Professional Documents

Culture Documents

Testing of Turbo Generator: Chapter-1Introduction

Testing of Turbo Generator: Chapter-1Introduction

Uploaded by

emmanuel akaCopyright:

Available Formats

You might also like

- Testing of TurbogeneratorDocument77 pagesTesting of Turbogeneratorsaitejajosyula100% (5)

- Transformer BhelDocument17 pagesTransformer BhelAayushiNo ratings yet

- SWITCHGEAR1Document53 pagesSWITCHGEAR1Ahemad100% (1)

- Unit 8 (SERVICEABILITY LIMIT STATE (SLS) )Document26 pagesUnit 8 (SERVICEABILITY LIMIT STATE (SLS) )Zara Nabilah100% (2)

- Strain-Life Fatigue AnalysisDocument17 pagesStrain-Life Fatigue AnalysisDeepak ChachraNo ratings yet

- Cera Sanitaryware CatalogueDocument51 pagesCera Sanitaryware CatalogueAnil Kumar50% (2)

- Ssangyong Rodius ABSDocument9 pagesSsangyong Rodius ABSMTK2016No ratings yet

- Advanced Control Systems For ESP 3Document97 pagesAdvanced Control Systems For ESP 3balajiesp05100% (1)

- Bhel Mini Pro Report On Turbo Generators 1Document53 pagesBhel Mini Pro Report On Turbo Generators 1Akirakumar100% (2)

- 10 - Bus Transfer System Retroffiting - Concept NoteDocument9 pages10 - Bus Transfer System Retroffiting - Concept Notevitthal01No ratings yet

- Machine Protection PDFDocument14 pagesMachine Protection PDFAbdelsalam ElhaffarNo ratings yet

- Control and Relay PanelDocument4 pagesControl and Relay PanelShiv Kumar VermaNo ratings yet

- M Excitation SystemDocument34 pagesM Excitation Systemjp mishra100% (1)

- LALPIR Power PlantDocument39 pagesLALPIR Power PlantMuhammad Haris Khan100% (2)

- Manufacturing of Turbo Generators in BHELDocument8 pagesManufacturing of Turbo Generators in BHELPraveen Kumar100% (2)

- St400pc PTDocument5 pagesSt400pc PTMURAD ALI SHAHNo ratings yet

- ProjectDocument84 pagesProjectgnikhilreddy2No ratings yet

- R&i - Generator, GT, UatDocument46 pagesR&i - Generator, GT, UatPradeep Singh100% (2)

- Awantha Power - Generator Cooling SystemDocument54 pagesAwantha Power - Generator Cooling SystemParvin KumarNo ratings yet

- 160L-4 15kW 400V 60Hz B3 DatasheetDocument2 pages160L-4 15kW 400V 60Hz B3 DatasheetTareq JildehNo ratings yet

- DC Faultr Location FinderDocument26 pagesDC Faultr Location Findergaurang1111100% (1)

- Volume-3 Davr PDFDocument213 pagesVolume-3 Davr PDFNaresh PattanaikNo ratings yet

- Generator Protection XZCDocument25 pagesGenerator Protection XZCblaagica100% (1)

- Case Study of The Application in A Large Industrial FacilityDocument10 pagesCase Study of The Application in A Large Industrial FacilityAndres VergaraNo ratings yet

- ts203b20130814 033640 SplitDocument2 pagests203b20130814 033640 Splitcdq powerplant67% (3)

- 600 MW Turbogenerator: Rating Plate Data For GeneratorDocument5 pages600 MW Turbogenerator: Rating Plate Data For Generatorjaaduscribd100% (1)

- Type VTT 11, 12: Definite Time Delay RelayDocument6 pagesType VTT 11, 12: Definite Time Delay RelayArun KumarNo ratings yet

- Maintenance On Rotating MachinesDocument8 pagesMaintenance On Rotating MachinesMario ArmelaoNo ratings yet

- Seminar Topic On: Circuit Breaker-IDocument25 pagesSeminar Topic On: Circuit Breaker-IParameshwar TummetiNo ratings yet

- 35MW Generator Test ReportDocument10 pages35MW Generator Test ReportAshok KumarNo ratings yet

- 415 V System Stage-1Document18 pages415 V System Stage-1raghavendran raghuNo ratings yet

- Transformer Tests According To IEC60076Document2 pagesTransformer Tests According To IEC60076grand_ammarNo ratings yet

- 4.various Tests Part 1Document53 pages4.various Tests Part 1Rohit JoshiNo ratings yet

- Siemens Make Motor Manual PDFDocument10 pagesSiemens Make Motor Manual PDFArindam SamantaNo ratings yet

- Common Problems Observed and Its RemedyDocument6 pagesCommon Problems Observed and Its RemedyMayank KumarNo ratings yet

- 2 FlashoverDocument17 pages2 Flashovervenky123456789No ratings yet

- Generator Protection Unit#3 KMPCLDocument15 pagesGenerator Protection Unit#3 KMPCLAmaresh Nayak100% (1)

- Varun Singh - (2006-2010) .EE... BHEL HaridwarDocument77 pagesVarun Singh - (2006-2010) .EE... BHEL Haridwarvaruns1nghNo ratings yet

- Step Voltage Regulators: Don Wareham - Field Application EngineerDocument60 pagesStep Voltage Regulators: Don Wareham - Field Application Engineerdevang singhNo ratings yet

- Electrostatic PrecipitatorDocument15 pagesElectrostatic PrecipitatorapofviewNo ratings yet

- Gen. TestingDocument62 pagesGen. TestingMani Kandan100% (1)

- 5 Modified Rankine CycleDocument3 pages5 Modified Rankine CycleMohammad Mussavvir100% (1)

- TRE - 72064N - TIS Rev-01Document18 pagesTRE - 72064N - TIS Rev-01ankushbahaleNo ratings yet

- Management of DC Supply Failure.05.07.2020Document66 pagesManagement of DC Supply Failure.05.07.2020ntpc bgtppNo ratings yet

- Type Testing of Generator TransformerDocument6 pagesType Testing of Generator TransformerAnonymous BBX2E87aHNo ratings yet

- Induction Motors Faults and ProtectionDocument2 pagesInduction Motors Faults and ProtectionMuhammad Ali Khan AwanNo ratings yet

- Grounding Transformer 1Document4 pagesGrounding Transformer 1MauricioNo ratings yet

- 330mw DEHDocument22 pages330mw DEHkeerthi dayarathna100% (1)

- Avr Trouble ShootingDocument2 pagesAvr Trouble ShootingJAYKUMAR SINGH100% (1)

- General Excitation SystemDocument58 pagesGeneral Excitation SystemReza Ghasemi100% (1)

- Nerator in Power PlantDocument13 pagesNerator in Power PlantChihiya Fitria Nurhayati100% (1)

- DG Trouble ShootingDocument10 pagesDG Trouble ShootingBala SubramanianNo ratings yet

- Sesi-Tspl-Opn-Sop-Btg-001 (Idf)Document14 pagesSesi-Tspl-Opn-Sop-Btg-001 (Idf)shubham vermaNo ratings yet

- Y25-029-0 Training For O&M Manual For Excitaion SystemDocument32 pagesY25-029-0 Training For O&M Manual For Excitaion SystemLiixoo Rojas100% (1)

- EE202 Synchronus N Induction MachinesDocument3 pagesEE202 Synchronus N Induction MachinesSREEHARI S JNo ratings yet

- WTD Test ReportDocument4 pagesWTD Test ReportBheem NaveenNo ratings yet

- 10-Transformer Cooling - Radiator AnalysisDocument18 pages10-Transformer Cooling - Radiator AnalysishakandaghanNo ratings yet

- Instrument Transformer.: Y. K. PandharipandeDocument19 pagesInstrument Transformer.: Y. K. Pandharipandeupt vadodaraNo ratings yet

- RSO Experience in The Utilization of Repetitive Surge OscillographsDocument4 pagesRSO Experience in The Utilization of Repetitive Surge OscillographscarlrvdvNo ratings yet

- Stator Earth Fault in 200MW Generator-A Case StudyDocument5 pagesStator Earth Fault in 200MW Generator-A Case StudylrpatraNo ratings yet

- Motor Selection 1Document22 pagesMotor Selection 1abhishek_918No ratings yet

- Neutral Displacement Relay PDFDocument4 pagesNeutral Displacement Relay PDFjoydeep_d3232No ratings yet

- Hvac BoqDocument72 pagesHvac BoqasifaliabidNo ratings yet

- Basics of Civil Engineering Cv0121 Unit 3 1Document139 pagesBasics of Civil Engineering Cv0121 Unit 3 1Hanish Manikanta100% (1)

- CFRP System - Horse ConstructionDocument37 pagesCFRP System - Horse ConstructionAyman ElMawardyNo ratings yet

- Filip Vanden AbeeleDocument8 pagesFilip Vanden Abeelewcjjang06078959No ratings yet

- CON4334A2TO130523BL Ch1 IntroductionDocument27 pagesCON4334A2TO130523BL Ch1 IntroductionLeung Wai YipNo ratings yet

- WTP Drawings PDFDocument3 pagesWTP Drawings PDFpastorgeeNo ratings yet

- .4 Minimum Necessary Preheat TemperatureDocument5 pages.4 Minimum Necessary Preheat Temperatureromanosky11No ratings yet

- MK003 - Why Use ICE Solair Over OthersDocument2 pagesMK003 - Why Use ICE Solair Over OthersFatmir KelmendiNo ratings yet

- 02-1. Risk Assessment Guide LineDocument67 pages02-1. Risk Assessment Guide LinePEng. Tech. Alvince KoreroNo ratings yet

- Chem 219 Lab DocumentDocument5 pagesChem 219 Lab Documentheather jaramilloNo ratings yet

- ATS - Design Manual CaterpillarDocument84 pagesATS - Design Manual CaterpillarSharik Khan100% (1)

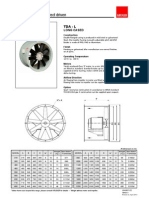

- Axial Flow Fan - LeafletDocument4 pagesAxial Flow Fan - LeafletZwe1991No ratings yet

- Wirand Application Re3 ValuesDocument2 pagesWirand Application Re3 ValuesSerbanDragosNo ratings yet

- Instruction Manual: Izml Electromagnetic FlowmeterDocument60 pagesInstruction Manual: Izml Electromagnetic FlowmeterelenanomgmmNo ratings yet

- Ruanta C-12 TDSDocument1 pageRuanta C-12 TDSm daneshpourNo ratings yet

- Chemistry Markscheme (All in One)Document728 pagesChemistry Markscheme (All in One)AliMushtaq50% (2)

- P334e MasterLife SRA 900Document3 pagesP334e MasterLife SRA 900Stevens NinanyaNo ratings yet

- Desaireador GKMOSS - Tray - Deaerator - Brochure PDFDocument6 pagesDesaireador GKMOSS - Tray - Deaerator - Brochure PDFCdMoraSNo ratings yet

- Ficha Técnica Cat DEO - 15W40 & 10W30Document2 pagesFicha Técnica Cat DEO - 15W40 & 10W30RhuanNo ratings yet

- Lenovo Yoga 500 HMM 201504Document99 pagesLenovo Yoga 500 HMM 201504AnonymusNo ratings yet

- Composite Action of Ferrocement Slabs Under Static and Cyclic Loading-Composite Action of Ferrocement Slabs Under Static and Cyclic LoadingDocument6 pagesComposite Action of Ferrocement Slabs Under Static and Cyclic Loading-Composite Action of Ferrocement Slabs Under Static and Cyclic LoadingKarrar MonarchNo ratings yet

- 1125 - Lever Butterfly ValveDocument22 pages1125 - Lever Butterfly Valveadita_cocoNo ratings yet

- 3745 PDFDocument524 pages3745 PDFaee ce officeNo ratings yet

- Isea Super Plus Public - Activated Sludge Plant - Treatment of Domestic Waste WatersDocument3 pagesIsea Super Plus Public - Activated Sludge Plant - Treatment of Domestic Waste WatersAG-Metal /Tretman Otpadnih Voda/Wastewater Treatment100% (1)

- Engineering Practice Lab ElectricalDocument23 pagesEngineering Practice Lab ElectricalKrishna Moorthy50% (2)

- Janda 400V PDFDocument11 pagesJanda 400V PDFJoel BrasilBorgesNo ratings yet

Testing of Turbo Generator: Chapter-1Introduction

Testing of Turbo Generator: Chapter-1Introduction

Uploaded by

emmanuel akaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Testing of Turbo Generator: Chapter-1Introduction

Testing of Turbo Generator: Chapter-1Introduction

Uploaded by

emmanuel akaCopyright:

Available Formats

TESTING OF TURBO GENERATOR

Dept. of EEE 1 AITS- HYD

CHAPTER-1INTRODUCTION

1.1. INTRODUCTION

A Generator is a rotating Electromagnetic device producing electrical power

takingmechanical input from prime mover (Gas Turbine / Steam Turbine) and

magnetic energyfrom excitation.Generator Design will be conforming to

International Standards like IEC & Nationalstandards like BS, VDE, IS

etc.Generators driven by steam or gas turbines have cylindrical/ round rotors with

slotsinto which distributed field windings are placed. These round rotor generators

are usuallyreferred to as turbo generators and they usually have 2 or 4 poles.

Generators driven byhydraulic turbines have laminated salient pole rotors with

concentrated field winding and alarge number of poles.Testing is the most

important process to be done on a machine after it is designed.The testing of

machine is necessary primarily to establish that the machine performancecomplies

with customer specifications. Tests ensure that the piece of equipment concerned

issuitable for and capable for performing duty for which it is intended.Testing has

to be done on a machine at every step in its manufacturing process for the

company to certify it to be a

deliverable good.

Test brings out the impact of processvariations. Testing is done in simulations

which tend to closely resemble the practicalscenario under which the machine

works.Testing provides the experimental data like the efficiency, losses,

characteristics,temperature limits etc. for the use of design office, both as

confirmation of design forecastand also as basic information for the production of

future designs.

1.2 NECESSITY OF TESTING

:

To ensure that all functional requirements are fulfilled, and to estimate

the performance of generator, the turbo generators are required to undergo some te

sts. Fortesting, the turbo generator was mechanically coupled to a drive motor-

motor generator set

TESTING OF TURBO GENERATORDept. of EEE 2 AITS - HYD

with gearbox. The rotor was excited by thyristor converter system located in an

independenttest room and the operation was controlled from the test gallery.The

following first two tests will be conducted on the stator and rotor before

assemblingand the third and final routine tests will be conducted after assembling

the turbo generator.a.

Tests conducted on Stator b.

Tests conducted on Rotor

1.3.

OBJECTIVE OF TESTING

:

Testing is the most important process to be conducted on a machine after it

isdesigned. The testing of machine is necessary primarily to establish that the

machine performance complies with the customer specifications. Tests ensure that

the piece ofequipment concerned is suitable for and capable for performing duty

for which it is intended.Testing is done under condition simulating closely as

possible to those, which will apply

when the set is finally installed with a view to demonstrate to purchasers

representative its

satisfactory operation.Test provides the experimental data like efficiency, losses,

characteristics,temperature limits, etc. for the use of design office, both as

confirmation of design forecastand also as basic information for the production of

future designs.With ever increasing rating of the modern turbo generators and

reliability of service

expected, testing at manufacturers works has becom

e of paramount importance. Themachine performance is evaluated from the results

of the equivalent tests.

Advantages of testing

1.

Provides data for optimization of design2.

Provides quality assurance3.

Meets the requirement of legal and contract requirements.4.

Reduction in rework cost.5.

Ensures process capability and develops checklist.6.

Increases confidence levels in manufacture.7.

Establishes control over raw materials.8.

Helps in building of safety and general operation and manual.

TESTING OF TURBO GENERATORDept. of EEE 3 AITS - HYD

1.4. THEME

Testing is an activity, which basically evaluates a component, and or a product

(builtup of component assemblies) as to whether it has the technical capability that

has been builtinto it by way of design, materials, and technological processes

employed whilemanufacturing and workmanship.

As such, testing activities can broadly be classified in to a number of categories as

follows:a.

Type tests. b.

Routine tests.c.

Process tests

The characteristics of testing:

1)

Provides quality assurance.2)

Meets the requirements of legal & contract requirements.3)

Ensures process capability & develops checklist.4)

Have an approved procedure.5)

Check the equipment before use.6)

Calibrate the test equipment & instruments.7)

Ensure interlocks of the equipment

1.5.

ORGANISATION

The definition and objective of the project as well as the design of the project

which is followed by the implementation and testing phases is studied in detail.

Finally the project

has been concluded successfully and also the future enhancements of the project w

ere shown.The organization of the project is as follows by1.

Introduction2.

Literature survey3.

System development4.

Analysis of a turbo generator is studied and the precise results are shown in order

toensure that the turbo generator chosen is deliverable good.

You're reading a preview. Unlock full access with a free trial.

Pages 4 to 40 are not shown in this preview.

You might also like

- Testing of TurbogeneratorDocument77 pagesTesting of Turbogeneratorsaitejajosyula100% (5)

- Transformer BhelDocument17 pagesTransformer BhelAayushiNo ratings yet

- SWITCHGEAR1Document53 pagesSWITCHGEAR1Ahemad100% (1)

- Unit 8 (SERVICEABILITY LIMIT STATE (SLS) )Document26 pagesUnit 8 (SERVICEABILITY LIMIT STATE (SLS) )Zara Nabilah100% (2)

- Strain-Life Fatigue AnalysisDocument17 pagesStrain-Life Fatigue AnalysisDeepak ChachraNo ratings yet

- Cera Sanitaryware CatalogueDocument51 pagesCera Sanitaryware CatalogueAnil Kumar50% (2)

- Ssangyong Rodius ABSDocument9 pagesSsangyong Rodius ABSMTK2016No ratings yet

- Advanced Control Systems For ESP 3Document97 pagesAdvanced Control Systems For ESP 3balajiesp05100% (1)

- Bhel Mini Pro Report On Turbo Generators 1Document53 pagesBhel Mini Pro Report On Turbo Generators 1Akirakumar100% (2)

- 10 - Bus Transfer System Retroffiting - Concept NoteDocument9 pages10 - Bus Transfer System Retroffiting - Concept Notevitthal01No ratings yet

- Machine Protection PDFDocument14 pagesMachine Protection PDFAbdelsalam ElhaffarNo ratings yet

- Control and Relay PanelDocument4 pagesControl and Relay PanelShiv Kumar VermaNo ratings yet

- M Excitation SystemDocument34 pagesM Excitation Systemjp mishra100% (1)

- LALPIR Power PlantDocument39 pagesLALPIR Power PlantMuhammad Haris Khan100% (2)

- Manufacturing of Turbo Generators in BHELDocument8 pagesManufacturing of Turbo Generators in BHELPraveen Kumar100% (2)

- St400pc PTDocument5 pagesSt400pc PTMURAD ALI SHAHNo ratings yet

- ProjectDocument84 pagesProjectgnikhilreddy2No ratings yet

- R&i - Generator, GT, UatDocument46 pagesR&i - Generator, GT, UatPradeep Singh100% (2)

- Awantha Power - Generator Cooling SystemDocument54 pagesAwantha Power - Generator Cooling SystemParvin KumarNo ratings yet

- 160L-4 15kW 400V 60Hz B3 DatasheetDocument2 pages160L-4 15kW 400V 60Hz B3 DatasheetTareq JildehNo ratings yet

- DC Faultr Location FinderDocument26 pagesDC Faultr Location Findergaurang1111100% (1)

- Volume-3 Davr PDFDocument213 pagesVolume-3 Davr PDFNaresh PattanaikNo ratings yet

- Generator Protection XZCDocument25 pagesGenerator Protection XZCblaagica100% (1)

- Case Study of The Application in A Large Industrial FacilityDocument10 pagesCase Study of The Application in A Large Industrial FacilityAndres VergaraNo ratings yet

- ts203b20130814 033640 SplitDocument2 pagests203b20130814 033640 Splitcdq powerplant67% (3)

- 600 MW Turbogenerator: Rating Plate Data For GeneratorDocument5 pages600 MW Turbogenerator: Rating Plate Data For Generatorjaaduscribd100% (1)

- Type VTT 11, 12: Definite Time Delay RelayDocument6 pagesType VTT 11, 12: Definite Time Delay RelayArun KumarNo ratings yet

- Maintenance On Rotating MachinesDocument8 pagesMaintenance On Rotating MachinesMario ArmelaoNo ratings yet

- Seminar Topic On: Circuit Breaker-IDocument25 pagesSeminar Topic On: Circuit Breaker-IParameshwar TummetiNo ratings yet

- 35MW Generator Test ReportDocument10 pages35MW Generator Test ReportAshok KumarNo ratings yet

- 415 V System Stage-1Document18 pages415 V System Stage-1raghavendran raghuNo ratings yet

- Transformer Tests According To IEC60076Document2 pagesTransformer Tests According To IEC60076grand_ammarNo ratings yet

- 4.various Tests Part 1Document53 pages4.various Tests Part 1Rohit JoshiNo ratings yet

- Siemens Make Motor Manual PDFDocument10 pagesSiemens Make Motor Manual PDFArindam SamantaNo ratings yet

- Common Problems Observed and Its RemedyDocument6 pagesCommon Problems Observed and Its RemedyMayank KumarNo ratings yet

- 2 FlashoverDocument17 pages2 Flashovervenky123456789No ratings yet

- Generator Protection Unit#3 KMPCLDocument15 pagesGenerator Protection Unit#3 KMPCLAmaresh Nayak100% (1)

- Varun Singh - (2006-2010) .EE... BHEL HaridwarDocument77 pagesVarun Singh - (2006-2010) .EE... BHEL Haridwarvaruns1nghNo ratings yet

- Step Voltage Regulators: Don Wareham - Field Application EngineerDocument60 pagesStep Voltage Regulators: Don Wareham - Field Application Engineerdevang singhNo ratings yet

- Electrostatic PrecipitatorDocument15 pagesElectrostatic PrecipitatorapofviewNo ratings yet

- Gen. TestingDocument62 pagesGen. TestingMani Kandan100% (1)

- 5 Modified Rankine CycleDocument3 pages5 Modified Rankine CycleMohammad Mussavvir100% (1)

- TRE - 72064N - TIS Rev-01Document18 pagesTRE - 72064N - TIS Rev-01ankushbahaleNo ratings yet

- Management of DC Supply Failure.05.07.2020Document66 pagesManagement of DC Supply Failure.05.07.2020ntpc bgtppNo ratings yet

- Type Testing of Generator TransformerDocument6 pagesType Testing of Generator TransformerAnonymous BBX2E87aHNo ratings yet

- Induction Motors Faults and ProtectionDocument2 pagesInduction Motors Faults and ProtectionMuhammad Ali Khan AwanNo ratings yet

- Grounding Transformer 1Document4 pagesGrounding Transformer 1MauricioNo ratings yet

- 330mw DEHDocument22 pages330mw DEHkeerthi dayarathna100% (1)

- Avr Trouble ShootingDocument2 pagesAvr Trouble ShootingJAYKUMAR SINGH100% (1)

- General Excitation SystemDocument58 pagesGeneral Excitation SystemReza Ghasemi100% (1)

- Nerator in Power PlantDocument13 pagesNerator in Power PlantChihiya Fitria Nurhayati100% (1)

- DG Trouble ShootingDocument10 pagesDG Trouble ShootingBala SubramanianNo ratings yet

- Sesi-Tspl-Opn-Sop-Btg-001 (Idf)Document14 pagesSesi-Tspl-Opn-Sop-Btg-001 (Idf)shubham vermaNo ratings yet

- Y25-029-0 Training For O&M Manual For Excitaion SystemDocument32 pagesY25-029-0 Training For O&M Manual For Excitaion SystemLiixoo Rojas100% (1)

- EE202 Synchronus N Induction MachinesDocument3 pagesEE202 Synchronus N Induction MachinesSREEHARI S JNo ratings yet

- WTD Test ReportDocument4 pagesWTD Test ReportBheem NaveenNo ratings yet

- 10-Transformer Cooling - Radiator AnalysisDocument18 pages10-Transformer Cooling - Radiator AnalysishakandaghanNo ratings yet

- Instrument Transformer.: Y. K. PandharipandeDocument19 pagesInstrument Transformer.: Y. K. Pandharipandeupt vadodaraNo ratings yet

- RSO Experience in The Utilization of Repetitive Surge OscillographsDocument4 pagesRSO Experience in The Utilization of Repetitive Surge OscillographscarlrvdvNo ratings yet

- Stator Earth Fault in 200MW Generator-A Case StudyDocument5 pagesStator Earth Fault in 200MW Generator-A Case StudylrpatraNo ratings yet

- Motor Selection 1Document22 pagesMotor Selection 1abhishek_918No ratings yet

- Neutral Displacement Relay PDFDocument4 pagesNeutral Displacement Relay PDFjoydeep_d3232No ratings yet

- Hvac BoqDocument72 pagesHvac BoqasifaliabidNo ratings yet

- Basics of Civil Engineering Cv0121 Unit 3 1Document139 pagesBasics of Civil Engineering Cv0121 Unit 3 1Hanish Manikanta100% (1)

- CFRP System - Horse ConstructionDocument37 pagesCFRP System - Horse ConstructionAyman ElMawardyNo ratings yet

- Filip Vanden AbeeleDocument8 pagesFilip Vanden Abeelewcjjang06078959No ratings yet

- CON4334A2TO130523BL Ch1 IntroductionDocument27 pagesCON4334A2TO130523BL Ch1 IntroductionLeung Wai YipNo ratings yet

- WTP Drawings PDFDocument3 pagesWTP Drawings PDFpastorgeeNo ratings yet

- .4 Minimum Necessary Preheat TemperatureDocument5 pages.4 Minimum Necessary Preheat Temperatureromanosky11No ratings yet

- MK003 - Why Use ICE Solair Over OthersDocument2 pagesMK003 - Why Use ICE Solair Over OthersFatmir KelmendiNo ratings yet

- 02-1. Risk Assessment Guide LineDocument67 pages02-1. Risk Assessment Guide LinePEng. Tech. Alvince KoreroNo ratings yet

- Chem 219 Lab DocumentDocument5 pagesChem 219 Lab Documentheather jaramilloNo ratings yet

- ATS - Design Manual CaterpillarDocument84 pagesATS - Design Manual CaterpillarSharik Khan100% (1)

- Axial Flow Fan - LeafletDocument4 pagesAxial Flow Fan - LeafletZwe1991No ratings yet

- Wirand Application Re3 ValuesDocument2 pagesWirand Application Re3 ValuesSerbanDragosNo ratings yet

- Instruction Manual: Izml Electromagnetic FlowmeterDocument60 pagesInstruction Manual: Izml Electromagnetic FlowmeterelenanomgmmNo ratings yet

- Ruanta C-12 TDSDocument1 pageRuanta C-12 TDSm daneshpourNo ratings yet

- Chemistry Markscheme (All in One)Document728 pagesChemistry Markscheme (All in One)AliMushtaq50% (2)

- P334e MasterLife SRA 900Document3 pagesP334e MasterLife SRA 900Stevens NinanyaNo ratings yet

- Desaireador GKMOSS - Tray - Deaerator - Brochure PDFDocument6 pagesDesaireador GKMOSS - Tray - Deaerator - Brochure PDFCdMoraSNo ratings yet

- Ficha Técnica Cat DEO - 15W40 & 10W30Document2 pagesFicha Técnica Cat DEO - 15W40 & 10W30RhuanNo ratings yet

- Lenovo Yoga 500 HMM 201504Document99 pagesLenovo Yoga 500 HMM 201504AnonymusNo ratings yet

- Composite Action of Ferrocement Slabs Under Static and Cyclic Loading-Composite Action of Ferrocement Slabs Under Static and Cyclic LoadingDocument6 pagesComposite Action of Ferrocement Slabs Under Static and Cyclic Loading-Composite Action of Ferrocement Slabs Under Static and Cyclic LoadingKarrar MonarchNo ratings yet

- 1125 - Lever Butterfly ValveDocument22 pages1125 - Lever Butterfly Valveadita_cocoNo ratings yet

- 3745 PDFDocument524 pages3745 PDFaee ce officeNo ratings yet

- Isea Super Plus Public - Activated Sludge Plant - Treatment of Domestic Waste WatersDocument3 pagesIsea Super Plus Public - Activated Sludge Plant - Treatment of Domestic Waste WatersAG-Metal /Tretman Otpadnih Voda/Wastewater Treatment100% (1)

- Engineering Practice Lab ElectricalDocument23 pagesEngineering Practice Lab ElectricalKrishna Moorthy50% (2)

- Janda 400V PDFDocument11 pagesJanda 400V PDFJoel BrasilBorgesNo ratings yet