Professional Documents

Culture Documents

Touchwood AC Sanding Sealer

Touchwood AC Sanding Sealer

Uploaded by

muthukumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Touchwood AC Sanding Sealer

Touchwood AC Sanding Sealer

Uploaded by

muthukumarCopyright:

Available Formats

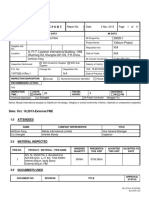

TECHNICAL DATA

ARCHITECTURAL COATINGS

TOUCHWOOD

www.asianpaints.com/oman AC Sanding Sealer

PRODUCT DESCRIPTION

BERGER Touchwood AC sanding sealer is a two pack acid curing product of premium quality, specially formulated as a

protective and decorative coating for wood for interiors.

It has an excellent filling property to fill the wood grains.

It offers substantial economy in terms of durability, decorative and protective value, compared to other conventional

coatings.

It also serves as a barrier coat between wooden surface & topcoat thus providing optimal finish to the topcoat.

RECOMMENDED AREAS OF APPLICATION

Natural wood, wood substitutes like plywood, particleboard, fibreboard etc.

For indoors use only.

TECHNICAL DATA

Finish : Dead matt

Solvent Resistance : Good resistance to aliphatic, aromatic hydrocarbons & polar solvents.

Composition Nominal : Acid catalysed Alkyd / Amino system

Specific gravity : 1.02 0.05

% Volume Solids : 40 2

Gloss level at 60 head : 5-10

Mixing ratio : 9:1 parts by volume (Base : Hardener)

Maturation time : 15 mins.

Pot Life : 8 hrs. at 30C

Viscosity of supply : 75-100 sec at 30C on FCB4

Pack Size : 1 USG, 5 USG

Theoretical Coverage Capacity : 12.6 - 14 Sqm. / Ltr. @ 30 DFT

Practical coverage : Practical coverage may depend on surface profile, method of application and weather conditions.

Surface dry Touch dry Recoatability Hard dry

Drying time at 30C :

15 min 30 min 4 hrs 18 hrs

APPLICATION DATA

Method of Application : Spray at an optimal spray pressure of 30-40 psi (2.2-2.8 kg/cm2)

Brushing is recommended for Touchups only.

Thinner : Thinner 124 for Spraying

:

Thinning ratio (by vol.) for spraying 30 - 40 %

SURFACE PREPARATION

Sand the Wooden surface with 180 Emery paper, followed by 400 Emery paper, dust off, remove all grease, loose flaking

paint etc.

Note : Sanding should be done along the grains only.

APPLICATIONS DETAILS

On the prepared surface apply two coats of Touchwood AC Sanding Sealer, on drying cut with emery paper 400 and then

topcoat with Gloss, Silkmatt or Matt depending on the finish required.

Stir the contents thoroughly before and during use, with a broad flat stirrer, using an upward lifting action.

Touchwood AC sealer is a two-component system consisting of a hardener and a base, which should be mixed, in the

recommended ratio.

Allow the mixture to stand for 15 min. and apply by spraying or brushing using the recommended thinner for viscosity

adjustments.

The mixture of base and hardener is to be used within eight hours.

RECOMMENDED PAINT SYSTEM

Two coats x Berger Touchwood AC Sanding Sealer

Two coats x Berger Touchwood AC Clear Top Coat

* For detailed system recommendation based on specific requirements please contact Berger representative.

STORAGE, SAFETY INFORMATION AND PRECAUTIONS

Flammability and Transport Information:

Flammable, Dangerous goods class 3.3, Flash 30C, UN 1263.

Safety information and precautions:

Do not apply at temperature below 10C.

Provide adequate ventilation during use.

Keep out of reach of children.

Avoid contact with skin and eyes, wear suitable Personal Protective Equipments such as overalls, goggles, dust

masks and gloves.

Dispose in landfill only.

DISCLAIMER

The information provided in this data sheet is not intended to be complete. It is the responsibility of the user to ensure that the product used is suitable for the purpose it is meant to serve.

In view of various factors affecting the performance of the coating, we cannot assume responsibility for the product performance, nor do we accept any liability arising from use of this

product, unless specifcally agreed to in writing by us. The information provided in the datasheet may be modifed by us without notice.

This Technical Data Sheet supersedes those previously issued with immediate effect.

BAHRAIN: + 973-17-730700 OMAN: + 968-24596709 UAE: +971-4-3391000

Version: 02/2007

You might also like

- Ionic Bonds FormDocument4 pagesIonic Bonds FormMyesha CookNo ratings yet

- Touchwood AC Colour: Architectural CoatingsDocument2 pagesTouchwood AC Colour: Architectural CoatingsmuthukumarNo ratings yet

- Touchwood AC Clear LacquerDocument2 pagesTouchwood AC Clear LacquermuthukumarNo ratings yet

- Touchwood PU Varnish: Architectural CoatingsDocument2 pagesTouchwood PU Varnish: Architectural CoatingsmuthukumarNo ratings yet

- Touchwood Wood Stain (SBZ) PDFDocument2 pagesTouchwood Wood Stain (SBZ) PDFmuthukumarNo ratings yet

- Touchwood NC Clear LacquerDocument2 pagesTouchwood NC Clear LacquermuthukumarNo ratings yet

- Touchwood NC Primer SurfacerDocument2 pagesTouchwood NC Primer SurfacermuthukumarNo ratings yet

- Touchwood NC Sanding SealerDocument2 pagesTouchwood NC Sanding SealermuthukumarNo ratings yet

- Touchwood Wood Stain (WB) PDFDocument2 pagesTouchwood Wood Stain (WB) PDFmuthukumarNo ratings yet

- Touchwood Wood Stain (SB)Document2 pagesTouchwood Wood Stain (SB)vitharvanNo ratings yet

- Touchwood NC Colour: Architectural CoatingsDocument2 pagesTouchwood NC Colour: Architectural CoatingsmuthukumarNo ratings yet

- Touchwood Woodorite Primer PDFDocument2 pagesTouchwood Woodorite Primer PDFmuthukumarNo ratings yet

- Touchwood 2 PK PU Floor CoatingDocument2 pagesTouchwood 2 PK PU Floor CoatingmuthukumarNo ratings yet

- Touchwood NC Thinner: Architectural CoatingsDocument2 pagesTouchwood NC Thinner: Architectural CoatingsmuthukumarNo ratings yet

- Touchwood CongoDocument3 pagesTouchwood CongomuthukumarNo ratings yet

- Majestic True Beauty Sheen PDFDocument3 pagesMajestic True Beauty Sheen PDFBilher SihombingNo ratings yet

- Berger Royale Semi-Gloss EnamelDocument3 pagesBerger Royale Semi-Gloss Enamelbhima irabattiNo ratings yet

- Decora Synthetic Gloss EnamelDocument2 pagesDecora Synthetic Gloss EnamelMuthuKumarNo ratings yet

- Touchwood Wood Stain (SBZ) PDFDocument2 pagesTouchwood Wood Stain (SBZ) PDFMuthuKumarNo ratings yet

- 3 - PC 7049 - Apcodur MioDocument3 pages3 - PC 7049 - Apcodur Miosujay AvatiNo ratings yet

- Thermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Document3 pagesThermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Veera PandiNo ratings yet

- PC 1752 - Asian Bituminous CoatingsDocument3 pagesPC 1752 - Asian Bituminous CoatingsRamesh BabuNo ratings yet

- Decora Primer Sealer PDFDocument2 pagesDecora Primer Sealer PDFMuthuKumarNo ratings yet

- Touchwood Woodorite PrimerDocument2 pagesTouchwood Woodorite PrimerMuthuKumarNo ratings yet

- Decora Synthetic Matt EnamelDocument2 pagesDecora Synthetic Matt EnamelMuthuKumarNo ratings yet

- Select Interior Emulsion Matt: Product DescriptionDocument2 pagesSelect Interior Emulsion Matt: Product DescriptionRahul RNo ratings yet

- Decora Synthetic Semi-Gloss EnamelDocument2 pagesDecora Synthetic Semi-Gloss EnamelMuthuKumarNo ratings yet

- Touchwood AC Thinner T-124Document2 pagesTouchwood AC Thinner T-124muthukumarNo ratings yet

- Hempadur Zinc 17380Document2 pagesHempadur Zinc 17380sizmaruNo ratings yet

- Spesifikasi Cat JotunDocument3 pagesSpesifikasi Cat JotunTeknoGayaNo ratings yet

- Transpoxy Tankguard 118 ESDocument5 pagesTranspoxy Tankguard 118 ESFadi MagdyNo ratings yet

- Transpoxy Masterbond 4.67N (FLOORING GRADE)Document3 pagesTranspoxy Masterbond 4.67N (FLOORING GRADE)Sami KahtaniNo ratings yet

- Penguard Special: Technical DataDocument3 pagesPenguard Special: Technical DataMohamed FarhanNo ratings yet

- Touchwood 2 PK PU Top CoatDocument2 pagesTouchwood 2 PK PU Top CoatmuthukumarNo ratings yet

- Touchwood AC Thinner With RetarderDocument2 pagesTouchwood AC Thinner With RetardermuthukumarNo ratings yet

- PC 4033 - Epoxy Mio CoatingDocument3 pagesPC 4033 - Epoxy Mio CoatingUmesh ShengalNo ratings yet

- Product Data Sheet: Transpoxy Masterbond 4.68Document2 pagesProduct Data Sheet: Transpoxy Masterbond 4.68rajeshNo ratings yet

- Temacoat SPA 50: Type Suitability Examples of USE Technical DataDocument2 pagesTemacoat SPA 50: Type Suitability Examples of USE Technical Datamiagheorghe25No ratings yet

- TDS 30020 Easyprimer Euk GBDocument4 pagesTDS 30020 Easyprimer Euk GBToun ChansombatNo ratings yet

- Apcotide 1000 pc2782Document1 pageApcotide 1000 pc2782hellmanyaNo ratings yet

- Fenomastic My Home Rich MattDocument3 pagesFenomastic My Home Rich Mattمحمد عزتNo ratings yet

- Gardex Premium Gloss: Technical Data SheetDocument3 pagesGardex Premium Gloss: Technical Data SheetBhayu Senoaji Dwi PrimasanjoyoNo ratings yet

- Hempadur Zinc 17360Document2 pagesHempadur Zinc 17360Bang OchimNo ratings yet

- TD CTC 998Document2 pagesTD CTC 998Meliany SariNo ratings yet

- TI Furadur Kitt 322 - enDocument3 pagesTI Furadur Kitt 322 - engonzalogvargas01No ratings yet

- Jotashield Extreme - TDS PDFDocument3 pagesJotashield Extreme - TDS PDFLITOGENT 893No ratings yet

- Decora Stucco Putty: Product DescriptionDocument2 pagesDecora Stucco Putty: Product DescriptionMuthuKumar100% (1)

- PDS Tikkurila Temathane 50Document3 pagesPDS Tikkurila Temathane 50Marcin HryciukNo ratings yet

- TDS - Penguard Midcoat - Issu.26.11.2010 PDFDocument4 pagesTDS - Penguard Midcoat - Issu.26.11.2010 PDFvitharvanNo ratings yet

- Transunilac Finish 331Document4 pagesTransunilac Finish 331bhukyanaik02No ratings yet

- Sikagard®-62: Product Data SheetDocument4 pagesSikagard®-62: Product Data Sheetantonsugiarto20_7049No ratings yet

- 2305-00 Simacrylic CoatingDocument2 pages2305-00 Simacrylic CoatingSAEFUDDIN SAEFUDDINNo ratings yet

- Touchwood 2 PK PU Interior ThinnerDocument2 pagesTouchwood 2 PK PU Interior ThinnermuthukumarNo ratings yet

- SPORTRACK SC - enDocument2 pagesSPORTRACK SC - enRAMINo ratings yet

- Essense Easy Clean TDSDocument3 pagesEssense Easy Clean TDSthar gyiNo ratings yet

- MS GF 35870 en-GBDocument2 pagesMS GF 35870 en-GBLinnie McleodNo ratings yet

- Bathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofFrom EverandBathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofNo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- Bresle Test Kit PDFDocument4 pagesBresle Test Kit PDFmuthukumarNo ratings yet

- Aselectionfromp01unkngoog PDFDocument135 pagesAselectionfromp01unkngoog PDFmuthukumarNo ratings yet

- Pds Luxol 5000 VocDocument2 pagesPds Luxol 5000 VocmuthukumarNo ratings yet

- Pds Luxol 1000 VocDocument2 pagesPds Luxol 1000 VocmuthukumarNo ratings yet

- Drying ConditionsDocument1 pageDrying ConditionsmuthukumarNo ratings yet

- Touchwood CongoDocument3 pagesTouchwood CongomuthukumarNo ratings yet

- Pds Luxaprime 1500 VocDocument2 pagesPds Luxaprime 1500 VocmuthukumarNo ratings yet

- Paint Problems: Water and WeatherDocument4 pagesPaint Problems: Water and WeathermuthukumarNo ratings yet

- Pds Luxaprime 1400 VocDocument2 pagesPds Luxaprime 1400 VocmuthukumarNo ratings yet

- Aspects of Salt Concentration On Prepared Steel SubstratesDocument6 pagesAspects of Salt Concentration On Prepared Steel Substratesmuthukumar100% (1)

- Touchwood 2 PK PU Top CoatDocument2 pagesTouchwood 2 PK PU Top CoatmuthukumarNo ratings yet

- Touchwood 2 PK PU Top CoatDocument2 pagesTouchwood 2 PK PU Top CoatmuthukumarNo ratings yet

- Pds Luxaprime 1000 VocDocument2 pagesPds Luxaprime 1000 VocmuthukumarNo ratings yet

- Touchwood AC Thinner With RetarderDocument2 pagesTouchwood AC Thinner With RetardermuthukumarNo ratings yet

- Touchwood NC Primer SurfacerDocument2 pagesTouchwood NC Primer SurfacermuthukumarNo ratings yet

- Touchwood AC Colour: Architectural CoatingsDocument2 pagesTouchwood AC Colour: Architectural CoatingsmuthukumarNo ratings yet

- Touchwood AC Clear LacquerDocument2 pagesTouchwood AC Clear LacquermuthukumarNo ratings yet

- Touchwood AC Thinner T-124Document2 pagesTouchwood AC Thinner T-124muthukumarNo ratings yet

- Touchwood NC Clear LacquerDocument2 pagesTouchwood NC Clear LacquermuthukumarNo ratings yet

- Touchwood NC Thinner: Architectural CoatingsDocument2 pagesTouchwood NC Thinner: Architectural CoatingsmuthukumarNo ratings yet

- Touchwood Wood Stain (WB) PDFDocument2 pagesTouchwood Wood Stain (WB) PDFmuthukumarNo ratings yet

- Touchwood NC Sanding SealerDocument2 pagesTouchwood NC Sanding SealermuthukumarNo ratings yet

- Touchwood PU Varnish: Architectural CoatingsDocument2 pagesTouchwood PU Varnish: Architectural CoatingsmuthukumarNo ratings yet

- Touchwood NC Colour: Architectural CoatingsDocument2 pagesTouchwood NC Colour: Architectural CoatingsmuthukumarNo ratings yet

- Touchwood Wood Stain (SBZ) PDFDocument2 pagesTouchwood Wood Stain (SBZ) PDFmuthukumarNo ratings yet

- Touchwood NC Clear LacquerDocument2 pagesTouchwood NC Clear LacquermuthukumarNo ratings yet

- Pds Epilux 218 Hs VocDocument2 pagesPds Epilux 218 Hs VocmuthukumarNo ratings yet

- Coaxial Heat ExchangersDocument8 pagesCoaxial Heat ExchangersMukul SinghNo ratings yet

- Hexamine 1Document4 pagesHexamine 1Yousuck Donny ChandraNo ratings yet

- What's New in HSC 7.0: October 5, 2009 09006-ORC-JDocument32 pagesWhat's New in HSC 7.0: October 5, 2009 09006-ORC-JSenthilkumar PragasamNo ratings yet

- Datasheet 33Document5 pagesDatasheet 33deivison sobrinhoNo ratings yet

- RAN Chemicals - Textile - Finishing - Ready To Use - Cationic - Hydrophilic - Finishing Softener For Textile - RSF-AT-40-SHDocument3 pagesRAN Chemicals - Textile - Finishing - Ready To Use - Cationic - Hydrophilic - Finishing Softener For Textile - RSF-AT-40-SHcrplzNo ratings yet

- 1 - F Noise in Cmos Transistors For AnalogDocument11 pages1 - F Noise in Cmos Transistors For AnalogBahar BaratiNo ratings yet

- Dutchak Hailey Chem 12 Unit 1 Learning Guide PDFDocument10 pagesDutchak Hailey Chem 12 Unit 1 Learning Guide PDFhaileydutchakNo ratings yet

- What Is The Work of Accumulator in Turbines - QuoraDocument4 pagesWhat Is The Work of Accumulator in Turbines - QuoraEr Suraj KumarNo ratings yet

- Western Blot ProtocolDocument35 pagesWestern Blot ProtocolH DegaïchiaNo ratings yet

- Pra PTS Xi SMS 2Document11 pagesPra PTS Xi SMS 2Ammar KhadafiNo ratings yet

- LayoutDocument55 pagesLayoutHenok Moges KassahunNo ratings yet

- 15 - Bbs & Stop CardDocument39 pages15 - Bbs & Stop CardJanVpotNo ratings yet

- Effects of Fermentation in Saltine Cracker ProductionDocument5 pagesEffects of Fermentation in Saltine Cracker ProductionValéria BritoNo ratings yet

- Critical Review and Exergy Analysis of Formaldehyde Production ProcessesDocument24 pagesCritical Review and Exergy Analysis of Formaldehyde Production ProcessesFahad AkbarNo ratings yet

- API 5L Inspection ReportDocument16 pagesAPI 5L Inspection ReportBuddy EkoNo ratings yet

- Results and DiscussionDocument6 pagesResults and DiscussionKim HanaNo ratings yet

- Is Oxidative Coupling The Royal Road For The Valorization of Methane To Olefines?Document50 pagesIs Oxidative Coupling The Royal Road For The Valorization of Methane To Olefines?anon_936836736No ratings yet

- Project ThesisDocument73 pagesProject Thesissumaiya jalalNo ratings yet

- Heat and Mass Transfer QuizDocument7 pagesHeat and Mass Transfer Quizdsathiya0% (1)

- HS 25Document20 pagesHS 25lovetoread_story8790No ratings yet

- The Handbook of Hazardous Materials Spills Technology 39. Sodium CyanideDocument22 pagesThe Handbook of Hazardous Materials Spills Technology 39. Sodium CyanideJoelCristobal100% (1)

- Method of Test For Bulk Relative Density of Compacted Bituminous Mixtures Using Paraffin Coated SpecimensDocument4 pagesMethod of Test For Bulk Relative Density of Compacted Bituminous Mixtures Using Paraffin Coated SpecimensdarcinaNo ratings yet

- Chapter 23 Functional GroupsDocument81 pagesChapter 23 Functional GroupsYudi PermanaNo ratings yet

- Copeland para CogeladoDocument1 pageCopeland para CogeladoAlvaro DiazNo ratings yet

- PHD Offer, Batteries, FranceDocument1 pagePHD Offer, Batteries, FranceSamehHamzawyNo ratings yet

- 734 Part2 EmulsionDocument28 pages734 Part2 EmulsionSuvin PsNo ratings yet

- Index Mil SpecDocument13 pagesIndex Mil SpecantblyNo ratings yet

- 4TH Sem B.pharm Time TableDocument1 page4TH Sem B.pharm Time TableDAMBALENo ratings yet

- The Kondo EffectDocument8 pagesThe Kondo Effectmarcalomar19No ratings yet