Professional Documents

Culture Documents

Sea Japan2002 - 295

Sea Japan2002 - 295

Uploaded by

Edson SerejoCopyright:

Available Formats

You might also like

- Japan ShipyardDocument7 pagesJapan ShipyardNguyễn Tấn TrưởngNo ratings yet

- Offshore HyuNDAIDocument26 pagesOffshore HyuNDAIbetahita_80174No ratings yet

- Methodical Series Tests For Fuller Ship Hull Forms: Ocean EngngDocument48 pagesMethodical Series Tests For Fuller Ship Hull Forms: Ocean EngngEdson SerejoNo ratings yet

- Sea 300Document6 pagesSea 300PetricaNo ratings yet

- Kobelco Welding Today2000-03Document12 pagesKobelco Welding Today2000-03Charles JacobNo ratings yet

- Strategy Sumitomo Heavy IndustriesDocument17 pagesStrategy Sumitomo Heavy IndustriesSomyata RastogiNo ratings yet

- HSL Final ReportDocument52 pagesHSL Final Reportkarthik raju100% (1)

- Memorandum of Understanding V3Document4 pagesMemorandum of Understanding V3Anas Sebtu PrawiraNo ratings yet

- Overview of Ship Building IndustryDocument32 pagesOverview of Ship Building IndustryAnna Smith100% (1)

- Ministrty of ShippingDocument81 pagesMinistrty of ShippingEshwar BabuNo ratings yet

- HSL1Document44 pagesHSL1karthik rajuNo ratings yet

- eDocument13 pagesepeyockNo ratings yet

- Presentasi Maritime DARMADIDocument11 pagesPresentasi Maritime DARMADIashkisaragiNo ratings yet

- Assignment CaseStudy SOGT CHALLENGES PRD and WBS KOG11203 Project ManagementDocument26 pagesAssignment CaseStudy SOGT CHALLENGES PRD and WBS KOG11203 Project ManagementLuqman OsmanNo ratings yet

- LNG MitsubishiDocument4 pagesLNG Mitsubishireade2011No ratings yet

- Ghana Ports and Harbours Authority FullDocument23 pagesGhana Ports and Harbours Authority FullKaren DavisNo ratings yet

- Prepared By:: DeclarationDocument6 pagesPrepared By:: DeclarationRakesh Kumar SenapatiNo ratings yet

- (OJT) Contents (Update)Document20 pages(OJT) Contents (Update)Alexander James T. TucayNo ratings yet

- Pre-Feasibility Desk Study Lamu Port Offshore Energy Industrial ParkDocument11 pagesPre-Feasibility Desk Study Lamu Port Offshore Energy Industrial ParkEric Mwangi NjorogeNo ratings yet

- Marine Engineering Progress in 1997: Annual ReviewDocument42 pagesMarine Engineering Progress in 1997: Annual Reviewнелля могурянNo ratings yet

- Ocean Network Express - WikipediaDocument10 pagesOcean Network Express - WikipediaĐhañushRaman KNo ratings yet

- General Catalogue 2016Document139 pagesGeneral Catalogue 2016Tri Wasda MarganingsihNo ratings yet

- Report Internship HSLDocument19 pagesReport Internship HSLNandhini ShanmugamNo ratings yet

- Japan Port ConsultantsDocument2 pagesJapan Port ConsultantsnewsaktNo ratings yet

- This Project Report Is Prepared During The Summer Industrial Training Undertaken atDocument62 pagesThis Project Report Is Prepared During The Summer Industrial Training Undertaken atBhanuprakashNo ratings yet

- Delivery of SHOFU MARU, World's First Cargo Vessel Equipped With 'Wind Challenger' Hard SailDocument2 pagesDelivery of SHOFU MARU, World's First Cargo Vessel Equipped With 'Wind Challenger' Hard SailSANDESH GHANDATNo ratings yet

- Assignmet # 2: Preston University (Lahore Campus)Document10 pagesAssignmet # 2: Preston University (Lahore Campus)j4jahanzaib99No ratings yet

- ShipbuildingDocument81 pagesShipbuildingpoetoetNo ratings yet

- Cerulean AceDocument3 pagesCerulean Acesasa7791No ratings yet

- PT Horiguchi Engineering Indonesia: General CatalogueDocument24 pagesPT Horiguchi Engineering Indonesia: General CatalogueAkhmad RamdaniNo ratings yet

- Sea 343Document6 pagesSea 343britties69No ratings yet

- MDL ReportDocument22 pagesMDL Reportroy thomas100% (1)

- ApplicationDocument11 pagesApplicationdiniezubirNo ratings yet

- LI ReportDocument74 pagesLI Reportfumakiller_23No ratings yet

- Komatsu India Private LimitedDocument20 pagesKomatsu India Private LimitedYeshwanth RainaNo ratings yet

- Cochin ShipyardDocument2 pagesCochin ShipyardATHUL KRISHNAN C RNo ratings yet

- K LineDocument5 pagesK LineGs MaheshNo ratings yet

- Offshore Support Vessels1712Document9 pagesOffshore Support Vessels1712sarkarraktim94No ratings yet

- Views Is A PR Magazine Published by Komatsu LTDDocument12 pagesViews Is A PR Magazine Published by Komatsu LTDShubhesh Gupta100% (1)

- Inpex Media Release - CPF Steel Cut 25 January 2013 FinalDocument3 pagesInpex Media Release - CPF Steel Cut 25 January 2013 Finalputra111213No ratings yet

- HSL REPORT_mergedDocument36 pagesHSL REPORT_mergedkenguvamanojkumar013No ratings yet

- Media Release - Ichthysfid (Final)Document4 pagesMedia Release - Ichthysfid (Final)Victor IkeNo ratings yet

- CV Sample For A Data-Entry VacancyDocument7 pagesCV Sample For A Data-Entry VacancyMahmoud ElNaggarNo ratings yet

- Tug Boat Desing PDFDocument61 pagesTug Boat Desing PDFGilson RolandoNo ratings yet

- KSY ProjectDocument48 pagesKSY Projectisrat jahanNo ratings yet

- Kelompok 1 - PT Karya Teknik Internusa AbadiDocument21 pagesKelompok 1 - PT Karya Teknik Internusa Abadiotsuka tecNo ratings yet

- Junr ProjectDocument44 pagesJunr ProjectAvinash GunnaNo ratings yet

- A Report On Shipbuilding Industry of BangladeshDocument13 pagesA Report On Shipbuilding Industry of Bangladeshruhul01No ratings yet

- Chiyoda Awarded EPC Contract For Tangguh Expansion Project in IndonesiaDocument1 pageChiyoda Awarded EPC Contract For Tangguh Expansion Project in IndonesiajurieskNo ratings yet

- F KomatsuDocument6 pagesF KomatsuneelgalaNo ratings yet

- Hindustan Shipyard Limited (Project)Document67 pagesHindustan Shipyard Limited (Project)Arish Adduri67% (6)

- From T-2 to Supertanker: Development of the Oil Tanker, 1940 - 2000, RevisedFrom EverandFrom T-2 to Supertanker: Development of the Oil Tanker, 1940 - 2000, RevisedNo ratings yet

- Osh Induction Program in Enhancing Safety Awareness Amongst Fabrication Workers in Brooke Dockyard, Kuching, SarawakFrom EverandOsh Induction Program in Enhancing Safety Awareness Amongst Fabrication Workers in Brooke Dockyard, Kuching, SarawakRating: 5 out of 5 stars5/5 (1)

- The Guidebook to Toyota's 13 Pillars System - Series Books 7 to 17: Toyota Production System ConceptsFrom EverandThe Guidebook to Toyota's 13 Pillars System - Series Books 7 to 17: Toyota Production System ConceptsNo ratings yet

- Journal of Ship Production and Design: Analysis On Hull Block Erection Process Considering VariabilityDocument12 pagesJournal of Ship Production and Design: Analysis On Hull Block Erection Process Considering VariabilityEdson SerejoNo ratings yet

- Ot Feeder 750Document1 pageOt Feeder 750Edson SerejoNo ratings yet

- Ot Feeder 500Document1 pageOt Feeder 500Edson SerejoNo ratings yet

- Ot Feeder 500Document1 pageOt Feeder 500Edson SerejoNo ratings yet

- Type: Bulker Model: Serial NumberDocument14 pagesType: Bulker Model: Serial NumberManikantaSumanthNo ratings yet

- Ship Size PDFDocument1 pageShip Size PDFrigelNo ratings yet

- Ocean Carriers Case StudyDocument7 pagesOcean Carriers Case Studyaida100% (1)

- Maritime English (Imo Model Course 3.17)Document97 pagesMaritime English (Imo Model Course 3.17)Haryadi Bakri100% (1)

- Ports and Terminal - Han LigteringenDocument383 pagesPorts and Terminal - Han LigteringenErmal Spahiu100% (2)

- GENESIS Off-Hire B&C PmoleDocument22 pagesGENESIS Off-Hire B&C PmoleRogério Tristão100% (2)

- 32p Neda Dry CargoDocument36 pages32p Neda Dry CargoFandy SipataNo ratings yet

- Self Checklist For Company Safety Management SystemDocument10 pagesSelf Checklist For Company Safety Management SystemErgul Neroglu100% (1)

- Class REportDocument20 pagesClass REportJagmohan SinghNo ratings yet

- Ship ConstructionDocument157 pagesShip ConstructionBehendu PereraNo ratings yet

- Always Moving Forward: Shipbuilding DivisionDocument31 pagesAlways Moving Forward: Shipbuilding DivisionАлиса ПестроваNo ratings yet

- 43 - Simple Model For Newbuilding Cost PDFDocument12 pages43 - Simple Model For Newbuilding Cost PDFRianNo ratings yet

- Inter-Global College Foundation, Inc.: Brgy. Bocohan, Lucena CityDocument8 pagesInter-Global College Foundation, Inc.: Brgy. Bocohan, Lucena CityLaica & AivanNo ratings yet

- Tramp ShippingDocument5 pagesTramp ShippingMosarof Hossain100% (1)

- Significant Ships 2003Document107 pagesSignificant Ships 2003Marcel SchmalNo ratings yet

- TBS Case Study - Grain Ship Loading ChuteDocument1 pageTBS Case Study - Grain Ship Loading ChuteKroya HunNo ratings yet

- Management Level Course For Maritime Deck OfficersDocument4 pagesManagement Level Course For Maritime Deck Officersjohnkevin.quilatonNo ratings yet

- Ship Chartering and Brokering Practice 1999Document335 pagesShip Chartering and Brokering Practice 1999Sillo Paul100% (11)

- MARITIME ENGLISH For N II BDocument13 pagesMARITIME ENGLISH For N II Bhaikals110504No ratings yet

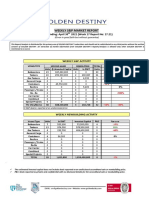

- Weekly SP Market Report Week Ending April 30th 2021 Week 17 Report No 17.21Document8 pagesWeekly SP Market Report Week Ending April 30th 2021 Week 17 Report No 17.21Sandesh Tukaram GhandatNo ratings yet

- 728 Marine Engineering Interview Questions Answers GuideDocument6 pages728 Marine Engineering Interview Questions Answers Guidepandavadra rajesh100% (1)

- MaritimeReporter1989 12 01Document58 pagesMaritimeReporter1989 12 01vinipaulinoNo ratings yet

- Primeship Steelcoil Loading Ver1.10-EDocument55 pagesPrimeship Steelcoil Loading Ver1.10-Erammech85100% (2)

- Dccmay 2022Document2 pagesDccmay 2022Manmeet Singh SandhuNo ratings yet

- Vessel Database: AIS Ship PositionsDocument3 pagesVessel Database: AIS Ship PositionsViraj SolankiNo ratings yet

- The Role of International Trade in The Global Economy & Its Effects On Economic GrowthDocument11 pagesThe Role of International Trade in The Global Economy & Its Effects On Economic Growthayush singhNo ratings yet

- Vessel Database: AIS Ship PositionsDocument3 pagesVessel Database: AIS Ship PositionsViraj SolankiNo ratings yet

- BulkDocument7 pagesBulkbigbang182No ratings yet

- PORT INFORMATION GUIDE BremerhavenDocument54 pagesPORT INFORMATION GUIDE BremerhavenOrxan TalibzadeNo ratings yet

- Rapport Port State ControlDocument56 pagesRapport Port State ControlReza AhmedNo ratings yet

Sea Japan2002 - 295

Sea Japan2002 - 295

Uploaded by

Edson SerejoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sea Japan2002 - 295

Sea Japan2002 - 295

Uploaded by

Edson SerejoCopyright:

Available Formats

No. 295 Oct. - Nov.

2002

MHI completes large membrane-type LNG carrier

Mitsubishi Heavy Industries, Ltd. (MHI) completed aging the physical distribution. The total welding length

construction of the Puteri Intan Satu (HN: 2165), a large measured approximately 100,000m. For this purpose, au-

membrane type LNG carrier with a tank capacity of tomatic welding was widely applied and training given to

137,489m3, at the Nagasaki Shipyard & Machinery Works the young welding workers.

on Aug. 29. Success in building the membrane type has encouraged

MHI has built many MOSS-type LNG carriers. The MHI to continue construction of LNG carriers of both

company received the first order for construction of the MOSS and membrane types in the future.

membrane type LNG carrier in March 1999. Subsequently, Principal particulars of Puteri Intan Satu

several orders for the membrane types were placed and Length, o.a.: Approx. 276.00m

construction was undertaken at the MHI Koyagi Ship- Length, b.p.: 263.00m

yard, Nagasaki. Breadth, mld.: 43.40m

The ship naming ceremony of the Puteri Intan Satu Depth, mld.: 25.50m

was conducted in the presence of Dr. Mahathir, the Prime Design draft: 11.06 (extreme)

Minister of Malaysia, on May 22. Since then, the final out- Gross tonnage: 93,038t

fitting work and gas tests have been carried out. Tank capacity: 137,489m3

The membrane type LNG carrier requires about 700,000 Speed, service: 19.5kt

separate materials and components per ship, which in- Main engine: Mitsubishi Marine Steam Turbine MS40-2

cludes heat insulation boxes. To handle these items effi- Output: 26,800kW x 89rpm

ciently, MHI has developed the LOGIQ system for man- Classification: LRS

For further information please contact:

JAPAN SHIP EXPORTERS' ASSOCIATION

15-16, Toranomon 1-chome, Minato-ku, Tokyo 105-0001 Tel: (03) 3508-9661 Fax: (03) 3508-2058 E-Mail: postmaster@jsea.or.jp

Topics No. 295 Oct. - Nov. Page 2

Three Japanese Shipbuilding Companies established

Three new shipbuilding companies have evolved from the previous con- of business comprise the design and

glomerates of Japanese heavy industry and marked their restart on October 1. construction of all types of ships and

Universal Shipbuilding Corporation resulted from the merger of the shipbuild- marine engineering. Kawasaki is ex-

ing divisions of NKK Corp. and Hitachi Zosen Corp., IHI Marine United Inc. posed to intense competition in this

was spun off from Ishikawajima-Harima Heavy Industries Co., Ltd., and Ka- single global shipbuilding market

wasaki Shipbuilding Corporation from Kawasaki Heavy Industries, Ltd. (KHI) shaken by the turbulent world eco-

nomic situation, but maintains an

IHI Marine United Inc. indispensable industry, and engineer- edge in advanced technology and a

ing capabilities of high standards con- substantial business basis. To make

stitute the lifeline for the survival of further strides ahead, taking the op-

our business. Only by supplying prod- portunity of its independence from

ucts that can fully satisfy our clients, KHI, the company is aiming at steady

we can make meaningful contribu- development of business and employ-

tions to society, Tsuda added. ment. The new organization prom-

Outline of IHI Marine United Inc. ises establishment of a more flexible

Chairman Ito and President Tsuda and speedy style of business manage-

(right) ment and will facilitate a further leap

forward in technological resources and

The whole shipbuilding and off-

competitiveness, said Shuichi

shore business of Ishikawajima-Ha-

Tadokoro, president of the new com-

rima Heavy Industries Co., Ltd. (IHI) Chairman: Mototsugu Ito pany, in his message to the staff. In

was divested on October 1, and IHI President: Naoteru Tsuda the past, all Japanese shipbuilding

Marine United Inc. (IHIMU) was Head Office: MSC Center Bldg., 22- companies were intent on business

newly established. 33 23, Kaigan 3-chome, Minato-ku, diversification. By specializing in ship-

The lines of business of the new Tokyo 108-0022, Japan building in the framework of the KHI

company will cover the whole ship- Tel: +81-3-3454-8900 group instead, Kawasaki is trying to

building and offshore sector including Fax: +81-3-3534-8953 think out a breakthrough concept in

merchant ships, naval vessels, equip- URL: http://www.ihi.co.jp/ihimu shipbuilding.

ment for offshore development Yokohama Shipyard: Outline of Kawasaki Shipbuilding

projects and floating structures. Our Shinsugita- cho 12, Isogo-ku, Yoko- Corporation

immediate target is to develop five hama 235-8501, Japan

product items in which IHIMU can Tel: +81-45-759-2643

hold the number one position in three Fax: +81-45-759-2914

years time, said Naoteru Tsuda, Kure Shipyard: Showamachi 2-1,

president of IHIMU, in his message President: Shuichi Tadokoro

Kure, Hiroshima 737-0027, Japan Head Office: 1-1, Higashikawasaki-

to about 2,000 employees of the new Tel: +81-823-26-2349

company. cho 3-chome, Chuo-ku, Kobe 650-

Fax: +81-823-26-2170 8670, Japan

The shipbuilding and offshore Aioi Production Dept.: Aioi 5292,

business had been the core compe- Tel: +81-78-682-5501

Aioi, Hyogo 678-0041, Japan Fax: +81-78-682-5514

tence of IHI in its 150-year history. I Tel: +81-791-24-2466

am profoundly impressed by this sig- URL: http://www.kawasakizosen.co.jp

Fax: +81-791-24-2410 Marketing & Sales Division:

nificant start of the second phase of

its history. Today, not only shipbuild- Kawasaki Shipbuilding Corp. World Trade Center Bldg, 4-1,

ing and offshore activities but all busi- Kawasaki Hamamatsu-cho 2-chome, Minato-

nesses in the world are borderless, and Shipbuilding ku Tokyo 105-6116, Japan

the business environment is chang- Corporation (Ka- Tel: +81-3-3435-2141

ing very dramatically. Unless we can wasaki) incorpo- Fax: +81-3-3436-3038

quickly respond to these changes and rates the tradi- Kobe Shipyard: 1 - 1 , H i g a s h i -

reshape ourselves, our business can- tional shipbuild- kawasaki-cho 3-chome, Chuo-ku,

not even survive. ing technology, Kobe 650-8670, Japan

The basis of our business is engi- facilities and Tel: 81-78-682-5501

neering capabilities, and the human President business of KHI Fax: 81-78-682-5514

Tadokoro restarted on Oc- Sakaide Shipyard: 1, Kawasaki-cho,

resources who create those capabili-

ties. For Japan surrounded by the sea, tober 1 to engage in shipbuilding and Sakaide, Kagawa 762-8507, Japan

shipbuilding will continue to be an related business activities. The lines (Cntinued on Page 3)

Topics No. 295 Oct. - Nov. Page 3

(Continued from Page 2) Hitachi Zosens 120-year history of ex- Fax: +81-3-5742-4060

Tel: 81-877-46-1473 perience, knowledge, specialist exper- URL http://www.u-zosen.co.jp

Fax: 81-877-46-7006 tise, and comprehensive service quali- Shipyards

ties which give both companies a glo- Ariake Shipyard: Ariake 1, Nagasu-

Universal Shipbuilding Corp. bal reputation of excellence in tech- machi,Tamana-gun, Kumamoto

set up by NKK and Hitachi nology and shipbuilding skills. The Pref., 869-0113 Ariake Shipyard

large docks of Ariake (Nagasumachi, Tel: +81-968-65-7100

Kumamoto Prefecture) and Tsu (Mie Fax: +81-968-65-7123

Prefecture) together with the manu- Tsu Shipyard: 1-3, Kumozu-Kokancho,

facturing facilities of Maizuru (Kyoto Tsu City, Mie Pref., 514-0398

Prefecture), Keihin (Kanagawa Pre- Tel: +81-59-238-6100

fecture), and Innoshima (Hiroshima Fax: +81-59-238-6430

Prefecture), uniquely position Univer- Maizuru Shipyard: 1180 Amarube-

sal Shipbuilding Corporation to sat- shimo, Maizuru City, Kyoto Pref.,

isfy diverse vessel requirements. 625-0045 Tel: 81-773-62-8700

Chairman Tazawa and President

Kamijo (right) Outline of Universal Shipbuilding Fax: +81-773-62-3007

Corp. Keihin Shipyard: 2-1, Suehirocho,

Tsurumi-ku, Yokohama City,

Kanagawa Pref., 230-0045

Tel: +81-45-500-3300

NKK Corporation and Hitachi Chairman and Executive Director: Fax: +81-45-500-3112

Zosen Corporation have integrated Kenzo Tazawa Innoshima Shipyard: 2477-16, Habu-

their shipbuilding operations to begin President and Executive Director: cho, Innoshima City, Hiroshima

a new era of efficiency and effective- Takehiko Kamijo Pref., 722-2393

ness as Universal Shipbuilding Cor- Head Office: 28-1, Oi 1-chome, Shina- Tel: +81-8452-2-1220

poration. Universal Shipbuilding Cor- gawa-ku, Tokyo 140-0014, Japan Fax: +81-8452-2-0383

poration inherits NKKs 90-year and Tel: +81-3-5742-4050

SHI delivers 1st double acting tanker, Tempera to Finnish owner

Sumitomo Heavy Industries, Ltd. stipulated by Finnish Maritime Ad- Designed draft, mld.: 14.50m

(SHI) has recently delivered the first ministration (FMA) and LRS. The Scantling draft, mld.: 15.30m

of two Aframax tankers with Ice Class podded propulsion system also en- DWT at scantling draft: Approx.

1A Super, built at the SHI Yokosuka sures safe navigation in the seas with 106,000 MT

Shipyard, to Fortum Oil & Gas OY of many islands around Finland. GT: Approx. 64,200

Finland. The Tempera recently received an Service speed, open water: Approx.

The tanker Tempera has joined the Award at the Shipbuilding, Machin- 15.4 knots (15% sea margin at

Fortum fleet to enter service between ery and Marine Technology (SMM) designed draft)

the North Sea and the Baltic Sea. The International Trade Fair in Hamburg Service speed, ice condition: Approx.

Tempera is the first newbuilding in in the Tankers Series as the most in- 8 knots (in channel ice at scantling

the world to utilize the DAT (Double novative newbuilding of the year 2002. draft)

Acting Tanker) concept and the Length, o.a.: Approx. 252.00m Main propulsion machinery

worlds largest tanker built in accor- Length, b.p.: 230.00m Type: Electric motor-driven podded

dance with the ice class 1A Super Breadth, mld.: 44.00m azimuthing propulsion unit

standards. Depth, mld.: 22.50m MCR: 16,000kW

The DAT is equipped with a pod-

ded azimuthing propulsion unit that

can rotate 360 degrees at the stern of

the vessel, and is designed to navigate

stern ahead in frozen ice conditions

and bow first in open water. The Tem-

pera can achieve a high level of reli-

ability and safety.

The hull construction and ice

breaking performance conform to the

Ice Class 1A Super requirements

Topics No. 295 Oct. - Nov. Page 4

SKDY completes caprolactam carrier Eishu

Shin Kurushima Dockyard Co., mal oil supplied by a thermal fluid

Ltd. (SKDY) has built the caprolac- boiler that is installed in the engine

tam carrier, Eishu (HN: 5188), for room.

Procyon Shipholding S. A. The carrier Ducts are installed between the

has a unique construction for the cargo tank and heat insulation to cir-

coastal transport of caprolactam, culate hot air constantly and evenly,

which is a nylon raw material. and thermosensors monitor the tem-

Caprolactam transport requires perature. The temperature monitor-

constant temperature control at ing system also controls the tempera-

around 80oC (plus/minus 2oC) to main- ture regulating valves for thermal oil

tain caprolactam in the molten state. supply.

Contact with air (oxygen), water, oil, fore, it was necessary to minimize At the open end of cargo tank ven-

and dust must be avoided for ensur- items and quantities of internal tilation system, a seal tank is installed

ing quality. If contaminated with outfittings. SKDY has developed a to prevent air penetration. Internal

these substances, caprolactam cannot unique tank heating system to resolve pressure gauges and thermometers

be used for nylon products. these problems. are also provided for recording the

Previous caprolactam carriers had In the new design, the heat insula- internal pressure and temperature.

generally used heating pipes in cargo tion is provided inside the cargo holds, Negative pressure and overheat inside

tanks. This method was not effective and no heat insulation covering cargo the cargo tanks are avoided by safety

to maintain an even temperature in tanks was attached, considering the devices including pump and fan stop-

the whole tank. Temperature around heat transfer of the cargo tanks. Hot ping systems.

the heating pipes could be maintained air is circulated in the space between Principal particulars

at the required level or higher but was the cargo tanks and heat insulation Ship type: Caprolactam Carrier

lower at areas distant from the pipes. to maintain the temperature evenly. L (o.a.) x L (b.p.) x B x D x d: 79.97m x

The resultant heat distribution devia- This unique double construction pro- 76.00m x 13.20m x 6.20m x

tion made the strict temperature con- vides flat walls and bottoms for the 4.30m DWT/GT: 1,866.14t/1,865t

trol difficult. inside of the tanks, facilitating tem- Main engine: Hanshin LH36L

Air oxidizes caprolactam, causing perature control at the required level. Speed, service : abt. 12.8 kt

changes in quality. To prevent oxidiza- The heating system uses a fan room Classification: NK

tion, the inside of the cargo tanks had in the upper section of the cargo pump Completion: July 2002

been sealed with nitrogen to exclude room. In the fan room, fans and air

air. The presence of any projecting heaters are installed. The air heaters

outfittings like heating pipes in cargo produce hot air, and fans send out the To our readers

tanks also causes the formation of air hot air into cargo holds. The heat

Please notify us of any change in

pockets behind the outfittings. There- source for the air heaters is 220oC ther-

address by letter or telefax to-

gether with the old mailing la-

ferent bore sizes. bel to ensure you continue to re-

ceive SEA-Japan.

MHI receives order for The first engine of the UEC43LSII

We welcome your comments

type will be mounted on the Ginga

UEC43LSII diesel Maru as its main engine, which is a

about SEA-Japan. Please ad-

dress all correspondence to the

engine from MES training ship being built by MES for Japan Ship Exporters' Associa-

the Institute for Sea Training of the tion (JSEA), or the Japan Ship

Mitsubishi Heavy Industries, Ltd. Ministry of Land, Infrastructure and Centre in London.

(MHI) has received an order for build- Transport of Japan. Address (Tokyo): 15-16, Torano-

ing the first Mitsubishi UEC43LSII The Ginga Maru is a 6,100GT mon 1-chome, Minato-ku, Tokyo

diesel engine from Mitsui Engineer- ocean-going training ship with the 105-0001 / Tel: (03) 3508-9661

Fax: (03) 3508-2058

ing & Shipbuilding Co., Ltd. (MES). navigation speed of 18 knots. Full

E-mail: postmaster@jsea.or.jp

The engine consists of seven cylin- complement will be 246. Commence- Address (London): Ground Floor,

ders with a bore of 43cm, which can ment is scheduled in June 2004. 9 Marshalsea Road, London SE1

develop 7,350kW at 160rpm. The en- 7UEC43SLII Main Specifications: 1EP, UK / Tel: +44 (0) 20 7403

gine has been developed for medium Bore: 430mm 1666 / Fax: +44 (0) 20 7403 1777

class ships. The UEC-LSII series con- Stroke: 1,500mm E-mail: info@jsc.org.uk

sists of seven types ranging from Maximum output: 7,350kW URL: http://www.jsc.org.uk

UEC33LSII to UEC85LSII with dif- Speed: 160rpm

Industry News in Brief No. 295 Oct. - Nov. Page 5

KHI establishes friction-stir welding system

for aluminum alloy

Kawasaki Heavy Industries, Ltd. 1990s and started the study to apply

(KHI) has established a friction-stir the technology to its own products.

welding (FSW) method to apply 5083 The company has also designed weld-

aluminum alloy plate. FSW was in- ing machines and tools, as well as set-

vented at The Welding Institute (TWI) ting of correct welding parameters

in the UK in 1991, and is a unique necessary for joining various alumi-

welding method to join base metals num alloys.

such as aluminum and magnesium As a result, KHI has established

alloys directly without using consum- the FSW process applicable to 5083 Based on the results, KHI will now

able materials used in the conven- aluminum alloy plate with a thickness use the FSW method for constructing

tional method. of up to 50mm. The aluminum alloy aluminum alloy hulls of high-speed

This welding method was first in- of this grade is used as structural ships such as Jet Piercers and Jet Foils

troduced into Japan in the middle of materials to build the hull of high- that are now becoming popular in the

the 1990s, then increasingly applied speed ships and cargo tanks of LNG Kyushu district and Izu Islands. The

to the manufacturing of various alu- carriers. 5083 alloy is known as a dif- FSW method will be also used for the

minum alloy structures. ficult material for applying FSW, in construction of cargo tanks for LNG

KHI introduced the FSW method comparison to the 6000 series alloys carriers, for which a high level of safety

from TWI in the latter half of the that are used for railcar bodies. is required.

KHI has also concluded a techni-

MES develops underwater welder using super cal license agreement with Mitsui

water-repellent material Engineering & Shipbuilding Co., Ltd.

(MES) to supply FSW technology.

Construction period and costs reduced Both companies have already con-

Mitsui Engineering & Shipbuilding corrosion developing in the gap be- cluded a business tie-up in shipbuild-

Co., Ltd. (MES) has developed the tween the weld and the backing strip ing for designing, production, and pro-

worlds first underwater full penetra- as well as deterioration of fatigue curement. The transfer of FSW tech-

tion welding technology. Underwater strength. Use of a removable backing nology from KHI to MES will increase

welding is now becoming important material made of ceramic had once technical exchange between the com-

as construction and maintenance of been considered but the material had panies further.

large offshore structures require weld- absorbency that made the material MES has already begun the tech-

ing work below the sea surface. inappropriate for use. nical study to apply the FSW method

The conventional pressurized and MES has developed a new super to the Techno Super Liner, a high-

dry welding method is costly since it water-repellent material (silica-sili- speed cargo-passenger carrier. If re-

requires expensive facilities such as a cone resin) to improve the perfor- alized, it will be the first large scale

pressure unit to exclude water from mance of the backing material. The application of the FSW process to a

the welding spot. So, elimination of newly developed material was coated ship in Japan.

expensive facilities has become impor- over the backing material of ceramic

tant. for underwater testing. Tests have diver to monitor the welding progress

To commercialize wet-type under- proved that the new backing material and adjust the welding wire point to

water welding, there are some prob- is applicable to underwater welding, the target. Thus, underwater welding

lems to be solved, i.e., how to prevent and the same welding conditions as is achieved in the same manner as car-

welding on land is ob- ried out in air.

tained. The combined use of the small

The company has welding machine and ceramic back-

also developed a handy- ing strip coated with the super water

type automatic welding repellent material has established

machine of the self- wet-type automatic underwater weld-

traveling type that does ing. This technique can eliminate vari-

not require traveling ous welding work preparations includ-

rails. The machine in- ing necessary equipment installation

corporates a CCD cam- at the site, and work procedures are

era to monitor the weld- simplified, drastically reducing the

ing spot. This allows a construction period and costs.

Shipyard Activities No. 295 Oct. - Nov. Page 6

Front Stratus 29.40m x 13.50m x 9.55m

DWT/GT: 31,842t/19,795t

Owner: Front Stratus Inc. Main engine: Mitsubishi

Builder: Hitachi Zosen Corop. 6UEC52LA diesel x 1 unit

Hull No.: 4979 Speed, service: 14.0 kt

Ship type: VLCC Classification: NK

L (o.a.) x B x D x d: 329.99m x Completion: Sept. 10, 2002

60.00m x 29.70m x 21.50m

DWT/GT: 299,157t/156,916t DWT/GT: 4,500t/10,000t Ocean Baron

Main engine: Hitachi-MAN B&W Main engine: Pielstick 18PC2-6V

7S80MC diesel x 1 unit diesel x 2 units

Speed, service: 16.0kt Speed, service: 23.2kt

Classification: ABS Classification: JG

Completion: Aug. 22, 2002 Completion: Aug. 31, 2002

Eliomar

Owner: Venus Ocean Navigation S.

A.

Builder: NKK Corp.

Hull No.: 219 Owner: Yamamoto Kaiun Co., Ltd.

Ship type: Tanker Builder: Namura Shipbuilding Co.,

L (o.a.) x B x D x d: 274.20m x Ltd.

48.00m x 22.40m x 15.96m Hull No.: 237

Pegasus Island DWT/GT: 149,991t/78,845t Ship type: Bulk carrier

Owner: Friend Shine Shipping S. A. Main engine: DU Sulzer 6RTA72 L (o.a.) x B x D x d: 224.89m x

Builder: Mitsui Engineering & Ship- diesel x 1 unit 32.20m x 19.30m x 13.950m

building Co., Ltd. DWT/GT: 74,193t/38,938t

Hull No.: 1543 Main engine: B&W 7S50MC (Mk 6)

Ship type: Coal carrier Speed, max. trial: 16.35kt

L (o.a.) x B x D x d: 229.00m x Classification: NK

36.50m x 18.50m x 12.80m Completion: Sept. 10, 2002

DWT/GT: 77,830t/43,321t

Cargo hold capacity: 93,011.4m3

Vega Eternity

Main engine: Mitsui-MAN B&W Owner: Venus Ocean Navigation S.

5S60MC diesel x 1 unit A.

Speed, service: 14.5kt Speed, service: 15.40kt Builder: Sanoyas Hishino Meisho

Classification: NK Classification: LRS

Completion: July 18, 2002 Completion: July 18, 2002

Patriarch

Owner: Crusade Shipping Ltd.

Builder: The Hakodate Dock Co.,

Ltd.

Hull No.: 785

Ship type: Bulk carrier Corp.

L (o.a.) x B x D x d: 168.00m x Hull No.: 1200

Ship type: Bulk carrier

Ferry Kyoto 2 L (o.a.) x B x D x d: 189.90m x

Owner: Meimon Taiyo Ferry Co., Ltd. 32.26m x 17.10m x 12.041m

Builder: Mitsubishi Heavy Indus- DWT/GT: 52,524t/29,369t

tries, Ltd. Main engine: MAN B&W 6S50MC-

Hull No.: 1086 C diesel x 1 unit

Ship type: Car/passenger ferry Speed, service: 14.5kt

L (o.a.) x B x D x d: 167.0m x 156.0m Classification: NK

x 25.60m x 8.0m x 6.0m Completion: Sept. 10, 2002

Prepared and edited by Eureka International Inc. Printed in Japan

You might also like

- Japan ShipyardDocument7 pagesJapan ShipyardNguyễn Tấn TrưởngNo ratings yet

- Offshore HyuNDAIDocument26 pagesOffshore HyuNDAIbetahita_80174No ratings yet

- Methodical Series Tests For Fuller Ship Hull Forms: Ocean EngngDocument48 pagesMethodical Series Tests For Fuller Ship Hull Forms: Ocean EngngEdson SerejoNo ratings yet

- Sea 300Document6 pagesSea 300PetricaNo ratings yet

- Kobelco Welding Today2000-03Document12 pagesKobelco Welding Today2000-03Charles JacobNo ratings yet

- Strategy Sumitomo Heavy IndustriesDocument17 pagesStrategy Sumitomo Heavy IndustriesSomyata RastogiNo ratings yet

- HSL Final ReportDocument52 pagesHSL Final Reportkarthik raju100% (1)

- Memorandum of Understanding V3Document4 pagesMemorandum of Understanding V3Anas Sebtu PrawiraNo ratings yet

- Overview of Ship Building IndustryDocument32 pagesOverview of Ship Building IndustryAnna Smith100% (1)

- Ministrty of ShippingDocument81 pagesMinistrty of ShippingEshwar BabuNo ratings yet

- HSL1Document44 pagesHSL1karthik rajuNo ratings yet

- eDocument13 pagesepeyockNo ratings yet

- Presentasi Maritime DARMADIDocument11 pagesPresentasi Maritime DARMADIashkisaragiNo ratings yet

- Assignment CaseStudy SOGT CHALLENGES PRD and WBS KOG11203 Project ManagementDocument26 pagesAssignment CaseStudy SOGT CHALLENGES PRD and WBS KOG11203 Project ManagementLuqman OsmanNo ratings yet

- LNG MitsubishiDocument4 pagesLNG Mitsubishireade2011No ratings yet

- Ghana Ports and Harbours Authority FullDocument23 pagesGhana Ports and Harbours Authority FullKaren DavisNo ratings yet

- Prepared By:: DeclarationDocument6 pagesPrepared By:: DeclarationRakesh Kumar SenapatiNo ratings yet

- (OJT) Contents (Update)Document20 pages(OJT) Contents (Update)Alexander James T. TucayNo ratings yet

- Pre-Feasibility Desk Study Lamu Port Offshore Energy Industrial ParkDocument11 pagesPre-Feasibility Desk Study Lamu Port Offshore Energy Industrial ParkEric Mwangi NjorogeNo ratings yet

- Marine Engineering Progress in 1997: Annual ReviewDocument42 pagesMarine Engineering Progress in 1997: Annual Reviewнелля могурянNo ratings yet

- Ocean Network Express - WikipediaDocument10 pagesOcean Network Express - WikipediaĐhañushRaman KNo ratings yet

- General Catalogue 2016Document139 pagesGeneral Catalogue 2016Tri Wasda MarganingsihNo ratings yet

- Report Internship HSLDocument19 pagesReport Internship HSLNandhini ShanmugamNo ratings yet

- Japan Port ConsultantsDocument2 pagesJapan Port ConsultantsnewsaktNo ratings yet

- This Project Report Is Prepared During The Summer Industrial Training Undertaken atDocument62 pagesThis Project Report Is Prepared During The Summer Industrial Training Undertaken atBhanuprakashNo ratings yet

- Delivery of SHOFU MARU, World's First Cargo Vessel Equipped With 'Wind Challenger' Hard SailDocument2 pagesDelivery of SHOFU MARU, World's First Cargo Vessel Equipped With 'Wind Challenger' Hard SailSANDESH GHANDATNo ratings yet

- Assignmet # 2: Preston University (Lahore Campus)Document10 pagesAssignmet # 2: Preston University (Lahore Campus)j4jahanzaib99No ratings yet

- ShipbuildingDocument81 pagesShipbuildingpoetoetNo ratings yet

- Cerulean AceDocument3 pagesCerulean Acesasa7791No ratings yet

- PT Horiguchi Engineering Indonesia: General CatalogueDocument24 pagesPT Horiguchi Engineering Indonesia: General CatalogueAkhmad RamdaniNo ratings yet

- Sea 343Document6 pagesSea 343britties69No ratings yet

- MDL ReportDocument22 pagesMDL Reportroy thomas100% (1)

- ApplicationDocument11 pagesApplicationdiniezubirNo ratings yet

- LI ReportDocument74 pagesLI Reportfumakiller_23No ratings yet

- Komatsu India Private LimitedDocument20 pagesKomatsu India Private LimitedYeshwanth RainaNo ratings yet

- Cochin ShipyardDocument2 pagesCochin ShipyardATHUL KRISHNAN C RNo ratings yet

- K LineDocument5 pagesK LineGs MaheshNo ratings yet

- Offshore Support Vessels1712Document9 pagesOffshore Support Vessels1712sarkarraktim94No ratings yet

- Views Is A PR Magazine Published by Komatsu LTDDocument12 pagesViews Is A PR Magazine Published by Komatsu LTDShubhesh Gupta100% (1)

- Inpex Media Release - CPF Steel Cut 25 January 2013 FinalDocument3 pagesInpex Media Release - CPF Steel Cut 25 January 2013 Finalputra111213No ratings yet

- HSL REPORT_mergedDocument36 pagesHSL REPORT_mergedkenguvamanojkumar013No ratings yet

- Media Release - Ichthysfid (Final)Document4 pagesMedia Release - Ichthysfid (Final)Victor IkeNo ratings yet

- CV Sample For A Data-Entry VacancyDocument7 pagesCV Sample For A Data-Entry VacancyMahmoud ElNaggarNo ratings yet

- Tug Boat Desing PDFDocument61 pagesTug Boat Desing PDFGilson RolandoNo ratings yet

- KSY ProjectDocument48 pagesKSY Projectisrat jahanNo ratings yet

- Kelompok 1 - PT Karya Teknik Internusa AbadiDocument21 pagesKelompok 1 - PT Karya Teknik Internusa Abadiotsuka tecNo ratings yet

- Junr ProjectDocument44 pagesJunr ProjectAvinash GunnaNo ratings yet

- A Report On Shipbuilding Industry of BangladeshDocument13 pagesA Report On Shipbuilding Industry of Bangladeshruhul01No ratings yet

- Chiyoda Awarded EPC Contract For Tangguh Expansion Project in IndonesiaDocument1 pageChiyoda Awarded EPC Contract For Tangguh Expansion Project in IndonesiajurieskNo ratings yet

- F KomatsuDocument6 pagesF KomatsuneelgalaNo ratings yet

- Hindustan Shipyard Limited (Project)Document67 pagesHindustan Shipyard Limited (Project)Arish Adduri67% (6)

- From T-2 to Supertanker: Development of the Oil Tanker, 1940 - 2000, RevisedFrom EverandFrom T-2 to Supertanker: Development of the Oil Tanker, 1940 - 2000, RevisedNo ratings yet

- Osh Induction Program in Enhancing Safety Awareness Amongst Fabrication Workers in Brooke Dockyard, Kuching, SarawakFrom EverandOsh Induction Program in Enhancing Safety Awareness Amongst Fabrication Workers in Brooke Dockyard, Kuching, SarawakRating: 5 out of 5 stars5/5 (1)

- The Guidebook to Toyota's 13 Pillars System - Series Books 7 to 17: Toyota Production System ConceptsFrom EverandThe Guidebook to Toyota's 13 Pillars System - Series Books 7 to 17: Toyota Production System ConceptsNo ratings yet

- Journal of Ship Production and Design: Analysis On Hull Block Erection Process Considering VariabilityDocument12 pagesJournal of Ship Production and Design: Analysis On Hull Block Erection Process Considering VariabilityEdson SerejoNo ratings yet

- Ot Feeder 750Document1 pageOt Feeder 750Edson SerejoNo ratings yet

- Ot Feeder 500Document1 pageOt Feeder 500Edson SerejoNo ratings yet

- Ot Feeder 500Document1 pageOt Feeder 500Edson SerejoNo ratings yet

- Type: Bulker Model: Serial NumberDocument14 pagesType: Bulker Model: Serial NumberManikantaSumanthNo ratings yet

- Ship Size PDFDocument1 pageShip Size PDFrigelNo ratings yet

- Ocean Carriers Case StudyDocument7 pagesOcean Carriers Case Studyaida100% (1)

- Maritime English (Imo Model Course 3.17)Document97 pagesMaritime English (Imo Model Course 3.17)Haryadi Bakri100% (1)

- Ports and Terminal - Han LigteringenDocument383 pagesPorts and Terminal - Han LigteringenErmal Spahiu100% (2)

- GENESIS Off-Hire B&C PmoleDocument22 pagesGENESIS Off-Hire B&C PmoleRogério Tristão100% (2)

- 32p Neda Dry CargoDocument36 pages32p Neda Dry CargoFandy SipataNo ratings yet

- Self Checklist For Company Safety Management SystemDocument10 pagesSelf Checklist For Company Safety Management SystemErgul Neroglu100% (1)

- Class REportDocument20 pagesClass REportJagmohan SinghNo ratings yet

- Ship ConstructionDocument157 pagesShip ConstructionBehendu PereraNo ratings yet

- Always Moving Forward: Shipbuilding DivisionDocument31 pagesAlways Moving Forward: Shipbuilding DivisionАлиса ПестроваNo ratings yet

- 43 - Simple Model For Newbuilding Cost PDFDocument12 pages43 - Simple Model For Newbuilding Cost PDFRianNo ratings yet

- Inter-Global College Foundation, Inc.: Brgy. Bocohan, Lucena CityDocument8 pagesInter-Global College Foundation, Inc.: Brgy. Bocohan, Lucena CityLaica & AivanNo ratings yet

- Tramp ShippingDocument5 pagesTramp ShippingMosarof Hossain100% (1)

- Significant Ships 2003Document107 pagesSignificant Ships 2003Marcel SchmalNo ratings yet

- TBS Case Study - Grain Ship Loading ChuteDocument1 pageTBS Case Study - Grain Ship Loading ChuteKroya HunNo ratings yet

- Management Level Course For Maritime Deck OfficersDocument4 pagesManagement Level Course For Maritime Deck Officersjohnkevin.quilatonNo ratings yet

- Ship Chartering and Brokering Practice 1999Document335 pagesShip Chartering and Brokering Practice 1999Sillo Paul100% (11)

- MARITIME ENGLISH For N II BDocument13 pagesMARITIME ENGLISH For N II Bhaikals110504No ratings yet

- Weekly SP Market Report Week Ending April 30th 2021 Week 17 Report No 17.21Document8 pagesWeekly SP Market Report Week Ending April 30th 2021 Week 17 Report No 17.21Sandesh Tukaram GhandatNo ratings yet

- 728 Marine Engineering Interview Questions Answers GuideDocument6 pages728 Marine Engineering Interview Questions Answers Guidepandavadra rajesh100% (1)

- MaritimeReporter1989 12 01Document58 pagesMaritimeReporter1989 12 01vinipaulinoNo ratings yet

- Primeship Steelcoil Loading Ver1.10-EDocument55 pagesPrimeship Steelcoil Loading Ver1.10-Erammech85100% (2)

- Dccmay 2022Document2 pagesDccmay 2022Manmeet Singh SandhuNo ratings yet

- Vessel Database: AIS Ship PositionsDocument3 pagesVessel Database: AIS Ship PositionsViraj SolankiNo ratings yet

- The Role of International Trade in The Global Economy & Its Effects On Economic GrowthDocument11 pagesThe Role of International Trade in The Global Economy & Its Effects On Economic Growthayush singhNo ratings yet

- Vessel Database: AIS Ship PositionsDocument3 pagesVessel Database: AIS Ship PositionsViraj SolankiNo ratings yet

- BulkDocument7 pagesBulkbigbang182No ratings yet

- PORT INFORMATION GUIDE BremerhavenDocument54 pagesPORT INFORMATION GUIDE BremerhavenOrxan TalibzadeNo ratings yet

- Rapport Port State ControlDocument56 pagesRapport Port State ControlReza AhmedNo ratings yet