Professional Documents

Culture Documents

Ijert Ijert: "Frequency Control of Smart Grid - MATLAB/SIMULINK Approach"

Ijert Ijert: "Frequency Control of Smart Grid - MATLAB/SIMULINK Approach"

Uploaded by

Mohan KrishnaCopyright:

Available Formats

You might also like

- Manual MyLab 5 PDFDocument80 pagesManual MyLab 5 PDFÉric Scolastici100% (1)

- Digital Electronics (Betty Lincoln)Document434 pagesDigital Electronics (Betty Lincoln)Rayhan Nur AhmadiNo ratings yet

- 05IPST080Document6 pages05IPST080Niveditha NamasivaayamNo ratings yet

- Control and Operation of Grid Connected DC Source Based Distribution GenerationDocument4 pagesControl and Operation of Grid Connected DC Source Based Distribution Generationgagan mahadevaNo ratings yet

- Irjet V5i520Document5 pagesIrjet V5i520baby hNo ratings yet

- A Hybrid Smart AC DC Power SystemDocument6 pagesA Hybrid Smart AC DC Power SystemYangyadatta TripathyNo ratings yet

- Unit - 4Document21 pagesUnit - 4Shock SignalNo ratings yet

- Grid Integration of Small-Scale Photovoltaic Systems in Secondary Distribution Network-A ReviewDocument18 pagesGrid Integration of Small-Scale Photovoltaic Systems in Secondary Distribution Network-A ReviewroyNo ratings yet

- Irjet V5i8304Document5 pagesIrjet V5i8304abdulrazaq bibinuNo ratings yet

- Micro-Grid Autonomous Operation During and Subs To Islanding ProcessDocument10 pagesMicro-Grid Autonomous Operation During and Subs To Islanding Processapi-3738286No ratings yet

- Modeling of A Centralized Microgrid Protection System and Distributed Energy Resources According To IEC 61850-7-420Document8 pagesModeling of A Centralized Microgrid Protection System and Distributed Energy Resources According To IEC 61850-7-420AbhishekAnandNo ratings yet

- Lecture-8: Introduction To Smart GridDocument38 pagesLecture-8: Introduction To Smart GridSuper SpecialNo ratings yet

- Protection of Domestic Solar Photovoltaic Based Microgrid: M.P Nthontho, S.P Chowdhury, S. Winberg, S. ChowdhuryDocument6 pagesProtection of Domestic Solar Photovoltaic Based Microgrid: M.P Nthontho, S.P Chowdhury, S. Winberg, S. ChowdhuryMashood NasirNo ratings yet

- Smart Grid Communication Infrastructure: Dr. Muhammad TariqDocument49 pagesSmart Grid Communication Infrastructure: Dr. Muhammad TariqAbdul HaseebNo ratings yet

- WP-30018 SmartGridSPDs Rev0 10-10Document6 pagesWP-30018 SmartGridSPDs Rev0 10-10manubraunNo ratings yet

- Smart Grid Technology Nciaee 002Document8 pagesSmart Grid Technology Nciaee 002Mayank YadavNo ratings yet

- Development of Automated Grid Monitoring and Control System Using IoT A ReviewDocument4 pagesDevelopment of Automated Grid Monitoring and Control System Using IoT A ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Overview GridKey - Print 09.10.18Document10 pagesOverview GridKey - Print 09.10.18Nikhil SisodiaNo ratings yet

- Development of A Smart Transformer To Control The Power Exchange of A MicrogridDocument5 pagesDevelopment of A Smart Transformer To Control The Power Exchange of A MicrogridRaghavendra LakshmanNo ratings yet

- Introduccion A TR InteligentesDocument10 pagesIntroduccion A TR Inteligentestu_novia_nos_enganiaNo ratings yet

- On Grid-Interactive Smart Inverters: Features and AdvancementsDocument10 pagesOn Grid-Interactive Smart Inverters: Features and AdvancementsTeki Vamsee KrishnaNo ratings yet

- Application of Internet of Things: Last Meter Smart Grid and Smart Energy Efficient SystemDocument6 pagesApplication of Internet of Things: Last Meter Smart Grid and Smart Energy Efficient SystemJose María CotesNo ratings yet

- A Control Strategy For Implementation of Enhanced Voltage Quality in Micro GridDocument7 pagesA Control Strategy For Implementation of Enhanced Voltage Quality in Micro GriderpublicationNo ratings yet

- IET Renewable Power Gen - 2024 - Sharma - A Low Voltage Microgrid Protection Scheme Using Digital Instrument TransformersDocument12 pagesIET Renewable Power Gen - 2024 - Sharma - A Low Voltage Microgrid Protection Scheme Using Digital Instrument Transformerskhitech2002No ratings yet

- Smart Grid Integration of Iot: Fig. 1 - Classical Electrical GridDocument5 pagesSmart Grid Integration of Iot: Fig. 1 - Classical Electrical GridMiguel Esteban MartinezNo ratings yet

- Absolute Energy Routing and Real-Time Power Monitoring For Grid-Connected Distribution NetworksDocument9 pagesAbsolute Energy Routing and Real-Time Power Monitoring For Grid-Connected Distribution NetworksDharshiniVenugopalNo ratings yet

- Control of Microgrid For Different Modes of Operation IJERTV5IS051001Document6 pagesControl of Microgrid For Different Modes of Operation IJERTV5IS051001Seerat Aaftaab BarkatNo ratings yet

- IoT Based Control and Monitoring of Smart Grid and Power Theft Detection by Locating AreaDocument5 pagesIoT Based Control and Monitoring of Smart Grid and Power Theft Detection by Locating AreaAnonymous kw8Yrp0R5rNo ratings yet

- Guerrero 2013Document18 pagesGuerrero 2013Prisila DinantiNo ratings yet

- Implementation of An Application For The Time-Spectral Analysis of Supra-Harmonic Interferences in Smart GridsDocument4 pagesImplementation of An Application For The Time-Spectral Analysis of Supra-Harmonic Interferences in Smart GridsAnaraida Garcia BaigorriNo ratings yet

- Export and Import of Renewable Energy by Hybrid Microgrid Via IotDocument4 pagesExport and Import of Renewable Energy by Hybrid Microgrid Via IotDorothy ManriqueNo ratings yet

- (IJCST-V8I5P7) :naveen Kumar, Gopal SinghDocument6 pages(IJCST-V8I5P7) :naveen Kumar, Gopal SinghEighthSenseGroupNo ratings yet

- Stability Enhancement of Decentralized Inverter Control Through Wireless Communications in MicrogridsDocument11 pagesStability Enhancement of Decentralized Inverter Control Through Wireless Communications in MicrogridsARUNIMA SNo ratings yet

- Low Voltage Distribution Substation Integration in Smart MicrogridDocument8 pagesLow Voltage Distribution Substation Integration in Smart Microgridcam.joeyNo ratings yet

- Implementation of SCADA Systems For A Real Microgrid Lab TestbedDocument7 pagesImplementation of SCADA Systems For A Real Microgrid Lab TestbedJuan PavaNo ratings yet

- Novel Protection Schema For A Radial Microgrid SystemDocument6 pagesNovel Protection Schema For A Radial Microgrid SystempouyanNo ratings yet

- Smart Grid - An Intelligent Power System: Review and Future ChallengesDocument4 pagesSmart Grid - An Intelligent Power System: Review and Future ChallengesManoj Karthik KingNo ratings yet

- Dynamic Modeling of Microgrid For Grid Connected and Intentional Islanding OperationDocument6 pagesDynamic Modeling of Microgrid For Grid Connected and Intentional Islanding OperationmedbNo ratings yet

- Overview of Intelligent Substation Automation in Distribution SystemsDocument6 pagesOverview of Intelligent Substation Automation in Distribution SystemsCESAR ARTURO ORTIZ BELLIDONo ratings yet

- Smart Grid, Smart Controllers and Home Energy Automation-Creating The Infrastructure For FutureDocument10 pagesSmart Grid, Smart Controllers and Home Energy Automation-Creating The Infrastructure For FutureFranco GionoNo ratings yet

- Security Considerations For Multicast Communication in Power SystemsDocument11 pagesSecurity Considerations For Multicast Communication in Power SystemsSantanuNo ratings yet

- Smart GridDocument4 pagesSmart GridJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Antenna Survey PaperDocument8 pagesAntenna Survey PaperPavithraNo ratings yet

- Optimal Smart Grid Operation and Control Enhancement by Edge ComputingDocument6 pagesOptimal Smart Grid Operation and Control Enhancement by Edge ComputingMuhammad Atiq Ur Rehman 22-FET/PHDEE/S19No ratings yet

- Protection Strategy For Fault Detection in Inverter-Dominated Low Voltage AC MicrogridDocument8 pagesProtection Strategy For Fault Detection in Inverter-Dominated Low Voltage AC MicrogridM8ow6fNo ratings yet

- Real-Time Power Flow Monitoring and Control System For Microgrids Integration in Islanded ScenariosDocument12 pagesReal-Time Power Flow Monitoring and Control System For Microgrids Integration in Islanded ScenariosVitovich DittaNo ratings yet

- PV Inverter TopoligiesDocument6 pagesPV Inverter TopoligieslegioNo ratings yet

- Wireless Alarm Microsystem Self-Powered by Vibration-Threshold-Triggered Energy HarvesterDocument10 pagesWireless Alarm Microsystem Self-Powered by Vibration-Threshold-Triggered Energy HarvesterHans Cabrera MankowskiNo ratings yet

- Wireless Alarm Microsystem Self-Powered by Vibration-Threshold-Triggered Energy HarvesterDocument10 pagesWireless Alarm Microsystem Self-Powered by Vibration-Threshold-Triggered Energy HarvesterHans Cabrera MankowskiNo ratings yet

- Power System Analysis of A Microgrid Using ETAP: April 2015Document6 pagesPower System Analysis of A Microgrid Using ETAP: April 2015Raja GurningNo ratings yet

- The Implementation of Smart Grid Technology With SCADA As The Main Infrastructure To Support The Integration of Renewable EnergyDocument6 pagesThe Implementation of Smart Grid Technology With SCADA As The Main Infrastructure To Support The Integration of Renewable EnergyArif PriyohutomoNo ratings yet

- Protection of DC Microgrids Based On Complex Power During Faults in On Off-Grid ScenariosDocument11 pagesProtection of DC Microgrids Based On Complex Power During Faults in On Off-Grid ScenariosNahil ShakerNo ratings yet

- Solar Photovoltaic Remote Monitoring System Using IOT: Ankit Kekre Suresh K. GawreDocument5 pagesSolar Photovoltaic Remote Monitoring System Using IOT: Ankit Kekre Suresh K. Gawreمصطفاوي محمدNo ratings yet

- A Review of Smart Grid Technology: XXX-X-XXXX-XXXX-X/XX/$XX.00 ©20XX IEEEDocument8 pagesA Review of Smart Grid Technology: XXX-X-XXXX-XXXX-X/XX/$XX.00 ©20XX IEEEMomal ARNo ratings yet

- A Power Electronic Smart Load Controller For Nanogrids and Autonomous Power SystemsDocument4 pagesA Power Electronic Smart Load Controller For Nanogrids and Autonomous Power SystemsjorgeNo ratings yet

- Wa0023.Document12 pagesWa0023.nikhilsuresh549No ratings yet

- LECTURE 1 From Smart Grid To Energy InternetDocument43 pagesLECTURE 1 From Smart Grid To Energy Internetwing fatt hiewNo ratings yet

- ALL 11 0935 TIE Part IDocument9 pagesALL 11 0935 TIE Part ISorin MiuNo ratings yet

- Zhaoxia 2017Document6 pagesZhaoxia 2017Maxime BatongaNo ratings yet

- Smartgrid 160224172537Document24 pagesSmartgrid 160224172537Umesh GowdaNo ratings yet

- Dynamic Model Microturbine: of Generation System For Grid Connected/Islanding OperationDocument6 pagesDynamic Model Microturbine: of Generation System For Grid Connected/Islanding OperationMahinder ChoudharyNo ratings yet

- Fault Analysis of Three Phase Alternator Sequence Impedance: Apparatus RequiredDocument9 pagesFault Analysis of Three Phase Alternator Sequence Impedance: Apparatus RequiredMohan KrishnaNo ratings yet

- Cs Unit-2 PDFDocument33 pagesCs Unit-2 PDFMohan KrishnaNo ratings yet

- Curriculum Vitae of Mohan KrishnaDocument2 pagesCurriculum Vitae of Mohan KrishnaMohan KrishnaNo ratings yet

- Ilovepdf Merged PDFDocument19 pagesIlovepdf Merged PDFMohan KrishnaNo ratings yet

- S187Document3 pagesS187Mohan KrishnaNo ratings yet

- IoT Ambulance With Automatic Traffic Light ControlDocument3 pagesIoT Ambulance With Automatic Traffic Light ControlMohan KrishnaNo ratings yet

- Eee Dept - Student Hour-Teams For GD Topic-Role of Women in The Society Teams Ii-A Ii-B Iii-A Iii-B 1Document2 pagesEee Dept - Student Hour-Teams For GD Topic-Role of Women in The Society Teams Ii-A Ii-B Iii-A Iii-B 1Mohan KrishnaNo ratings yet

- Electrical Technology LaboratoryDocument1 pageElectrical Technology LaboratoryMohan KrishnaNo ratings yet

- Malathi ResumeDocument1 pageMalathi ResumeMohan KrishnaNo ratings yet

- C.Mohan Krishna S. Imran Khan K.Purushotham Assistant Professor Alits College of Engineering AnantapurDocument13 pagesC.Mohan Krishna S. Imran Khan K.Purushotham Assistant Professor Alits College of Engineering AnantapurMohan KrishnaNo ratings yet

- Explain The Dynamic Characteristics of SCR in Detail? 2. Explain The Constructional Details of GTO and CharacteristicsDocument1 pageExplain The Dynamic Characteristics of SCR in Detail? 2. Explain The Constructional Details of GTO and CharacteristicsMohan KrishnaNo ratings yet

- 9A02504 Power ElectronicsDocument4 pages9A02504 Power ElectronicsMohan Krishna100% (1)

- Lecture 29Document9 pagesLecture 29Guadalajara JaliscoNo ratings yet

- LM 321 LVDocument51 pagesLM 321 LVRodrigo ForrequiNo ratings yet

- T480 User GuideDocument170 pagesT480 User Guideanon_831483663No ratings yet

- 15-8 Feeder Cable - 500 009 03Document2 pages15-8 Feeder Cable - 500 009 03Brian A. MuhammadNo ratings yet

- H61 Pro BTCDocument56 pagesH61 Pro BTCKev InNo ratings yet

- Welding Procedure Specification (WPS) : Accordance To ISO 15609-1 (Arc Welding)Document1 pageWelding Procedure Specification (WPS) : Accordance To ISO 15609-1 (Arc Welding)Ramzi BEN AHMEDNo ratings yet

- IECEE - Brochure - Taking Conformity Assessment FurtherDocument20 pagesIECEE - Brochure - Taking Conformity Assessment FurtherPhoenix PhosphorescentNo ratings yet

- Dynamic Modeling Chen1999Document10 pagesDynamic Modeling Chen1999Erzsébet PállNo ratings yet

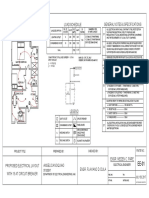

- General Notes & Specifications Load Schedule: StudentDocument1 pageGeneral Notes & Specifications Load Schedule: StudentAngelica NoquiaoNo ratings yet

- Microprocessor FundamentalsDocument29 pagesMicroprocessor FundamentalsrakhileshpkNo ratings yet

- Liebert gxt4 230v 5000 10000va User Manual SLI 23197Document66 pagesLiebert gxt4 230v 5000 10000va User Manual SLI 23197highwtonNo ratings yet

- Wireless World 1983 03Document126 pagesWireless World 1983 03Adrian DinuNo ratings yet

- 99 Guitar PhraseDocument9 pages99 Guitar PhraseCirù Monia FalcoNo ratings yet

- Esp ComponentsDocument19 pagesEsp ComponentsnawarsNo ratings yet

- 1SNC110001C0201 GB BRDocument68 pages1SNC110001C0201 GB BREdgar AlvarezNo ratings yet

- UF-450AX Catalog 2PDocument2 pagesUF-450AX Catalog 2PHuỳnh Bảo SơnNo ratings yet

- Product Data Sheet: Earth-Leakage Relay RH10M - 30 Ma - 240 VDocument3 pagesProduct Data Sheet: Earth-Leakage Relay RH10M - 30 Ma - 240 VDarwin LibrandaNo ratings yet

- Short-Circuit Analysis IEC StandardDocument46 pagesShort-Circuit Analysis IEC StandardAbdel-Rahman Saifedin Arandas100% (1)

- 100KW 500RPM Permanent Magnet Generator PDFDocument3 pages100KW 500RPM Permanent Magnet Generator PDFNicole PalomaresNo ratings yet

- DFDFDFDF PDFDocument3 pagesDFDFDFDF PDFBoubker BellahnaNo ratings yet

- B737-3 ATA 23 CommunicationsDocument112 pagesB737-3 ATA 23 CommunicationsPaul RizlNo ratings yet

- ANT-APE4518R19v07-2333-002 DatasheetDocument2 pagesANT-APE4518R19v07-2333-002 Datasheetпавел100% (1)

- Unit-4 Elecrical Drives and Controls II PartDocument29 pagesUnit-4 Elecrical Drives and Controls II PartsentamilselvanNo ratings yet

- Inverter Power Supply Design Based On Single Chip MicrocomputerDocument4 pagesInverter Power Supply Design Based On Single Chip MicrocomputeramirNo ratings yet

- BOM Transmission - OSN 1800 II Pro - 31032023xlsxDocument5 pagesBOM Transmission - OSN 1800 II Pro - 31032023xlsxThanhNN0312No ratings yet

- Exp1 Lab Report A4Document16 pagesExp1 Lab Report A4asad baigNo ratings yet

- C-118-H Acoustic System: Screen Channel Cinema Sound System Especially Designed For SubwoofersDocument2 pagesC-118-H Acoustic System: Screen Channel Cinema Sound System Especially Designed For SubwoofersGokul KrishnanNo ratings yet

- Rotron Transportation CatalogDocument54 pagesRotron Transportation CatalogSolikin PatiNo ratings yet

Ijert Ijert: "Frequency Control of Smart Grid - MATLAB/SIMULINK Approach"

Ijert Ijert: "Frequency Control of Smart Grid - MATLAB/SIMULINK Approach"

Uploaded by

Mohan KrishnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijert Ijert: "Frequency Control of Smart Grid - MATLAB/SIMULINK Approach"

Ijert Ijert: "Frequency Control of Smart Grid - MATLAB/SIMULINK Approach"

Uploaded by

Mohan KrishnaCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 10, October - 2013

Frequency Control of Smart Grid - A MATLAB/SIMULINK Approach

Vikash Kumar Dr. Pankaj Rai Dr. Ghanshyam

M.tech Student Department of Electrical Engg. Dept. of Physics

Department of Electrical Engg. BIT Sindri, Dhanbad BIT Sindri,Dhanbad

BIT Sindri, Dhanbad

Frequency is the main parameter to show the

stability of any power system network like

Abstract conventional power grid, micro grid or any virtual

In this paper, a Smart Grid has been designed power plant. These distributed generators along

using MATLAB/SIMULINK approach for with local loads and storage constitute micro grids

synchronization of Thermal and Wind power [4]. The analysis of frequency control has already

plant. The Smart Grid is regarded as the next been done in Isolated Micro grids [5]. Micro grid is

generation power grid, uses two-way flow of designed to operate in grid connected and isolated

electricity and information to create a widely mode [6]. In the case of grid connected system, the

distributed automated energy delivery network. supply and demand gap shall be taken care by main

Output Voltage and frequency of these power grid and hence the system is more stable i.e.,

plants must be same to avoid circulating current voltage and frequency are maintained within the

in existing power system network in the limits [7]. To control the frequency in isolated

micro grid, storage element is necessary [8].

RT

synchronization process. The maximum and

minimum frequency deviation calculated for Different rating of storage and integrating devices

this smart power system network explains about are used to control the frequency which can create a

very complex situation. Since micro grids are a low

IJE

the permissible range of active and inductive

load applied at different load bus , from which voltage network which is generally not the case of

stable working condition of the system has been modern power system network [9].

deduced in order to satisfy the frequency

In present scenario of power system network,

deviation of + 3%.

conventional and distributed generation are used

Index: SIMULINK, Smart Grid, Frequency together to control the power flow in order to get a

Deviation, DFIG, Load Analysis highly stable network. The proposed smart grid

model includes four units of Thermal power plant

(conventional generation) and six units of Wind

I. INRTODUCTION

power plant (distributed generation). Wind power

plant has been connected to the side of major load.

A Smart Grid is an electrical grid that uses

In Thermal power plant power generation is done

information and communication technology to

by Synchronous generator and in Wind power plant

gather and act on information, such as information

by Doubly Feded induction generator (DFIG) [10].

about the behaviours of suppliers and consumers, in

The rating of each thermal power plant is 900 MW

an automated fashion to improve the efficiency,

where as wind power plant rating is 12 MW. 13.8

reliability, economics, and sustainability of the

KV is generated by synchronous generator which is

production and distribution of electricity [1]. Smart

then step-up to 230 KV of voltage level and 575 V

grid is technically classified in three categories

is generated by DFIG which is again step-up to 230

namely Smart Infrastructure System, Smart

KV to maintain the transmission voltage at 230

Management System and Smart Protection System

KV. The overall Frequency of system has been

[2]. The design & simulation work of this paper has

controlled by controlling the frequency of both

been done under the Smart Power generation [3]

synchronous generator and DFIG independently.

technique which is a part of Smart Infrastructure

System.

IJERTV2IS100438 www.ijert.org 1351

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 10, October - 2013

II. FREQUENCY CONTROL SCHEME adjusted automatically to restore the frequency to

the normal value. This scheme is known as

Frequency control of the proposed power

Automatic Generation Control. In an

system model has been done by two processes:

interconnected system consisting of several pools,

the role of the AGC is to divide the load among the

(i) Automatic load frequency control (ALFC)

system, stations and generators so as to achieve

loops of synchronous generator.

maximum economy and reasonable uniform

(ii) Automatic frequency control of doubly fed

frequency.

induction generator.

When a group of generators are closely coupled

A. Frequency control of synchronous generator internally and swing in unison, the generator

When loads increase or decrease the turbines tend to have the same response

frequency decreases or increases characteristics. Such a group of generators are said

accordingly. For automatic frequency to be coherent. It is assumed that the LFC loop

control, ALFC has been used in both single represent the whole system and the group is called

and double area loop. the control group. For a two area system, during

normal operation the real power transferred over

Block diagram of Synchronous Generator:

the tie line is given by:

E1 E2

P12 sin 12

X 12

Where X12 X1 X tie X 2

and 12 1 2

RT

For a small deviation in the tie-line flow

IJE

dP12

P12 12 Ps 12

d12

12

P12 Ps 1 2

Where

Fig 1. Block Diagram of Synchronous Generator P12 power flow between area 1 and area 2.

In thermal power plant, frequency can be controlled E1 generated voltage of area 1.

by automatic frequency control loop (ALFC) which

comprises generator, load, prime mover and E2 generated voltage of area 2.

governor.

The steam input of governor system is adjusted X 12 reactance between area 1 & area 2.

with respect to turbine speed which is directly

proportional to load variation. As the change in the X 1 reactance of area 1.

value of speed diminishes, the error signal becomes

smaller and the position of the governor and fly X 2 reactance of area 2.

balls get closer to the point, required to maintain

the constant speed. One way to restore the speed or

1 load angle of area 1.

frequency to its nominal value is to add an

integrator on the way. The integrator unit shall

monitor the average error over a period of time and

2 load angle of area 2.

will overcome the offset. Thus as the load of the

system changes continuously, the generation is 12 load angle between area 1 & area 2.

IJERTV2IS100438 www.ijert.org 1352

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 10, October - 2013

The tie-line power deviation then takes on the form When the magnetic field at the rotor rotates in

the same direction as the generator rotor, the rotor

speed nRotor and the speed n , rotor of the rotor

magnetic field (proportional to f Stator ) add up. The

frequency of the voltages induced across the stator

windings of the generator can thus be calculated

using the following equation:

nRotor N Poles

f Stator f Rotor

120

Where

f Stator is the frequency of the voltage induced

across the stator winding

and

Fig.2 Tie Line Power Representation

f Rotor is the frequency of the ac currents fed into

the doubly-fed induction generator rotor windings,

B. Frequency Control of DFIG:

expressed in hertz (Hz).

Conversely, when the magnetic field at the

rotor rotates in the direction opposite to that of the

RT

generator rotor, the rotor speed nRotor and the

speed n , rotor of the rotor magnetic field subtract

IJE

from each other. The frequency f Stator of the

voltages induced across the stator windings of the

generator can thus be calculated using the

following equation:

nRotor N Poles

f Stator f Rotor

120

The SIMULATION model of frequency control

scheme is shown below in fig.4.

The smart grid simulation model comprises of

Fig.3 Wind Turbine and Doubly-fed Induction Generator four units of thermal power plant i.e. P1, P2, P3

System and P4, each having 900 MW capacity. Six units of

wind power plant are added to this power system

In doubly feded electric machines, ac

network having the total capacity of 12 MW.

current is fed into both stator and rotor windings.

Doubly-fed induction generators work on the Two different set of loads are used at bus bar

doubly fed machines principle which is used in B3 ant at bus bar B6. Magnitude of inductive and

wind turbines to get the constant voltage and active loads are varied keeping the capacitive load

constant frequency irrespective of variation in constants to get the frequency of the system.

wind speed. Due to this great feature of DFIG ,

doubly-fed induction generators can be directly

connected to the ac power network and remain

synchronized with the ac power network.

IJERTV2IS100438 www.ijert.org 1353

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 10, October - 2013

s

SIMULATION MODEL

Fig 4. Frequency Control Scheme

The effect of load variation has been studied,which is as follows:

RT

Sl No Load at Bus 3 Load at Bus 6 Frequencies(In Hz) %

Frequency

Deviation

IJE

Inductive Active Capacitive Inductive Active capacitive Minimum Maximum Negative Positive

deviation deviation

(MVAr) (MW) (MVAr) (MVAr) (MW) (MVAr)

1. 150 1100 200 120 1900 350 49.90 50.292 -0.584% 0.20%

2. 180 1030 200 190 1950 350 49.72 50.105 -0.21% 0.56%

3. 190 1200 200 210 2100 350 49.81 50.06 -0.12% 0.38%

4. 130 1050 200 140 1850 350 49.87 50.03 -0.06% 0.26%

5. 120 1000 200 120 1800 350 49.96 50.33 -0.66% 0.08%

6. 100 960 200 100 1760 350 49.78 51.23 -2.46% 0.44%

7. 80 900 200 80 1700 350 49.72 50.24 -0.48% 0.56%

8. 70 800 200 65 1600 350 49.70 50.34 -0.68% 0.60%

9. 60 700 200 50 1500 350 49.63 50.55 -1.10% 0.74%

10. 50 650 200 40 1400 350 49.20 50.8 -1.60% 1.60%

IJERTV2IS100438 www.ijert.org 1354

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 10, October - 2013

III. RESULT AND DISCUSSION:

Four cases of different loads has been taken

to check the stability of system:

A. CASE I

Load at BUS 3

Inductive Active Capacitive

(MVAr) (MW) (MVAr)

150 1100 200

Load at BUS 6 Fig.6 Frequency of Thermal power plant for case-II

Inductive Active Capacitive It is observed that the fmax=50.06 Hz AND

fmin=49.81 Hz. This is a stable working region of a

(MVAr) (MW) (MVAr) power system network.

120 1900 350 C. CASE III

Load at BUS 3

Inductive Active Capacitive

(MVAr) (MW) (MVAr)

RT

100 960 200

Load at BUS 6

IJE

Inductive Active Capacitive

(MVAr) (MW) (MVAr)

100 1760 350

Fig. 5 Frequency of Thermal power plant for case-I.

It is observed that the fmax=50.29 Hz AND

fmin=49.9 Hz. This is a stable working region of a

power system network.

B. CASE II

Load at BUS 3

Inductive(MVAr) Active(MW) Capacitive(MVAr)

190 1200 200

Load at BUS 6

Fig.7 Frequency of Thermal power plant for case-III

Inductive(MVAr) Active(MW) Capacitive(MVAr) It is observed that the fmax=51.23 Hz AND

fmin=49.78 Hz. This is a stable working region of a

210 2100 350 power system network.

IJERTV2IS100438 www.ijert.org 1355

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 10, October - 2013

D. CASE IV frequency deviation is 0.584%. Since both the

positive and negative frequency deviation result

Load at BUS 3

comes under the defined stable frequency deviation

Inductive Active Capacitive range which is + 3%. This result shows that this

(MVAr) (MW) (MVAr) smart grid power system is stable on these load

50 650 200 values.

Inductive and Active loads at both buses

Load at BUS 6

has increased simultaneously and this is found that

Inductive Active Capacitive when inductive and active load values at bus B3 is

(MVAr) (MW) (MVAr) 190 MVAr and 1200MW and load value at bus B6

40 1400 350 is 210 MVAr and 2100 MW then active power

measured at all buses namely B1, B2, B3, B4 and

B5 are not constant throughout the process and it is

varying time to time which is an undesirable result

for a stable power system network. Although

frequencies measured are within the stable range.

Minimum and maximum frequencies measured at

these load values are 49.81 Hz and 50.06 Hz

RT

respectively. The positive frequency deviation is

0.12% and 0.38% which is within + 3%.

IJE

The maximum values of load has been taken

Fig.8 Frequency of Thermal power plant for case-4

to check the maximum load limit of this smart grid

It is observed that the fmax=50.80 Hz AND

network and it has seen that at that maximum

fmin=49.2 Hz. This is a stable working region of a

power system network. values of load, frequency is under stable range but

nature of active power is no more compatible for

In load analysis of above simulation model,

applied load to their corresponding buses. So in

Inductive and Active loads are varied in RL series

another case, magnitude of both active and

load which is taken at both load buses i.e. B3 and

inductive loads has been decreased on both load

B6, whereas capacitive load is kept as it is with the

buses to know the range of loads that can be

initial value taken in series load. The value of

attached to the power system network for a stable

capacitive load at bus bar B3 is 200 MVAr where

operation. To know these load ranges, value of

as 350 MVAr of capacitive value is taken at bus bar

inductive load on bus bar B3 is decreased to

B6. Initially active and inductive load at B3 is

50MVAr from their initial value which is

taken as 1100MW and 150 MVAr respectively and

150MVAr and value of active load is decreased to

at B6 the value of active load is 1900 MW and the

650MW from their initial value of 1100MW where

value of inductive load is 120 MVAr. The

as at bus bar B6, inductive load is decreased from

maximum and minimum frequency measured at

120MVAr to 40MVAr and active load is decreased

these loads is 50.252 Hz and 49.90 Hz respectively.

from 1900MW to 1400MW. At these lowest load

The positive frequency deviation is calculated to be

values, the values of maximum and minimum

0.20% and the calculated value of negative

frequencies are measured to be 50.80 Hz and 49.20

IJERTV2IS100438 www.ijert.org 1356

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 10, October - 2013

References

Hz. The positive and negative frequency deviation [1]. Xi Fang, Student Member, IEEE,Satyajayant

Misra, Member, IEEE, Guoliang Xue, Fellow,

is calculated to the same value of 1.60%. Although

IEEE, and Dejun Yang, Student Member,

this frequency deviation comes under the defined IEEE, Smart Grid The New and Improved

Power Grid: A Survey, IEEE Trans. Smart

frequency deviation range i.e. +3% but it is seen

Grid, 2011

that the worst power blackout which happened on [2]. F. Rahimi, A. Ipakchi, Demand response as a

market resource under the smart grid

July 2013 in India occurred at 49.20 Hz only. So

paradigm. IEEE Trans. Smart Grid, 1(1):82

to take the standard of 49.20Hz, the load is varied 88, 2010.

[3]. P. B. Andersen, B. Poulsen, M. Decker, C.

to get the frequency value of 49.20Hz. So final

Trholt, and J. stergaard. Evaluation of a

range of inductive load on bus bar B3 is from 190 generic virtual power plant framework using

service oriented architecture. IEEE

MVAr to 50 MVAr and final range of active load is

PECon08, pages 12121217, 2008.

from 1200 MW to 650 MW where as maximum [4]. P. B. Andersen, B. Poulsen, M. Decker, C.

Trholt, and J. stergaard. Evaluation of a

variation of active load on bus bar B6 is from 2100

generic virtual power plant framework using

MW to 1400 MW and for inductive load the range service oriented architecture. IEEE

PECon08, pages 12121217, 2008

is from 210 MVAr to 40 MVAr.

[5]. C. Marinescu and S. I, Analysis of frequency

stability in a residential autonomous microgrid

based on the wind turbine and microhydel

power plant, Optimization of electrical and

electronic equipment, vol. 50, pp. 11861191,

IV.CONCLUSION 2010

[6]. P.Piagi, Microgrid control, Ph.D.

In this paper, load analysis has been done on the dissertation, Electrical enginnering department,

RT

designed smart grid to check the stability in terms University of Wisconsin -Madisson, August

2005.

of frequency deviation. Since the standard [7]. P.Piagi and R. Lasseter, Autonomous control

IJE

frequency deviation is defined in + 3% range. of microgrids, 2006.

[8]. G.Lalor, Frequency control on an isolated

Synchronization of the proposed system consists of power system with evolving plant mix, Ph.D.

both wind and thermal power plant has been dissertation, School of electrical and

mechanical Engineering, University College

considered to get a constant frequency output of the Dublin, September 2005.

system. Constant frequency system is the combined [9]. Suryanarayana Doolla, Jayesh Priolkar,

Analysis of Frequency Control in Isolated

effect of DFIG in wind power plant and ALFC loop Microgrids IEEE PES Innovative Smart Grid

in thermal power plant. Load Analysis has been Technologies India, 2011

[10]. R. Doherty, etal, System operation with a

done to know the maximum capacity of whole significant wind power penetration, IEEE

power system network by maximum positive and Power Engineering Society General Meeting,

Vol.1, pp. 1002-1007, 2004.

negative frequency deviation. The base frequency

of the system is taken as 49.2 Hz considering the

case of 2012 power blackout of India making the

permissible limit to be + 1.6% in place of +3%.

IJERTV2IS100438 www.ijert.org 1357

You might also like

- Manual MyLab 5 PDFDocument80 pagesManual MyLab 5 PDFÉric Scolastici100% (1)

- Digital Electronics (Betty Lincoln)Document434 pagesDigital Electronics (Betty Lincoln)Rayhan Nur AhmadiNo ratings yet

- 05IPST080Document6 pages05IPST080Niveditha NamasivaayamNo ratings yet

- Control and Operation of Grid Connected DC Source Based Distribution GenerationDocument4 pagesControl and Operation of Grid Connected DC Source Based Distribution Generationgagan mahadevaNo ratings yet

- Irjet V5i520Document5 pagesIrjet V5i520baby hNo ratings yet

- A Hybrid Smart AC DC Power SystemDocument6 pagesA Hybrid Smart AC DC Power SystemYangyadatta TripathyNo ratings yet

- Unit - 4Document21 pagesUnit - 4Shock SignalNo ratings yet

- Grid Integration of Small-Scale Photovoltaic Systems in Secondary Distribution Network-A ReviewDocument18 pagesGrid Integration of Small-Scale Photovoltaic Systems in Secondary Distribution Network-A ReviewroyNo ratings yet

- Irjet V5i8304Document5 pagesIrjet V5i8304abdulrazaq bibinuNo ratings yet

- Micro-Grid Autonomous Operation During and Subs To Islanding ProcessDocument10 pagesMicro-Grid Autonomous Operation During and Subs To Islanding Processapi-3738286No ratings yet

- Modeling of A Centralized Microgrid Protection System and Distributed Energy Resources According To IEC 61850-7-420Document8 pagesModeling of A Centralized Microgrid Protection System and Distributed Energy Resources According To IEC 61850-7-420AbhishekAnandNo ratings yet

- Lecture-8: Introduction To Smart GridDocument38 pagesLecture-8: Introduction To Smart GridSuper SpecialNo ratings yet

- Protection of Domestic Solar Photovoltaic Based Microgrid: M.P Nthontho, S.P Chowdhury, S. Winberg, S. ChowdhuryDocument6 pagesProtection of Domestic Solar Photovoltaic Based Microgrid: M.P Nthontho, S.P Chowdhury, S. Winberg, S. ChowdhuryMashood NasirNo ratings yet

- Smart Grid Communication Infrastructure: Dr. Muhammad TariqDocument49 pagesSmart Grid Communication Infrastructure: Dr. Muhammad TariqAbdul HaseebNo ratings yet

- WP-30018 SmartGridSPDs Rev0 10-10Document6 pagesWP-30018 SmartGridSPDs Rev0 10-10manubraunNo ratings yet

- Smart Grid Technology Nciaee 002Document8 pagesSmart Grid Technology Nciaee 002Mayank YadavNo ratings yet

- Development of Automated Grid Monitoring and Control System Using IoT A ReviewDocument4 pagesDevelopment of Automated Grid Monitoring and Control System Using IoT A ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Overview GridKey - Print 09.10.18Document10 pagesOverview GridKey - Print 09.10.18Nikhil SisodiaNo ratings yet

- Development of A Smart Transformer To Control The Power Exchange of A MicrogridDocument5 pagesDevelopment of A Smart Transformer To Control The Power Exchange of A MicrogridRaghavendra LakshmanNo ratings yet

- Introduccion A TR InteligentesDocument10 pagesIntroduccion A TR Inteligentestu_novia_nos_enganiaNo ratings yet

- On Grid-Interactive Smart Inverters: Features and AdvancementsDocument10 pagesOn Grid-Interactive Smart Inverters: Features and AdvancementsTeki Vamsee KrishnaNo ratings yet

- Application of Internet of Things: Last Meter Smart Grid and Smart Energy Efficient SystemDocument6 pagesApplication of Internet of Things: Last Meter Smart Grid and Smart Energy Efficient SystemJose María CotesNo ratings yet

- A Control Strategy For Implementation of Enhanced Voltage Quality in Micro GridDocument7 pagesA Control Strategy For Implementation of Enhanced Voltage Quality in Micro GriderpublicationNo ratings yet

- IET Renewable Power Gen - 2024 - Sharma - A Low Voltage Microgrid Protection Scheme Using Digital Instrument TransformersDocument12 pagesIET Renewable Power Gen - 2024 - Sharma - A Low Voltage Microgrid Protection Scheme Using Digital Instrument Transformerskhitech2002No ratings yet

- Smart Grid Integration of Iot: Fig. 1 - Classical Electrical GridDocument5 pagesSmart Grid Integration of Iot: Fig. 1 - Classical Electrical GridMiguel Esteban MartinezNo ratings yet

- Absolute Energy Routing and Real-Time Power Monitoring For Grid-Connected Distribution NetworksDocument9 pagesAbsolute Energy Routing and Real-Time Power Monitoring For Grid-Connected Distribution NetworksDharshiniVenugopalNo ratings yet

- Control of Microgrid For Different Modes of Operation IJERTV5IS051001Document6 pagesControl of Microgrid For Different Modes of Operation IJERTV5IS051001Seerat Aaftaab BarkatNo ratings yet

- IoT Based Control and Monitoring of Smart Grid and Power Theft Detection by Locating AreaDocument5 pagesIoT Based Control and Monitoring of Smart Grid and Power Theft Detection by Locating AreaAnonymous kw8Yrp0R5rNo ratings yet

- Guerrero 2013Document18 pagesGuerrero 2013Prisila DinantiNo ratings yet

- Implementation of An Application For The Time-Spectral Analysis of Supra-Harmonic Interferences in Smart GridsDocument4 pagesImplementation of An Application For The Time-Spectral Analysis of Supra-Harmonic Interferences in Smart GridsAnaraida Garcia BaigorriNo ratings yet

- Export and Import of Renewable Energy by Hybrid Microgrid Via IotDocument4 pagesExport and Import of Renewable Energy by Hybrid Microgrid Via IotDorothy ManriqueNo ratings yet

- (IJCST-V8I5P7) :naveen Kumar, Gopal SinghDocument6 pages(IJCST-V8I5P7) :naveen Kumar, Gopal SinghEighthSenseGroupNo ratings yet

- Stability Enhancement of Decentralized Inverter Control Through Wireless Communications in MicrogridsDocument11 pagesStability Enhancement of Decentralized Inverter Control Through Wireless Communications in MicrogridsARUNIMA SNo ratings yet

- Low Voltage Distribution Substation Integration in Smart MicrogridDocument8 pagesLow Voltage Distribution Substation Integration in Smart Microgridcam.joeyNo ratings yet

- Implementation of SCADA Systems For A Real Microgrid Lab TestbedDocument7 pagesImplementation of SCADA Systems For A Real Microgrid Lab TestbedJuan PavaNo ratings yet

- Novel Protection Schema For A Radial Microgrid SystemDocument6 pagesNovel Protection Schema For A Radial Microgrid SystempouyanNo ratings yet

- Smart Grid - An Intelligent Power System: Review and Future ChallengesDocument4 pagesSmart Grid - An Intelligent Power System: Review and Future ChallengesManoj Karthik KingNo ratings yet

- Dynamic Modeling of Microgrid For Grid Connected and Intentional Islanding OperationDocument6 pagesDynamic Modeling of Microgrid For Grid Connected and Intentional Islanding OperationmedbNo ratings yet

- Overview of Intelligent Substation Automation in Distribution SystemsDocument6 pagesOverview of Intelligent Substation Automation in Distribution SystemsCESAR ARTURO ORTIZ BELLIDONo ratings yet

- Smart Grid, Smart Controllers and Home Energy Automation-Creating The Infrastructure For FutureDocument10 pagesSmart Grid, Smart Controllers and Home Energy Automation-Creating The Infrastructure For FutureFranco GionoNo ratings yet

- Security Considerations For Multicast Communication in Power SystemsDocument11 pagesSecurity Considerations For Multicast Communication in Power SystemsSantanuNo ratings yet

- Smart GridDocument4 pagesSmart GridJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Antenna Survey PaperDocument8 pagesAntenna Survey PaperPavithraNo ratings yet

- Optimal Smart Grid Operation and Control Enhancement by Edge ComputingDocument6 pagesOptimal Smart Grid Operation and Control Enhancement by Edge ComputingMuhammad Atiq Ur Rehman 22-FET/PHDEE/S19No ratings yet

- Protection Strategy For Fault Detection in Inverter-Dominated Low Voltage AC MicrogridDocument8 pagesProtection Strategy For Fault Detection in Inverter-Dominated Low Voltage AC MicrogridM8ow6fNo ratings yet

- Real-Time Power Flow Monitoring and Control System For Microgrids Integration in Islanded ScenariosDocument12 pagesReal-Time Power Flow Monitoring and Control System For Microgrids Integration in Islanded ScenariosVitovich DittaNo ratings yet

- PV Inverter TopoligiesDocument6 pagesPV Inverter TopoligieslegioNo ratings yet

- Wireless Alarm Microsystem Self-Powered by Vibration-Threshold-Triggered Energy HarvesterDocument10 pagesWireless Alarm Microsystem Self-Powered by Vibration-Threshold-Triggered Energy HarvesterHans Cabrera MankowskiNo ratings yet

- Wireless Alarm Microsystem Self-Powered by Vibration-Threshold-Triggered Energy HarvesterDocument10 pagesWireless Alarm Microsystem Self-Powered by Vibration-Threshold-Triggered Energy HarvesterHans Cabrera MankowskiNo ratings yet

- Power System Analysis of A Microgrid Using ETAP: April 2015Document6 pagesPower System Analysis of A Microgrid Using ETAP: April 2015Raja GurningNo ratings yet

- The Implementation of Smart Grid Technology With SCADA As The Main Infrastructure To Support The Integration of Renewable EnergyDocument6 pagesThe Implementation of Smart Grid Technology With SCADA As The Main Infrastructure To Support The Integration of Renewable EnergyArif PriyohutomoNo ratings yet

- Protection of DC Microgrids Based On Complex Power During Faults in On Off-Grid ScenariosDocument11 pagesProtection of DC Microgrids Based On Complex Power During Faults in On Off-Grid ScenariosNahil ShakerNo ratings yet

- Solar Photovoltaic Remote Monitoring System Using IOT: Ankit Kekre Suresh K. GawreDocument5 pagesSolar Photovoltaic Remote Monitoring System Using IOT: Ankit Kekre Suresh K. Gawreمصطفاوي محمدNo ratings yet

- A Review of Smart Grid Technology: XXX-X-XXXX-XXXX-X/XX/$XX.00 ©20XX IEEEDocument8 pagesA Review of Smart Grid Technology: XXX-X-XXXX-XXXX-X/XX/$XX.00 ©20XX IEEEMomal ARNo ratings yet

- A Power Electronic Smart Load Controller For Nanogrids and Autonomous Power SystemsDocument4 pagesA Power Electronic Smart Load Controller For Nanogrids and Autonomous Power SystemsjorgeNo ratings yet

- Wa0023.Document12 pagesWa0023.nikhilsuresh549No ratings yet

- LECTURE 1 From Smart Grid To Energy InternetDocument43 pagesLECTURE 1 From Smart Grid To Energy Internetwing fatt hiewNo ratings yet

- ALL 11 0935 TIE Part IDocument9 pagesALL 11 0935 TIE Part ISorin MiuNo ratings yet

- Zhaoxia 2017Document6 pagesZhaoxia 2017Maxime BatongaNo ratings yet

- Smartgrid 160224172537Document24 pagesSmartgrid 160224172537Umesh GowdaNo ratings yet

- Dynamic Model Microturbine: of Generation System For Grid Connected/Islanding OperationDocument6 pagesDynamic Model Microturbine: of Generation System For Grid Connected/Islanding OperationMahinder ChoudharyNo ratings yet

- Fault Analysis of Three Phase Alternator Sequence Impedance: Apparatus RequiredDocument9 pagesFault Analysis of Three Phase Alternator Sequence Impedance: Apparatus RequiredMohan KrishnaNo ratings yet

- Cs Unit-2 PDFDocument33 pagesCs Unit-2 PDFMohan KrishnaNo ratings yet

- Curriculum Vitae of Mohan KrishnaDocument2 pagesCurriculum Vitae of Mohan KrishnaMohan KrishnaNo ratings yet

- Ilovepdf Merged PDFDocument19 pagesIlovepdf Merged PDFMohan KrishnaNo ratings yet

- S187Document3 pagesS187Mohan KrishnaNo ratings yet

- IoT Ambulance With Automatic Traffic Light ControlDocument3 pagesIoT Ambulance With Automatic Traffic Light ControlMohan KrishnaNo ratings yet

- Eee Dept - Student Hour-Teams For GD Topic-Role of Women in The Society Teams Ii-A Ii-B Iii-A Iii-B 1Document2 pagesEee Dept - Student Hour-Teams For GD Topic-Role of Women in The Society Teams Ii-A Ii-B Iii-A Iii-B 1Mohan KrishnaNo ratings yet

- Electrical Technology LaboratoryDocument1 pageElectrical Technology LaboratoryMohan KrishnaNo ratings yet

- Malathi ResumeDocument1 pageMalathi ResumeMohan KrishnaNo ratings yet

- C.Mohan Krishna S. Imran Khan K.Purushotham Assistant Professor Alits College of Engineering AnantapurDocument13 pagesC.Mohan Krishna S. Imran Khan K.Purushotham Assistant Professor Alits College of Engineering AnantapurMohan KrishnaNo ratings yet

- Explain The Dynamic Characteristics of SCR in Detail? 2. Explain The Constructional Details of GTO and CharacteristicsDocument1 pageExplain The Dynamic Characteristics of SCR in Detail? 2. Explain The Constructional Details of GTO and CharacteristicsMohan KrishnaNo ratings yet

- 9A02504 Power ElectronicsDocument4 pages9A02504 Power ElectronicsMohan Krishna100% (1)

- Lecture 29Document9 pagesLecture 29Guadalajara JaliscoNo ratings yet

- LM 321 LVDocument51 pagesLM 321 LVRodrigo ForrequiNo ratings yet

- T480 User GuideDocument170 pagesT480 User Guideanon_831483663No ratings yet

- 15-8 Feeder Cable - 500 009 03Document2 pages15-8 Feeder Cable - 500 009 03Brian A. MuhammadNo ratings yet

- H61 Pro BTCDocument56 pagesH61 Pro BTCKev InNo ratings yet

- Welding Procedure Specification (WPS) : Accordance To ISO 15609-1 (Arc Welding)Document1 pageWelding Procedure Specification (WPS) : Accordance To ISO 15609-1 (Arc Welding)Ramzi BEN AHMEDNo ratings yet

- IECEE - Brochure - Taking Conformity Assessment FurtherDocument20 pagesIECEE - Brochure - Taking Conformity Assessment FurtherPhoenix PhosphorescentNo ratings yet

- Dynamic Modeling Chen1999Document10 pagesDynamic Modeling Chen1999Erzsébet PállNo ratings yet

- General Notes & Specifications Load Schedule: StudentDocument1 pageGeneral Notes & Specifications Load Schedule: StudentAngelica NoquiaoNo ratings yet

- Microprocessor FundamentalsDocument29 pagesMicroprocessor FundamentalsrakhileshpkNo ratings yet

- Liebert gxt4 230v 5000 10000va User Manual SLI 23197Document66 pagesLiebert gxt4 230v 5000 10000va User Manual SLI 23197highwtonNo ratings yet

- Wireless World 1983 03Document126 pagesWireless World 1983 03Adrian DinuNo ratings yet

- 99 Guitar PhraseDocument9 pages99 Guitar PhraseCirù Monia FalcoNo ratings yet

- Esp ComponentsDocument19 pagesEsp ComponentsnawarsNo ratings yet

- 1SNC110001C0201 GB BRDocument68 pages1SNC110001C0201 GB BREdgar AlvarezNo ratings yet

- UF-450AX Catalog 2PDocument2 pagesUF-450AX Catalog 2PHuỳnh Bảo SơnNo ratings yet

- Product Data Sheet: Earth-Leakage Relay RH10M - 30 Ma - 240 VDocument3 pagesProduct Data Sheet: Earth-Leakage Relay RH10M - 30 Ma - 240 VDarwin LibrandaNo ratings yet

- Short-Circuit Analysis IEC StandardDocument46 pagesShort-Circuit Analysis IEC StandardAbdel-Rahman Saifedin Arandas100% (1)

- 100KW 500RPM Permanent Magnet Generator PDFDocument3 pages100KW 500RPM Permanent Magnet Generator PDFNicole PalomaresNo ratings yet

- DFDFDFDF PDFDocument3 pagesDFDFDFDF PDFBoubker BellahnaNo ratings yet

- B737-3 ATA 23 CommunicationsDocument112 pagesB737-3 ATA 23 CommunicationsPaul RizlNo ratings yet

- ANT-APE4518R19v07-2333-002 DatasheetDocument2 pagesANT-APE4518R19v07-2333-002 Datasheetпавел100% (1)

- Unit-4 Elecrical Drives and Controls II PartDocument29 pagesUnit-4 Elecrical Drives and Controls II PartsentamilselvanNo ratings yet

- Inverter Power Supply Design Based On Single Chip MicrocomputerDocument4 pagesInverter Power Supply Design Based On Single Chip MicrocomputeramirNo ratings yet

- BOM Transmission - OSN 1800 II Pro - 31032023xlsxDocument5 pagesBOM Transmission - OSN 1800 II Pro - 31032023xlsxThanhNN0312No ratings yet

- Exp1 Lab Report A4Document16 pagesExp1 Lab Report A4asad baigNo ratings yet

- C-118-H Acoustic System: Screen Channel Cinema Sound System Especially Designed For SubwoofersDocument2 pagesC-118-H Acoustic System: Screen Channel Cinema Sound System Especially Designed For SubwoofersGokul KrishnanNo ratings yet

- Rotron Transportation CatalogDocument54 pagesRotron Transportation CatalogSolikin PatiNo ratings yet