Professional Documents

Culture Documents

Waste PDF

Waste PDF

Uploaded by

HansonCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Waters of KosovoDocument40 pagesWaters of Kosovorimi7alNo ratings yet

- ZAF CH 019 InkongweniRiver Eng Rev03Document2 pagesZAF CH 019 InkongweniRiver Eng Rev03rimi7alNo ratings yet

- Law No. 02 L-78 On Public HealthDocument11 pagesLaw No. 02 L-78 On Public Healthrimi7alNo ratings yet

- Law No.03 L-233 of Nature Protection (Incl. Biologjical Minimum)Document62 pagesLaw No.03 L-233 of Nature Protection (Incl. Biologjical Minimum)rimi7alNo ratings yet

- Fire ProtectionDocument15 pagesFire Protectionrimi7alNo ratings yet

- Separat Kanalizacine I Atmosferske Mreže (19 Trasa) Za Grad BrusDocument36 pagesSeparat Kanalizacine I Atmosferske Mreže (19 Trasa) Za Grad Brusrimi7alNo ratings yet

- Kosovo - Terms of Reference LandfillsDocument28 pagesKosovo - Terms of Reference Landfillsrimi7alNo ratings yet

- Administrative Instruction (Mesp) No. 23 2013 On The Manner and Conditions of Performing The Ranger Tasks For Nature ProtectionDocument5 pagesAdministrative Instruction (Mesp) No. 23 2013 On The Manner and Conditions of Performing The Ranger Tasks For Nature Protectionrimi7alNo ratings yet

- Swimming Pool TestingDocument38 pagesSwimming Pool Testingrimi7alNo ratings yet

- NIS2011 enDocument388 pagesNIS2011 enrimi7alNo ratings yet

- Kosovo & UsDocument15 pagesKosovo & Usrimi7alNo ratings yet

- Efo 34344Document77 pagesEfo 34344John KupchaNo ratings yet

- Kosovo Declaration of IndependenceDocument4 pagesKosovo Declaration of Independencerimi7alNo ratings yet

- FrameworkPocket ENG Dec2002Document17 pagesFrameworkPocket ENG Dec2002rimi7alNo ratings yet

- 0107Document30 pages0107Prakash ThangavelNo ratings yet

- D6224Document13 pagesD6224rimi7al100% (1)

- Case Study 8 Copper Mine Brook, Burlington, Connecticut: Lined WaterwayDocument20 pagesCase Study 8 Copper Mine Brook, Burlington, Connecticut: Lined Waterwayrimi7alNo ratings yet

- D5972Document5 pagesD5972rimi7alNo ratings yet

- D6186Document5 pagesD6186rimi7alNo ratings yet

- Determination of C Through C Hydrocarbons in Gasolines by Gas ChromatographyDocument7 pagesDetermination of C Through C Hydrocarbons in Gasolines by Gas Chromatographyrimi7alNo ratings yet

- D1747Document4 pagesD1747rimi7alNo ratings yet

- D2509Document8 pagesD2509rimi7alNo ratings yet

- 5 Oil Properties Part 1Document51 pages5 Oil Properties Part 1Haziq YussofNo ratings yet

- 2014 MP NtseDocument37 pages2014 MP NtseXxyyzzNo ratings yet

- Book orDocument8 pagesBook orahsanNo ratings yet

- Mathematics Yearly Plan 2014 Year 5 Week Topic / Learning Area Learning Objectives / Learning OutcomesDocument8 pagesMathematics Yearly Plan 2014 Year 5 Week Topic / Learning Area Learning Objectives / Learning OutcomesMohd ZahariNo ratings yet

- Volume, Surface Area and SymmetryDocument29 pagesVolume, Surface Area and SymmetrySabbir Ahamed ShohanNo ratings yet

- Sizing of Steam Coil of Insulated Tank Rev 3Document2 pagesSizing of Steam Coil of Insulated Tank Rev 3ypatels50% (2)

- Accuload - Side Stream Blending - Ab06054 PDFDocument4 pagesAccuload - Side Stream Blending - Ab06054 PDFwNo ratings yet

- 1.1 MeasurementsDocument9 pages1.1 MeasurementskookiemonsterNo ratings yet

- Area and Volume WorksheetDocument2 pagesArea and Volume Worksheetsatarupa PMISNo ratings yet

- Free Jet LabDocument7 pagesFree Jet Labaeroscribble0% (1)

- 20200727-Mini Road Roller series-SRD04Document12 pages20200727-Mini Road Roller series-SRD04Lacatusu MirceaNo ratings yet

- Ujian Semester 2 Matematik T (Soalan)Document4 pagesUjian Semester 2 Matematik T (Soalan)johnNo ratings yet

- Grafik SG APIDocument2 pagesGrafik SG APIMiftahul IrhamiNo ratings yet

- Volume of ConeDocument1 pageVolume of Conemv1970No ratings yet

- Lab 8 Using The Ideal Gas Law: Student Name: Access Code (Located On The Lid of Your Lab Kit)Document5 pagesLab 8 Using The Ideal Gas Law: Student Name: Access Code (Located On The Lid of Your Lab Kit)meNo ratings yet

- 04 Assignment 1Document2 pages04 Assignment 1pemzyboi07No ratings yet

- Tanks Lecture 3Document70 pagesTanks Lecture 3zikzak2011No ratings yet

- Volume Integral FinalDocument26 pagesVolume Integral FinalSreevignesh GNo ratings yet

- Formation Design Systems Maxsurf Stability Tank TableDocument43 pagesFormation Design Systems Maxsurf Stability Tank TableDiego SotoNo ratings yet

- Comparative Information 7 - 10Document34 pagesComparative Information 7 - 10Bob CrossNo ratings yet

- GPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For RevisionDocument15 pagesGPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For Revisionrkm_rkmNo ratings yet

- RFP NO. ASPA14.1216 ASPA AND PUBLIC JOINT VENTURE RECYCLING-Appendix ADocument4 pagesRFP NO. ASPA14.1216 ASPA AND PUBLIC JOINT VENTURE RECYCLING-Appendix ASalvador Dagsa CaacbayNo ratings yet

- (11-16) 3B-Ch.7-Areas - Volumes (III) - CQDocument10 pages(11-16) 3B-Ch.7-Areas - Volumes (III) - CQsophia yeungNo ratings yet

- API Procedure For Inspection of Chemical Cargo by InspectorsDocument31 pagesAPI Procedure For Inspection of Chemical Cargo by Inspectorsdassi99No ratings yet

- Q4 Science10 Week1 LAS2Document1 pageQ4 Science10 Week1 LAS2AvaricioElPecadoNo ratings yet

- SSC CHSL 2013Document19 pagesSSC CHSL 2013Ias Aspirant AbhiNo ratings yet

- Molar Mass Volatile Liquid - F09-1Document8 pagesMolar Mass Volatile Liquid - F09-1Ridlo TjNo ratings yet

- Reservoir Fluids Properties BookDocument219 pagesReservoir Fluids Properties Bookkexadex2100% (5)

- © Global Mediastreet Sdn. Bhd. (762284-U) : Paper2 Answer31 - 10.indd 1 01/11/2018 8:29 PMDocument70 pages© Global Mediastreet Sdn. Bhd. (762284-U) : Paper2 Answer31 - 10.indd 1 01/11/2018 8:29 PMMathana SuriaNo ratings yet

- Density and Specific GravityDocument8 pagesDensity and Specific GravityHaste OsmanNo ratings yet

Waste PDF

Waste PDF

Uploaded by

HansonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Waste PDF

Waste PDF

Uploaded by

HansonCopyright:

Available Formats

WASTE NEUTRALIZATION

Text may appear fuzzy or blocky due to file compression. You may be able to change the

appearence (Acrobat Reader 3.x) by going to the menu item File and selecting Preferences,

then General. Click the box next to the item Smooth text and monochrome images and

then the OK box at the bottom.

Contents

11.1 Fundamentals ......................................................................................................... 2

11.2 Process and Operation Overview ....................................................................... 3

11.2.1 Wastewater Collection ................................................................................ 3

11.2.2 Wastewater Mixing ...................................................................................... 3

11.2.3 pH Measurement ......................................................................................... 5

11.2.4 Wastewater pH Adjustment ....................................................................... 6

11.3 Equipment Design and Options ......................................................................... 7

11.3.1 Batch Tank ..................................................................................................... 7

11.3.2 Tank Mixing Eductor ................................................................................... 7

11.3.3 Centrifugal Pumps ...................................................................................... 8

11.3.4 pH Sensor ...................................................................................................... 9

11.3.5 Valves and Piping ........................................................................................ 9

11.4 Application and Design ..................................................................................... 10

11.4.1 Application.................................................................................................. 10

11.4.2 Design Calculations .................................................................................. 10

11.4.3 Expected Results ......................................................................................... 13

34a_m11_r0 11-1 Waste Neutralization

Acceptable

pH for

Alkaline Discharge

Wastewater Neutralization to Drain

Acidic

Wastewater

Figure 11.1-1: Acidic and Alkaline Wastewaters Neutralize Each Other

34a_m11_r0 11-2a Waste Neutralization

table of contents

Module 11

WASTE NEUTRALIZATION

11.1 Fundamentals

Neutralization involves adjusting the pH of a liquid to approach the neutral pH of

7.0 (neither acid nor base). The concept of pH is discussed in detail in Module 2,

Section 7. Generally, neutralization involves the use of an acid (pH less than 7) to

lower the pH of a tank of basic (or alkaline) liquid (pH greater than 7), or the use of a

base (or alkali) to raise the pH of a tank of acidic liquid.

In the water treatment industry, wastewater is generated from the regeneration of

the resins used in cation, anion, and mixed bed ion exchange systems. The chemicals

used to regenerate the resins have extreme pH levels. For example, sulfuric acid,

with a pH of 1-2, is used for regeneration of cation resin and sodium hydroxide, with

a pH of 13-14, is used for regeneration of the anion resin. After the regeneration

process, the water containing these chemicals must be disposed of. Due to its ex-

treme pH, the wastewater cannot be sent directly to drain, as this will typically vio-

late local regulations regarding the pH of wastewater discharge. For example, the

NPDES (National Pollutant Discharge Elimination System) standard for stream

discharge pH is 6-9. The acceptable pH of the discharge varies by location and the

destination of the discharge (such as a stream, a well or a sewer leading to a

municipal waste treatment plant).

To neutralize the highly acidic wastewater from a cation resin regeneration, a supply

of alkaline liquid is needed. An anion resin regeneration is usually performed at the

same time, and its wastewater is alkaline. When these two wastewater streams are

combined, the pH is neutralized and approaches 7. If the resulting pH of the

combined liquids is not within the acceptable range for discharge, an additional

amount of either acid or base must be added to shift the pH into the acceptable

range. Figure 11.1-1 on the opposite page shows this concept. Generally, the

chemicals used to adjust the wastewater are the same chemicals used to regenerate

the resins in the ion exchange systems.

The regeneration of resin from a mixed bed ion exchange system generates both

highly acidic wastewater and highly basic wastewater. The total amount of

wastewater generated is generally a lower volume than the combined wastewater

streams from a pair of cation and anion ion exchange systems. Regardless of the

volume, the two wastewater streams resulting from the regeneration of a mixed bed

system can be combined to nearly neutralize each other.

34a_m11_r0 11-2 Waste Neutralization

table of contents

Batch

Neutralization

Tank

Figure 11.2-1: Batch Neutralization Tank

34a_m11_r0 11-3a Waste Neutralization

table of contents

11.2 Process and Operation Overview

The process of neutralization involves the following:

Collection of wastewater resulting from the regeneration of various ion

exchange systems

Combining and mixing wastewater streams

Measuring the pH of the combined wastewater streams

Adjusting the pH of the wastewater so it is within acceptable limits for

discharge to drain

11.2.1 Wastewater Collection

The wastewater remaining at the conclusion of an ion exchange resin regeneration

cycle generally has an extreme pH and cannot simply be sent to drain. Instead the

wastewater is directed to a batch neutralization tank. Figure 11.2-1 on the

opposite page shows a typical batch neutralization tank. The purpose of the tank is

to hold the wastewater streams in one location. Once collected, the goal is to use the

wide variations in pH of the streams and cause them to neutralize each other.

11.2.2 Wastewater Mixing

For complete neutralization to occur in a reasonable amount of time, the acidic and

alkaline waste volumes in the batch tank must be thoroughly mixed. There are

several mixing approaches that can be considered.

A motor-driven mixer on a shaft can be used to mix the contents of the tank. The

tall tanks often used in this application necessitate the use of long shafts that require

careful balancing with submerged bearings to keep the shafts in place. Mounting

the mixer assembly on the side of the tank removes these requirements but adds an

underwater seal. The maintenance for either of these approaches can be difficult.

Mixing can also be achieved by blowing air into the bottom of the neutralization

tank. This method avoids the use of moving parts and the associated maintenance

concerns, but requires a suitable supply of air. This procedure usually requires a

large set of blowers to produce the volume and pressure of air required to mix a full

tank of water.

34a_m11_r0 11-3 Waste Neutralization

table of contents

Another mixing method lets centrifugal pumps recycle the wastewater in the tank.

This approach provides a fast and efficient mix with a relatively low-maintenance

piece of equipment. Only one pump operates, and any additional pumps are for

redundancy. Figure 11.2-2 below shows a pair of recycle pumps.

Recycle/Discharge Pumps

Figure 11.2-2: Recycle / Discharge Pumps

In a recycle mixing design, water flows from the bottom of the neutralization tank

and proceeds to the suction of the operating recycle pump. After being discharged

from the pump, the water is directed back into the batch tank. The time required to

pump the entire contents of the tank one time is the turnover rate. This can be

measured in turns per hour, with one turn being equal to the volume of the batch

tank flowing through the pump one time.

34a_m11_r0 11-4 Waste Neutralization

table of contents

Suction Parallel

Section

..Five gallons

One gallon circulated

pumped

Suction

Nozzle

Figure 11.2-4: Principle of Tank Mixing Eductor

34a_m11_r0 11-5a Waste Neutralization

table of contents

As it enters the tank, the water passes through an eductor that mixes water from

the pump (the motive fluid) and water from another part of the tank (the entrained

fluid). The batch tank contains a series of eductors, equally spaced on laterals, to

thoroughly mix the tanks contents. Figure 11.2-3 below shows the arrangement of

eductors inside the batch tank.

Tank Mixing Eductors

Figure 11.2-3: Tank Mixing Eductors

The flow of water from the recycle pump through an eductor creates suction that

pulls in approximately four times the amount of water being pumped. For every

gallon pumped into a single tank mixing eductor, five gallons are discharged, which

significantly reduces the turnover rate. Figure 11.2-4 on the opposite page shows a

schematic of how an individual eductor functions. The agitation caused by the

discharge stream also encourages mixing of the tank contents, especially when using

a series of eductors arrayed through the batch tank.

11.2.3 pH Measurement

While the wastewater is being recycled, an inline sensor continuously monitors its

pH. As the wastewater in the tank is being mixed, the pH is checked to verify that it

is within acceptable limits for discharge. If the pH of the batch is acceptable, the

water is sent to drain. If the pH of the batch is outside the acceptable range, addi-

tional chemicals are added to bring the pH to a desirable level before it is discharged.

34a_m11_r0 11-5 Waste Neutralization

table of contents

11.2.4 Wastewater pH Adjustment

If the batch of mixed wastewater from a cation resin regeneration and an anion resin

regeneration does not yield an acceptable pH for discharge, then the batch must be

adjusted. Based on the pH measurement, an algorithm in the control system

determines the amount of acid or caustic that must be added to the batch tank.

Figure 11.2-5 below shows where the chemicals are added. If the pH of the batch is

too high, acid is added. If the pH of the batch is too low, caustic is added. The

amount added should be sufficient to bring the pH of the batch tank contents into

the acceptable range. The chemicals used are commonly the same chemicals used

for cation or anion resin regeneration.

Acid Caustic

Figure 11.2-5: Location of Chemical Additions

After the adjustment chemical is added and the contents of the tank are thoroughly

mixed, the pH of the wastewater batch is measured again to confirm that it is within

the acceptable range. If the pH is acceptable, the contents of the batch neutralization

tank are sent to drain. If the pH is not acceptable, another adjustment cycle is

executed until the pH of the batch is acceptable.

34a_m11_r0 11-6 Waste Neutralization

table of contents

Batch

Neutralization

Tank

Figure 11.3-1: Batch Neutralization Tank

34a_m11_r0 11-7a Waste Neutralization

table of contents

11.3 Equipment Design and Options

The equipment for a waste neutralization system is relatively straightforward. Due

to the extreme pH of the wastewater and the adjustment chemicals, the choice of

construction materials is critical.

11.3.1 Batch Tank

The batch tank is an atmospheric tank designed to withstand the extreme pH of the

cation and anion resin wastewater. Figure 11.3-1 on the opposite page shows the

batch tank. The tank itself is made of either fiberglass (FRP) or carbon steel. Due to

the extreme pH of the wastewater streams, a carbon steel tank is lined with an epoxy

polyamide sprayed lining or natural rubber sheet lining. For more information on

atmospheric tanks, see Section 9.1.

11.3.2 Tank Mixing Eductor

A series of eductors are used to mix the contents of the batch tank in a shorter

amount of time than required by a traditional agitator. By using the flow of water

through the eductors to create suction, water is drawn into the eductor from other

parts of the tank and combined with the water from the recycle pump. Typically, for

every gallon of water pumped into an individual eductor, four additional gallons are

drawn in to be mixed. This creates a circulation ratio of 5:1; five gallons leave the

eductor for every one that is pumped in. Figure 11.3-2 below shows a single tank

mixing eductor.

For good mixing, the discharge plume

of the eductor should cover most of

the height of the tank. An eductor

typically provides a discharge plume

(in feet) of about half the driving

pressure (in psi). Since tanks are

usually taller than they are wide, and

eductors are mounted at an angle, a 60

psig driving pressure is typically used.

Figure 11.3-2: Tank Mixing Eductor

34a_m11_r0 11-7 Waste Neutralization

table of contents

11.3.3 Centrifugal Pumps

The centrifugal pumps supply the mixing energy for the system. They can also be

used to send the neutralized tank contents to drain. Figure 11.3-3 below shows a

typical centrifugal pump arrangement.

Motor

Pump

Figure 11.3-3: Centrifugal Pumps

The pump materials of construction must be able to withstand the pH extremes of

the wastewater and the chemicals present. For more information on centrifugal

pumps, see Section 9.2.

34a_m11_r0 11-8 Waste Neutralization

table of contents

11.3.4 pH Sensor

The inline pH sensor monitors the pH of the wastewater. The sensor measures the

electrical potential between a reference material and the wastewater flowing past an

inline probe. The signal is

converted to electrical

current and transmitted to

the control system. The

results are used to

determine whether the

Reference wastewater batch is

Material Display

within an acceptable

range for discharge. It

also monitors the batch as

it is being discharged. If

the pH is not acceptable,

the control system

determines what type of

adjustment chemical

should be added to bring

the batch into the

In-line acceptable range.

Probes Figure 11.3-4 shows pH

probes and associated

electronics.

Figure 11.3-4: Inline pH Monitor

11.3.5 Valves and Piping

Like other components of the waste neutralization system, the valves and piping

must be able to withstand the extremes in pH of the incoming wastewater streams.

Stainless steel is a typical choice as the material of construction due to its corrosion

resistance. However, if hydrochloric acid (HCl) is used as an adjustment chemical,

components that come in contact with the concentrated acid must be protected

(due to the corrosive effects of high chloride levels). If carbon steel is used, it must

be lined with polypropylene (PPL) or a Teflon-type material (TFE). PVC pipe is often

a good choice in sizes smaller than 8 inches. Larger size PVC fittings tend to be

fragile. Similarly, piping just downstream of a sulfuric acid injection point must be

protected from the heat generated by the dilution reaction. Plastic pipe is not a wise

choice in this application.

34a_m11_r0 11-9 Waste Neutralization

table of contents

Batch Tank

Volume

Pump

Size

Eductor

Quantity

and Size

Figure 11.4-1: Waste Neutralization System Calculated Attributes

34a_m11_r0 11-10a Waste Neutralization

table of contents

11.4 Application and Design

11.4.1 Application

A waste neutralization system is generally used when wastewaters with extreme pH

values are generated by the regeneration of resins in ion exchange systems. If the

facility or municipal waste treatment systems cannot handle the wide variations in

pH along with the peak flows, a neutralization system is required.

11.4.2 Design Calculations

Figure 11.4-1 on the opposite page shows the components of a waste neutralization

system for which key attributes must be calculated. The following input data are

assumed:

The amount of wastewater (in resin volumes) generated by each resin

regeneration step:

ANION Volumes CATION Volumes

Backwash 2 Backwash 2

Pre-Heat 1 - -

Caustic 2 Acid 2

Displace 1 Displace 1

Rinse 10 Rinse 6

Total volumes 16 Total volumes 11

Volumes could be lower depending on the ion exchange vessel and

whether rinse water is recycled. Actual volumes of waste produced are

normally calculated with detailed ion exchange process calculations.

The desired turnover rate. (Assume 4 turnovers to thoroughly mix the batch

and 10 minutes per turnover to quickly process the batch.)

34a_m11_r0 11-10 Waste Neutralization

table of contents

Batch Tank Volume

To use the wastewater from an anion resin regeneration to neutralize the wastewater

from a cation resin regeneration, the batch tank must be able to hold all of the

wastewater from the regeneration of both systems. A safety factor of 50% is added

to this total to account for conditions (for example, regeneration cycle alarms) that

might increase the amount of wastewater generated. The batch tank must also

include extra volume for the low level cut-off alarm (5% of total), high level alarm

(5% of total) and overflow alarm (5% of total).

The total volume of the batch tank is calculated as follows:

VTotal = (Vcation waste + Vanion waste ) x 1.5 [safety factors] x 1.15 [total alarm factors}

Where:

Vcation waste = cation resin volume x waste volume generated per cation resin volume

Vanion waste = anion resin volume x waste volume generated per anion resin volume

The calculations must be done in consistent units, usually cubic feet (as resin vol-

umes are mostly expressed in cubic feet) then converted to U.S. gallons using the

conversion factor 7.5 U.S. gallons/cubic foot.

For a system with 170 cubic feet of cation resin and 226 cubic feet of anion resin per

vessel:

Vcation waste = 170 ft3 x 11 ft3 waste per ft3 resin = 1,870 ft3 waste

Vanion waste = 226 ft3 x 16 ft3 waste per ft3 resin = 3,616 ft3 waste

VTotal= (1,870 ft3 + 3,616 ft3) x 1.5 x 1.15 = 9,463.35 ft3

Converting to US gallons:

VTotal= 9,463.35 ft3 x 7.5 USgal/ft3= 70,975 US gallons (or 71,000 gallons)

The height and diameter of the tank can be adjusted to accommodate this volume

and the location of the waste neutralization system.

34a_m11_r0 11-11 Waste Neutralization

table of contents

Eductor Quantity and Size

Eductors are available in a range of sizes, however, larger sizes tend to be machined

and thus quite expensive. If small units are selected, the installation cost tends to be

high because of the large quantity required. Currently, a 1 unit appears to be the

largest standard size available at a cost-effective price. Table 11.4-1 below provides

the operating characteristics of this unit as a function of operating pressure. Note

that, at all pressures, the circulation ratio is very close to 5 gpm of circulation per gpm

of motive flow.

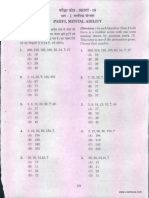

Eductor Model ME4OP (1.5 inch)

Pump Pressure

10 15 20 25 30 35 40 50 60

(psi)

Motive Flow

33 40 47 52 57 62 66 74 81

(gpm)

Circulating Flow

165 202 233 261 286 309 330 369 404

(gpm)

Table 11.4-1: Elmridge 1 inch Eductor Capacities

The mixing flow, or total eductor capacity, is calculated by dividing the tank volume

by the desired turnover time:

Mixing flow (gpm) = VTotal (gal) / turnover time (minutes)

The mixing flow is divided by the eductor circulation ratio to determine the actual

flow to the eductors, called the motive flow:

Motive flow (gpm) = mixing flow (gpm) / circulation ratio

The circulation ratio depends on the eductor selected but usually varies only slightly

across a specific eductor product line.

The minimum number of eductors required is calculated by dividing the total motive

flow by the motive flow per eductor at the operating pressure selected, and rounding

up to the next integer. Mechanical layout considerations may increase this number

slightly but do not need to be considered during process calculations with standard

eductors.

34a_m11_r0 11-12 Waste Neutralization

table of contents

Continuing with the sample system and using the 10-minute turnover time initially

selected, the values for mixing flow and motive flow can be calculated as follows:

Mixing flow = 71,000 gallons / 10 minutes = 7,100 gpm

Motive flow = 7,100 gpm / 5 = 1,420 gpm

At 60 psi driving pressure, each 1 eductor uses 81 gpm of water, yielding a total

eductor count of 18:

Eductor count = 1,420 / 81 = 17.53, or 18

Pump Size

The pump size is fixed by the number of eductors selected (above). The pump flow

equals the number of eductors times the motive flow per eductor. The pump pres-

sure is the operating pressure (normally 60 psig) selected to get a reasonable plume

height.

For the example above:

Pump flow = 18 eductors x 81 gpm per eductor = 1,458 gpm

Pump head = 60 psig x 2.3 ft TDH per psig = 138 ft TDH.

11.4.3 Expected Results

After mixing and potential adjustments, the contents of the batch neutralization tank

will have a pH within local acceptable limits for discharge to the wastewaters final

destination (stream, well, or sewer leading to a municipal waste treatment plant).

34a_m11_r0 11-13 Waste Neutralization

table of contents

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Waters of KosovoDocument40 pagesWaters of Kosovorimi7alNo ratings yet

- ZAF CH 019 InkongweniRiver Eng Rev03Document2 pagesZAF CH 019 InkongweniRiver Eng Rev03rimi7alNo ratings yet

- Law No. 02 L-78 On Public HealthDocument11 pagesLaw No. 02 L-78 On Public Healthrimi7alNo ratings yet

- Law No.03 L-233 of Nature Protection (Incl. Biologjical Minimum)Document62 pagesLaw No.03 L-233 of Nature Protection (Incl. Biologjical Minimum)rimi7alNo ratings yet

- Fire ProtectionDocument15 pagesFire Protectionrimi7alNo ratings yet

- Separat Kanalizacine I Atmosferske Mreže (19 Trasa) Za Grad BrusDocument36 pagesSeparat Kanalizacine I Atmosferske Mreže (19 Trasa) Za Grad Brusrimi7alNo ratings yet

- Kosovo - Terms of Reference LandfillsDocument28 pagesKosovo - Terms of Reference Landfillsrimi7alNo ratings yet

- Administrative Instruction (Mesp) No. 23 2013 On The Manner and Conditions of Performing The Ranger Tasks For Nature ProtectionDocument5 pagesAdministrative Instruction (Mesp) No. 23 2013 On The Manner and Conditions of Performing The Ranger Tasks For Nature Protectionrimi7alNo ratings yet

- Swimming Pool TestingDocument38 pagesSwimming Pool Testingrimi7alNo ratings yet

- NIS2011 enDocument388 pagesNIS2011 enrimi7alNo ratings yet

- Kosovo & UsDocument15 pagesKosovo & Usrimi7alNo ratings yet

- Efo 34344Document77 pagesEfo 34344John KupchaNo ratings yet

- Kosovo Declaration of IndependenceDocument4 pagesKosovo Declaration of Independencerimi7alNo ratings yet

- FrameworkPocket ENG Dec2002Document17 pagesFrameworkPocket ENG Dec2002rimi7alNo ratings yet

- 0107Document30 pages0107Prakash ThangavelNo ratings yet

- D6224Document13 pagesD6224rimi7al100% (1)

- Case Study 8 Copper Mine Brook, Burlington, Connecticut: Lined WaterwayDocument20 pagesCase Study 8 Copper Mine Brook, Burlington, Connecticut: Lined Waterwayrimi7alNo ratings yet

- D5972Document5 pagesD5972rimi7alNo ratings yet

- D6186Document5 pagesD6186rimi7alNo ratings yet

- Determination of C Through C Hydrocarbons in Gasolines by Gas ChromatographyDocument7 pagesDetermination of C Through C Hydrocarbons in Gasolines by Gas Chromatographyrimi7alNo ratings yet

- D1747Document4 pagesD1747rimi7alNo ratings yet

- D2509Document8 pagesD2509rimi7alNo ratings yet

- 5 Oil Properties Part 1Document51 pages5 Oil Properties Part 1Haziq YussofNo ratings yet

- 2014 MP NtseDocument37 pages2014 MP NtseXxyyzzNo ratings yet

- Book orDocument8 pagesBook orahsanNo ratings yet

- Mathematics Yearly Plan 2014 Year 5 Week Topic / Learning Area Learning Objectives / Learning OutcomesDocument8 pagesMathematics Yearly Plan 2014 Year 5 Week Topic / Learning Area Learning Objectives / Learning OutcomesMohd ZahariNo ratings yet

- Volume, Surface Area and SymmetryDocument29 pagesVolume, Surface Area and SymmetrySabbir Ahamed ShohanNo ratings yet

- Sizing of Steam Coil of Insulated Tank Rev 3Document2 pagesSizing of Steam Coil of Insulated Tank Rev 3ypatels50% (2)

- Accuload - Side Stream Blending - Ab06054 PDFDocument4 pagesAccuload - Side Stream Blending - Ab06054 PDFwNo ratings yet

- 1.1 MeasurementsDocument9 pages1.1 MeasurementskookiemonsterNo ratings yet

- Area and Volume WorksheetDocument2 pagesArea and Volume Worksheetsatarupa PMISNo ratings yet

- Free Jet LabDocument7 pagesFree Jet Labaeroscribble0% (1)

- 20200727-Mini Road Roller series-SRD04Document12 pages20200727-Mini Road Roller series-SRD04Lacatusu MirceaNo ratings yet

- Ujian Semester 2 Matematik T (Soalan)Document4 pagesUjian Semester 2 Matematik T (Soalan)johnNo ratings yet

- Grafik SG APIDocument2 pagesGrafik SG APIMiftahul IrhamiNo ratings yet

- Volume of ConeDocument1 pageVolume of Conemv1970No ratings yet

- Lab 8 Using The Ideal Gas Law: Student Name: Access Code (Located On The Lid of Your Lab Kit)Document5 pagesLab 8 Using The Ideal Gas Law: Student Name: Access Code (Located On The Lid of Your Lab Kit)meNo ratings yet

- 04 Assignment 1Document2 pages04 Assignment 1pemzyboi07No ratings yet

- Tanks Lecture 3Document70 pagesTanks Lecture 3zikzak2011No ratings yet

- Volume Integral FinalDocument26 pagesVolume Integral FinalSreevignesh GNo ratings yet

- Formation Design Systems Maxsurf Stability Tank TableDocument43 pagesFormation Design Systems Maxsurf Stability Tank TableDiego SotoNo ratings yet

- Comparative Information 7 - 10Document34 pagesComparative Information 7 - 10Bob CrossNo ratings yet

- GPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For RevisionDocument15 pagesGPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For Revisionrkm_rkmNo ratings yet

- RFP NO. ASPA14.1216 ASPA AND PUBLIC JOINT VENTURE RECYCLING-Appendix ADocument4 pagesRFP NO. ASPA14.1216 ASPA AND PUBLIC JOINT VENTURE RECYCLING-Appendix ASalvador Dagsa CaacbayNo ratings yet

- (11-16) 3B-Ch.7-Areas - Volumes (III) - CQDocument10 pages(11-16) 3B-Ch.7-Areas - Volumes (III) - CQsophia yeungNo ratings yet

- API Procedure For Inspection of Chemical Cargo by InspectorsDocument31 pagesAPI Procedure For Inspection of Chemical Cargo by Inspectorsdassi99No ratings yet

- Q4 Science10 Week1 LAS2Document1 pageQ4 Science10 Week1 LAS2AvaricioElPecadoNo ratings yet

- SSC CHSL 2013Document19 pagesSSC CHSL 2013Ias Aspirant AbhiNo ratings yet

- Molar Mass Volatile Liquid - F09-1Document8 pagesMolar Mass Volatile Liquid - F09-1Ridlo TjNo ratings yet

- Reservoir Fluids Properties BookDocument219 pagesReservoir Fluids Properties Bookkexadex2100% (5)

- © Global Mediastreet Sdn. Bhd. (762284-U) : Paper2 Answer31 - 10.indd 1 01/11/2018 8:29 PMDocument70 pages© Global Mediastreet Sdn. Bhd. (762284-U) : Paper2 Answer31 - 10.indd 1 01/11/2018 8:29 PMMathana SuriaNo ratings yet

- Density and Specific GravityDocument8 pagesDensity and Specific GravityHaste OsmanNo ratings yet