Professional Documents

Culture Documents

Cantilever Small

Cantilever Small

Uploaded by

vtalexCopyright:

Available Formats

You might also like

- Hilti - Pull Out Test Report-SampleDocument3 pagesHilti - Pull Out Test Report-SamplevtalexNo ratings yet

- Gift FormatDocument5 pagesGift FormatHeryudi100% (1)

- WellDocument12 pagesWellmuklis anggaraNo ratings yet

- Sandvik Bantlı KonveyörlerDocument71 pagesSandvik Bantlı KonveyörlerEmin KorkmazNo ratings yet

- Quikjoint - Eaves Haunch Calculations PDFDocument9 pagesQuikjoint - Eaves Haunch Calculations PDFvtalexNo ratings yet

- SK Fert F50ag-MsdsDocument6 pagesSK Fert F50ag-MsdsEmadNo ratings yet

- 4600-018-MC Latchways RoofingSolutionsDocument4 pages4600-018-MC Latchways RoofingSolutionsElio SaldañaNo ratings yet

- NEDCON Pallet Racks enDocument2 pagesNEDCON Pallet Racks enNELSON BOCANEGRANo ratings yet

- 2020 Derrick BrochureDocument9 pages2020 Derrick BrochurehaukuopexobNo ratings yet

- Connolly Expansion Joint SystemDocument16 pagesConnolly Expansion Joint Systemm_mahfuz118187No ratings yet

- Dokascaff: One Scaffold, Multiple ApplicationsDocument36 pagesDokascaff: One Scaffold, Multiple Applicationscuong voNo ratings yet

- VBA Box Gutter DesignDocument2 pagesVBA Box Gutter DesignbradleyrobinsonNo ratings yet

- Fixed Platforms Products ServicesDocument14 pagesFixed Platforms Products Services魏永涛No ratings yet

- Stop Logs Brochure Folder Stop Logs Brochure-WebDocument8 pagesStop Logs Brochure Folder Stop Logs Brochure-WebAnand RatnaNo ratings yet

- Analysis and Design of Hammer Head Bridge Pier Using Strut and Tie MethodDocument20 pagesAnalysis and Design of Hammer Head Bridge Pier Using Strut and Tie Methodဒုကၡ သစၥာNo ratings yet

- Header LateralsDocument2 pagesHeader LateralsRuvi MuhammadNo ratings yet

- Fixed Platforms Products ServicesDocument14 pagesFixed Platforms Products Servicesabimael quiroga rodriguezNo ratings yet

- Fixed Platforms Products ServicesDocument14 pagesFixed Platforms Products ServicesAril PatungguNo ratings yet

- ZE - E - (July 2006)Document8 pagesZE - E - (July 2006)ZhagiNo ratings yet

- Weir Oil Gas BrochureDocument33 pagesWeir Oil Gas BrochureRatnakar Patil100% (1)

- WeldFit Energy BrochureDocument8 pagesWeldFit Energy BrochureRaymundo AlarconNo ratings yet

- CFC Usen PDFDocument436 pagesCFC Usen PDFpiping1522No ratings yet

- Completion & Protection Products: Smart Solutions. Powerful ProductsDocument2 pagesCompletion & Protection Products: Smart Solutions. Powerful ProductsGerman PinedaNo ratings yet

- Allround BrochureDocument24 pagesAllround BrochureMs. ThuNo ratings yet

- Engineered Systems: Designed Solutions by Hdpe WeholiteDocument14 pagesEngineered Systems: Designed Solutions by Hdpe WeholiteLonelyBoyBuddyQNo ratings yet

- Centralizer WTFDocument8 pagesCentralizer WTFJhonathan MirandaNo ratings yet

- Skiold Chain Conveyors S: SkioldgroupDocument2 pagesSkiold Chain Conveyors S: SkioldgroupLuis NunesNo ratings yet

- Planning Guide FINAL WEBDocument16 pagesPlanning Guide FINAL WEBDrGanesh KameNo ratings yet

- SuperCor 2008Document16 pagesSuperCor 2008PD AWSSIESPNo ratings yet

- UMC SystemScaffoldingDocument3 pagesUMC SystemScaffoldingSayed AbbasNo ratings yet

- Multi Plate ProductGuideDocument17 pagesMulti Plate ProductGuideYusuf Rendra PratamaNo ratings yet

- Count On Our Support... : Building With Bricks?Document2 pagesCount On Our Support... : Building With Bricks?marslanawanNo ratings yet

- Sandvik ConveyorsDocument8 pagesSandvik ConveyorsMilan SjausNo ratings yet

- Catalogu Lenx Cable Trays and Cable Ledders 3Document68 pagesCatalogu Lenx Cable Trays and Cable Ledders 3mladennovakovicNo ratings yet

- Thickeners and Clarifiers - ENDocument12 pagesThickeners and Clarifiers - ENPedro PastenNo ratings yet

- Halfen HEK3 23-1-EN v10-23Document20 pagesHalfen HEK3 23-1-EN v10-23Mika SinghNo ratings yet

- Brochure Oil and GasDocument12 pagesBrochure Oil and GasAyub YaakobNo ratings yet

- EIK Full Range BrochureDocument20 pagesEIK Full Range BrochurepanoskidiscordNo ratings yet

- Kwikdek Slab Formwork SystemDocument7 pagesKwikdek Slab Formwork SystemJyles SirabNo ratings yet

- Aquaterra Riser SystemDocument8 pagesAquaterra Riser SystemAgus SetiawanNo ratings yet

- Pipe Racking: "Helping Our Customers Achieve Superior Results"Document6 pagesPipe Racking: "Helping Our Customers Achieve Superior Results"KACEM100% (1)

- WaterControlGatesGeneral FINDocument8 pagesWaterControlGatesGeneral FINkarimNo ratings yet

- Col 713824Document16 pagesCol 713824barouniamineNo ratings yet

- Rittal Data Center PDFDocument32 pagesRittal Data Center PDFJove MultisystemsNo ratings yet

- JEB Brochure 2013Document17 pagesJEB Brochure 2013thomvalensiNo ratings yet

- 3M Dual-Lock ReclFastrsDesignSelectGuideDocument8 pages3M Dual-Lock ReclFastrsDesignSelectGuidePhil MartinNo ratings yet

- Module H ScaffoldingDocument19 pagesModule H ScaffoldingRyanM.PradelNo ratings yet

- Geodesic Dome Brochure Rev 02-2017Document2 pagesGeodesic Dome Brochure Rev 02-2017frmarzoNo ratings yet

- Roof Truss GuideDocument12 pagesRoof Truss Guidedgib100% (1)

- Support Structure DesignDocument22 pagesSupport Structure Design7spacexNo ratings yet

- Design & Detailing of Steel Shelters: by Abir MallickDocument63 pagesDesign & Detailing of Steel Shelters: by Abir Mallickmorriaty100% (4)

- Construction Overview: Varco Pruden BuildingsDocument2 pagesConstruction Overview: Varco Pruden BuildingsDanrage BoodramNo ratings yet

- Superior Downhole Tools: 75 YearsDocument20 pagesSuperior Downhole Tools: 75 YearsTaras ByloNo ratings yet

- Chapter 7 - Johnson Sheaves - MetricDocument16 pagesChapter 7 - Johnson Sheaves - MetricVíctor FaríasNo ratings yet

- WRAP Wheelchair Ramp Design Construction Guidelines 11 06 10Document11 pagesWRAP Wheelchair Ramp Design Construction Guidelines 11 06 10Keith A. OlsenNo ratings yet

- HV/MV Onshore/offshore Substation Manager: Reporting To RoleDocument1 pageHV/MV Onshore/offshore Substation Manager: Reporting To RoleWilliam CoreyNo ratings yet

- Layher: Cut Costs, Improve Safety, Increase Efficiency: Layher AllroundscaffoldingDocument8 pagesLayher: Cut Costs, Improve Safety, Increase Efficiency: Layher Allroundscaffoldinging_costeroNo ratings yet

- Marley Alutec Price ListDocument92 pagesMarley Alutec Price ListdduffyNo ratings yet

- Rexnord® High Performance Bucket Elevators PDFDocument12 pagesRexnord® High Performance Bucket Elevators PDFJavier Alejandro Rodriguez MelgozaNo ratings yet

- Slewing Bearings by Liebherr: Application-Optimised, Reliable and RobustDocument24 pagesSlewing Bearings by Liebherr: Application-Optimised, Reliable and Robustrobson2015No ratings yet

- M Series DM Series Inclined Screens: Terex Minerals Processing Systems Simplicity M and DMDocument8 pagesM Series DM Series Inclined Screens: Terex Minerals Processing Systems Simplicity M and DMjahangir_alam44_6764No ratings yet

- The Home Owner's Manual: Operating Instructions, Troubleshooting Tips, and Advice on System MaintenanceFrom EverandThe Home Owner's Manual: Operating Instructions, Troubleshooting Tips, and Advice on System MaintenanceRating: 5 out of 5 stars5/5 (1)

- Shipping Container Homes: The best guide to building a shipping container home, including plans, FAQs, and much more!From EverandShipping Container Homes: The best guide to building a shipping container home, including plans, FAQs, and much more!No ratings yet

- Finkster-Python CheatsheetDocument11 pagesFinkster-Python CheatsheetvtalexNo ratings yet

- Kec Metro ReactionsDocument157 pagesKec Metro ReactionsvtalexNo ratings yet

- Scia Engineer - Load Generators en 2Document3 pagesScia Engineer - Load Generators en 2vtalexNo ratings yet

- Pinned Base PlateDocument7 pagesPinned Base PlatevtalexNo ratings yet

- Interpolation - MathDocument1 pageInterpolation - MathvtalexNo ratings yet

- Purlin Bracing CriteriaDocument19 pagesPurlin Bracing CriteriavtalexNo ratings yet

- DM04 04 PDFDocument16 pagesDM04 04 PDFvtalexNo ratings yet

- Calculation Headline: Roof GeometryDocument2 pagesCalculation Headline: Roof GeometryvtalexNo ratings yet

- Purlin Girt ReinforcementDocument16 pagesPurlin Girt ReinforcementmaheshbandhamNo ratings yet

- Purlin Bracing CriteriaDocument19 pagesPurlin Bracing CriteriavtalexNo ratings yet

- Quikjoint - ResultsDocument15 pagesQuikjoint - ResultsvtalexNo ratings yet

- Commentary: Standards Secondary and Structural Girts Practices DesignDocument2 pagesCommentary: Standards Secondary and Structural Girts Practices DesignvtalexNo ratings yet

- Fixed Base Plate ExampleDocument5 pagesFixed Base Plate ExamplevtalexNo ratings yet

- TNEB Online Payment ReceiptDocument1 pageTNEB Online Payment Receiptvtalex0% (1)

- Pinned Base Plate DesignDocument12 pagesPinned Base Plate DesignvtalexNo ratings yet

- Quick Dashboard in Excel: Service Level Quality ScoreDocument3 pagesQuick Dashboard in Excel: Service Level Quality ScorevtalexNo ratings yet

- Aluminum CurtainwallDocument8 pagesAluminum CurtainwallvtalexNo ratings yet

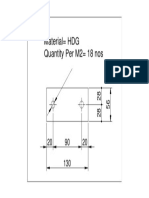

- Material HDG Quantity Per M2 18 NosDocument1 pageMaterial HDG Quantity Per M2 18 NosvtalexNo ratings yet

- A1 60 Stone CladdingDocument1 pageA1 60 Stone CladdingvtalexNo ratings yet

- Doha Festival CIty Aug 16 Rev. 1Document6 pagesDoha Festival CIty Aug 16 Rev. 1vtalexNo ratings yet

- DNV RP A201-00Document22 pagesDNV RP A201-00Igor ScudellerNo ratings yet

- Cisco Aironet 2800 Series Access PointsDocument11 pagesCisco Aironet 2800 Series Access Pointsreshma rapoleNo ratings yet

- API-650 Preguntas y Respuestas ImpresoDocument49 pagesAPI-650 Preguntas y Respuestas ImpresoJuan Bedolla FloresNo ratings yet

- 2016 Electrical Standards & Products GuideDocument93 pages2016 Electrical Standards & Products GuidereinaldonarvaezNo ratings yet

- Brinell TestDocument32 pagesBrinell TestAshish Agarwal100% (1)

- Fluidized BedsDocument2 pagesFluidized BedsAdil AminNo ratings yet

- Ansi Infocomm 2m-2010Document30 pagesAnsi Infocomm 2m-2010Maged AminNo ratings yet

- VCloud Usage Meter User's Guide 3.3Document60 pagesVCloud Usage Meter User's Guide 3.3cmundaca2009No ratings yet

- Budgetary Control: Standard Costing and Variance AnalysisDocument4 pagesBudgetary Control: Standard Costing and Variance AnalysisKumar KaushalNo ratings yet

- G BuildingAutomation WebDocument32 pagesG BuildingAutomation Weblfrn20044593No ratings yet

- Cisco Unity Connection SIP Integration With CUCM Step by Step GuideDocument17 pagesCisco Unity Connection SIP Integration With CUCM Step by Step Guideeyob_2No ratings yet

- Perlite Sproule1200 Data SheetDocument2 pagesPerlite Sproule1200 Data Sheetkresimir.mikoc9765No ratings yet

- Introduction of Automobile Industry: VolkswagenDocument6 pagesIntroduction of Automobile Industry: VolkswagenTejas AjmeraNo ratings yet

- Electric Actuator India, Motorized Valves Manufacturer IndiaDocument2 pagesElectric Actuator India, Motorized Valves Manufacturer IndiaCair Euromatic Automation Pvt. Ltd.No ratings yet

- Appendex 2Document3 pagesAppendex 2nofal AdreesNo ratings yet

- rz220 PDFDocument2 pagesrz220 PDFThinkplus TradingNo ratings yet

- Accommodation of Structural Movement inDocument9 pagesAccommodation of Structural Movement inwal1547No ratings yet

- Hsn8500Na Product Overview: Primary Application Key FeaturesDocument2 pagesHsn8500Na Product Overview: Primary Application Key FeaturesArun Balaji VNNo ratings yet

- An Assessment of Ethical Standards in Management Students of JaipurDocument4 pagesAn Assessment of Ethical Standards in Management Students of JaipurVlkjogfijnb LjunvodiNo ratings yet

- Dunning ProcedureDocument6 pagesDunning ProcedureKarunesh Srivastava100% (1)

- Fortigate Traffic Shaping 60Document59 pagesFortigate Traffic Shaping 60Mohamed MaherNo ratings yet

- About These Guidance Notes General GuidanceDocument5 pagesAbout These Guidance Notes General GuidanceHariharanNo ratings yet

- Lab Manual: Department of Computer Science and EngineeringDocument21 pagesLab Manual: Department of Computer Science and EngineeringGayatri KusumanchiNo ratings yet

- Wood FastenersDocument23 pagesWood FastenersDzulkifli AwangNo ratings yet

- Aan-32 Datasheet Ver3.1 PDFDocument2 pagesAan-32 Datasheet Ver3.1 PDFDasth HertoNo ratings yet

- ISO 9000 - Key Skills For Squeezing The Lemon: Case StudyDocument4 pagesISO 9000 - Key Skills For Squeezing The Lemon: Case Studykoib789No ratings yet

- Presentation LaturDocument51 pagesPresentation LaturKedar JoshiNo ratings yet

- DMM GW Istek GDM-8261A-manual PDFDocument230 pagesDMM GW Istek GDM-8261A-manual PDFDycki RizqiNo ratings yet

Cantilever Small

Cantilever Small

Uploaded by

vtalexOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cantilever Small

Cantilever Small

Uploaded by

vtalexCopyright:

Available Formats

Designed to easily store and retrieve products with varying weights, lengths, and sizes.

Cantilever systems do not

require uprights, allowing for easy product accessibility and selectivity paired with high down-aisle density.

Cantilever systems offer easy arm adjustability, providing a full range of loading capabilities that can be customized

to your storage application.

Ideal applications: Long or bulky items such as lumber, furniture, and plumbing.

STRUCTURAL CANTILEVER RACK

Fastened through a high-strength bolted connection

Arm lengths for storage depth can range from

24 to 72 per shelf

Adjustable on 4 centers

3 arm slope options

Towers are designed to match your height requirements

Decked-arm shelf-configuration is available with wire- mesh

deck, plywood platforms, or specialized steel decking

Aisle guidance systems are available

Entry guides are available

ROLL FORMED CANTILEVER RACK

Fastened through a bracket pin connection

Arm lengths for storage depth can range from 24 to 72

per shelf and are adjustable vertically on 3 centers

Towers are designed to match your height requirements

Decked-arm shelf-configuration available with wire mesh

deck, plywood platforms, or specialized steel decking

Aisle guidance systems are available

Entry guides are available

Roof Supports Core/Axle Removable Pipe

Saddles End Stops

Attaches to arms

to accept stringers Attaches to arms Attaches to arms

for roof structure. for accepting or base, includes

core/axle of rolled pipe, bracket and

materials. plastic caps

Deck Support Welded-on Bolted-on

Saddles End Lips End Lips

Attaches to arms. Welded to arms or Arms punched to

Used for decking base. Many accept optional

supports. heights available. removable end lip.

Very strong, able to hold very heavy loads.

Ideal for high trac and forklift impact prone areas.

Ideal for outdoor storage and freezer storage.

Beams are bolted to the uprights.

Formed with an open back and is therefore easy to keep

debris-free. This makes structural steel rack ideal for food

storage applications.

Can be designed as a selective system, flow system,

push back system, and drive-in and drive-through systems.

Can produce many dierent shapes, making it ideal

for various engineered solutions.

Less expensive than structural.

Ideal for most standard warehouse applications.

Allows for easy adjustability, reconfiguration, and relocation.

Most commonly manufactured as teardrop style.

Beams are attached to uprights by inserting the raised

portion of the beam into the corresponding hole on the

upright and secured with safety locks.

Can be designed as a selective system, flow system, push

back system, and drive-in and drive-through systems.

REB Storage Systems Internationals large project management department is

unparalleled in terms of product knowledge and project experience. REBs

project manager will be the single point of contact throughout every phase of Repair & Project

the project, including assessment, design, manufacturing, installation, Protection Management

permitting, testing, and completion.

The experience and skills of our project managers ensure the ultimate success of Design &

your project. Theyll manage all sub-contractors and continuously monitor the Installation

Engineering

progress of the entire project so that it is completed on time and within

budgetary guidelines. Permitting

Support

Our project management services are available for all projects, large or small.

Proper planning and communication is key to the successful

completion of every project. REB project managers obtain

commitments on lead times for all materials and set a project

schedule, highlighting all milestones and producing a firm

completion date.

This schedule is then communicated to all stakeholders as

needed including customers, vendors, contractors, building

ocials, and internal resources to ensure that all have an

understanding of the scope of the project. Weekly updates are

also provided to keep the project on-track.

REB project managers evaluate all subcontractor and

manufacturer bids based on lead time, quality, and price with

the intention of retaining high-quality services and products

while reducing overall costs and project completion time.

We manage the logistics of all materials, often from various

distribution points. REB project managers work with multiple

freight brokers to ensure that you received the best value on

your freight.

Once the project is completed, the project manager will perform

a final walkthrough of your system with you to confirm the

quality of the installation and the conformance to the system

specifications.

To maximize storage and ensure that trac can move eciently through your

facility requires careful planning.

Repair & Project

REBs engineering team is backed by over 53 years of storage system design Protection Management

experience in a wide variety of settings. No matter what the needs of your space,

we can create the professionally engineered solution that will help you manage

your inventory. Design &

Installation

Engineering

Permitting

Support

Our services begin with a full assessment of your warehouse,

taking into account the layout of your space, the characteristics

of your inventory, and the material handling equipment that

your team uses.

Our project engineers then utilize Computer Aided Design (CAD)

to produce detailed drawings that enable us to review various

designs to ultimately create the plans for your storage system

that will facilitate the success of your project and your

operations.

Well conduct the research necessary to ensure that our designs

comply fully with the federal, state and local regulations that

govern your area to make obtaining the necessary permits a

simpler task.

REB product integration experience, fabrication knowledge, and

manufacturer relationships deliver turn-key storage system

solutions for our customers.

REB engineers work with sprinkler and electrical contractors to

include required information on rack drawings as required by

local and federal regulations specific to your storage system size

and layout.

Our designs can integrate material handling equipment in the

best possible locations within your storage system to optimize

your storage and retrieval process. This can include conveyors,

chutes, hoists, and other equipment.

Obtaining the necessary permits to begin construction of your racking system is

a time-consuming and often frustrating process. Each state and local area has its

own set of requirements that projects must meet to obtain approval. Repair & Project

Protection Management

With our building permit preparation and support services, REB Storage Systems

International helps you obtain the necessary permits to ensure the on-time

implementation of your rack system. Well help you complete the paperwork, Design &

gather the required documentation, and submit your applications to the Installation

Engineering

appropriate authorities.

Permitting

Support

Our team will research the requirements for the location

of your facility including building construction type,

sprinklers, zoning, and occupancy classifications. Our

engineers will use this data to produce a storage system

design that fully meets these regulations.

A licensed project engineer will then prepare and review

all drawings, bill of material, and calculation drawings for

approval and stamping.

After receiving approval for the storage system designs,

well arrange for building, fire, and other departments to

conduct necessary inspections as needed.

We will schedule the system installation as permitted and

provide as much continued support as needed until the

final occupancy permit is issued.

Even the most innovative racking and shelving design is only as good as the

quality of the craftsmanship that brings it from the design phase to reality. The

role of your racking system to the overall success of your operations makes Repair & Project

finding the best professionals to install your new racks and shelves of the utmost Protection Management

importance.

REBs project managers oversee the installation process, troubleshoot solutions, Design &

and facilitate completion. We retain quality installers located throughout the Installation

Engineering

country who have experience working in a wide array of environments and can

meet the challenges presented by any space to ensure that the job is done Permitting

correctly and on time. Support

All installation drawings are reviewed by our project engineers to

verify compliance with building codes, load applications, rack

configuration drawings, and rack component manufacturers

requirements. This is then communicated to our installers so that

all specifications are adhered to during the installation process.

REB certified installers are highly skilled in warehouse rack,

shelving, conveyor, and mezzanine installation, configuration,

anchorage, reconfiguration, additions and alterations.

Since we are typically installing systems in buildings which must

continue ongoing operations, our project managers and

subcontractors will work with you in order to minimize the

disruption to your day-to-day business while keeping

everyone safe.

REB has a tremendous amount of experience in the dismantling

and repurposing of pre-owned material nationwide. Our crew

carefully disassembles racks and shelves without damaging

them or the building.

Our team can knockdown, inventory, stack and band the

material to and arrange for transport to your new location. We

can also reinstall the system at your new location as well as

modify or add on to the system if needed.

Conversely, if you are looking to liquidate your current facility or

are changing locations and do not need to utilize all of your

racking, REB may purchase your used equipment and resell

them.

Contact REB Storage Systems International to speak with one of our material handling

specialists who can answer any questions you may have regarding your storage requirements.

For more than 50 years, REB Storage Systems International has handled every aspect of racking, shelving, and material

handling needs of some of the worlds biggest and most successful companies. We are the exclusive racking and

shelving designer and installer for many Fortune 500 companies, and have extensive experience designing custom

solutions for small and medium businesses. We hope you will invite us to help you.

Please contact one of our specialists below according to your requirements. If you require more

than one of the categories found below, please include all inquiries in one request.

STORAGE SYSTEMS & MEZZANINES

Phone: 800-252-5955

Email: storagesystems@rebstorage.com

MATERIAL HANDLING PRODUCTS

Phone: 800-252-5955

Email: mhp@rebstorage.com

RACK INSPECTION, REPAIR, & MAINTENANCE SERVICES

Phone 800-252-5955

Email: rackrepair@rebstorage.com

MODULAR OFFICES

Phone: 800-252-5955

Email: classicmodular@rebstorage.com

CHICAGO (HEADQUARTERS) DUBLIN

REB Storage System International REB Storage Systems International

4556 W. Grand Ave. Unit 15D Kinsealy Business Park

Chicago, IL 60639 Kinsealy, Co. Dublin

Phone: 773-252-0400 Ireland

Global Toll Free: 800-252-5955

Fax: 773-252-0303 Phone: (+353)-1-685-4860

Email: info@rebstorage.com Email: info@rebstorage.com

www.rebstorage.com www.rebstorage.eu

BRANCH OFFICES

California Massachusetts Michigan New York Pennsylvania

You might also like

- Hilti - Pull Out Test Report-SampleDocument3 pagesHilti - Pull Out Test Report-SamplevtalexNo ratings yet

- Gift FormatDocument5 pagesGift FormatHeryudi100% (1)

- WellDocument12 pagesWellmuklis anggaraNo ratings yet

- Sandvik Bantlı KonveyörlerDocument71 pagesSandvik Bantlı KonveyörlerEmin KorkmazNo ratings yet

- Quikjoint - Eaves Haunch Calculations PDFDocument9 pagesQuikjoint - Eaves Haunch Calculations PDFvtalexNo ratings yet

- SK Fert F50ag-MsdsDocument6 pagesSK Fert F50ag-MsdsEmadNo ratings yet

- 4600-018-MC Latchways RoofingSolutionsDocument4 pages4600-018-MC Latchways RoofingSolutionsElio SaldañaNo ratings yet

- NEDCON Pallet Racks enDocument2 pagesNEDCON Pallet Racks enNELSON BOCANEGRANo ratings yet

- 2020 Derrick BrochureDocument9 pages2020 Derrick BrochurehaukuopexobNo ratings yet

- Connolly Expansion Joint SystemDocument16 pagesConnolly Expansion Joint Systemm_mahfuz118187No ratings yet

- Dokascaff: One Scaffold, Multiple ApplicationsDocument36 pagesDokascaff: One Scaffold, Multiple Applicationscuong voNo ratings yet

- VBA Box Gutter DesignDocument2 pagesVBA Box Gutter DesignbradleyrobinsonNo ratings yet

- Fixed Platforms Products ServicesDocument14 pagesFixed Platforms Products Services魏永涛No ratings yet

- Stop Logs Brochure Folder Stop Logs Brochure-WebDocument8 pagesStop Logs Brochure Folder Stop Logs Brochure-WebAnand RatnaNo ratings yet

- Analysis and Design of Hammer Head Bridge Pier Using Strut and Tie MethodDocument20 pagesAnalysis and Design of Hammer Head Bridge Pier Using Strut and Tie Methodဒုကၡ သစၥာNo ratings yet

- Header LateralsDocument2 pagesHeader LateralsRuvi MuhammadNo ratings yet

- Fixed Platforms Products ServicesDocument14 pagesFixed Platforms Products Servicesabimael quiroga rodriguezNo ratings yet

- Fixed Platforms Products ServicesDocument14 pagesFixed Platforms Products ServicesAril PatungguNo ratings yet

- ZE - E - (July 2006)Document8 pagesZE - E - (July 2006)ZhagiNo ratings yet

- Weir Oil Gas BrochureDocument33 pagesWeir Oil Gas BrochureRatnakar Patil100% (1)

- WeldFit Energy BrochureDocument8 pagesWeldFit Energy BrochureRaymundo AlarconNo ratings yet

- CFC Usen PDFDocument436 pagesCFC Usen PDFpiping1522No ratings yet

- Completion & Protection Products: Smart Solutions. Powerful ProductsDocument2 pagesCompletion & Protection Products: Smart Solutions. Powerful ProductsGerman PinedaNo ratings yet

- Allround BrochureDocument24 pagesAllround BrochureMs. ThuNo ratings yet

- Engineered Systems: Designed Solutions by Hdpe WeholiteDocument14 pagesEngineered Systems: Designed Solutions by Hdpe WeholiteLonelyBoyBuddyQNo ratings yet

- Centralizer WTFDocument8 pagesCentralizer WTFJhonathan MirandaNo ratings yet

- Skiold Chain Conveyors S: SkioldgroupDocument2 pagesSkiold Chain Conveyors S: SkioldgroupLuis NunesNo ratings yet

- Planning Guide FINAL WEBDocument16 pagesPlanning Guide FINAL WEBDrGanesh KameNo ratings yet

- SuperCor 2008Document16 pagesSuperCor 2008PD AWSSIESPNo ratings yet

- UMC SystemScaffoldingDocument3 pagesUMC SystemScaffoldingSayed AbbasNo ratings yet

- Multi Plate ProductGuideDocument17 pagesMulti Plate ProductGuideYusuf Rendra PratamaNo ratings yet

- Count On Our Support... : Building With Bricks?Document2 pagesCount On Our Support... : Building With Bricks?marslanawanNo ratings yet

- Sandvik ConveyorsDocument8 pagesSandvik ConveyorsMilan SjausNo ratings yet

- Catalogu Lenx Cable Trays and Cable Ledders 3Document68 pagesCatalogu Lenx Cable Trays and Cable Ledders 3mladennovakovicNo ratings yet

- Thickeners and Clarifiers - ENDocument12 pagesThickeners and Clarifiers - ENPedro PastenNo ratings yet

- Halfen HEK3 23-1-EN v10-23Document20 pagesHalfen HEK3 23-1-EN v10-23Mika SinghNo ratings yet

- Brochure Oil and GasDocument12 pagesBrochure Oil and GasAyub YaakobNo ratings yet

- EIK Full Range BrochureDocument20 pagesEIK Full Range BrochurepanoskidiscordNo ratings yet

- Kwikdek Slab Formwork SystemDocument7 pagesKwikdek Slab Formwork SystemJyles SirabNo ratings yet

- Aquaterra Riser SystemDocument8 pagesAquaterra Riser SystemAgus SetiawanNo ratings yet

- Pipe Racking: "Helping Our Customers Achieve Superior Results"Document6 pagesPipe Racking: "Helping Our Customers Achieve Superior Results"KACEM100% (1)

- WaterControlGatesGeneral FINDocument8 pagesWaterControlGatesGeneral FINkarimNo ratings yet

- Col 713824Document16 pagesCol 713824barouniamineNo ratings yet

- Rittal Data Center PDFDocument32 pagesRittal Data Center PDFJove MultisystemsNo ratings yet

- JEB Brochure 2013Document17 pagesJEB Brochure 2013thomvalensiNo ratings yet

- 3M Dual-Lock ReclFastrsDesignSelectGuideDocument8 pages3M Dual-Lock ReclFastrsDesignSelectGuidePhil MartinNo ratings yet

- Module H ScaffoldingDocument19 pagesModule H ScaffoldingRyanM.PradelNo ratings yet

- Geodesic Dome Brochure Rev 02-2017Document2 pagesGeodesic Dome Brochure Rev 02-2017frmarzoNo ratings yet

- Roof Truss GuideDocument12 pagesRoof Truss Guidedgib100% (1)

- Support Structure DesignDocument22 pagesSupport Structure Design7spacexNo ratings yet

- Design & Detailing of Steel Shelters: by Abir MallickDocument63 pagesDesign & Detailing of Steel Shelters: by Abir Mallickmorriaty100% (4)

- Construction Overview: Varco Pruden BuildingsDocument2 pagesConstruction Overview: Varco Pruden BuildingsDanrage BoodramNo ratings yet

- Superior Downhole Tools: 75 YearsDocument20 pagesSuperior Downhole Tools: 75 YearsTaras ByloNo ratings yet

- Chapter 7 - Johnson Sheaves - MetricDocument16 pagesChapter 7 - Johnson Sheaves - MetricVíctor FaríasNo ratings yet

- WRAP Wheelchair Ramp Design Construction Guidelines 11 06 10Document11 pagesWRAP Wheelchair Ramp Design Construction Guidelines 11 06 10Keith A. OlsenNo ratings yet

- HV/MV Onshore/offshore Substation Manager: Reporting To RoleDocument1 pageHV/MV Onshore/offshore Substation Manager: Reporting To RoleWilliam CoreyNo ratings yet

- Layher: Cut Costs, Improve Safety, Increase Efficiency: Layher AllroundscaffoldingDocument8 pagesLayher: Cut Costs, Improve Safety, Increase Efficiency: Layher Allroundscaffoldinging_costeroNo ratings yet

- Marley Alutec Price ListDocument92 pagesMarley Alutec Price ListdduffyNo ratings yet

- Rexnord® High Performance Bucket Elevators PDFDocument12 pagesRexnord® High Performance Bucket Elevators PDFJavier Alejandro Rodriguez MelgozaNo ratings yet

- Slewing Bearings by Liebherr: Application-Optimised, Reliable and RobustDocument24 pagesSlewing Bearings by Liebherr: Application-Optimised, Reliable and Robustrobson2015No ratings yet

- M Series DM Series Inclined Screens: Terex Minerals Processing Systems Simplicity M and DMDocument8 pagesM Series DM Series Inclined Screens: Terex Minerals Processing Systems Simplicity M and DMjahangir_alam44_6764No ratings yet

- The Home Owner's Manual: Operating Instructions, Troubleshooting Tips, and Advice on System MaintenanceFrom EverandThe Home Owner's Manual: Operating Instructions, Troubleshooting Tips, and Advice on System MaintenanceRating: 5 out of 5 stars5/5 (1)

- Shipping Container Homes: The best guide to building a shipping container home, including plans, FAQs, and much more!From EverandShipping Container Homes: The best guide to building a shipping container home, including plans, FAQs, and much more!No ratings yet

- Finkster-Python CheatsheetDocument11 pagesFinkster-Python CheatsheetvtalexNo ratings yet

- Kec Metro ReactionsDocument157 pagesKec Metro ReactionsvtalexNo ratings yet

- Scia Engineer - Load Generators en 2Document3 pagesScia Engineer - Load Generators en 2vtalexNo ratings yet

- Pinned Base PlateDocument7 pagesPinned Base PlatevtalexNo ratings yet

- Interpolation - MathDocument1 pageInterpolation - MathvtalexNo ratings yet

- Purlin Bracing CriteriaDocument19 pagesPurlin Bracing CriteriavtalexNo ratings yet

- DM04 04 PDFDocument16 pagesDM04 04 PDFvtalexNo ratings yet

- Calculation Headline: Roof GeometryDocument2 pagesCalculation Headline: Roof GeometryvtalexNo ratings yet

- Purlin Girt ReinforcementDocument16 pagesPurlin Girt ReinforcementmaheshbandhamNo ratings yet

- Purlin Bracing CriteriaDocument19 pagesPurlin Bracing CriteriavtalexNo ratings yet

- Quikjoint - ResultsDocument15 pagesQuikjoint - ResultsvtalexNo ratings yet

- Commentary: Standards Secondary and Structural Girts Practices DesignDocument2 pagesCommentary: Standards Secondary and Structural Girts Practices DesignvtalexNo ratings yet

- Fixed Base Plate ExampleDocument5 pagesFixed Base Plate ExamplevtalexNo ratings yet

- TNEB Online Payment ReceiptDocument1 pageTNEB Online Payment Receiptvtalex0% (1)

- Pinned Base Plate DesignDocument12 pagesPinned Base Plate DesignvtalexNo ratings yet

- Quick Dashboard in Excel: Service Level Quality ScoreDocument3 pagesQuick Dashboard in Excel: Service Level Quality ScorevtalexNo ratings yet

- Aluminum CurtainwallDocument8 pagesAluminum CurtainwallvtalexNo ratings yet

- Material HDG Quantity Per M2 18 NosDocument1 pageMaterial HDG Quantity Per M2 18 NosvtalexNo ratings yet

- A1 60 Stone CladdingDocument1 pageA1 60 Stone CladdingvtalexNo ratings yet

- Doha Festival CIty Aug 16 Rev. 1Document6 pagesDoha Festival CIty Aug 16 Rev. 1vtalexNo ratings yet

- DNV RP A201-00Document22 pagesDNV RP A201-00Igor ScudellerNo ratings yet

- Cisco Aironet 2800 Series Access PointsDocument11 pagesCisco Aironet 2800 Series Access Pointsreshma rapoleNo ratings yet

- API-650 Preguntas y Respuestas ImpresoDocument49 pagesAPI-650 Preguntas y Respuestas ImpresoJuan Bedolla FloresNo ratings yet

- 2016 Electrical Standards & Products GuideDocument93 pages2016 Electrical Standards & Products GuidereinaldonarvaezNo ratings yet

- Brinell TestDocument32 pagesBrinell TestAshish Agarwal100% (1)

- Fluidized BedsDocument2 pagesFluidized BedsAdil AminNo ratings yet

- Ansi Infocomm 2m-2010Document30 pagesAnsi Infocomm 2m-2010Maged AminNo ratings yet

- VCloud Usage Meter User's Guide 3.3Document60 pagesVCloud Usage Meter User's Guide 3.3cmundaca2009No ratings yet

- Budgetary Control: Standard Costing and Variance AnalysisDocument4 pagesBudgetary Control: Standard Costing and Variance AnalysisKumar KaushalNo ratings yet

- G BuildingAutomation WebDocument32 pagesG BuildingAutomation Weblfrn20044593No ratings yet

- Cisco Unity Connection SIP Integration With CUCM Step by Step GuideDocument17 pagesCisco Unity Connection SIP Integration With CUCM Step by Step Guideeyob_2No ratings yet

- Perlite Sproule1200 Data SheetDocument2 pagesPerlite Sproule1200 Data Sheetkresimir.mikoc9765No ratings yet

- Introduction of Automobile Industry: VolkswagenDocument6 pagesIntroduction of Automobile Industry: VolkswagenTejas AjmeraNo ratings yet

- Electric Actuator India, Motorized Valves Manufacturer IndiaDocument2 pagesElectric Actuator India, Motorized Valves Manufacturer IndiaCair Euromatic Automation Pvt. Ltd.No ratings yet

- Appendex 2Document3 pagesAppendex 2nofal AdreesNo ratings yet

- rz220 PDFDocument2 pagesrz220 PDFThinkplus TradingNo ratings yet

- Accommodation of Structural Movement inDocument9 pagesAccommodation of Structural Movement inwal1547No ratings yet

- Hsn8500Na Product Overview: Primary Application Key FeaturesDocument2 pagesHsn8500Na Product Overview: Primary Application Key FeaturesArun Balaji VNNo ratings yet

- An Assessment of Ethical Standards in Management Students of JaipurDocument4 pagesAn Assessment of Ethical Standards in Management Students of JaipurVlkjogfijnb LjunvodiNo ratings yet

- Dunning ProcedureDocument6 pagesDunning ProcedureKarunesh Srivastava100% (1)

- Fortigate Traffic Shaping 60Document59 pagesFortigate Traffic Shaping 60Mohamed MaherNo ratings yet

- About These Guidance Notes General GuidanceDocument5 pagesAbout These Guidance Notes General GuidanceHariharanNo ratings yet

- Lab Manual: Department of Computer Science and EngineeringDocument21 pagesLab Manual: Department of Computer Science and EngineeringGayatri KusumanchiNo ratings yet

- Wood FastenersDocument23 pagesWood FastenersDzulkifli AwangNo ratings yet

- Aan-32 Datasheet Ver3.1 PDFDocument2 pagesAan-32 Datasheet Ver3.1 PDFDasth HertoNo ratings yet

- ISO 9000 - Key Skills For Squeezing The Lemon: Case StudyDocument4 pagesISO 9000 - Key Skills For Squeezing The Lemon: Case Studykoib789No ratings yet

- Presentation LaturDocument51 pagesPresentation LaturKedar JoshiNo ratings yet

- DMM GW Istek GDM-8261A-manual PDFDocument230 pagesDMM GW Istek GDM-8261A-manual PDFDycki RizqiNo ratings yet