Professional Documents

Culture Documents

1.terminology Primer

1.terminology Primer

Uploaded by

mdasifkhan20130 ratings0% found this document useful (0 votes)

20 views2 pagessqc

Original Title

1.Terminology Primer

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsqc

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

20 views2 pages1.terminology Primer

1.terminology Primer

Uploaded by

mdasifkhan2013sqc

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

HARVARD

BUSINESS

TERMINOLOGY PRIMER

Operations Management Simulation: Quality Analytics

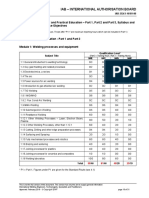

Control Limits

UCLa = DsR

LCLp = Dak

‘Sample Ad Ds Di |

Size

2 1.880 ~ 3.267 |

3 T0278 2578

4 0729 2282

5 0577 24

6 0.483 2.004

7 aio | 0076 | 1924

a oa73_| 0186 | 1864

3 0337 | 0464 | 1ai6

10 308 | 0223 | 1777

5 0223 | 0347 | 1653

3 0153] 0459 | 1541

(Operations Management Simulation: Quality Analytic

Terminology Primer

Process Capability

Use C, when the process mean is centered between the specification limits,

USL-LSL

oo

Use Cp, when the process mean is not centered between the specification limits.

3a

& ISL

USL = Upper specification limit

LSL = Lower specification limit

fi = Process mean, which is the centerline between the UCL and LCL

standard deviations from the process mean.

Process standard deviation, which can be calculated from the control limits, which are +3

Higher values of €, and Cx indicate a more capable process, Experts recommend a process

capability index of at least 1.33 for a two-sided specification. For a one-sided specification that

consists of an upper limit only (for example, concentration) or a lower limit only (for example,

for strength), the process is considered capable if the process capability index > 1.25.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Back Bay Battery AnalysisDocument15 pagesBack Bay Battery AnalysisDavid van G87% (55)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- ISO 9001 Lead Auditor PDFDocument1 pageISO 9001 Lead Auditor PDFmdasifkhan201350% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Practice Multi Choice Questions: Page 1 of 32Document32 pagesPractice Multi Choice Questions: Page 1 of 32mdasifkhan2013100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Stat211 122 03 Q1Document4 pagesStat211 122 03 Q1mdasifkhan2013No ratings yet

- Career Objective: - : Bashirul MustafaDocument3 pagesCareer Objective: - : Bashirul Mustafamdasifkhan2013No ratings yet

- IWE SyllabusDocument4 pagesIWE Syllabusmdasifkhan2013No ratings yet

- Md. Mosarraf Hossain: Professional ExperienceDocument1 pageMd. Mosarraf Hossain: Professional Experiencemdasifkhan2013No ratings yet

- PNR/Booking Ref.: XPBV7KDocument3 pagesPNR/Booking Ref.: XPBV7Kmdasifkhan2013No ratings yet

- Project 1 - Number Guessing GameDocument1 pageProject 1 - Number Guessing Gamemdasifkhan2013No ratings yet

- 3 Piece Men SuitDocument1 page3 Piece Men Suitmdasifkhan2013No ratings yet

- Personal Information: Application Form: Jharkhand Police Sub Inspector Competitive Examination 2017Document2 pagesPersonal Information: Application Form: Jharkhand Police Sub Inspector Competitive Examination 2017mdasifkhan2013No ratings yet

- ARC Welding: Name N AWS Characteristics ApplicationsDocument1 pageARC Welding: Name N AWS Characteristics Applicationsmdasifkhan2013No ratings yet

- CH 01Document29 pagesCH 01mdasifkhan2013No ratings yet

- Preheat Formula PDFDocument1 pagePreheat Formula PDFmdasifkhan2013No ratings yet

- MM ZG611Document9 pagesMM ZG611mdasifkhan2013No ratings yet

- Virtual BAJA 2016 ResultsDocument5 pagesVirtual BAJA 2016 Resultsmdasifkhan2013No ratings yet

- SQC Simulation SolutionDocument2 pagesSQC Simulation Solutionmdasifkhan2013No ratings yet

- MM ZG523Document18 pagesMM ZG523mdasifkhan2013No ratings yet

- Academic Programs & PedagogyDocument1 pageAcademic Programs & Pedagogymdasifkhan2013No ratings yet

- Subject Semester Group Name Student Id Student Name: Little Field Simulation Technology Strategy SubmissionDocument1 pageSubject Semester Group Name Student Id Student Name: Little Field Simulation Technology Strategy Submissionmdasifkhan2013No ratings yet

- Ab Life: Aapki ZarooratDocument22 pagesAb Life: Aapki Zarooratmdasifkhan2013No ratings yet

- Introductory RunDocument11 pagesIntroductory Runmdasifkhan2013No ratings yet

- GP0001Document12 pagesGP0001mdasifkhan2013No ratings yet