Professional Documents

Culture Documents

Vinnolit S 3160 Englisch

Vinnolit S 3160 Englisch

Uploaded by

Francisco Venegas ZuñigaCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2) February 2015Document68 pages2) February 2015Oswaldo ZavalaNo ratings yet

- PLC 2 Unity ReferenceDocument698 pagesPLC 2 Unity ReferenceRodolfo BelchiorNo ratings yet

- Middleware - Servlet - MAVENDocument7 pagesMiddleware - Servlet - MAVENbadsmileNo ratings yet

- 9931 Continuous Descent Operations (CDO) Manual EnglishDocument76 pages9931 Continuous Descent Operations (CDO) Manual EnglishJAIRONo ratings yet

- Ansi Tia Standards CompressDocument33 pagesAnsi Tia Standards CompressNguyễn Văn CườngNo ratings yet

- Job Title TeacherDocument1 pageJob Title TeacherAlina PoenaruNo ratings yet

- 中美两国药典药品分析方法和方法验证Document72 pages中美两国药典药品分析方法和方法验证JasonNo ratings yet

- Corporate Operations - Engineering: Buscar en Este Sitio..Document3 pagesCorporate Operations - Engineering: Buscar en Este Sitio..Rafael Didier Ramírez SánchezNo ratings yet

- A New European Standard For Biocontamination Control - EN 17141 Will Replace EN ISO 14698 Parts 1 and 2:2003Document6 pagesA New European Standard For Biocontamination Control - EN 17141 Will Replace EN ISO 14698 Parts 1 and 2:2003Rakesh MariNo ratings yet

- SAP GTS - Sanctioned Party ListingDocument16 pagesSAP GTS - Sanctioned Party ListingSuprabhat Suman100% (1)

- Bulk Carrier SafetyDocument3 pagesBulk Carrier SafetySuvesh nlnNo ratings yet

- RT600E Product Guide Imperial PDFDocument16 pagesRT600E Product Guide Imperial PDFm_925No ratings yet

- RAD V8 ProgramminRAD-V8-Programming-Guide-Redbook-sg247835g Guide Redbook Sg247835Document1,916 pagesRAD V8 ProgramminRAD-V8-Programming-Guide-Redbook-sg247835g Guide Redbook Sg247835maldoreurNo ratings yet

- Cable ColoursDocument1 pageCable ColoursStephen FrayneNo ratings yet

- Jis G3459Document25 pagesJis G3459Jihoom ShinNo ratings yet

- 1FN19100AA000AA0 Datasheet en PDFDocument1 page1FN19100AA000AA0 Datasheet en PDFredaNo ratings yet

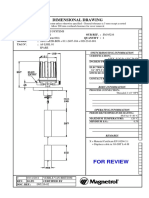

- Dimensional Drawing: For ReviewDocument2 pagesDimensional Drawing: For ReviewmoiNo ratings yet

- Vacancy For A Technician LumwanaDocument3 pagesVacancy For A Technician LumwanaMorassa ChonaNo ratings yet

- Fuse (Automotive) - WikipediaDocument4 pagesFuse (Automotive) - WikipediamegatornadoNo ratings yet

- ACI UtilityDocument254 pagesACI UtilitySheky HaroldNo ratings yet

- EPS Q 0885 RT PD Indah DIDDocument2 pagesEPS Q 0885 RT PD Indah DIDDeni SutisnaNo ratings yet

- TN Public Buildings Licensing Rules 1966 PDFDocument10 pagesTN Public Buildings Licensing Rules 1966 PDFprabhuNo ratings yet

- Fire Extinguisher Maintenance and Recharge Service Manual MODELS 204-354-504Document3 pagesFire Extinguisher Maintenance and Recharge Service Manual MODELS 204-354-504Nego1975No ratings yet

- Aseptic Process Validation, SimultationDocument17 pagesAseptic Process Validation, SimultationSean SmithNo ratings yet

- Quality ControlDocument33 pagesQuality ControlAydaLeeNo ratings yet

- Catalogo TransductoresDocument24 pagesCatalogo TransductoresCOCHINITO123100% (1)

- 2.2.Tds Astm-Abs Lgchem Hi121Document2 pages2.2.Tds Astm-Abs Lgchem Hi121Wilda Sania MtNo ratings yet

- Prelim Reviewer ADocument4 pagesPrelim Reviewer AMike SerafinoNo ratings yet

- (Theory) Lecture Notes Programming in CDocument48 pages(Theory) Lecture Notes Programming in CabhinavNo ratings yet

- Catalogue 8djh36 enDocument44 pagesCatalogue 8djh36 enJoanna BaileyNo ratings yet

Vinnolit S 3160 Englisch

Vinnolit S 3160 Englisch

Uploaded by

Francisco Venegas ZuñigaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vinnolit S 3160 Englisch

Vinnolit S 3160 Englisch

Uploaded by

Francisco Venegas ZuñigaCopyright:

Available Formats

Product Information

Vinnolit S 3160

Suspension PVC for

thermoplastic processing

Brief Description

Vinnolit S 3160 is a free-flowing suspension

polymer with excellent fusion properties.

It is recommended for sheet, profile and film

manufacturing. A distinguishing feature of

Vinnolit S 3160 is its extremely low fish-eye

count.

Test Method

Typical

Raw Material Properties Unit

Value*

DIN EN ISO ISO

K-Value 60 - 1628-2 1628-2

Reduced viscosity 89 ml/g 1628-2 1628-2

Apparent bulk density 0.560 g/ml 60 60

Particle size distribution:

Sieve retention R

retained on 0.063 mm screen 97 % - -

retained on 0.250 mm screen 1 % - -

Volatile matter 0.3 % - -

* The values given above are typical test results which should be used as a guide only. They do not form the whole or part of

a specification or guarantee.

Vinnolit = registered trademark of Vinnolit GmbH & Co. KG, Germany

Product Information

Processing and Applications Packaging, Delivery and Storage

Vinnolit S 3160 can be converted into The product is supplied in 25 kg bags as well

free-flowing mixtures using common PVC as in bulk form.

stabilizer and lubricant blends.

Vinnolit S 3160 should be stored dry and away

In suitable formulations, finished parts from direct or indirect sources of heat. Please

made of Vinnolit S 3160 show the consult the safety data sheet for information

following properties: about the safety precautions necessary for

transport, storage, blending and processing.

- high transparency

- low fish-eye count

- low water uptake General Information

Further processing information and recom-

mendations can be obtained from our Techni-

cal Service or our local representatives.

Vinnolit S 3160 is used in a variety of

applications and processes:

- oriented and unoriented rigid film pro-

duced on calenders and extruders

- extruded and compression-moulded

sheets

- rigid profiles

- sheets and profiles produced by

Celuka or free-foaming processes

Vinnolit S 3160 may also be converted

into finished articles and blow mouldings

on standard injection moulding equipment.

The data and recommendations contained in this product information

represent the current state of our knowledge and serve as a guide only

Ismaning, November 2014

to our products and their potential applications. Therefore, no warranty

of specific properties of the products mentioned herein nor of their Vinnolit GmbH & Co. KG

suitability or fitness for a particular purpose is implied.

The information given in this leaflet should be checked by preliminary Carl-Zeiss-Ring 25

trials because of conditions during processing over which we have no

control, especially where other companies' raw materials are also used.

85737 Ismaning

Patent or other proprietary rights of third parties must be observed. The Germany

quality of our products is warranted under the terms of our General

Conditions of Sale.

Tel.: +49 89 9 61 03-0

Fax: +49 89 9 61 03-103

www.vinnolit.com

A Westlake Company

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2) February 2015Document68 pages2) February 2015Oswaldo ZavalaNo ratings yet

- PLC 2 Unity ReferenceDocument698 pagesPLC 2 Unity ReferenceRodolfo BelchiorNo ratings yet

- Middleware - Servlet - MAVENDocument7 pagesMiddleware - Servlet - MAVENbadsmileNo ratings yet

- 9931 Continuous Descent Operations (CDO) Manual EnglishDocument76 pages9931 Continuous Descent Operations (CDO) Manual EnglishJAIRONo ratings yet

- Ansi Tia Standards CompressDocument33 pagesAnsi Tia Standards CompressNguyễn Văn CườngNo ratings yet

- Job Title TeacherDocument1 pageJob Title TeacherAlina PoenaruNo ratings yet

- 中美两国药典药品分析方法和方法验证Document72 pages中美两国药典药品分析方法和方法验证JasonNo ratings yet

- Corporate Operations - Engineering: Buscar en Este Sitio..Document3 pagesCorporate Operations - Engineering: Buscar en Este Sitio..Rafael Didier Ramírez SánchezNo ratings yet

- A New European Standard For Biocontamination Control - EN 17141 Will Replace EN ISO 14698 Parts 1 and 2:2003Document6 pagesA New European Standard For Biocontamination Control - EN 17141 Will Replace EN ISO 14698 Parts 1 and 2:2003Rakesh MariNo ratings yet

- SAP GTS - Sanctioned Party ListingDocument16 pagesSAP GTS - Sanctioned Party ListingSuprabhat Suman100% (1)

- Bulk Carrier SafetyDocument3 pagesBulk Carrier SafetySuvesh nlnNo ratings yet

- RT600E Product Guide Imperial PDFDocument16 pagesRT600E Product Guide Imperial PDFm_925No ratings yet

- RAD V8 ProgramminRAD-V8-Programming-Guide-Redbook-sg247835g Guide Redbook Sg247835Document1,916 pagesRAD V8 ProgramminRAD-V8-Programming-Guide-Redbook-sg247835g Guide Redbook Sg247835maldoreurNo ratings yet

- Cable ColoursDocument1 pageCable ColoursStephen FrayneNo ratings yet

- Jis G3459Document25 pagesJis G3459Jihoom ShinNo ratings yet

- 1FN19100AA000AA0 Datasheet en PDFDocument1 page1FN19100AA000AA0 Datasheet en PDFredaNo ratings yet

- Dimensional Drawing: For ReviewDocument2 pagesDimensional Drawing: For ReviewmoiNo ratings yet

- Vacancy For A Technician LumwanaDocument3 pagesVacancy For A Technician LumwanaMorassa ChonaNo ratings yet

- Fuse (Automotive) - WikipediaDocument4 pagesFuse (Automotive) - WikipediamegatornadoNo ratings yet

- ACI UtilityDocument254 pagesACI UtilitySheky HaroldNo ratings yet

- EPS Q 0885 RT PD Indah DIDDocument2 pagesEPS Q 0885 RT PD Indah DIDDeni SutisnaNo ratings yet

- TN Public Buildings Licensing Rules 1966 PDFDocument10 pagesTN Public Buildings Licensing Rules 1966 PDFprabhuNo ratings yet

- Fire Extinguisher Maintenance and Recharge Service Manual MODELS 204-354-504Document3 pagesFire Extinguisher Maintenance and Recharge Service Manual MODELS 204-354-504Nego1975No ratings yet

- Aseptic Process Validation, SimultationDocument17 pagesAseptic Process Validation, SimultationSean SmithNo ratings yet

- Quality ControlDocument33 pagesQuality ControlAydaLeeNo ratings yet

- Catalogo TransductoresDocument24 pagesCatalogo TransductoresCOCHINITO123100% (1)

- 2.2.Tds Astm-Abs Lgchem Hi121Document2 pages2.2.Tds Astm-Abs Lgchem Hi121Wilda Sania MtNo ratings yet

- Prelim Reviewer ADocument4 pagesPrelim Reviewer AMike SerafinoNo ratings yet

- (Theory) Lecture Notes Programming in CDocument48 pages(Theory) Lecture Notes Programming in CabhinavNo ratings yet

- Catalogue 8djh36 enDocument44 pagesCatalogue 8djh36 enJoanna BaileyNo ratings yet