Professional Documents

Culture Documents

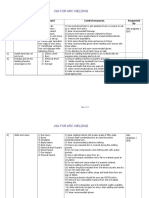

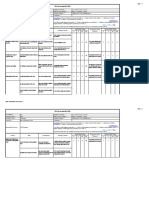

Compound Characteristics: 1. Reinforcement

Compound Characteristics: 1. Reinforcement

Uploaded by

tnssbhaskarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compound Characteristics: 1. Reinforcement

Compound Characteristics: 1. Reinforcement

Uploaded by

tnssbhaskarCopyright:

Available Formats

Compound characteristics

1. Reinforcement

Carbon black is added to the rubber used in tire treads, to high-pressure hoses, and has other demanding

applications, as well as added to plastics as material reinforcement.

This characteristic can be divided into carbon black and material physical adsorption (depending on the carbon

black's particle size and structure), and carbon black's particle surface and material chemical reaction (depending on

the carbon black's surface properties).

2. Conductivity

Conductive carbon black is added to natural rubber or other materials to decrease their electrical resistance.

For example: the conductivity of natural rubber is 1015cm, whereas the conductivity of conductive rubber (natural

rubber + conductive carbon black) is between 1-1015cm.

It is believed that this characteristic is the result of the structure of carbon black particles contacting each other which

forms conductive channels or because of the "tunnel effect" of electrons jumping between dispersed carbon black

particles.

3. Pigmentation

Carbon black has strong tint properties, it is heat stable and suitable for plastic and film coloring.

This property is believed to result from the particle size and the structure's interaction with light.

4. Preventive properties against ultraviolet degradation

Carbon black's absorption of ultraviolet light is excellent. Adding carbon black to other materials prevents ultraviolet

degradation.

This is due to stress-fissure prevention in plastics with carbon black, which refines their crystals.

You might also like

- JSA For Dismantel of StructureDocument2 pagesJSA For Dismantel of Structuretnssbhaskar73% (15)

- Chinagbf.comDocument3 pagesChinagbf.comRaul FrancoNo ratings yet

- Project Report.....Document19 pagesProject Report.....Hitesh Parghi100% (2)

- JSA For Fall ProtectionDocument2 pagesJSA For Fall ProtectiontnssbhaskarNo ratings yet

- Jsa For Arc WeldingDocument3 pagesJsa For Arc Weldingtnssbhaskar100% (5)

- Basalt Impact TestDocument11 pagesBasalt Impact TestMarisol Cortes OlanoNo ratings yet

- The Influence of Fiber On The Resistance To Chloride-Ion Penetration of Concrete Under The Environment of CarbonationDocument6 pagesThe Influence of Fiber On The Resistance To Chloride-Ion Penetration of Concrete Under The Environment of CarbonationArfazNo ratings yet

- Carbon Fibre As A Recent Material Use in ConstructionDocument7 pagesCarbon Fibre As A Recent Material Use in ConstructionVimlesh KumarNo ratings yet

- CM NotesDocument136 pagesCM NotesFayaz KhanNo ratings yet

- (12302945 - Archives of Civil Engineering) Load-Deflection Characteristics of Steel, Polypropylene and Hybrid Fiber Reinforced Concrete BeamsDocument14 pages(12302945 - Archives of Civil Engineering) Load-Deflection Characteristics of Steel, Polypropylene and Hybrid Fiber Reinforced Concrete Beamselmitodeherta3No ratings yet

- Karbon Cam Karşılaştırma 2Document10 pagesKarbon Cam Karşılaştırma 2Hasanmert KaymakNo ratings yet

- Carbon BlackDocument7 pagesCarbon BlackJahidul OnirNo ratings yet

- Studying The Electrical Conductivity of Different Carbon Fillers Reinforced Polyvinyl Chloride Composite MaterialsDocument10 pagesStudying The Electrical Conductivity of Different Carbon Fillers Reinforced Polyvinyl Chloride Composite MaterialsyasameenNo ratings yet

- Transparent ConcreteDocument20 pagesTransparent ConcreteAbhipsha SwainNo ratings yet

- Manufacturing Process of An Open Wheel Car BodyDocument20 pagesManufacturing Process of An Open Wheel Car BodyGediz EdremitlioğluNo ratings yet

- Engineering MaterialsDocument90 pagesEngineering Materials2k22cscys2213057No ratings yet

- A Review Paper On Properties of Carbon Fiber Reinforced PolymersDocument7 pagesA Review Paper On Properties of Carbon Fiber Reinforced PolymersSayan MahapatraNo ratings yet

- Seminar Report FinalDocument22 pagesSeminar Report Finalshaaz v s m100% (1)

- FRC1Document49 pagesFRC1Pavan Kalyan YadavNo ratings yet

- CFRPDocument9 pagesCFRPphitahnNo ratings yet

- Translucent ConcreteDocument10 pagesTranslucent ConcreteSamuel Julca HuingoNo ratings yet

- CompositesDocument34 pagesCompositesHarsimran KaurNo ratings yet

- Literature Review On Carbon Fiber Reinforcement: GeneralDocument7 pagesLiterature Review On Carbon Fiber Reinforcement: GeneralIrfankhan OfficialNo ratings yet

- 2b Advanced MaterialsDocument78 pages2b Advanced MaterialsL PircyNo ratings yet

- Simulation of Acoustic Performance of Ceramic FoamDocument5 pagesSimulation of Acoustic Performance of Ceramic FoamCășeriu BiancaNo ratings yet

- Enhancement The Strength of Conventional Concrete by Using Nylon FibreDocument4 pagesEnhancement The Strength of Conventional Concrete by Using Nylon FibreinventyNo ratings yet

- Conductive Plastics For Electrical and Electronic Applications PDFDocument4 pagesConductive Plastics For Electrical and Electronic Applications PDFsonchemenNo ratings yet

- Experimental Study On Concrete Using AlccofineDocument7 pagesExperimental Study On Concrete Using AlccofineIJRASETPublicationsNo ratings yet

- Performance of Functionally Modified Epoxy Nano Composites For FRP ApplicationsDocument7 pagesPerformance of Functionally Modified Epoxy Nano Composites For FRP ApplicationsHOD CIVIL DEPARTMENTNo ratings yet

- IJEAS0307005Document9 pagesIJEAS0307005erpublicationNo ratings yet

- ATH Pada FRPDocument41 pagesATH Pada FRPDPMAchmad Faisal SaniNo ratings yet

- Tribology International 2023 KarolinaDocument13 pagesTribology International 2023 KarolinaboikoNo ratings yet

- Carbon Fiber Polymer CompositesDocument5 pagesCarbon Fiber Polymer CompositesMalak ShatiNo ratings yet

- 2015 A Study On Strength Properties of Hybrid Fiber Reinforced PDFDocument5 pages2015 A Study On Strength Properties of Hybrid Fiber Reinforced PDFSrikanth KonikiNo ratings yet

- Reinforcement and Its Types: Composite Materials TechnologiesDocument17 pagesReinforcement and Its Types: Composite Materials TechnologiesKrishnaVkNo ratings yet

- Properties Advantages:: High Strength To Weight RatioDocument7 pagesProperties Advantages:: High Strength To Weight RatioShahZaib AnwarNo ratings yet

- Composite Materials 1Document7 pagesComposite Materials 1Kiruba ShankerNo ratings yet

- Finite Element Analysis of Delamination in Laminated Composite PlatesDocument44 pagesFinite Element Analysis of Delamination in Laminated Composite PlatesSrini RaoNo ratings yet

- AR-Glass and Carbon Fibers in Textile Reinforced Concrete Simulation and DesignDocument20 pagesAR-Glass and Carbon Fibers in Textile Reinforced Concrete Simulation and DesignShankar NarenNo ratings yet

- Akhil ProDocument100 pagesAkhil ProNI KH ILNo ratings yet

- Seminar Report 2019-22 Carbon Fiber Used in ConstructionDocument11 pagesSeminar Report 2019-22 Carbon Fiber Used in ConstructionAdarsh SooryaNo ratings yet

- Wrapping Concrete Project-RajeshDocument41 pagesWrapping Concrete Project-RajeshMEHALA SNo ratings yet

- Polypropylene Fiber Reinforced Concrete and Its Application in Creating Architectural Forms of Public Spaces - ScienceDirectDocument40 pagesPolypropylene Fiber Reinforced Concrete and Its Application in Creating Architectural Forms of Public Spaces - ScienceDirectKrishnaprabha K TNo ratings yet

- Group 19 Thesis ProposalDocument11 pagesGroup 19 Thesis ProposalJericko Allen ResusNo ratings yet

- Emf 3 PDFDocument4 pagesEmf 3 PDFSUDARSHAN dAWNo ratings yet

- Emf 2 PDFDocument4 pagesEmf 2 PDFSUDARSHAN dAWNo ratings yet

- Study On Mechanical Properties of Basalt Fiber Reinforced ConcreteDocument5 pagesStudy On Mechanical Properties of Basalt Fiber Reinforced ConcreteTohidNo ratings yet

- Materials For Laptop BodyDocument6 pagesMaterials For Laptop BodySuparna KhasnabisNo ratings yet

- Dissertation Phase 1Document33 pagesDissertation Phase 1Syed Mohd Mehdi100% (1)

- Introduction To CompositesDocument44 pagesIntroduction To CompositesSyed Muhammad AliNo ratings yet

- Charan 3Document15 pagesCharan 3yakubsamadshaikNo ratings yet

- Jeas 1216 5411 PDFDocument6 pagesJeas 1216 5411 PDFHAJARA SULTHANANo ratings yet

- Tailoring Composite MaterialsDocument23 pagesTailoring Composite MaterialsRama Rifqi100% (1)

- Fiberconcrete EnglishDocument9 pagesFiberconcrete EnglishEdgar DimasNo ratings yet

- Mape HaDocument7 pagesMape HaShreyash patilNo ratings yet

- Glass Fibre Concrete: Investigation On Strength and Fire Resistant PropertiesDocument5 pagesGlass Fibre Concrete: Investigation On Strength and Fire Resistant Propertiessushma chandrikaNo ratings yet

- Performance Evaluation of Steel-Polypropylene Hybrid Fiber ReinforcedDocument12 pagesPerformance Evaluation of Steel-Polypropylene Hybrid Fiber ReinforcedScientific GamerNo ratings yet

- Fiber Reinforced ConcreteDocument14 pagesFiber Reinforced ConcretenutakkivaralakshmiNo ratings yet

- 218-1641666926 Experimental Analysis On Self SensingDocument11 pages218-1641666926 Experimental Analysis On Self SensingV.Hemanth kumarNo ratings yet

- Transparent Concrete 7442 LoKcVAMDocument21 pagesTransparent Concrete 7442 LoKcVAMChetan HalladNo ratings yet

- Mechanism and Strengthening Effects of Carbon Fiber On Mechanical Properties of Cement MortarDocument6 pagesMechanism and Strengthening Effects of Carbon Fiber On Mechanical Properties of Cement MortarIJAERS JOURNALNo ratings yet

- Ver.7 Effects of Fibrin 23 and ARG Fibers On Porous ConcreteDocument55 pagesVer.7 Effects of Fibrin 23 and ARG Fibers On Porous ConcreteNico Torres100% (1)

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Safe Work Practices: Manual LiftingDocument1 pageSafe Work Practices: Manual LiftingtnssbhaskarNo ratings yet

- Risk Assesment For LAB: Severity (S) Likelihood (L)Document9 pagesRisk Assesment For LAB: Severity (S) Likelihood (L)tnssbhaskarNo ratings yet

- Heat Wave PosterDocument2 pagesHeat Wave PostertnssbhaskarNo ratings yet

- Daily Check Sheet For Bar Bending Machine: Back Side of The M/CDocument1 pageDaily Check Sheet For Bar Bending Machine: Back Side of The M/CtnssbhaskarNo ratings yet

- Daily Check Sheet For Generator Daily Check Sheet For Generator Daily Check Sheet For Generator Daily Check Sheet For GeneratorDocument1 pageDaily Check Sheet For Generator Daily Check Sheet For Generator Daily Check Sheet For Generator Daily Check Sheet For GeneratortnssbhaskarNo ratings yet

- JSA FOR Using The LadderDocument4 pagesJSA FOR Using The Laddertnssbhaskar100% (1)

- Safe Work Practice: Electrical SafetyDocument2 pagesSafe Work Practice: Electrical SafetytnssbhaskarNo ratings yet

- Palmarosa Essential OilDocument13 pagesPalmarosa Essential OiltnssbhaskarNo ratings yet

- Incipient Wetness ImpregnationDocument1 pageIncipient Wetness ImpregnationtnssbhaskarNo ratings yet

- Perfumes (Fragrance Materials) : Ingredient Safety Information - Phys-Chem, Environmental Hazard and Fate DataDocument6 pagesPerfumes (Fragrance Materials) : Ingredient Safety Information - Phys-Chem, Environmental Hazard and Fate DatatnssbhaskarNo ratings yet

- SolarEnergy EDay 2008 Eric-ChristensenDocument4 pagesSolarEnergy EDay 2008 Eric-ChristensentnssbhaskarNo ratings yet

- Perfume 1Document8 pagesPerfume 1tnssbhaskarNo ratings yet

- Solar System WorkshopDocument12 pagesSolar System WorkshoptnssbhaskarNo ratings yet

- Rent Receipt: Received With Thanks Rs. 8000/ - (Rupees Eight Thousand Only) FromDocument2 pagesRent Receipt: Received With Thanks Rs. 8000/ - (Rupees Eight Thousand Only) FromtnssbhaskarNo ratings yet

- Tania Sun ItDocument50 pagesTania Sun IttnssbhaskarNo ratings yet

- Solar System NotesDocument3 pagesSolar System Notestnssbhaskar0% (1)

- The Solar SystemDocument4 pagesThe Solar SystemtnssbhaskarNo ratings yet

- Safety in Handling of Chlorine Gas CylindersDocument2 pagesSafety in Handling of Chlorine Gas CylinderstnssbhaskarNo ratings yet