Professional Documents

Culture Documents

Iso 898

Iso 898

Uploaded by

Shaikh Adil0 ratings0% found this document useful (0 votes)

100 views2 pagesISO 898

Original Title

ISO 898

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentISO 898

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

100 views2 pagesIso 898

Iso 898

Uploaded by

Shaikh AdilISO 898

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

\ers Ltd, Latest version as of 20/04/2009 16:17. Not to be distributed/networked. For multi-user access go to

‘www. bsigroup.comilicense © British Standards Institution

Bought by Alicja Bogdanowicz, Andrews Fasten’

BS EN ISO 898-1:2009

180 898-1:2009(E)

b) machined tet pieces made from studs:

= 3mm < d< 38mm;

— thread length 62 1

— thread length ofthe stud (metal) end by > 1 a

— ‘total length f > 6 +2 r+ 2 (as indicated in Figure 6) to determine 4;

— ‘total length > 4 dp +2 r+ 2d (as indicated in Figure 6) to determine 2

©) property ck

928 4.6, 56, 8.8, 9.8, 10:9 and 12.9/12.9,

NOTE Machined test pieces made from bolls end scrows can also be made from fasteners which, due to their

‘geometry, have reduced loadabity. proved thatthe head is stronger than the cross-sectional area, S,, of he test piece,

Sand also of fasteners with untieaded shark diameter d,< da (8ee 8.2,

Fasteners in property classes 4.8, 5.8 and 6.8 (work-hardened fasteners) shall be tensile tested full-size,

see 9.3.

97.3 Apparatus

‘The tensile testing machine shall be in accordance with !SO 7500-1. Side thrust on the

avoided, e.. by self-aligning grips.

stener shall be

974 Testing device

“The grips andthe adaptors shat be as follows:

— hardness of 45 HRC min;

— hoe diameter, dy according to Table 18;

_— thread tolerance cass ofthe intemally threaded adaptr(s) according to Table 14

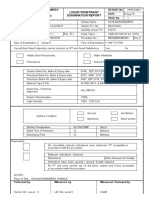

9.7.5 Machined test places

‘The test piece shall be machined from the fastener as received. The test piece shown in Figure 6 shall be

used for the tensile test

“The diameter of the machined test piece shall be do 3 mm.

‘When machining the test pieces of quenched and tempered fasteners with nominal diameter d > 16 mm the

duction of the original clameter, d, shall not exceed 25 % (about 44 % of the inital cross-sectional area). For

test pieces made from stud, bth ends shall have a thread length of micimum 1 d. J

97.6 Test procedure

‘The tensile test shall be carried out in accordance with ISO 6892-1. The speed of testing, as determined with

a free running cross head, shall not exceed 10 mm/min up to the load at lower yield strength, Ray, or the load

at the stress at 0,2 % non-proportional elongation, yg 2, and 25 mmimin beyond.

‘The tensile test shall be continued until fracture occurs.

‘Measure the uitimate tensile load, Fry.

36 (©180 2000 Al ghsresoned

‘Andrews Fasteners Ltd. Latest version as of 30/04/2009 16:17. Not to be distributed/networked. For multi-user access go to

Bought by Alicia Bogdanowicz,

\wwnw.bsigroup. comlicense © British Standards Institution

BS EN ISO 898-1:2009

180 898-1:2009()

tal length

&

shes

‘iamelar of machined test piece (do < ds min but, whenever possibi

thvead length (6 >)

‘1g. siginal gauge length of machined test pice

Key

nominal thread diameter

4

>

— for determination of elongation: Lg = 8d oF (5,65.

for determination of reducton of area: Ly Sd D> it nears legth must

1, lengh of ataight portion of machined tst piece (Ly * d) he

1, toallengtn of machined test place (F,* 2+ 8) se Above Zraxser0l.

5, cose seconal area of machined tes piece before tensile test 7

7 fillet radius (+ = 4mm) ae ott could de seet

Figure 6 — Machined test piece fortensile test ere

yletel — srongith, redveti

877 Test results

9.774 Method a. mt6x20

‘The following properties shall be determined in accordance with ISO 6892-1 fr Mib min sate longh

i

eet = AKI xCt 2Kb

Fin

aga 2 Jomm

b) lower yield strangth, Ray, or stress at 0,2 % non-proportional elongation, Ryo; 7” Mx 7° cool not

1) percentage elongation after fracture, providing that Lis at least 5d, do gel test

arch, legato ,

reductin

where

bys the final gauge length of machined test piece (see ISO 8882-1)

4) percentage reduction of area after fracture, providing that Lis atleast 3 dy

where

5, isthe cross-sectional area of machined test piece after fracture

(6180 2009 A ih recored 37

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Api 650Document1 pageApi 650Shaikh AdilNo ratings yet

- General Notes. 04.gasket Contact Finish Shall Be Serrated Finish To 125 To 250 (3.2 To 6.3um) & Waviness High of 0.05 MaxDocument1 pageGeneral Notes. 04.gasket Contact Finish Shall Be Serrated Finish To 125 To 250 (3.2 To 6.3um) & Waviness High of 0.05 MaxShaikh AdilNo ratings yet

- 3 OoboDocument1 page3 OoboShaikh AdilNo ratings yet

- India's Imports From China: Chapter-5Document30 pagesIndia's Imports From China: Chapter-5Shaikh AdilNo ratings yet

- PC Records For PMP Personnel: SL User Name Hard Drive Monitor Remark User Signature IT SignatureDocument2 pagesPC Records For PMP Personnel: SL User Name Hard Drive Monitor Remark User Signature IT SignatureShaikh AdilNo ratings yet

- Kingdom of Saudi Arabia: Saudi Standards, Metrology and Quality OrganizationDocument41 pagesKingdom of Saudi Arabia: Saudi Standards, Metrology and Quality OrganizationShaikh AdilNo ratings yet

- 520082272054091201Document1 page520082272054091201Shaikh AdilNo ratings yet

- List of Applicable Specifications For 190043 As Per A98-RC-A-1320374, Sheet 2 of 2, Rev.BDocument15 pagesList of Applicable Specifications For 190043 As Per A98-RC-A-1320374, Sheet 2 of 2, Rev.BShaikh AdilNo ratings yet

- List of Applicable Specifications For 190043 As Per A98-RC-A-1320374, Sheet 2 of 2, Rev.BDocument15 pagesList of Applicable Specifications For 190043 As Per A98-RC-A-1320374, Sheet 2 of 2, Rev.BShaikh AdilNo ratings yet

- L.P.T Reports.Document12 pagesL.P.T Reports.Shaikh AdilNo ratings yet

- Bin Malik Oil Field & Ind. Co. LLC: (Steel Trading Company)Document3 pagesBin Malik Oil Field & Ind. Co. LLC: (Steel Trading Company)Shaikh AdilNo ratings yet

- RR Items ReportsDocument54 pagesRR Items ReportsShaikh AdilNo ratings yet

- Carlton Industrial Engineers: Nde RequisitionDocument1 pageCarlton Industrial Engineers: Nde RequisitionShaikh AdilNo ratings yet

- Is 875 (Part 5) - Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresDocument26 pagesIs 875 (Part 5) - Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresShaikh AdilNo ratings yet

- Flange - Bolt Size ChartDocument6 pagesFlange - Bolt Size ChartShaikh AdilNo ratings yet

- Repair Procedure ANNEXUREDocument16 pagesRepair Procedure ANNEXUREShaikh AdilNo ratings yet

- Is 875 (Part 4) - Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresDocument11 pagesIs 875 (Part 4) - Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresShaikh AdilNo ratings yet