfNo ratings yet

- DBX PA Cut SheetA2Document2 pagesDBX PA Cut SheetA2Willy WakkerNo ratings yet

- Appliacation LetterDocument7 pagesAppliacation LetterTriantoNo ratings yet

- SchedulingDocument44 pagesSchedulingKonark PatelNo ratings yet

- Oana Adriana GICADocument42 pagesOana Adriana GICAPhilippe BrunoNo ratings yet

- Measurement of Steam ConsumptionDocument5 pagesMeasurement of Steam ConsumptionkingkakingNo ratings yet

- Gibbs Reflective Cycle EssaysDocument7 pagesGibbs Reflective Cycle Essaysertzyzbaf100% (2)

- Carole King - Hard Rock CafeDocument1 pageCarole King - Hard Rock CafeauresmikeNo ratings yet

- BRSM Class Test ExamDocument3 pagesBRSM Class Test ExamFernando SidikNo ratings yet

- DCS Slips PartsDocument2 pagesDCS Slips PartsCarlig Radu MihaiNo ratings yet

- Electromagnetic Shielding Salvatore Celozzi Full ChapterDocument56 pagesElectromagnetic Shielding Salvatore Celozzi Full Chapternorma.catron566100% (10)

- TV BroadcastingDocument6 pagesTV Broadcastingpinoy foreverNo ratings yet

- Trichomona FoetusDocument19 pagesTrichomona FoetusJuanjoc Cruz Calderón50% (2)

Dimecote 9 Inorganic Zinc Silicate Coating

Dimecote 9 Inorganic Zinc Silicate Coating

Uploaded by

abdulgafoor54Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dimecote 9 Inorganic Zinc Silicate Coating

Dimecote 9 Inorganic Zinc Silicate Coating

Uploaded by

abdulgafoor54Copyright:

Available Formats

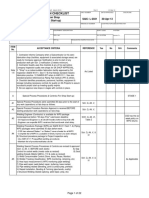

Dimetcote 9

Inorganic Zinc Silicate Coating

Product Data/

Application Instructions Physical Data

Finish ..................................... flat

A heavy-duty primer that protects with just a Colour .................................... grey

single coat Components .......................... 2

Outstanding application characteristics over a

Mixing ratio (by weight)

wide range of atmospheric conditions powder ................................ 1.92 parts

Can be applied by airless or conventional liquid ................................... 1 part

spray

Curing mechanism ................ solvent release and reaction with

Excellent heavy-build film tolerance in corners and atmospheric moisture

angles

High-metallic zinc content provides long-term VOC ....................................... 20% by weight

corrosion protection that reduces maintenance 480 g/l

costs Dry film thickness .................. 65 m (2,5 mils) per coat

Dimetcote 9 is a self-curing, solvent based inorganic zinc Number of coats .................... 1

coating used as a heavy duty primer with recommended 2 2/gal

topcoats or as a single coat protective coating in recommended Calculated coverage .............. 9.7 m / (397 ft at 65 m (2.5

servicesTo obtain the maximum performance for which mils)

Dimetcote 9 is formulated, strict adherence to all application

instructions, precautions, conditions and limitations is Allow for application losses, surface irregularities, etc.

necessary. If conditions exist that are not within the

requirements or limitations described, consult your Ameron Specific gravity ...................... 2.38 kg/l (mixed product)

representative.

Flash points (Closed Cup)...... C F

liquid ................................... 13 55

Typical Uses

Amercoat 13 ....................... 12 54

As a single coat, Dimetcote 9 resists severe weathering and

Amercoat 12 ....................... 24 75

marine environments. As a primer with recommended topcoats,

Dimetcote 9 is resistant to industrial and chemical exposure as Thinner .................................. Amercoat 13

well as marine exposure of structural steel and pipes, tank

exteriors, bridges, offshore platforms, marine hulls, Cleaner .................................. Amercoat 12

superstructures and decks.

Qualifications

SSPC Paint 20

AISC Specification for Structural Joints Using ASTM A325

or A490 Bolts RCSC Specification for Structural Joints

Table 3 Class B

Recommended Systems

Dimetcote 9 can be topcoated with epoxies vinyls, acrylics,

chlorinated rubbers polysiloxanes andother topcoats when

used in industrial and marine systems. Typical Ameron

topcoats are

Amercoat 383H, Amercoat 385, Amerlock 400; for intermediate

coat Amercoat 185HS. In some cases a mist coat/full coat

technique may be required to prevent application bubbling.

Page 1 of 4 Revision date: 03-04-2006

Dimetcote 9

Resistance

Dimetcote 9 without a topcoat has excellent resistance to

weathering and ultraviolet exposure. With suitable topcoats

Application Data

Dimetcote 9 is recommended for fumes and splash of mild Substrate ............................... steel

alkalies, dilute acids (fumes only), salt solutions of most types.

Dimetcote 9 is not recommended for spillage of acid or alkaline Application methods .............. airless or conventional spray

solutions.

Environmental Conditions (during application)

Air temperature .................... -18 to 50C 0-122F

Surface Preparation Surface temperature ............ -18 to 55C 0-131F

STEEL - Dry abrasive blast in accordance with Swedish Relative Humidity................. 50 % - 90 %

Standard Sa 2 SIS 05 5900 - 1967, ISO 8501-1 or

SSPC-SP10. Surface temperature must be at least 3C/5F above dew point to

NOTE: Blast to achieve a 35 to 65 m profile as determined prevent moisture condensation on the surface. At freezing

with Testex Tape or similar instrument. Rougher profiles are temperatures surface must be free of ice.

acceptable but requires increased film thickness for equivalent Never apply coatings under reverse environmental conditions.

protection. Remove abrasive residues and dust from surface. Ensure good ventilation when applied in confined areas to assist

Apply Dimetcote 9 as soon as possible after surface evaporation and elimination of solvents.

preparation to prevent any contamination. Do not leave blasted

Potlife (at 20C/68F) ............ 8 hours

steel uncoated overnight. Spot reblast steel if needed.

Galvanizing Remove oil, soap film or grease with neutral Potlife is dependent on temperature and quantities mixed.

detergent or emulsion cleaner and blast lightly with fine

abrasive to SSPC-SP7. Drying times at 20C/68F, 65 m dft and 50-90% RH

dry to touch ......................... 5 minutes

dry to handle ....................... 30 minutes

Application Equipment dry to topcoat ...................... 16 hours (RH 70% or higher)

The following equipment is listed as a guide and suitable 32 hours (RH 50% minimum)

equipment from other manufacturers may be used.

Adjustments of pressure and change of tip size may be needed Drying times are dependent on air and steel temperature, applied

to obtain the proper spray characteristics. film thickness, ventilation and other environmental conditions.

AIRLESS SPRAY - Standard airless spray equipment, such as Times are proportionally shorter at higher temperature and longer

Graco, DeVilbiss, Nordson-Bede, Spee-Flo or others having a at lower temperatures. Prior to recoating ensure the surface is

28:1 or higher pump ratio and a fluid tip with a 0.48 mm (0.019 clean. Maximum recoating time depends on coating system to be

inch) orifice or larger. used.

CONVENTIONAL SPRAY - Industrial equipment such as

Note Drying and topcoating times will be longer when film

DeVilbiss MBC or JGA gun with 704 or 765 air cap and "E"

thickness is over 65 microns (21/2 mils), ventilation and air

nozzle with leather or teflon needle packing and heavy mastic

movement are restricted, temperatures are lower or relative

spring. Separate air and fluid pressure regulators, variable humidities are lower. A water mist sprayed over the coating when

speed agitator in the pressure pot and a moisture and oil trap in the film is dry to touch will accelerate hardening at lower humidities.

the main air supply line are essential.

MIXER - Use power mixer powered by an air motor or an Thinner .................................. Amercoat 13

explosion proof electric motor.

Cleaner .................................. Amercoat 12

Repair

Rusted areas must be spot blasted in accordance with

instructions under Surface Preparation before touching up with

Dimetcote 9. When blasting is not practical, suitable Amercoat

zinc-based primers may be used for repair. See product

literature for selection according to topcoat compatibility.

Topcoating

Dimetcote 9 surface must be clean and dry before topcoating.

Water soluble contaminants may be washed off with water. Oil,

grease and similar contaminants may be removed with an

emulsion-type cleaner such as Amercoat 57 oil cleaner. Rinse

with clean water and allow to dry. Solvent wiping is not

Page 2 of 4 Revision date: 03-04-2006

Dimetcote 9

satisfactory as contamination may be spread and not removed.

NOTE: a mist coat / full coat may be required when applying a

subsequent coat on top of Dimetcote 9 to prevent application

bubbling. Shipping Data

Packaging............................... as 10 litre unit

Application Procedure powder ................................ 2.2 l (15.60 kg) in 10 l can

Dimetcote 9 is packaged in the proper mixing proportions liquid ................................... 7.8 l (8.15 kg) in 10 l jerrycan

of powder and liquid.

Powder 15.60 kg in a 10 l can. Shipping weight

Liquid 8.15 kg in a 10 l jerrycan. powder ................................ approx. 16.5 kg

1. Flush all equipment with recommended cleaner to remove any liquid ................................... approx. 8.7 kg

moisture that may be present. Moisture can cause hardening of

Dimetcote 9 in equipment. Shelf life

2. Stir liquid. powder ................................ 1 year from shipment date when

3. Discard desiccant bag from powder can and gradually stir stored indoors in unopened,

powder into liquid. Continue stirring until powder is well original containers at 5 to 40C (41-

dispersed and mixture is free of lumps. 104F)

4. Strain material through 590 m (30 mesh) screen to prevent liquid ................................... 1 year from shipment date when

possible clogging of equipment. stored indoors in unopened,

5. Since potlife is limited and shortened by high temperatures, do original containers at 5 to 40C (41-

not mix more material than will be used within recommended 104F)

potlife times.

IMPORTANT At the end of the potlife, 'kick-out' or separation of

the liquid and solids occur, together with gassing. Do not keep

mixed material which will not be used before the end of the

potlife in tightly closed containers as gassing can create

enough pressure to cause containers to burst. Cover

containers loosely.

6. Keep containers loosely covered until ready to use to prevent

skinning or gelling due to moisture in air. Skins should be

skimmed off the top and the material strained through cheese-

cloth or 60 mesh screen to remove any remaining pieces of

skin. Discard gelled material.

7. Thinning is normally not required. If thinning is necessary for

workability or when a rough film or "dry spray" is obtained

because of fast evaporation during hot weather or high wind,

thin with no more than 10 vol % of recommended thinner.

8. Adjust spray equipment to apply to an even wet coat with

minimum overspray.

9. Continue slow stirring during application to maintain uniformity

of material. Avoid fast stirring as this may cause a rise in

materialtemperature shortening potlife.

10. Apply in even, parallel passes and overlapping each pass 50%.

Pay special attention to welds, cut-outs, sharp edges, rivets,

bolts, etc. to ensure proper thickness.

11. Check thickness of dry coating with a non-destructive dry film

thickness gauge, such as Mikrotest or Elcometer. Recoat if

greater thickness is required. Normal recommended thickness

is 65 m and 75 m for immersion service. Allowable thickness

range is 50 to 150 m, assuming the surface profile is within

the recommended range. Greater thickness may develop

cracking.

12. Random pinholes, holidays and small damaged or bare areas

can be touched up by brush when film is dry to touch. Larger

areas should be resprayed.

NOTE: Maximum recoat time with itself is 16 hours. No

condensation or rain may be allowed on the surface of the dry

coating before recoating.

13. Prevent contact with water until the freshly applied coating is at

least dry to touch.

14. In confined areas ventilate with clean air during application and

drying until all solvents are removed. Temperature and

humidity of ventilating air must be such that moisture

condensation will not form on surface.

15. Clean all equipment with recommended cleaner immediately after use or

at least at the end of each working day or shift. Clean spray guns more

often during hot weather. When left in equipment Dimetcote 9 will

harden and plug spray equipment.

Page 3 of 4 Revision date: 03-04-2006

Dimetcote 9

Caution

This product is highly flammable. Ameron makes no other warranties concerning

Dimetcote 9 powder is harmful dust. Contains zinc. the product. No other warranties, whether

Avoid breathing dust. Wash thoroughly before eating express, implied or statutory, such as warranties

or smoking. Keep away from feed or food products. of merchantability or fitness particular purpose,

Contact with water liberates highly flammable gases, shall apply. In no event shall Ameron be liable for

spontaneously flammable in air. If welding is to be consequential or incidental damages.

performed in confined spaces on steel coated with

Dimetcote 9, do so in accordance with instructions in Any recommendations or suggestion relating to the

USA Standard Z 49.1-1973 "Safety in Welding and use of the products made by Ameron, whether in its

Cutting". technical literature, or response to specific enquiry, or

For specific information on hazardous ingredients, otherwise, is based on data believed to be reliable;

required ventilation, possible consequences of however, the products and information are intended

contact and safety measures see Safety Data Sheet. for use by Buyers having requisite skill and know-

how in the industry, and therefore it is Buyer to satisfy

Safety itself of the suitability of the products for its own

Since improper use and handling can be hazardous particular use and it shall be deemed that Buyer has

to health and cause of fire or explosion, safety done so, as its sole descretion and risk. Variation in

precautions included with application instructions environment, changes in procedures of use, or

must be observed during all storage, handling, use extrapolation of data may cause unsatisfactory

and drying periods. results.

To avoid any confusion that may arise through

translation into other languages, the English version Limitation of Liability

of the Product Data/Application Instructions will be the Amerons liability on any claim of any kind, including

governing literature and must be referred to in case of claims based upon Amerons negligence or strict

deviations with product literature in other languages. liability, for any loss or damage arising out of,

connected with, or resulting from the use of the

Warranty products, shall in no case exceed the purchase price

Ameron warrants its products to be free from defects allocable to the products or part thereof which give

in material and workmanship. Amerons sole rise to the claim.

obligations and Buyers exclusive remedy in In no event shall Ameron be liable for consequential

connection with the products shall be limited, at or incidental damages.

Amerons option, to either replacement of products

not conforming this warranty or credit to Buyers Condition of Sale

account in the invoiced amount of the non-confirming All our transactions are subject to our Terms and

products. Any claim under this warranty must be Conditions of Sale.

made by Buyer to Ameron in writing within five (5)

days of Buyers discovery of the claimed defect, but in

no event later than the expiration of the applicable

shelf life, or one year from the delivery date,

whichever is earlier. Buyers failure to notify Ameron

of such non-conformance as required herein shall bar

Buyer from recovery under this warranty.

Performance Coatings & Performance Coatings & Performance Coatings & Performance Coatings &

Finishes Europe Finishes/USA Finishes/Australia Finishes/New Zealand

Tel +(31) 345 587 587 Tel +(1) 678 393 0653 Tel +(61) 2 9421 8000 Tel +(64) 9 573 1620

www.ameron-bv.com www.ameroncoatings.com www.ameron.com.au www.ameron.co.nz

Page 4 of 4 Revision date: 03-04-2006

You might also like

- Cen-Tr 16999-2019Document75 pagesCen-Tr 16999-2019Muhammed Hasan GüçlüNo ratings yet

- Bus. Fin. WEEk 5-6Document14 pagesBus. Fin. WEEk 5-6Jessa Gallardo100% (1)

- Carboline Carboguard 890 PDSDocument2 pagesCarboline Carboguard 890 PDSSamNo ratings yet

- SSPC - Paint 41 PDFDocument5 pagesSSPC - Paint 41 PDFIvanSanchez100% (1)

- Amercoat 68hs - Ingles 2015Document6 pagesAmercoat 68hs - Ingles 2015Peter CallánNo ratings yet

- The Industrial Coatings MarketDocument5 pagesThe Industrial Coatings MarketjagrititanuNo ratings yet

- Amercoat 56E Polyamide Epoxy High Solids Tank LiningDocument4 pagesAmercoat 56E Polyamide Epoxy High Solids Tank LiningMuhammad MustahsinNo ratings yet

- Painting Inspection Report Final CoatDocument3 pagesPainting Inspection Report Final Coatabdulgafoor54100% (1)

- A Quantum Explanation of Sheldrakes Morphic Resonance by A GoswamiRupert SheldrakeDocument13 pagesA Quantum Explanation of Sheldrakes Morphic Resonance by A GoswamiRupert SheldrakeDavid Jaramillo KlinkertNo ratings yet

- SES Amercoat Dimetcote 9Document4 pagesSES Amercoat Dimetcote 9kamalkashNo ratings yet

- AI Hempel's Galvosil 15700 EnglishDocument7 pagesAI Hempel's Galvosil 15700 EnglishvitharvanNo ratings yet

- Sigmaprime 700Document7 pagesSigmaprime 700Trịnh Minh KhoaNo ratings yet

- Interseal 670HS BR Eng PDFDocument2 pagesInterseal 670HS BR Eng PDFandreaju2013No ratings yet

- 7570 SigmaZinc 170 Sigmazinc 9 (January 2014)Document6 pages7570 SigmaZinc 170 Sigmazinc 9 (January 2014)Akhtar AnsariNo ratings yet

- AAA Passivation MethodsDocument7 pagesAAA Passivation Methodsdianita nurnandaNo ratings yet

- Hempadur Avantguard 750 1736g - Product DatasheetDocument2 pagesHempadur Avantguard 750 1736g - Product DatasheetWisnu Wardhana0% (1)

- Surface Prep StandardsDocument2 pagesSurface Prep StandardsAnonymous 5mN1tLMNo ratings yet

- ASTM D 1186 Pelicula SecaDocument3 pagesASTM D 1186 Pelicula SecaFelipe montana100% (1)

- Requisitos de PinturaDocument4 pagesRequisitos de PinturaPablo Hidalgo ValenzuelaNo ratings yet

- 1411 - Explanation To Product Data SheetsDocument0 pages1411 - Explanation To Product Data SheetseraswastaNo ratings yet

- Schedule For Sand BlastingDocument2 pagesSchedule For Sand BlastingPratik GurungNo ratings yet

- Ventilation and Dehumidification of Ship Ballast Tanks For Blasting and Coating WorkDocument10 pagesVentilation and Dehumidification of Ship Ballast Tanks For Blasting and Coating WorkMehman Nasibov100% (1)

- SSPC SP-16 (2010) - Brush-Off Blast CleaningDocument13 pagesSSPC SP-16 (2010) - Brush-Off Blast CleaningPubcrawlNo ratings yet

- Flash Rust Formed After WaterjettingDocument12 pagesFlash Rust Formed After WaterjettingPedro Michell Rodriguez PerezNo ratings yet

- Sae Spec For Steel Shot & GritDocument3 pagesSae Spec For Steel Shot & Gritsanoopvk100% (1)

- Apcodur CF 699: Product DescriptionDocument4 pagesApcodur CF 699: Product DescriptionShravana PrasadNo ratings yet

- Coatings Bro PDFDocument8 pagesCoatings Bro PDFMBastawyNo ratings yet

- API 6A Licensing Information Form 20190510Document1 pageAPI 6A Licensing Information Form 20190510Guillermo Aponte RiañoNo ratings yet

- 1.2.4 HDG - Painting Issues PDFDocument2 pages1.2.4 HDG - Painting Issues PDFAnonymous 1AAjd0No ratings yet

- Paint Specification No.: SSPC: The Society For Protective CoatingsDocument5 pagesPaint Specification No.: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- SSPC Qp1 Application, Instructions, and Program RulesDocument21 pagesSSPC Qp1 Application, Instructions, and Program RulesRejoy BabyNo ratings yet

- Hempel Product Data SheetDocument6 pagesHempel Product Data SheetHendri Arief SetyawanNo ratings yet

- Control of The Mat Gloss BalanceDocument3 pagesControl of The Mat Gloss Balancejulio100% (1)

- Sigmacover 380Document18 pagesSigmacover 380eitan-dalia4971No ratings yet

- The Challenges of Designing and Complying With Paint ICorr AberdeenDocument60 pagesThe Challenges of Designing and Complying With Paint ICorr Aberdeenzaxader100% (1)

- SSPC Guide 3 - Paint Safety PDFDocument19 pagesSSPC Guide 3 - Paint Safety PDFAlexander SaulNo ratings yet

- Salt TestDocument16 pagesSalt Testم.ذكى فضل ذكى100% (1)

- Dry Coating Thickness Lab ReportDocument9 pagesDry Coating Thickness Lab Reportwidad100% (2)

- Dichtol ThermalSpraying SealantDocument2 pagesDichtol ThermalSpraying SealantLuis Aguilar GNo ratings yet

- Astm D6132-22Document5 pagesAstm D6132-22jesus.cwiengineerNo ratings yet

- Metco 34F 10-046Document8 pagesMetco 34F 10-046JSH100No ratings yet

- Immersion Testing of Industrial Protective Coatings: Standard Practice ForDocument6 pagesImmersion Testing of Industrial Protective Coatings: Standard Practice ForJhon Jeiwer SantosNo ratings yet

- Rust TestDocument16 pagesRust TestManolo CastilloNo ratings yet

- Blastline Institute of Surface Preparation & PaintingDocument12 pagesBlastline Institute of Surface Preparation & PaintingKawish TamourNo ratings yet

- Visual Comparative Guide Degrees of CleanlinessDocument1 pageVisual Comparative Guide Degrees of CleanlinessAhmad GhafouriNo ratings yet

- Dichtol Sealer Broschure ENDocument12 pagesDichtol Sealer Broschure ENgersom100% (1)

- FBE Testleri - DeFelskoDocument54 pagesFBE Testleri - DeFelskoÖzgür TuştaşNo ratings yet

- SSPC Paint 22 Nov 2004 PDFDocument6 pagesSSPC Paint 22 Nov 2004 PDFMuhammad PervaizNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 6Document6 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 6anony8103No ratings yet

- Intershield 163 Inerta 160 - Underwater Hull AntiabrasionDocument20 pagesIntershield 163 Inerta 160 - Underwater Hull AntiabrasionrbmtavNo ratings yet

- Painting STDSDocument4 pagesPainting STDSAshok KsNo ratings yet

- Hard Chrome ReplacementDocument7 pagesHard Chrome ReplacementPhu, Le HuuNo ratings yet

- Aga CourseDocument40 pagesAga CourseTarek YehiaNo ratings yet

- Data Sheet Proguard CN 200 A.SDocument3 pagesData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieNo ratings yet

- Amine Blush (Rubor de Amina)Document2 pagesAmine Blush (Rubor de Amina)Melissa Edith Vega Reynoso100% (1)

- Iso12944 Technical PaperDocument10 pagesIso12944 Technical PaperGuillermo Arnulfo Villa Garay100% (1)

- 05500Document6 pages05500khalid764No ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data Sheetajuhaseen100% (1)

- Visco-Elastic Coating MaterialDocument17 pagesVisco-Elastic Coating Materialosmanmop100% (1)

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- Dimetcote 6: Inorganic Zinc Silicate Coating Product Data/ Application InstructionsDocument4 pagesDimetcote 6: Inorganic Zinc Silicate Coating Product Data/ Application InstructionsYokesh Anand RNo ratings yet

- Amercoat 68 BSDocument4 pagesAmercoat 68 BSStephen Francis BothelloNo ratings yet

- PN78HBCDocument4 pagesPN78HBCLassadNo ratings yet

- Amercoat 253Document4 pagesAmercoat 253Sherif AbdelhameedNo ratings yet

- Flat Bed Reactor Loading& UnloadingDocument12 pagesFlat Bed Reactor Loading& Unloadingabdulgafoor54No ratings yet

- Gerard B. Hawkins Managing DirectorDocument37 pagesGerard B. Hawkins Managing Directorabdulgafoor54No ratings yet

- Purchase Request Form: Position: Delevery Instruction (Place) : Purpose: SN. Item Description With SpecificationDocument6 pagesPurchase Request Form: Position: Delevery Instruction (Place) : Purpose: SN. Item Description With Specificationabdulgafoor54No ratings yet

- Weld Matrix - PAGE 1&2Document20 pagesWeld Matrix - PAGE 1&2abdulgafoor54No ratings yet

- Straight Tees Inches / Pounds: Schedule 160Document1 pageStraight Tees Inches / Pounds: Schedule 160abdulgafoor54No ratings yet

- Weld Matrix - PAGE 1&2Document20 pagesWeld Matrix - PAGE 1&2abdulgafoor54No ratings yet

- Datasheet Penguard TopcoatDocument5 pagesDatasheet Penguard Topcoatabdulgafoor54No ratings yet

- Quality Management System (Qms Iso 9001:2008) Department Log of FilesDocument2 pagesQuality Management System (Qms Iso 9001:2008) Department Log of Filesabdulgafoor54No ratings yet

- Industrial Cadre For Operation and Maintenance: 15-Jan-18 25-Feb-18Document2 pagesIndustrial Cadre For Operation and Maintenance: 15-Jan-18 25-Feb-18abdulgafoor54No ratings yet

- Industrial Cadre For Operation and Maintenance: Date: 1/3/2018Document1 pageIndustrial Cadre For Operation and Maintenance: Date: 1/3/2018abdulgafoor54No ratings yet

- Chemanol-PRJ-17096: 18-Dec-17 25-Dec-17Document762 pagesChemanol-PRJ-17096: 18-Dec-17 25-Dec-17abdulgafoor54No ratings yet

- Ik MFC T CJ DJ CM 2174 PDFDocument1 pageIk MFC T CJ DJ CM 2174 PDFabdulgafoor54No ratings yet

- SN5 Cutting PlanDocument1 pageSN5 Cutting Planabdulgafoor54No ratings yet

- Job Safety Analysis Identifying Hazards Checklist: SN Hazards YES NO N/A 1 2 3 4 5 6 7Document3 pagesJob Safety Analysis Identifying Hazards Checklist: SN Hazards YES NO N/A 1 2 3 4 5 6 7abdulgafoor54No ratings yet

- No. Vehicle Plate Vehicle Name Vehicle Company Vehicle Color Driver Name Vehicle ModelDocument2 pagesNo. Vehicle Plate Vehicle Name Vehicle Company Vehicle Color Driver Name Vehicle Modelabdulgafoor54No ratings yet

- G M Fluidtech PVT LTD: Forged Gate Valve GM160-F11-SWDocument3 pagesG M Fluidtech PVT LTD: Forged Gate Valve GM160-F11-SWabdulgafoor54No ratings yet

- Purchase Request Form: Position: Delevery Instruction (Place) : Purpose: SN. Item Description With SpecificationDocument6 pagesPurchase Request Form: Position: Delevery Instruction (Place) : Purpose: SN. Item Description With Specificationabdulgafoor54No ratings yet

- Saudi Aramco Inspection ChecklistDocument22 pagesSaudi Aramco Inspection Checklistabdulgafoor54100% (2)

- Product DataDocument2 pagesProduct Dataabdulgafoor54No ratings yet

- Industrial Cadre For Operation and MaintenanceDocument1 pageIndustrial Cadre For Operation and Maintenanceabdulgafoor54No ratings yet

- Product DataDocument2 pagesProduct Dataabdulgafoor54No ratings yet

- Key Features Designed For Limited Access Boiler Tube BevelingDocument1 pageKey Features Designed For Limited Access Boiler Tube Bevelingabdulgafoor54No ratings yet

- 1cutting PlanDocument1 page1cutting Planabdulgafoor54No ratings yet

- Liner Installation in Sump S 8416 Liner Installation in Sump S 8416Document2 pagesLiner Installation in Sump S 8416 Liner Installation in Sump S 8416abdulgafoor54No ratings yet

- Qa/Qc Department Welding Inspection ReportDocument3 pagesQa/Qc Department Welding Inspection Reportabdulgafoor54No ratings yet

- SN4 Orthographic ViewsDocument1 pageSN4 Orthographic Viewsabdulgafoor54No ratings yet

- Cutting PlanDocument1 pageCutting Planabdulgafoor54No ratings yet

- DN670 Ductile Iron Manhole Cover D400 EN124Document11 pagesDN670 Ductile Iron Manhole Cover D400 EN124munisipalcastings100% (1)

- Piping Material Specification - Tsmto 99fu M 99 Pt0 001 Rev0!3!65Document64 pagesPiping Material Specification - Tsmto 99fu M 99 Pt0 001 Rev0!3!65epbamdad100% (1)

- Creating A Trading RoutineDocument8 pagesCreating A Trading Routinekumarcuk4143No ratings yet

- PDF File Rites of The Lock-Picking With Surgat Lapaca by AftahhDocument7 pagesPDF File Rites of The Lock-Picking With Surgat Lapaca by AftahhvrsNo ratings yet

- ProxxonDocument32 pagesProxxonZoran LazicNo ratings yet

- Water Proofing CompoundDocument17 pagesWater Proofing CompoundDharmendra KumarNo ratings yet

- Effective Learning StrategiesDocument5 pagesEffective Learning StrategiesRossy Milena JarabaNo ratings yet

- Epta Pilot Set 22Document13 pagesEpta Pilot Set 22Max ChanNo ratings yet

- UnivibeDocument1 pageUnivibePablo EspinosaNo ratings yet

- K-2 Ela-1Document219 pagesK-2 Ela-1Julie SuteraNo ratings yet

- Rift Valley University: Department: - Weekend Computer ScienceDocument13 pagesRift Valley University: Department: - Weekend Computer ScienceAyele MitkuNo ratings yet

- Fire Awareness PresentationDocument37 pagesFire Awareness Presentationshailu178No ratings yet

- M.najib CV 2023 Foto ScaffDocument12 pagesM.najib CV 2023 Foto Scaffamad copyitamNo ratings yet

- Widiastini, P.M.F and Et Al. (2023) - Prima Wiyata Health. 4 (2) : 47-56pDocument10 pagesWidiastini, P.M.F and Et Al. (2023) - Prima Wiyata Health. 4 (2) : 47-56pnayla nadrahNo ratings yet

- 4 Lista Teme Disertatie 2020-2021 BSCMC EnglezaDocument3 pages4 Lista Teme Disertatie 2020-2021 BSCMC EnglezaqawsfawsfNo ratings yet

- DBX PA Cut SheetA2Document2 pagesDBX PA Cut SheetA2Willy WakkerNo ratings yet

- Appliacation LetterDocument7 pagesAppliacation LetterTriantoNo ratings yet

- SchedulingDocument44 pagesSchedulingKonark PatelNo ratings yet

- Oana Adriana GICADocument42 pagesOana Adriana GICAPhilippe BrunoNo ratings yet

- Measurement of Steam ConsumptionDocument5 pagesMeasurement of Steam ConsumptionkingkakingNo ratings yet

- Gibbs Reflective Cycle EssaysDocument7 pagesGibbs Reflective Cycle Essaysertzyzbaf100% (2)

- Carole King - Hard Rock CafeDocument1 pageCarole King - Hard Rock CafeauresmikeNo ratings yet

- BRSM Class Test ExamDocument3 pagesBRSM Class Test ExamFernando SidikNo ratings yet

- DCS Slips PartsDocument2 pagesDCS Slips PartsCarlig Radu MihaiNo ratings yet

- Electromagnetic Shielding Salvatore Celozzi Full ChapterDocument56 pagesElectromagnetic Shielding Salvatore Celozzi Full Chapternorma.catron566100% (10)

- TV BroadcastingDocument6 pagesTV Broadcastingpinoy foreverNo ratings yet

- Trichomona FoetusDocument19 pagesTrichomona FoetusJuanjoc Cruz Calderón50% (2)