Professional Documents

Culture Documents

Revised PWPS 001

Revised PWPS 001

Uploaded by

stdshopOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Revised PWPS 001

Revised PWPS 001

Uploaded by

stdshopCopyright:

Available Formats

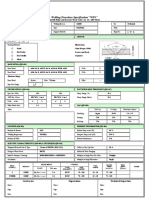

GLYCOL REBOILER STILL

NGL400A-MAROON

PRE WELDING PROCEDURE SPECIFICATION

( PWPS ) N.I.S.O.C

as per ASME Sec.IX

WPS NO. :PWPS-001 REV. : 1 DATE : 08 JUN 2017 page :1 of 2 SUPPORTING PQR :

WELDING PROCESS : GTAW+SMAW TYPE(S) : MANUAL

JOINT(S) (QW-402) PREHEAT (QW-406)

Joint Design see page 2 of 2 Preheat Temp. Min. 10 C

Backing Yes No Interpass Temp. Max. 250 C

Backing Material Type Preheat Maintenance N/A

Metal Nonfusing Metal Nonmetallic Other POST WELD HEAT TREATMENT :(QW-407)

BASE METALS (QW-403) Heating Rate N/A

P-No. 1 Group No. 1 Or 2 TO P-NO 1 Group No 1 Or 2 Holding Temperature N/A

Diameter Of Test Coupon:Pipe:10" Holding Time N/A

Thickness Of Test Coupon :pipe: 9.27 mm / plate : 10 mm GAS (QW-408)

Specification type and grade pipe:A-106 Gr.B / plate:A515 GR70 Gas(es) (Mixture) Flow Rate

to Specification type and grade pipe:A-106 Gr.B / plate:A515 GR70 Shielding Argon 99.99% 6~12 Lit/Min

Chem. Analyses and Mech. Prop. CARBON STEEL Trailing N/A N/A N/A

to Chem. Analyses and Mech.Prop. CARBON STEEL Backing N/A N/A N/A

Thickness Range : ELECTRICAL CHARACTERISTICS: (QW-409)

Base Metal : Groove 3.2~19 mm Fillet : Min 3.2 mm Current AC or DC DC

GTAW: UP TO 5mm

Weld Metal : Groove Fillet : ALL Polarity: GTAW DCSP SMAW DCRP

SMAW:up to 14mm

Pipe Dia. Range : Groove/Fillet : 1" & ABOVE

Tungsten Electrode Size and Type : (2.4 & EWTH-2)

Other :N/A

FILLER METALS (QW-404) Mode of Metal Transfer for GTAW N/A

GTAW SMAW Electrode Wire feed speed range N/A

Spec No. (SFA) SFA 5.18 SFA 5.1 TECHNIQUE :(QW-410)

String or Weave Bead : Root&Hot pass String bead & other passes Weave

AWS No. (Class) ER 70S-2 E 7018

Bead

F-No. 6 4 Orifice or Gas Cup Size N/A

A-No. 1 1 Initial and Interpass Cleaning (Brushing, Grinding, etc. )

Size of Filler Metals (mm) 1.6,2.4 2.5,3.25,4 BRUSHING AND GRINDING

Electrode-Flux (Class) N/A N/A Method of Back Gouging N/A

Flux Trade Name N/A N/A Oscillation Max 3 Time of electrode dia.

Consumable Insert N/A N/A Contact Tube to work Distance N/A

Trade Name ESAB OK TIGROD

ESAB OK 48.18

12.62

Multiple or Single Pass (Per side ) Multiple

Other : Baking / Storage : As per Manuf. Std.

POSITION (QW-405) Multiple or Single Electrodes Single

Position(s) of Groove : ALL Travel Speed (Range ) 4-10 CM / Min

Welding Progression : UP HILL Peening NONE

Position(s) of Fillet : ALL Other --------

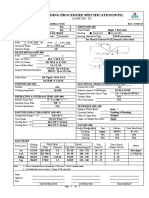

Preliminary Welding Pocedure Specification

( P.W.P.S )

WPS NO. : PWPS-001 DATE : 08 JUN 2017 PAGE : 2 of 2

JOINT DESIGN :

37.5 2.5

2.50.5 MM 1.60.8 MM

RUN SEQUENCE

EDGE PREPARATION : NDT ( RT)

FIT-UP

WELDING ( First Side )

BACK WELDING ( IF REQUIRED )

CHIPPING (Grinding )

NOTE :

RT AS PER SPEC.

FILLER METAL CURRENT TRAVEL SPEED

VOLT.(V)

WELD LAYER(S) PROCESS OTHER

DIA POLAR. AMP.(A) RANGE

CLASS (CM. / MIN.)

(mm) TYPE RANGE

1 ST GTAW ER 70S-2 2.4 DCSP 80 - 120 6-12 4-10

2 ND GTAW ER 70S-2 2.4 DCSP 80 - 120 7-14 5-10

OTHER PASSES SMAW E7018 2.5,3.25,4 DCRP 90 - 140 15-25 6-12 NOTE2

NOTE1 : Normal Carbon Steel up to 19 mm thickness , No PWHT

NOTE2: The Use Of 4.0 mm ElectrodeIs Not An Obligation

PREPARED BY :M.m.Eydipour APPROVED BY :

N.I.S.O.C. REP.

NAME: NAME:

SIGN : SIGN :

DATE : DATE :

You might also like

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- Wps 316L SMAW+GTAW R00Document2 pagesWps 316L SMAW+GTAW R00Richard Periyanayagam87% (15)

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocument31 pagesALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- WPS Sitelca S002Document2 pagesWPS Sitelca S002Jose Antonio GomezNo ratings yet

- WPSDocument2 pagesWPSJuli Agus50% (2)

- Sample Wps-Carbon Steel GTAW+SMAWDocument2 pagesSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarNo ratings yet

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- WpsDocument2 pagesWpssamer8saifNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- Wps Magi Tig ExempleDocument6 pagesWps Magi Tig ExempleDanem HalasNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- Welder Operator TrainingDocument22 pagesWelder Operator TrainingsniperiNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Document2 pagesWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- wps63 PDFDocument4 pageswps63 PDFErick HoganNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- PWHT Procedure PDFDocument9 pagesPWHT Procedure PDFAbhishek AnandNo ratings yet

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- Summary List WPS & PQR Structure RE - AFCDocument8 pagesSummary List WPS & PQR Structure RE - AFCFerdie OS100% (1)

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- WPS-PQR Gmaw LtiDocument2 pagesWPS-PQR Gmaw Ltibgonzalez198150% (2)

- 003-WPS For CS & Itcs With PWHT (C.S-19-40MM) (Itcs-20-44mm) PDFDocument7 pages003-WPS For CS & Itcs With PWHT (C.S-19-40MM) (Itcs-20-44mm) PDFKöksal PatanNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Wps A53 SMAW+GTAW R00Document3 pagesWps A53 SMAW+GTAW R00Richard Periyanayagam50% (2)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Back Gouging ProcedureDocument8 pagesBack Gouging Proceduremahi1437100% (1)

- PWPS WPS CAP 039 PQR 035Document15 pagesPWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRNo ratings yet

- PQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0Document12 pagesPQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0rodwellbNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi Jerbi100% (1)

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- NGWK PK 0001 VDQC Plit 0006Document7 pagesNGWK PK 0001 VDQC Plit 0006stdshopNo ratings yet

- Ahwaz Pipe Mills Test Certificate Quality Control LaboratoryDocument2 pagesAhwaz Pipe Mills Test Certificate Quality Control LaboratorystdshopNo ratings yet

- Ngwk-0025-Enpn-Mtpn-7530-D03 (Water Pipelines-Material Take Off For) PDFDocument4 pagesNgwk-0025-Enpn-Mtpn-7530-D03 (Water Pipelines-Material Take Off For) PDFstdshopNo ratings yet

- Test Certificate: Quality Control Laboratory Mechanical Laboratory ReportDocument2 pagesTest Certificate: Quality Control Laboratory Mechanical Laboratory ReportstdshopNo ratings yet

- Item Pipe Batch Value Exposure Time Result Remarks NO. NO. NO. G/10minDocument1 pageItem Pipe Batch Value Exposure Time Result Remarks NO. NO. NO. G/10minstdshopNo ratings yet

- Item Pipe Batch Value Result Remarks NO. NO. NO. Ohm × M: Ahwaz Pipe Mills Test Report Quality Control LaboratoryDocument1 pageItem Pipe Batch Value Result Remarks NO. NO. NO. Ohm × M: Ahwaz Pipe Mills Test Report Quality Control LaboratorystdshopNo ratings yet

- WeldDocument1 pageWeldstdshopNo ratings yet

- Ahwaz Pipe Mills Test Certificate Quality Control LaboratoryDocument1 pageAhwaz Pipe Mills Test Certificate Quality Control LaboratorystdshopNo ratings yet

- Hic 2208-01-15Document1 pageHic 2208-01-15stdshopNo ratings yet

- Sakht & Tolid: Iran Manufacturing & Production MagazineDocument43 pagesSakht & Tolid: Iran Manufacturing & Production MagazinestdshopNo ratings yet

- Resume EydipourDocument2 pagesResume EydipourstdshopNo ratings yet

- Specimen No Results Acceptance Ceriteria Yes No: Ahwaz Pipe Mills Quality Control LaboratoryDocument1 pageSpecimen No Results Acceptance Ceriteria Yes No: Ahwaz Pipe Mills Quality Control LaboratorystdshopNo ratings yet

- Techinco.: Technical Inspection & Corrosion Control CoDocument1 pageTechinco.: Technical Inspection & Corrosion Control CostdshopNo ratings yet

- Ahwaz Pipe Mills Quality Control Laboratory: Corrosion Lab. Report Hydrogen Induced Cracking TestDocument1 pageAhwaz Pipe Mills Quality Control Laboratory: Corrosion Lab. Report Hydrogen Induced Cracking TeststdshopNo ratings yet

- MT6582 Android ScatterDocument6 pagesMT6582 Android ScatterSathish KumarNo ratings yet

- Painting ProcedureDocument17 pagesPainting Procedurestdshop75% (4)

- Radiographic Testing Method: Acceptance / Rejection CriteriaDocument1 pageRadiographic Testing Method: Acceptance / Rejection CriteriastdshopNo ratings yet

- Surface Coating IndustryDocument15 pagesSurface Coating Industrystdshop100% (1)

- Astm G14Document5 pagesAstm G14stdshop100% (1)

- Paint Technical TrainingDocument100 pagesPaint Technical Trainingstdshop100% (4)

- Coating SelectionDocument16 pagesCoating Selectionstdshop100% (2)

- Bolt / Nut Coating & Color TableDocument2 pagesBolt / Nut Coating & Color TablestdshopNo ratings yet

- CorrosionDocument40 pagesCorrosionRekha PantNo ratings yet