Professional Documents

Culture Documents

International Fire Code.: Plastic

International Fire Code.: Plastic

Uploaded by

keerthivasan_mrvCopyright:

Available Formats

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Cellulosic Fiber Insulating Board: Standard Specification ForDocument4 pagesCellulosic Fiber Insulating Board: Standard Specification ForingluisalejoNo ratings yet

- Precast Construction: ConceptDocument19 pagesPrecast Construction: ConceptSanjana BhandiwadNo ratings yet

- Chapter 26 PDFDocument10 pagesChapter 26 PDFruel delacruzNo ratings yet

- Pittsburgh Corning Foamglass Cold Process Piping Installation GuidelineDocument7 pagesPittsburgh Corning Foamglass Cold Process Piping Installation Guidelinenaseema1No ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07200-1 Building InsulationDocument5 pagesITCC in Riyadh Residential Complex J10-13300 07200-1 Building InsulationuddinnadeemNo ratings yet

- Code of Practice For The Installation of Cellular Pvc-U (Pvc-Ue) Roofline SystemsDocument14 pagesCode of Practice For The Installation of Cellular Pvc-U (Pvc-Ue) Roofline SystemsmazniseinNo ratings yet

- Chapter 8 - Interior FinishesDocument6 pagesChapter 8 - Interior FinishesPODNo ratings yet

- SECTION 15081: Duct Insulation 15081Document5 pagesSECTION 15081: Duct Insulation 15081fatREVITNo ratings yet

- Certificate 062 99Document6 pagesCertificate 062 99ferdinandbataraNo ratings yet

- Certificate 032 96Document9 pagesCertificate 032 96ferdinandbataraNo ratings yet

- SECTION 15082 Equipment Insulation Part 1 - General 1.1 GeneralDocument5 pagesSECTION 15082 Equipment Insulation Part 1 - General 1.1 GeneralfatREVITNo ratings yet

- Cladding To Timber FrameDocument34 pagesCladding To Timber Framecolinbooth91No ratings yet

- C34 PDFDocument3 pagesC34 PDFJayakumar AnanthaNo ratings yet

- Building Fire SafetyDocument9 pagesBuilding Fire SafetyrishiNo ratings yet

- Foamglas Insulation SpecificationsDocument7 pagesFoamglas Insulation Specificationsjohn_p47No ratings yet

- Technobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFDocument5 pagesTechnobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFJohn SmithNo ratings yet

- Polyethylene InsulationDocument2 pagesPolyethylene InsulationJeghi100% (1)

- IMG - 0088 PSME Code 2012 86Document1 pageIMG - 0088 PSME Code 2012 86Bugoy2023No ratings yet

- New York City - CombustibleDocument57 pagesNew York City - Combustiblesubham sahuNo ratings yet

- Park House 1001Document6 pagesPark House 1001IvanBaptistaSegoviaNo ratings yet

- 06/30/22 DESIGN NO. - SECTION 15514 Ductwork Insulation Part 1 - General 1.01 Description of WorkDocument16 pages06/30/22 DESIGN NO. - SECTION 15514 Ductwork Insulation Part 1 - General 1.01 Description of WorkJhoNo ratings yet

- FOAMGLAS Liquid Nitrogen & Oxygen Pipes I02-10Document4 pagesFOAMGLAS Liquid Nitrogen & Oxygen Pipes I02-10kaizadNo ratings yet

- Section Pb-428 - InsulationDocument3 pagesSection Pb-428 - Insulationjames_chan2178No ratings yet

- Sabisa Drywall GuideDocument31 pagesSabisa Drywall GuideprongsakNo ratings yet

- TB 34 - Steel Building Frames June 2020 EarthingDocument8 pagesTB 34 - Steel Building Frames June 2020 EarthingRethish KochukavilakathNo ratings yet

- Brick Veneer/Concrete Masonry Walls: Technical Notes 28DDocument19 pagesBrick Veneer/Concrete Masonry Walls: Technical Notes 28DKen SuNo ratings yet

- Tarecpir Project Spec Inst GuideDocument64 pagesTarecpir Project Spec Inst GuideFaizal YaacobNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07150-1 DampproofingDocument3 pagesITCC in Riyadh Residential Complex J10-13300 07150-1 DampproofinguddinnadeemNo ratings yet

- Chapter 14 Thru Index PDFDocument446 pagesChapter 14 Thru Index PDFMita PutriNo ratings yet

- SECTION 03 52 00 Lightweight Concrete Roof InsulationDocument7 pagesSECTION 03 52 00 Lightweight Concrete Roof InsulationJuanPaoloYbañezNo ratings yet

- QFSS-3.5.2 - Exterior Non Load Bearing Walls - Rev ADocument2 pagesQFSS-3.5.2 - Exterior Non Load Bearing Walls - Rev ARotsapNayrbNo ratings yet

- Manual Firetherm 30.90Document13 pagesManual Firetherm 30.90osmarphiNo ratings yet

- Insulation SpecificationDocument19 pagesInsulation SpecificationmnsNo ratings yet

- 07270-Fire StoppingDocument4 pages07270-Fire StoppingEfz EfzNo ratings yet

- Aci523 - ImportanteDocument5 pagesAci523 - ImportanteCledson2No ratings yet

- Group 6 Rule 16 18Document30 pagesGroup 6 Rule 16 18Melvin AlarillaNo ratings yet

- Project Standard Specification: Pipe Insulation 15083 - Page 1/15Document15 pagesProject Standard Specification: Pipe Insulation 15083 - Page 1/15adel rihanaNo ratings yet

- Piping and Equipment InsulationDocument4 pagesPiping and Equipment InsulationttshareefNo ratings yet

- Sabisa Drywall Guide PDFDocument31 pagesSabisa Drywall Guide PDFErickson MalicsiNo ratings yet

- The National Building CodeDocument7 pagesThe National Building Codemike jobernard f. solangonNo ratings yet

- Cellulosic Fiber Insulating Board: Standard Specification ForDocument4 pagesCellulosic Fiber Insulating Board: Standard Specification ForLupita RamirezNo ratings yet

- PROMATECT® H Double Layer Steel Stud PartitionsDocument14 pagesPROMATECT® H Double Layer Steel Stud PartitionsjeffNo ratings yet

- Rule 16 - Plastics (Book Format)Document3 pagesRule 16 - Plastics (Book Format)Thea AbelardoNo ratings yet

- PTH Internal Partition PDFDocument17 pagesPTH Internal Partition PDFMartin KwanNo ratings yet

- Kimmco InsulationDocument7 pagesKimmco InsulationMujjo SahbNo ratings yet

- CF5134 Promat Fire Protection PROMATEC HDocument28 pagesCF5134 Promat Fire Protection PROMATEC HJESSIKANo ratings yet

- By Arthur J. Parker, PE and Jesse J. Beitel: Modern MaterialsDocument3 pagesBy Arthur J. Parker, PE and Jesse J. Beitel: Modern MaterialsHaroun EdressNo ratings yet

- 2009 Panel Systems Compared.TDocument6 pages2009 Panel Systems Compared.Tdiplomat1969No ratings yet

- Promat Wall SystemDocument12 pagesPromat Wall SystemBaljit SinghNo ratings yet

- MORTH 1600 2 Acrylic Elastomeric CoatingDocument4 pagesMORTH 1600 2 Acrylic Elastomeric CoatingRameshNo ratings yet

- Saes N 004 PDFDocument5 pagesSaes N 004 PDFRampal Rahul Rampal RahulNo ratings yet

- CCRR-0467 Omega DiamondWallDocument17 pagesCCRR-0467 Omega DiamondWallj.saiyathNo ratings yet

- Construction Details: Foot - FacadeDocument12 pagesConstruction Details: Foot - FacadeWieda Ahmad MujtabaNo ratings yet

- C 208 - 95 - Qziwoc05nqDocument4 pagesC 208 - 95 - Qziwoc05nqElvis Lionel FLORES ROCANo ratings yet

- Guide Spec For High Temperature Pipe InsulationDocument6 pagesGuide Spec For High Temperature Pipe InsulationferzeleeNo ratings yet

- 07 2100 - Building InsulationDocument7 pages07 2100 - Building InsulationAngelo Carlo MalabananNo ratings yet

- Enquiry - Passive Fire Protection SystemDocument6 pagesEnquiry - Passive Fire Protection Systemrkpatel40No ratings yet

- Project Standard Specification: Duct Insulation 15081 - Page 1/11Document11 pagesProject Standard Specification: Duct Insulation 15081 - Page 1/11adel rihanaNo ratings yet

- FM Global Property Loss Prevention Data Sheets: List of TablesDocument6 pagesFM Global Property Loss Prevention Data Sheets: List of Tablesthongtn2007No ratings yet

- Purlin Data:-: 26-Apr-2022 1 OF 2 Port RK SSK Design of Int Girt 0 SSK Vizag IS: 801Document2 pagesPurlin Data:-: 26-Apr-2022 1 OF 2 Port RK SSK Design of Int Girt 0 SSK Vizag IS: 801keerthivasan_mrvNo ratings yet

- Purlin Data:-: 10-Sep-2014 1 OF 2 VGC SMA Design of Intermediate Purlin 0 IS: 801Document2 pagesPurlin Data:-: 10-Sep-2014 1 OF 2 VGC SMA Design of Intermediate Purlin 0 IS: 801keerthivasan_mrvNo ratings yet

- Project: Document No Date 21-05-2022 Designed Checked Description Visakhapatnam Port TrustDocument1 pageProject: Document No Date 21-05-2022 Designed Checked Description Visakhapatnam Port Trustkeerthivasan_mrvNo ratings yet

- Check For Tension: TF TDF: MF m1 M MWDocument4 pagesCheck For Tension: TF TDF: MF m1 M MWkeerthivasan_mrvNo ratings yet

- PJR Projects Construction PVT.: Design Basis ReportDocument96 pagesPJR Projects Construction PVT.: Design Basis Reportkeerthivasan_mrvNo ratings yet

- InputsDocument6 pagesInputskeerthivasan_mrvNo ratings yet

- Chain Link ManualDocument34 pagesChain Link Manualkeerthivasan_mrv100% (2)

- Defects/imperfections in Welds - Slag Inclusions: ! " # # $ # % # # # # & Type of Flux Coating Welder Technique ! # &Document3 pagesDefects/imperfections in Welds - Slag Inclusions: ! " # # $ # % # # # # & Type of Flux Coating Welder Technique ! # &keerthivasan_mrvNo ratings yet

- Purlin Data:-: 26-Apr-2022 1 OF 2 Port RK SSK Design of End Purlin 0 SSK Vizag IS: 801Document2 pagesPurlin Data:-: 26-Apr-2022 1 OF 2 Port RK SSK Design of End Purlin 0 SSK Vizag IS: 801keerthivasan_mrvNo ratings yet

- Defects - Lamellar TearingDocument5 pagesDefects - Lamellar Tearingkeerthivasan_mrvNo ratings yet

- Locktite 2701Document3 pagesLocktite 2701keerthivasan_mrvNo ratings yet

- Shear Stud WeldingDocument1 pageShear Stud Weldingkeerthivasan_mrvNo ratings yet

- AESS Finish PDFDocument32 pagesAESS Finish PDFkeerthivasan_mrvNo ratings yet

- SDBDocument5 pagesSDBkeerthivasan_mrvNo ratings yet

- Tension: Unity Check For Bolt in Tension 87.28/112 0.77 Hence SafeDocument2 pagesTension: Unity Check For Bolt in Tension 87.28/112 0.77 Hence Safekeerthivasan_mrvNo ratings yet

- DBRDocument3 pagesDBRkeerthivasan_mrvNo ratings yet

- Load CombinationsDocument2 pagesLoad Combinationskeerthivasan_mrvNo ratings yet

- Design of Splicing of RafterDocument3 pagesDesign of Splicing of Rafterkeerthivasan_mrvNo ratings yet

- A Review On Hybrid Fiber Reinforced Concrete Pavements TechnologyJournal of Physics Conference SeriesDocument15 pagesA Review On Hybrid Fiber Reinforced Concrete Pavements TechnologyJournal of Physics Conference SeriesJuan ReyesNo ratings yet

- Garden Design Book Ver 2Document38 pagesGarden Design Book Ver 2Marwa AlriffaiNo ratings yet

- Quotation La Moraleja Tejado 1 20230606Document4 pagesQuotation La Moraleja Tejado 1 20230606Juan PalomoNo ratings yet

- Article Rotorua NZversionfinaleDocument19 pagesArticle Rotorua NZversionfinaleyihenew assefaNo ratings yet

- Diamond Coring Tool DD 160Document1 pageDiamond Coring Tool DD 160AntoNo ratings yet

- 4 Penilaian BisingDocument22 pages4 Penilaian Bisingyusir yatalattafNo ratings yet

- 2019 - Experimental Study of RC Deep Beam With Opening and FRP Composites Installed by Means of EBR and EBROGDocument12 pages2019 - Experimental Study of RC Deep Beam With Opening and FRP Composites Installed by Means of EBR and EBROGARNABNo ratings yet

- Notasi GambarDocument9 pagesNotasi GambarTeguh GuntoroNo ratings yet

- Storage Tank - Construction-Inspection & Tank Gauging System PDFDocument268 pagesStorage Tank - Construction-Inspection & Tank Gauging System PDFEbenezer DonkohNo ratings yet

- Vermiculite Gypsum-PlastersDocument8 pagesVermiculite Gypsum-PlastersSiddhesh Kamat MhamaiNo ratings yet

- Construction Labor Productivity PhilippinesDocument40 pagesConstruction Labor Productivity PhilippinesNico Jaylo100% (1)

- EuroCode 4 - Lecture 1Document28 pagesEuroCode 4 - Lecture 1Tấn Đạt PhanNo ratings yet

- RLT-Guideline 01: General Requirements For Air Handling UnitsDocument25 pagesRLT-Guideline 01: General Requirements For Air Handling UnitsJorge RoblesNo ratings yet

- Ascott Office New AreaDocument1 pageAscott Office New AreaMuh IhwanzNo ratings yet

- Nuvoco Vistas: Company Business Portfolio IncludesDocument4 pagesNuvoco Vistas: Company Business Portfolio Includesshiv rathNo ratings yet

- EPAS Module 1 - Preparation of Tools and WorkplaceDocument15 pagesEPAS Module 1 - Preparation of Tools and WorkplaceJulius Andrew G. SalenNo ratings yet

- Sheet 8Document8 pagesSheet 8Bharat GouripurNo ratings yet

- NVS Capability StatementDocument10 pagesNVS Capability StatementNayanajithNo ratings yet

- RISA-3D Quick Start HandoutDocument9 pagesRISA-3D Quick Start HandoutAlan LiuNo ratings yet

- Balance of Works Labor and Materials - 1updatedDocument1 pageBalance of Works Labor and Materials - 1updatedFiehl Amor LarozaNo ratings yet

- AD&D 2.0 Ravenloft Adventure - Church of The Poisoned MindDocument14 pagesAD&D 2.0 Ravenloft Adventure - Church of The Poisoned MindXiahouscream HellscreamNo ratings yet

- CE 54100 Lecture - 4 Earth Moving Heavy Construction Excavation LiftingDocument14 pagesCE 54100 Lecture - 4 Earth Moving Heavy Construction Excavation LiftingRohit Ramesh100% (1)

- UPR-377-MSRA-MEP-ISG-001 - Site Office & Welfare FacilityDocument28 pagesUPR-377-MSRA-MEP-ISG-001 - Site Office & Welfare Facilityjagathmukundhan00No ratings yet

- Udyam Registration CertificateDocument4 pagesUdyam Registration CertificateAvinash TiwariNo ratings yet

- Fall Protection Plan Template DownloadDocument3 pagesFall Protection Plan Template Downloadabdalla el-saadaneyNo ratings yet

- Civil Works CW05 R1 (Submission Drawings 16.03.22)Document1 pageCivil Works CW05 R1 (Submission Drawings 16.03.22)Joel AganNo ratings yet

- Rehabilitation of Malir Football Ground (Chatai Ground) Assoo Goth Uc-10 Ghazi Dawood, DMC Malir Karachi (Pp-01)Document1 pageRehabilitation of Malir Football Ground (Chatai Ground) Assoo Goth Uc-10 Ghazi Dawood, DMC Malir Karachi (Pp-01)Syed Mohsin AliNo ratings yet

- 04 2002csDocument6 pages04 2002csmarc naganoNo ratings yet

- The Method Statement For Construction WorkDocument13 pagesThe Method Statement For Construction WorkAinAniza100% (1)

International Fire Code.: Plastic

International Fire Code.: Plastic

Uploaded by

keerthivasan_mrvOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

International Fire Code.: Plastic

International Fire Code.: Plastic

Uploaded by

keerthivasan_mrvCopyright:

Available Formats

PLASTIC

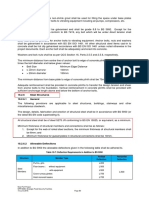

not less than 2 inches (51 mm) of mineral fiber insulation be tested separately in the thickness intended for use, but not

or equivalent or where applied as insulation with to exceed 4 inches (102 mm), and shall each have a flame

re-siding over existing wall construction. spread index of 25 or less and a smoke-developed index of

450 or less as determined in accordance with ASTM E 84.

2603.4.1.11 Interior trim. Foam plastic used as interior

trim in accordance with Section 2604 shall be permitted Exception: Prefabricated or factory-manufactured pan-

without a thermal barrier. els having minimum 0.020-inch (0.51 mm) aluminum

facings and a total thickness of 0.25 inch (6.4 mm) or less

2603.4.1.12 Interior signs. Foam plastic used for inte-

are permitted to be tested as an assembly where the foam

rior signs in covered mall buildings in accordance with

plastic core is not exposed in the course of construction.

Section 402.15 shall be permitted without a thermal bar-

rier. Foam plastic signs that are not affixed to interior 2603.5.5 Test standard. The wall assembly shall be tested

building surfaces shall comply with Chapter 8 of the in accordance with and comply with the acceptance criteria

International Fire Code. of NFPA 285.

2603.4.1.13 Type V construction. Foam plastic spray Exception: One-story buildings complying with Section

applied to a sill plate and header of Type V construction 2603.4.1.4.

is subject to all of the following: 2603.5.6 Label required. The edge or face of each piece of

1. The maximum thickness of the foam plastic shall foam plastic insulation shall bear the label of an approved

be 31/4 inches (82.6 mm). agency. The label shall contain the manufacturers or dis-

tributors identification, model number, serial number or

2. The density of the foam plastic shall be in the range

definitive information describing the product or materials

of 1.5 to 2.0 pcf (24 to 32 kg/m3).

performance characteristics and approved agencys identifi-

3. The foam plastic shall have a flame spread index of cation.

25 or less and an accompanying smoke-developed

2603.5.7 Ignition. Exterior walls shall not exhibit sustained

index of 450 or less when tested in accordance

flaming where tested in accordance with NFPA 268. Where

with ASTM E 84.

a material is intended to be installed in more than one thick-

2603.5 Exterior walls of buildings of any height. Exterior ness, tests of the minimum and maximum thickness

walls of buildings of Type I, II, III or IV construction of any intended for use shall be performed.

height shall comply with Sections 2603.5.1 through 2603.5.7.

Exception: Assemblies protected on the outside with

Exterior walls of cold storage buildings required to be con-

one of the following:

structed of noncombustible materials, where the building is

more than one story in height, shall also comply with the provi- 1. A thermal barrier complying with Section 2603.4.

sions of Sections 2603.5.1 through 2603.5.7. Exterior walls of 2. A minimum 1 inch (25 mm) thickness of concrete

buildings of Type V construction shall comply with Sections or masonry.

2603.2, 2603.3 and 2603.4.

3. Glass-fiber-reinforced concrete panels of a mini-

2603.5.1 Fire-resistance-rated walls. Where the wall is mum thickness of 0.375 inch (9.5 mm).

required to have a fire-resistance rating, data based on tests

conducted in accordance with ASTM E 119 shall be pro- 4. Metal-faced panels having minimum 0.019-

vided to substantiate that the fire-resistance rating is main- inch-thick (0.48 mm) aluminum or 0.016-inch-

tained. thick (0.41 mm) corrosion-resistant steel outer fac-

ings.

2603.5.2 Thermal barrier. Any foam plastic insulation

shall be separated from the building interior by a thermal 5. A minimum 0.875 inch (22.2 mm) thickness of

barrier meeting the provisions of Section 2603.4, unless stucco complying with Section 2510.

special approval is obtained on the basis of Section 2603.8. 2603.6 Roofing. Foam plastic insulation meeting the require-

ments of Sections 2603.2, 2603.3 and 2603.4 shall be permit-

Exception: One-story buildings complying with Section

ted as part of a roof-covering assembly, provided the assembly

2603.4.1.4.

with the foam plastic insulation is a Class A, B or C roofing

2603.5.3 Potential heat. The potential heat of foam plastic assembly where tested in accordance with ASTM E 108 or UL

insulation in any portion of the wall or panel shall not 790.

exceed the potential heat expressed in Btu per square feet

2603.7 Plenums. Foam plastic insulation shall not be used as

(mJ/m2) of the foam plastic insulation contained in the wall

interior wall or ceiling finish in plenums except as permitted in

assembly tested in accordance with Section 2603.5.5. The

Section 2604 or when protected by a thermal barrier in accor-

potential heat of the foam plastic insulation shall be deter-

dance with Section 2603.4.

mined by tests conducted in accordance with NFPA 259 and

the results shall be expressed in Btu per square feet (mJ/m2). 2603.8 Protection against termites. In areas where the proba-

bility of termite infestation is very heavy in accordance with

Exception: One-story buildings complying with Section Figure 2603.8, extruded and expanded polystyrene,

2603.4.1.4. polyisocyanurate and other foam plastics shall not be installed

2603.5.4 Flame spread and smoke-developed indexes. on the exterior face or under interior or exterior foundation

Foam plastic insulation, exterior coatings and facings shall walls or slab foundations located below grade. The clearance

2006 INTERNATIONAL BUILDING CODE 509

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Cellulosic Fiber Insulating Board: Standard Specification ForDocument4 pagesCellulosic Fiber Insulating Board: Standard Specification ForingluisalejoNo ratings yet

- Precast Construction: ConceptDocument19 pagesPrecast Construction: ConceptSanjana BhandiwadNo ratings yet

- Chapter 26 PDFDocument10 pagesChapter 26 PDFruel delacruzNo ratings yet

- Pittsburgh Corning Foamglass Cold Process Piping Installation GuidelineDocument7 pagesPittsburgh Corning Foamglass Cold Process Piping Installation Guidelinenaseema1No ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07200-1 Building InsulationDocument5 pagesITCC in Riyadh Residential Complex J10-13300 07200-1 Building InsulationuddinnadeemNo ratings yet

- Code of Practice For The Installation of Cellular Pvc-U (Pvc-Ue) Roofline SystemsDocument14 pagesCode of Practice For The Installation of Cellular Pvc-U (Pvc-Ue) Roofline SystemsmazniseinNo ratings yet

- Chapter 8 - Interior FinishesDocument6 pagesChapter 8 - Interior FinishesPODNo ratings yet

- SECTION 15081: Duct Insulation 15081Document5 pagesSECTION 15081: Duct Insulation 15081fatREVITNo ratings yet

- Certificate 062 99Document6 pagesCertificate 062 99ferdinandbataraNo ratings yet

- Certificate 032 96Document9 pagesCertificate 032 96ferdinandbataraNo ratings yet

- SECTION 15082 Equipment Insulation Part 1 - General 1.1 GeneralDocument5 pagesSECTION 15082 Equipment Insulation Part 1 - General 1.1 GeneralfatREVITNo ratings yet

- Cladding To Timber FrameDocument34 pagesCladding To Timber Framecolinbooth91No ratings yet

- C34 PDFDocument3 pagesC34 PDFJayakumar AnanthaNo ratings yet

- Building Fire SafetyDocument9 pagesBuilding Fire SafetyrishiNo ratings yet

- Foamglas Insulation SpecificationsDocument7 pagesFoamglas Insulation Specificationsjohn_p47No ratings yet

- Technobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFDocument5 pagesTechnobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFJohn SmithNo ratings yet

- Polyethylene InsulationDocument2 pagesPolyethylene InsulationJeghi100% (1)

- IMG - 0088 PSME Code 2012 86Document1 pageIMG - 0088 PSME Code 2012 86Bugoy2023No ratings yet

- New York City - CombustibleDocument57 pagesNew York City - Combustiblesubham sahuNo ratings yet

- Park House 1001Document6 pagesPark House 1001IvanBaptistaSegoviaNo ratings yet

- 06/30/22 DESIGN NO. - SECTION 15514 Ductwork Insulation Part 1 - General 1.01 Description of WorkDocument16 pages06/30/22 DESIGN NO. - SECTION 15514 Ductwork Insulation Part 1 - General 1.01 Description of WorkJhoNo ratings yet

- FOAMGLAS Liquid Nitrogen & Oxygen Pipes I02-10Document4 pagesFOAMGLAS Liquid Nitrogen & Oxygen Pipes I02-10kaizadNo ratings yet

- Section Pb-428 - InsulationDocument3 pagesSection Pb-428 - Insulationjames_chan2178No ratings yet

- Sabisa Drywall GuideDocument31 pagesSabisa Drywall GuideprongsakNo ratings yet

- TB 34 - Steel Building Frames June 2020 EarthingDocument8 pagesTB 34 - Steel Building Frames June 2020 EarthingRethish KochukavilakathNo ratings yet

- Brick Veneer/Concrete Masonry Walls: Technical Notes 28DDocument19 pagesBrick Veneer/Concrete Masonry Walls: Technical Notes 28DKen SuNo ratings yet

- Tarecpir Project Spec Inst GuideDocument64 pagesTarecpir Project Spec Inst GuideFaizal YaacobNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07150-1 DampproofingDocument3 pagesITCC in Riyadh Residential Complex J10-13300 07150-1 DampproofinguddinnadeemNo ratings yet

- Chapter 14 Thru Index PDFDocument446 pagesChapter 14 Thru Index PDFMita PutriNo ratings yet

- SECTION 03 52 00 Lightweight Concrete Roof InsulationDocument7 pagesSECTION 03 52 00 Lightweight Concrete Roof InsulationJuanPaoloYbañezNo ratings yet

- QFSS-3.5.2 - Exterior Non Load Bearing Walls - Rev ADocument2 pagesQFSS-3.5.2 - Exterior Non Load Bearing Walls - Rev ARotsapNayrbNo ratings yet

- Manual Firetherm 30.90Document13 pagesManual Firetherm 30.90osmarphiNo ratings yet

- Insulation SpecificationDocument19 pagesInsulation SpecificationmnsNo ratings yet

- 07270-Fire StoppingDocument4 pages07270-Fire StoppingEfz EfzNo ratings yet

- Aci523 - ImportanteDocument5 pagesAci523 - ImportanteCledson2No ratings yet

- Group 6 Rule 16 18Document30 pagesGroup 6 Rule 16 18Melvin AlarillaNo ratings yet

- Project Standard Specification: Pipe Insulation 15083 - Page 1/15Document15 pagesProject Standard Specification: Pipe Insulation 15083 - Page 1/15adel rihanaNo ratings yet

- Piping and Equipment InsulationDocument4 pagesPiping and Equipment InsulationttshareefNo ratings yet

- Sabisa Drywall Guide PDFDocument31 pagesSabisa Drywall Guide PDFErickson MalicsiNo ratings yet

- The National Building CodeDocument7 pagesThe National Building Codemike jobernard f. solangonNo ratings yet

- Cellulosic Fiber Insulating Board: Standard Specification ForDocument4 pagesCellulosic Fiber Insulating Board: Standard Specification ForLupita RamirezNo ratings yet

- PROMATECT® H Double Layer Steel Stud PartitionsDocument14 pagesPROMATECT® H Double Layer Steel Stud PartitionsjeffNo ratings yet

- Rule 16 - Plastics (Book Format)Document3 pagesRule 16 - Plastics (Book Format)Thea AbelardoNo ratings yet

- PTH Internal Partition PDFDocument17 pagesPTH Internal Partition PDFMartin KwanNo ratings yet

- Kimmco InsulationDocument7 pagesKimmco InsulationMujjo SahbNo ratings yet

- CF5134 Promat Fire Protection PROMATEC HDocument28 pagesCF5134 Promat Fire Protection PROMATEC HJESSIKANo ratings yet

- By Arthur J. Parker, PE and Jesse J. Beitel: Modern MaterialsDocument3 pagesBy Arthur J. Parker, PE and Jesse J. Beitel: Modern MaterialsHaroun EdressNo ratings yet

- 2009 Panel Systems Compared.TDocument6 pages2009 Panel Systems Compared.Tdiplomat1969No ratings yet

- Promat Wall SystemDocument12 pagesPromat Wall SystemBaljit SinghNo ratings yet

- MORTH 1600 2 Acrylic Elastomeric CoatingDocument4 pagesMORTH 1600 2 Acrylic Elastomeric CoatingRameshNo ratings yet

- Saes N 004 PDFDocument5 pagesSaes N 004 PDFRampal Rahul Rampal RahulNo ratings yet

- CCRR-0467 Omega DiamondWallDocument17 pagesCCRR-0467 Omega DiamondWallj.saiyathNo ratings yet

- Construction Details: Foot - FacadeDocument12 pagesConstruction Details: Foot - FacadeWieda Ahmad MujtabaNo ratings yet

- C 208 - 95 - Qziwoc05nqDocument4 pagesC 208 - 95 - Qziwoc05nqElvis Lionel FLORES ROCANo ratings yet

- Guide Spec For High Temperature Pipe InsulationDocument6 pagesGuide Spec For High Temperature Pipe InsulationferzeleeNo ratings yet

- 07 2100 - Building InsulationDocument7 pages07 2100 - Building InsulationAngelo Carlo MalabananNo ratings yet

- Enquiry - Passive Fire Protection SystemDocument6 pagesEnquiry - Passive Fire Protection Systemrkpatel40No ratings yet

- Project Standard Specification: Duct Insulation 15081 - Page 1/11Document11 pagesProject Standard Specification: Duct Insulation 15081 - Page 1/11adel rihanaNo ratings yet

- FM Global Property Loss Prevention Data Sheets: List of TablesDocument6 pagesFM Global Property Loss Prevention Data Sheets: List of Tablesthongtn2007No ratings yet

- Purlin Data:-: 26-Apr-2022 1 OF 2 Port RK SSK Design of Int Girt 0 SSK Vizag IS: 801Document2 pagesPurlin Data:-: 26-Apr-2022 1 OF 2 Port RK SSK Design of Int Girt 0 SSK Vizag IS: 801keerthivasan_mrvNo ratings yet

- Purlin Data:-: 10-Sep-2014 1 OF 2 VGC SMA Design of Intermediate Purlin 0 IS: 801Document2 pagesPurlin Data:-: 10-Sep-2014 1 OF 2 VGC SMA Design of Intermediate Purlin 0 IS: 801keerthivasan_mrvNo ratings yet

- Project: Document No Date 21-05-2022 Designed Checked Description Visakhapatnam Port TrustDocument1 pageProject: Document No Date 21-05-2022 Designed Checked Description Visakhapatnam Port Trustkeerthivasan_mrvNo ratings yet

- Check For Tension: TF TDF: MF m1 M MWDocument4 pagesCheck For Tension: TF TDF: MF m1 M MWkeerthivasan_mrvNo ratings yet

- PJR Projects Construction PVT.: Design Basis ReportDocument96 pagesPJR Projects Construction PVT.: Design Basis Reportkeerthivasan_mrvNo ratings yet

- InputsDocument6 pagesInputskeerthivasan_mrvNo ratings yet

- Chain Link ManualDocument34 pagesChain Link Manualkeerthivasan_mrv100% (2)

- Defects/imperfections in Welds - Slag Inclusions: ! " # # $ # % # # # # & Type of Flux Coating Welder Technique ! # &Document3 pagesDefects/imperfections in Welds - Slag Inclusions: ! " # # $ # % # # # # & Type of Flux Coating Welder Technique ! # &keerthivasan_mrvNo ratings yet

- Purlin Data:-: 26-Apr-2022 1 OF 2 Port RK SSK Design of End Purlin 0 SSK Vizag IS: 801Document2 pagesPurlin Data:-: 26-Apr-2022 1 OF 2 Port RK SSK Design of End Purlin 0 SSK Vizag IS: 801keerthivasan_mrvNo ratings yet

- Defects - Lamellar TearingDocument5 pagesDefects - Lamellar Tearingkeerthivasan_mrvNo ratings yet

- Locktite 2701Document3 pagesLocktite 2701keerthivasan_mrvNo ratings yet

- Shear Stud WeldingDocument1 pageShear Stud Weldingkeerthivasan_mrvNo ratings yet

- AESS Finish PDFDocument32 pagesAESS Finish PDFkeerthivasan_mrvNo ratings yet

- SDBDocument5 pagesSDBkeerthivasan_mrvNo ratings yet

- Tension: Unity Check For Bolt in Tension 87.28/112 0.77 Hence SafeDocument2 pagesTension: Unity Check For Bolt in Tension 87.28/112 0.77 Hence Safekeerthivasan_mrvNo ratings yet

- DBRDocument3 pagesDBRkeerthivasan_mrvNo ratings yet

- Load CombinationsDocument2 pagesLoad Combinationskeerthivasan_mrvNo ratings yet

- Design of Splicing of RafterDocument3 pagesDesign of Splicing of Rafterkeerthivasan_mrvNo ratings yet

- A Review On Hybrid Fiber Reinforced Concrete Pavements TechnologyJournal of Physics Conference SeriesDocument15 pagesA Review On Hybrid Fiber Reinforced Concrete Pavements TechnologyJournal of Physics Conference SeriesJuan ReyesNo ratings yet

- Garden Design Book Ver 2Document38 pagesGarden Design Book Ver 2Marwa AlriffaiNo ratings yet

- Quotation La Moraleja Tejado 1 20230606Document4 pagesQuotation La Moraleja Tejado 1 20230606Juan PalomoNo ratings yet

- Article Rotorua NZversionfinaleDocument19 pagesArticle Rotorua NZversionfinaleyihenew assefaNo ratings yet

- Diamond Coring Tool DD 160Document1 pageDiamond Coring Tool DD 160AntoNo ratings yet

- 4 Penilaian BisingDocument22 pages4 Penilaian Bisingyusir yatalattafNo ratings yet

- 2019 - Experimental Study of RC Deep Beam With Opening and FRP Composites Installed by Means of EBR and EBROGDocument12 pages2019 - Experimental Study of RC Deep Beam With Opening and FRP Composites Installed by Means of EBR and EBROGARNABNo ratings yet

- Notasi GambarDocument9 pagesNotasi GambarTeguh GuntoroNo ratings yet

- Storage Tank - Construction-Inspection & Tank Gauging System PDFDocument268 pagesStorage Tank - Construction-Inspection & Tank Gauging System PDFEbenezer DonkohNo ratings yet

- Vermiculite Gypsum-PlastersDocument8 pagesVermiculite Gypsum-PlastersSiddhesh Kamat MhamaiNo ratings yet

- Construction Labor Productivity PhilippinesDocument40 pagesConstruction Labor Productivity PhilippinesNico Jaylo100% (1)

- EuroCode 4 - Lecture 1Document28 pagesEuroCode 4 - Lecture 1Tấn Đạt PhanNo ratings yet

- RLT-Guideline 01: General Requirements For Air Handling UnitsDocument25 pagesRLT-Guideline 01: General Requirements For Air Handling UnitsJorge RoblesNo ratings yet

- Ascott Office New AreaDocument1 pageAscott Office New AreaMuh IhwanzNo ratings yet

- Nuvoco Vistas: Company Business Portfolio IncludesDocument4 pagesNuvoco Vistas: Company Business Portfolio Includesshiv rathNo ratings yet

- EPAS Module 1 - Preparation of Tools and WorkplaceDocument15 pagesEPAS Module 1 - Preparation of Tools and WorkplaceJulius Andrew G. SalenNo ratings yet

- Sheet 8Document8 pagesSheet 8Bharat GouripurNo ratings yet

- NVS Capability StatementDocument10 pagesNVS Capability StatementNayanajithNo ratings yet

- RISA-3D Quick Start HandoutDocument9 pagesRISA-3D Quick Start HandoutAlan LiuNo ratings yet

- Balance of Works Labor and Materials - 1updatedDocument1 pageBalance of Works Labor and Materials - 1updatedFiehl Amor LarozaNo ratings yet

- AD&D 2.0 Ravenloft Adventure - Church of The Poisoned MindDocument14 pagesAD&D 2.0 Ravenloft Adventure - Church of The Poisoned MindXiahouscream HellscreamNo ratings yet

- CE 54100 Lecture - 4 Earth Moving Heavy Construction Excavation LiftingDocument14 pagesCE 54100 Lecture - 4 Earth Moving Heavy Construction Excavation LiftingRohit Ramesh100% (1)

- UPR-377-MSRA-MEP-ISG-001 - Site Office & Welfare FacilityDocument28 pagesUPR-377-MSRA-MEP-ISG-001 - Site Office & Welfare Facilityjagathmukundhan00No ratings yet

- Udyam Registration CertificateDocument4 pagesUdyam Registration CertificateAvinash TiwariNo ratings yet

- Fall Protection Plan Template DownloadDocument3 pagesFall Protection Plan Template Downloadabdalla el-saadaneyNo ratings yet

- Civil Works CW05 R1 (Submission Drawings 16.03.22)Document1 pageCivil Works CW05 R1 (Submission Drawings 16.03.22)Joel AganNo ratings yet

- Rehabilitation of Malir Football Ground (Chatai Ground) Assoo Goth Uc-10 Ghazi Dawood, DMC Malir Karachi (Pp-01)Document1 pageRehabilitation of Malir Football Ground (Chatai Ground) Assoo Goth Uc-10 Ghazi Dawood, DMC Malir Karachi (Pp-01)Syed Mohsin AliNo ratings yet

- 04 2002csDocument6 pages04 2002csmarc naganoNo ratings yet

- The Method Statement For Construction WorkDocument13 pagesThe Method Statement For Construction WorkAinAniza100% (1)