Professional Documents

Culture Documents

Seg 979 2 25 01 Aa LM - NBC

Seg 979 2 25 01 Aa LM - NBC

Uploaded by

Epure GabrielCopyright:

Available Formats

You might also like

- Roscas Api Planos 1-29 PDFDocument41 pagesRoscas Api Planos 1-29 PDFJesus Cacharuco100% (3)

- JCB 444 Tier III Electronic Supplement - Issue2Document38 pagesJCB 444 Tier III Electronic Supplement - Issue2Epure Gabriel100% (6)

- JCB 444 Tier III Electronic Supplement - Issue2Document38 pagesJCB 444 Tier III Electronic Supplement - Issue2Epure Gabriel100% (6)

- Linked PDFDocument379 pagesLinked PDFEpure Gabriel50% (2)

- TDL Reference ManualDocument567 pagesTDL Reference Manualdcpkahdar100% (1)

- PO Purchase Order in ExcelDocument2 pagesPO Purchase Order in ExcelAziz Khan LodhiNo ratings yet

- 710DDocument798 pages710DSegundo Francisco Jauregui Valencia75% (4)

- Linear System Theory and Design (3rd Ed) - Chi-Tsang ChenDocument176 pagesLinear System Theory and Design (3rd Ed) - Chi-Tsang Chenabnaod5363No ratings yet

- Dystopian Wars FluffDocument13 pagesDystopian Wars FluffFinin Chisholm100% (2)

- Drawing Standard Amada Xtreme: Rolling MarkingDocument1 pageDrawing Standard Amada Xtreme: Rolling MarkingSami SAADINo ratings yet

- Ibcm 102Document1 pageIbcm 102Shyam J VyasNo ratings yet

- Spoun MouldDocument8 pagesSpoun MouldRajanNo ratings yet

- In/Mm 2:1: B-SIZE 172672Document2 pagesIn/Mm 2:1: B-SIZE 172672GeeNo ratings yet

- LS900161V01 - CustDocument1 pageLS900161V01 - CustAWNISH PRASAD SINGHNo ratings yet

- Grayhill 07272021 7db2d6 0ae3ffad0fce4a2db89a57cea-2509346Document17 pagesGrayhill 07272021 7db2d6 0ae3ffad0fce4a2db89a57cea-2509346ALEJANDRONo ratings yet

- NUT 11.500 4TPI OTIS - IdwDocument1 pageNUT 11.500 4TPI OTIS - IdwNhoj AicragNo ratings yet

- Drawing Standard Amada Xtreme: Lmax 580 3 Lmin 450 3 Stroke 130 3Document1 pageDrawing Standard Amada Xtreme: Lmax 580 3 Lmin 450 3 Stroke 130 3Sami SAADINo ratings yet

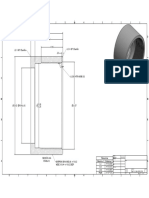

- Section A-A Scale 1 / 2: Pete Lenz 8/21/2010Document8 pagesSection A-A Scale 1 / 2: Pete Lenz 8/21/2010Manish PatilNo ratings yet

- Drawing 1Document1 pageDrawing 1Monse HernándezNo ratings yet

- Released CEM Standard ACS M/L/XL Heatsink FDocument1 pageReleased CEM Standard ACS M/L/XL Heatsink FAmc Forklift ElektrikNo ratings yet

- Seal Assy Stationary, Oil-Brg: Holes To Be Match Drilled I +-0002 0 .1884 - .000 3Document2 pagesSeal Assy Stationary, Oil-Brg: Holes To Be Match Drilled I +-0002 0 .1884 - .000 3primaasiapasifikNo ratings yet

- Datasheet CM100DU-34KADocument4 pagesDatasheet CM100DU-34KAOscar Ortega EstarriagaNo ratings yet

- RB 2885 0101Document1 pageRB 2885 0101AWNISH PRASAD SINGHNo ratings yet

- 2-3 Turk'S Head Roll SM120A - 75x75 - L75: 33047 REMANZACCO (UD)Document2 pages2-3 Turk'S Head Roll SM120A - 75x75 - L75: 33047 REMANZACCO (UD)Alejandra ChocueNo ratings yet

- Cm200dy-24nf eDocument4 pagesCm200dy-24nf eWesamNo ratings yet

- H12092021-004 CIW Drilling Choke GADocument1 pageH12092021-004 CIW Drilling Choke GAJitendra BhosaleNo ratings yet

- 337970A Mast System EX141-18-3.9Document5 pages337970A Mast System EX141-18-3.9Simion NechitiNo ratings yet

- Drawing Standard Amada Xtreme: Lmax 580 3 227 3 Lmin 450 3 Stroke 130 3 130 3Document1 pageDrawing Standard Amada Xtreme: Lmax 580 3 227 3 Lmin 450 3 Stroke 130 3 130 3Sami SAADINo ratings yet

- SMA - MOLEX Drawing 732511150 - SDDocument1 pageSMA - MOLEX Drawing 732511150 - SDJose MatutesNo ratings yet

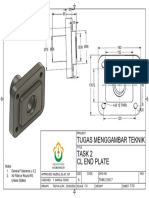

- TASK 2. 07 CL END PLATE Drawing v1Document1 pageTASK 2. 07 CL END PLATE Drawing v1Asni BerlianNo ratings yet

- CM100DY-24NF MitsubishiElectricSemiconductorDocument4 pagesCM100DY-24NF MitsubishiElectricSemiconductorJerry LeeNo ratings yet

- Cold Strecth Tank DesignDocument1 pageCold Strecth Tank DesignjirrsamaNo ratings yet

- OL-388.8-Hitachi 20211203184635.614 XDocument1 pageOL-388.8-Hitachi 20211203184635.614 XWilson AlvesNo ratings yet

- TB Driven Pully 140 TeethDocument2 pagesTB Driven Pully 140 TeethshreerajpatiloppNo ratings yet

- TCD 2013, 2200 090 KW TCD 2013 L04 2V Q680 Tier3Document1 pageTCD 2013, 2200 090 KW TCD 2013 L04 2V Q680 Tier3Michael BogdanNo ratings yet

- Measurement Protocol/ Quality Control Report Required: X-Stand-SHEETMETAL-1,5mmDocument1 pageMeasurement Protocol/ Quality Control Report Required: X-Stand-SHEETMETAL-1,5mmmeteforex1No ratings yet

- Cm100dy-24a eDocument5 pagesCm100dy-24a eDamian MadryNo ratings yet

- Governor Adjustment Data Sheet: Adjustments: Droop Aneroid /LDA Torque SettingDocument1 pageGovernor Adjustment Data Sheet: Adjustments: Droop Aneroid /LDA Torque SettingMichael BogdanNo ratings yet

- R Linear Bearings - Product Range: Closed, Anodised Aluminium AdapterDocument1 pageR Linear Bearings - Product Range: Closed, Anodised Aluminium Adapterlifnur hadiNo ratings yet

- Flyer Robot GP180 E 11.2020Document2 pagesFlyer Robot GP180 E 11.2020pruma.ruNo ratings yet

- Block Mill Pass Profile PDFDocument1 pageBlock Mill Pass Profile PDFAmit RayNo ratings yet

- Section A-A (1:3) : 220Ø P Ø3 in A 4 PlacesDocument1 pageSection A-A (1:3) : 220Ø P Ø3 in A 4 PlacesCarlos LópezNo ratings yet

- Ibcm 142Document1 pageIbcm 142Shyam J VyasNo ratings yet

- TCD 2013, 2300 093 KW TCD 2013 L04 2V Q410 Tier3Document1 pageTCD 2013, 2300 093 KW TCD 2013 L04 2V Q410 Tier3Michael BogdanNo ratings yet

- TCD 2013, 2200 099 KW TCD 2013 L04 2V Q410 Tier3 NOX4Document1 pageTCD 2013, 2200 099 KW TCD 2013 L04 2V Q410 Tier3 NOX4Michael BogdanNo ratings yet

- Adapter Spool FlangDocument1 pageAdapter Spool FlangRuslan BayramovNo ratings yet

- Cylinder Ripper LiftDocument8 pagesCylinder Ripper LiftVins SquadNo ratings yet

- Mandrel SWD IndustriDocument1 pageMandrel SWD IndustriDinsosnakertrans KudusNo ratings yet

- TCD 2013, 2200 087 KW TCD 2013 L04 2V Q410 Tier3 NOX4Document1 pageTCD 2013, 2200 087 KW TCD 2013 L04 2V Q410 Tier3 NOX4Michael BogdanNo ratings yet

- AR-15 Bolt Schematic Part 1Document1 pageAR-15 Bolt Schematic Part 1S KlarsNo ratings yet

- TCD 2013, 2200 071 KW TCD 2013 L04 2V Q400 Tier3Document1 pageTCD 2013, 2200 071 KW TCD 2013 L04 2V Q400 Tier3Michael BogdanNo ratings yet

- Tctl-U (RLLB) Terminales de Compresión IDocument1 pageTctl-U (RLLB) Terminales de Compresión Ijavier SuarezNo ratings yet

- TCD 2013, 2300 088 KW TCD 2013 L04 2V Q410 Tier3Document1 pageTCD 2013, 2300 088 KW TCD 2013 L04 2V Q410 Tier3Michael BogdanNo ratings yet

- Wi A Al: ArmipmDocument3 pagesWi A Al: ArmipmDinesh YkatilNo ratings yet

- Molex Micro-Fit (3.0) Bmi Vertical ReceptacleDocument2 pagesMolex Micro-Fit (3.0) Bmi Vertical ReceptacleVijoy PaulNo ratings yet

- It Should Be Less Than R /3 or 10mDocument5 pagesIt Should Be Less Than R /3 or 10mMawan BentzNo ratings yet

- TCD 2013, 2200 064 KW TCD 2013 L04 2V Q400 Tier3Document1 pageTCD 2013, 2200 064 KW TCD 2013 L04 2V Q400 Tier3Michael BogdanNo ratings yet

- TCD 2013, 2200 099 KW TCD 2013 L04 2V Q680 Tier3Document1 pageTCD 2013, 2200 099 KW TCD 2013 L04 2V Q680 Tier3Michael BogdanNo ratings yet

- Week 2 HomeworkDocument1 pageWeek 2 HomeworkGibsonNo ratings yet

- Cm200du 12FDocument4 pagesCm200du 12FAna Cuahutli Sanchez MartinezNo ratings yet

- MFD03074 - HSS TS STEP DRILL Ø8.2XSL19.54XR0.5XØ16XSL5XC45°XØ22XFL80XOAL165XMT2-ModelDocument1 pageMFD03074 - HSS TS STEP DRILL Ø8.2XSL19.54XR0.5XØ16XSL5XC45°XØ22XFL80XOAL165XMT2-Modell.a.s.t.t.r.y.1.7.2.9No ratings yet

- Series 77: Single Deck Rotary SwitchesDocument5 pagesSeries 77: Single Deck Rotary SwitchesJosé Ignacio CandelaNo ratings yet

- Ibcm 84Document1 pageIbcm 84Shyam J VyasNo ratings yet

- Fiat 8065 PDFDocument6 pagesFiat 8065 PDFigorkov100% (1)

- Drw. Surface Texture: 1. Break All Edges. 2Document1 pageDrw. Surface Texture: 1. Break All Edges. 2Ruslan BayramovNo ratings yet

- Green Pin Open Spelter Sockets Group MBL: G-6412: SKGOS042: 170tDocument1 pageGreen Pin Open Spelter Sockets Group MBL: G-6412: SKGOS042: 170tSergioHurtadoAvellaNo ratings yet

- Pa000006-Guide Rod - Dia12x215Document1 pagePa000006-Guide Rod - Dia12x215YAGNA V YAGNA VNo ratings yet

- Kit 12 TFDocument1 pageKit 12 TFEpure GabrielNo ratings yet

- Motor DataDocument1 pageMotor DataEpure GabrielNo ratings yet

- QXL230817ADocument1 pageQXL230817AEpure GabrielNo ratings yet

- ReceiptDocument1 pageReceiptEpure GabrielNo ratings yet

- Screencapture Kamarkhani Info Calculation Single Girder 2022 11 01 21 - 51 - 01Document3 pagesScreencapture Kamarkhani Info Calculation Single Girder 2022 11 01 21 - 51 - 01Epure GabrielNo ratings yet

- Buletin JCB Platou CutieDocument2 pagesBuletin JCB Platou CutieEpure GabrielNo ratings yet

- Attestation Certificate of Machinery and Electromagnetic Compatibility DirectivesDocument1 pageAttestation Certificate of Machinery and Electromagnetic Compatibility DirectivesEpure GabrielNo ratings yet

- Manual Misia1 End CarriageDocument44 pagesManual Misia1 End CarriageEpure GabrielNo ratings yet

- Screencapture Kamarkhani Info Calculation Double Girder 2022 11 01 21 - 53 - 14Document3 pagesScreencapture Kamarkhani Info Calculation Double Girder 2022 11 01 21 - 53 - 14Epure GabrielNo ratings yet

- Holdwell Inventory JCB Catalogue 2020Document16 pagesHoldwell Inventory JCB Catalogue 2020Epure GabrielNo ratings yet

- 3.ELK Crane Geared Motor CatalogueDocument6 pages3.ELK Crane Geared Motor CatalogueEpure GabrielNo ratings yet

- 10 Ton American Crane DG TR 17534503r1Document1 page10 Ton American Crane DG TR 17534503r1Epure GabrielNo ratings yet

- Joystick TerexDocument16 pagesJoystick TerexEpure GabrielNo ratings yet

- Payment in Full or A 10% Deposit Is Required To Secure An EngineDocument1 pagePayment in Full or A 10% Deposit Is Required To Secure An EngineEpure Gabriel100% (1)

- Hydra Perm Co LTD Unit 20 Silver Court Intercity Way Bramley, Leeds West Yorkshire LS13 4LYDocument1 pageHydra Perm Co LTD Unit 20 Silver Court Intercity Way Bramley, Leeds West Yorkshire LS13 4LYEpure GabrielNo ratings yet

- Power Shift TransmissionDocument10 pagesPower Shift TransmissionEpure GabrielNo ratings yet

- Genuine Delphi "Cva Kits": (Nozzle+ D/Valve)Document2 pagesGenuine Delphi "Cva Kits": (Nozzle+ D/Valve)smail bl100% (2)

- Manual Misia2Document64 pagesManual Misia2Epure GabrielNo ratings yet

- Design and Analysis of Column Mounted JIDocument21 pagesDesign and Analysis of Column Mounted JIEpure GabrielNo ratings yet

- Manuale Misia Chain HoistDocument40 pagesManuale Misia Chain HoistEpure GabrielNo ratings yet

- R05001D, Injector CR, Common Rail System DELPHI 320-06623Document1 pageR05001D, Injector CR, Common Rail System DELPHI 320-06623Epure GabrielNo ratings yet

- Ciocan Omp JCB PDFDocument2 pagesCiocan Omp JCB PDFEpure GabrielNo ratings yet

- 28317158,320-06881 Injector CR, Common Rail System DELPHIDocument1 page28317158,320-06881 Injector CR, Common Rail System DELPHIEpure GabrielNo ratings yet

- Echivalenti Filtre CatDocument5 pagesEchivalenti Filtre CatEpure GabrielNo ratings yet

- Echivalenti Clarcor JCBDocument18 pagesEchivalenti Clarcor JCBEpure GabrielNo ratings yet

- Technical Information: ! Safety Notice Page 1 of 5Document5 pagesTechnical Information: ! Safety Notice Page 1 of 5Epure Gabriel100% (2)

- Cmsis End User Licence AgreementDocument3 pagesCmsis End User Licence AgreementSindhuja VsNo ratings yet

- MydealsDocument23 pagesMydealsShagun BkumarNo ratings yet

- FILE TÓM TẮT SÁCH QTCCU - TIẾNG ANHDocument132 pagesFILE TÓM TẮT SÁCH QTCCU - TIẾNG ANHVit BeNo ratings yet

- Writing The Project Report 2Document3 pagesWriting The Project Report 2api-222015490No ratings yet

- 4.B Students Profile and Progress Report Fillable PDF Prof. Sam Bernales Jr. 2Document1 page4.B Students Profile and Progress Report Fillable PDF Prof. Sam Bernales Jr. 2Edgar Vergara CamoroNo ratings yet

- SOPRA Banking Tool PDFDocument27 pagesSOPRA Banking Tool PDFavNo ratings yet

- 1-Legal Tech and The Future of Civil JusticeDocument4 pages1-Legal Tech and The Future of Civil JusticejoaocoelhoNo ratings yet

- 7 OrderReshop 18.1 Implementation GuideDocument295 pages7 OrderReshop 18.1 Implementation Guidesubhayan.nittNo ratings yet

- PM 120A Fork Lift - May 2009 - Bhequipment - Co.zaDocument137 pagesPM 120A Fork Lift - May 2009 - Bhequipment - Co.zaMark Ferries-ScottNo ratings yet

- Case Study Slum RehabilitationDocument5 pagesCase Study Slum RehabilitationBerisha PearlNo ratings yet

- Weld Information Collection SystemDocument46 pagesWeld Information Collection Systemaabhimittal0% (1)

- dhc6 400 Relavop Original VersionDocument30 pagesdhc6 400 Relavop Original VersionJose Francisco Colina100% (1)

- Zvldor - Quot 20211013073547Document2 pagesZvldor - Quot 20211013073547ULLAS KRISHNAN J NNo ratings yet

- Datasheet LA1805 (AM-FM-IF-MPX Tuner System)Document13 pagesDatasheet LA1805 (AM-FM-IF-MPX Tuner System)vanmarteNo ratings yet

- SEO Tools: 7:google: Webmaster Tool, Google Analytics (Total Website InformationDocument8 pagesSEO Tools: 7:google: Webmaster Tool, Google Analytics (Total Website InformationTOP RSNo ratings yet

- Anticipated Failure DeterminationDocument19 pagesAnticipated Failure Determinationangelesmtz69927No ratings yet

- HCM15R Manual - 2002 - Issue 1Document4 pagesHCM15R Manual - 2002 - Issue 1hamidon3No ratings yet

- Mmmmmetro Electrical VariationDocument80 pagesMmmmmetro Electrical VariationchristianNo ratings yet

- Timetable HogwartsDocument36 pagesTimetable Hogwartsharshit.royNo ratings yet

- Creating UI Elements Dynamically in Abap Webdynpro ApplicationDocument5 pagesCreating UI Elements Dynamically in Abap Webdynpro ApplicationHarkesh Kumar YadavNo ratings yet

- Circulation in A LaundryDocument4 pagesCirculation in A LaundryDyna Wylene GardoniaNo ratings yet

- Journal of Cleaner ProductionDocument7 pagesJournal of Cleaner ProductionmarilauraNo ratings yet

- Nissan hr16 Taller PDFDocument237 pagesNissan hr16 Taller PDFJhon Sanchez Lopez100% (2)

- DNV OS D301 Fire ProtectionDocument46 pagesDNV OS D301 Fire ProtectionRicardo Gavilan Bendezu100% (1)

Seg 979 2 25 01 Aa LM - NBC

Seg 979 2 25 01 Aa LM - NBC

Uploaded by

Epure GabrielOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seg 979 2 25 01 Aa LM - NBC

Seg 979 2 25 01 Aa LM - NBC

Uploaded by

Epure GabrielCopyright:

Available Formats

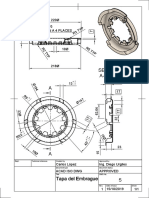

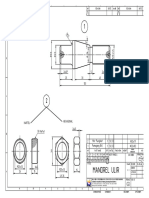

GEN. TOLERANCES 0.5 - 6 0.1 6 - 30 0.2 30 - 120 0.3 120 - 315 0.5 315 - 1000 0.

30 0.2 30 - 120 0.3 120 - 315 0.5 315 - 1000 0.8 1000 - 2000 1.2 2000 - 4000 2 4000 - 8000 3

GEN. MACHINING 0.4 1.6 3.2 6.3 12.6 25 ROUGH

VIEW ON 'A' SHOWING DRILLING PATTERN AND OTHER DETAILS

A

979

893 0.5

819 G

21 718 +0/+0.4

G1,2

31

15

G1

18

102 1

92

83

18

G2

9

21 G1,2

G 31 716

753 0.5 G

823

935 +0/-0.4

xM=11 940

REV DATE MODIFICATION REVISED BY

Non toleranced dimensions to ISO 2768-1 m;

GEAR DATA SPUR GEAR

All burrs and sharp edges to be removed; Standard corner chamfer 1mm x 45

Internal radial and axial clearance figures to JB/T 10471-2004

Orleton Lane, Wellington, Telford, TF1 2BG, England

HARDENED GEAR NO

The HARDNESS GAP is to be indicated either by stamped letter R or a RED PAINT mark on the

NUMBER OF TEETH (z)

94 MODULE (m) 10 exterior surface Ph 01952 222300 Fax 01952 242938

The high point of gear eccentricity to be indicated by GREEN or BLUE paint on 3 teeth

PRESSURE ANGLE (Q) 20 DP www.nbcgroup.co.uk

ADDENDUM COEFFICIENT (x) 1.1 AXIAL PLAY 0.04 - 0.22 mm

BOLT DATA

PROFILE CORRECTION (xm) 11 mm CALCULATED GEAR STRENGTH RADIAL PLAY 0.04 - 0.22 mm

TRUNCATION (km) -1.5 mm Fz (Normal) 152 KN INNER 36 = MOUNTING HOLES 21 CS TURNING TORQUE NBC DRAWING NUMBER DRAWN: LJM

PITCH CIRCLE DIAMETER 940 mm Fz (Max) KN OUTER 36 = MOUNTING HOLES 21 CS MATERIAL 42CrMo4 DATE: 01/05/2012

MEASUREMENT ON K TEETH

RUNOUT NOT HARDENED/HARDENED

'G'

'FS'

2+4

LOADING PLUG

GREASE HOLES

'R'

M10

SOFT ZONE

WEIGHT

DEPTH OF HARDENING (55-60HRc)

208 kg (est)

mm

SEG 979 2 25 01 AA LM

You might also like

- Roscas Api Planos 1-29 PDFDocument41 pagesRoscas Api Planos 1-29 PDFJesus Cacharuco100% (3)

- JCB 444 Tier III Electronic Supplement - Issue2Document38 pagesJCB 444 Tier III Electronic Supplement - Issue2Epure Gabriel100% (6)

- JCB 444 Tier III Electronic Supplement - Issue2Document38 pagesJCB 444 Tier III Electronic Supplement - Issue2Epure Gabriel100% (6)

- Linked PDFDocument379 pagesLinked PDFEpure Gabriel50% (2)

- TDL Reference ManualDocument567 pagesTDL Reference Manualdcpkahdar100% (1)

- PO Purchase Order in ExcelDocument2 pagesPO Purchase Order in ExcelAziz Khan LodhiNo ratings yet

- 710DDocument798 pages710DSegundo Francisco Jauregui Valencia75% (4)

- Linear System Theory and Design (3rd Ed) - Chi-Tsang ChenDocument176 pagesLinear System Theory and Design (3rd Ed) - Chi-Tsang Chenabnaod5363No ratings yet

- Dystopian Wars FluffDocument13 pagesDystopian Wars FluffFinin Chisholm100% (2)

- Drawing Standard Amada Xtreme: Rolling MarkingDocument1 pageDrawing Standard Amada Xtreme: Rolling MarkingSami SAADINo ratings yet

- Ibcm 102Document1 pageIbcm 102Shyam J VyasNo ratings yet

- Spoun MouldDocument8 pagesSpoun MouldRajanNo ratings yet

- In/Mm 2:1: B-SIZE 172672Document2 pagesIn/Mm 2:1: B-SIZE 172672GeeNo ratings yet

- LS900161V01 - CustDocument1 pageLS900161V01 - CustAWNISH PRASAD SINGHNo ratings yet

- Grayhill 07272021 7db2d6 0ae3ffad0fce4a2db89a57cea-2509346Document17 pagesGrayhill 07272021 7db2d6 0ae3ffad0fce4a2db89a57cea-2509346ALEJANDRONo ratings yet

- NUT 11.500 4TPI OTIS - IdwDocument1 pageNUT 11.500 4TPI OTIS - IdwNhoj AicragNo ratings yet

- Drawing Standard Amada Xtreme: Lmax 580 3 Lmin 450 3 Stroke 130 3Document1 pageDrawing Standard Amada Xtreme: Lmax 580 3 Lmin 450 3 Stroke 130 3Sami SAADINo ratings yet

- Section A-A Scale 1 / 2: Pete Lenz 8/21/2010Document8 pagesSection A-A Scale 1 / 2: Pete Lenz 8/21/2010Manish PatilNo ratings yet

- Drawing 1Document1 pageDrawing 1Monse HernándezNo ratings yet

- Released CEM Standard ACS M/L/XL Heatsink FDocument1 pageReleased CEM Standard ACS M/L/XL Heatsink FAmc Forklift ElektrikNo ratings yet

- Seal Assy Stationary, Oil-Brg: Holes To Be Match Drilled I +-0002 0 .1884 - .000 3Document2 pagesSeal Assy Stationary, Oil-Brg: Holes To Be Match Drilled I +-0002 0 .1884 - .000 3primaasiapasifikNo ratings yet

- Datasheet CM100DU-34KADocument4 pagesDatasheet CM100DU-34KAOscar Ortega EstarriagaNo ratings yet

- RB 2885 0101Document1 pageRB 2885 0101AWNISH PRASAD SINGHNo ratings yet

- 2-3 Turk'S Head Roll SM120A - 75x75 - L75: 33047 REMANZACCO (UD)Document2 pages2-3 Turk'S Head Roll SM120A - 75x75 - L75: 33047 REMANZACCO (UD)Alejandra ChocueNo ratings yet

- Cm200dy-24nf eDocument4 pagesCm200dy-24nf eWesamNo ratings yet

- H12092021-004 CIW Drilling Choke GADocument1 pageH12092021-004 CIW Drilling Choke GAJitendra BhosaleNo ratings yet

- 337970A Mast System EX141-18-3.9Document5 pages337970A Mast System EX141-18-3.9Simion NechitiNo ratings yet

- Drawing Standard Amada Xtreme: Lmax 580 3 227 3 Lmin 450 3 Stroke 130 3 130 3Document1 pageDrawing Standard Amada Xtreme: Lmax 580 3 227 3 Lmin 450 3 Stroke 130 3 130 3Sami SAADINo ratings yet

- SMA - MOLEX Drawing 732511150 - SDDocument1 pageSMA - MOLEX Drawing 732511150 - SDJose MatutesNo ratings yet

- TASK 2. 07 CL END PLATE Drawing v1Document1 pageTASK 2. 07 CL END PLATE Drawing v1Asni BerlianNo ratings yet

- CM100DY-24NF MitsubishiElectricSemiconductorDocument4 pagesCM100DY-24NF MitsubishiElectricSemiconductorJerry LeeNo ratings yet

- Cold Strecth Tank DesignDocument1 pageCold Strecth Tank DesignjirrsamaNo ratings yet

- OL-388.8-Hitachi 20211203184635.614 XDocument1 pageOL-388.8-Hitachi 20211203184635.614 XWilson AlvesNo ratings yet

- TB Driven Pully 140 TeethDocument2 pagesTB Driven Pully 140 TeethshreerajpatiloppNo ratings yet

- TCD 2013, 2200 090 KW TCD 2013 L04 2V Q680 Tier3Document1 pageTCD 2013, 2200 090 KW TCD 2013 L04 2V Q680 Tier3Michael BogdanNo ratings yet

- Measurement Protocol/ Quality Control Report Required: X-Stand-SHEETMETAL-1,5mmDocument1 pageMeasurement Protocol/ Quality Control Report Required: X-Stand-SHEETMETAL-1,5mmmeteforex1No ratings yet

- Cm100dy-24a eDocument5 pagesCm100dy-24a eDamian MadryNo ratings yet

- Governor Adjustment Data Sheet: Adjustments: Droop Aneroid /LDA Torque SettingDocument1 pageGovernor Adjustment Data Sheet: Adjustments: Droop Aneroid /LDA Torque SettingMichael BogdanNo ratings yet

- R Linear Bearings - Product Range: Closed, Anodised Aluminium AdapterDocument1 pageR Linear Bearings - Product Range: Closed, Anodised Aluminium Adapterlifnur hadiNo ratings yet

- Flyer Robot GP180 E 11.2020Document2 pagesFlyer Robot GP180 E 11.2020pruma.ruNo ratings yet

- Block Mill Pass Profile PDFDocument1 pageBlock Mill Pass Profile PDFAmit RayNo ratings yet

- Section A-A (1:3) : 220Ø P Ø3 in A 4 PlacesDocument1 pageSection A-A (1:3) : 220Ø P Ø3 in A 4 PlacesCarlos LópezNo ratings yet

- Ibcm 142Document1 pageIbcm 142Shyam J VyasNo ratings yet

- TCD 2013, 2300 093 KW TCD 2013 L04 2V Q410 Tier3Document1 pageTCD 2013, 2300 093 KW TCD 2013 L04 2V Q410 Tier3Michael BogdanNo ratings yet

- TCD 2013, 2200 099 KW TCD 2013 L04 2V Q410 Tier3 NOX4Document1 pageTCD 2013, 2200 099 KW TCD 2013 L04 2V Q410 Tier3 NOX4Michael BogdanNo ratings yet

- Adapter Spool FlangDocument1 pageAdapter Spool FlangRuslan BayramovNo ratings yet

- Cylinder Ripper LiftDocument8 pagesCylinder Ripper LiftVins SquadNo ratings yet

- Mandrel SWD IndustriDocument1 pageMandrel SWD IndustriDinsosnakertrans KudusNo ratings yet

- TCD 2013, 2200 087 KW TCD 2013 L04 2V Q410 Tier3 NOX4Document1 pageTCD 2013, 2200 087 KW TCD 2013 L04 2V Q410 Tier3 NOX4Michael BogdanNo ratings yet

- AR-15 Bolt Schematic Part 1Document1 pageAR-15 Bolt Schematic Part 1S KlarsNo ratings yet

- TCD 2013, 2200 071 KW TCD 2013 L04 2V Q400 Tier3Document1 pageTCD 2013, 2200 071 KW TCD 2013 L04 2V Q400 Tier3Michael BogdanNo ratings yet

- Tctl-U (RLLB) Terminales de Compresión IDocument1 pageTctl-U (RLLB) Terminales de Compresión Ijavier SuarezNo ratings yet

- TCD 2013, 2300 088 KW TCD 2013 L04 2V Q410 Tier3Document1 pageTCD 2013, 2300 088 KW TCD 2013 L04 2V Q410 Tier3Michael BogdanNo ratings yet

- Wi A Al: ArmipmDocument3 pagesWi A Al: ArmipmDinesh YkatilNo ratings yet

- Molex Micro-Fit (3.0) Bmi Vertical ReceptacleDocument2 pagesMolex Micro-Fit (3.0) Bmi Vertical ReceptacleVijoy PaulNo ratings yet

- It Should Be Less Than R /3 or 10mDocument5 pagesIt Should Be Less Than R /3 or 10mMawan BentzNo ratings yet

- TCD 2013, 2200 064 KW TCD 2013 L04 2V Q400 Tier3Document1 pageTCD 2013, 2200 064 KW TCD 2013 L04 2V Q400 Tier3Michael BogdanNo ratings yet

- TCD 2013, 2200 099 KW TCD 2013 L04 2V Q680 Tier3Document1 pageTCD 2013, 2200 099 KW TCD 2013 L04 2V Q680 Tier3Michael BogdanNo ratings yet

- Week 2 HomeworkDocument1 pageWeek 2 HomeworkGibsonNo ratings yet

- Cm200du 12FDocument4 pagesCm200du 12FAna Cuahutli Sanchez MartinezNo ratings yet

- MFD03074 - HSS TS STEP DRILL Ø8.2XSL19.54XR0.5XØ16XSL5XC45°XØ22XFL80XOAL165XMT2-ModelDocument1 pageMFD03074 - HSS TS STEP DRILL Ø8.2XSL19.54XR0.5XØ16XSL5XC45°XØ22XFL80XOAL165XMT2-Modell.a.s.t.t.r.y.1.7.2.9No ratings yet

- Series 77: Single Deck Rotary SwitchesDocument5 pagesSeries 77: Single Deck Rotary SwitchesJosé Ignacio CandelaNo ratings yet

- Ibcm 84Document1 pageIbcm 84Shyam J VyasNo ratings yet

- Fiat 8065 PDFDocument6 pagesFiat 8065 PDFigorkov100% (1)

- Drw. Surface Texture: 1. Break All Edges. 2Document1 pageDrw. Surface Texture: 1. Break All Edges. 2Ruslan BayramovNo ratings yet

- Green Pin Open Spelter Sockets Group MBL: G-6412: SKGOS042: 170tDocument1 pageGreen Pin Open Spelter Sockets Group MBL: G-6412: SKGOS042: 170tSergioHurtadoAvellaNo ratings yet

- Pa000006-Guide Rod - Dia12x215Document1 pagePa000006-Guide Rod - Dia12x215YAGNA V YAGNA VNo ratings yet

- Kit 12 TFDocument1 pageKit 12 TFEpure GabrielNo ratings yet

- Motor DataDocument1 pageMotor DataEpure GabrielNo ratings yet

- QXL230817ADocument1 pageQXL230817AEpure GabrielNo ratings yet

- ReceiptDocument1 pageReceiptEpure GabrielNo ratings yet

- Screencapture Kamarkhani Info Calculation Single Girder 2022 11 01 21 - 51 - 01Document3 pagesScreencapture Kamarkhani Info Calculation Single Girder 2022 11 01 21 - 51 - 01Epure GabrielNo ratings yet

- Buletin JCB Platou CutieDocument2 pagesBuletin JCB Platou CutieEpure GabrielNo ratings yet

- Attestation Certificate of Machinery and Electromagnetic Compatibility DirectivesDocument1 pageAttestation Certificate of Machinery and Electromagnetic Compatibility DirectivesEpure GabrielNo ratings yet

- Manual Misia1 End CarriageDocument44 pagesManual Misia1 End CarriageEpure GabrielNo ratings yet

- Screencapture Kamarkhani Info Calculation Double Girder 2022 11 01 21 - 53 - 14Document3 pagesScreencapture Kamarkhani Info Calculation Double Girder 2022 11 01 21 - 53 - 14Epure GabrielNo ratings yet

- Holdwell Inventory JCB Catalogue 2020Document16 pagesHoldwell Inventory JCB Catalogue 2020Epure GabrielNo ratings yet

- 3.ELK Crane Geared Motor CatalogueDocument6 pages3.ELK Crane Geared Motor CatalogueEpure GabrielNo ratings yet

- 10 Ton American Crane DG TR 17534503r1Document1 page10 Ton American Crane DG TR 17534503r1Epure GabrielNo ratings yet

- Joystick TerexDocument16 pagesJoystick TerexEpure GabrielNo ratings yet

- Payment in Full or A 10% Deposit Is Required To Secure An EngineDocument1 pagePayment in Full or A 10% Deposit Is Required To Secure An EngineEpure Gabriel100% (1)

- Hydra Perm Co LTD Unit 20 Silver Court Intercity Way Bramley, Leeds West Yorkshire LS13 4LYDocument1 pageHydra Perm Co LTD Unit 20 Silver Court Intercity Way Bramley, Leeds West Yorkshire LS13 4LYEpure GabrielNo ratings yet

- Power Shift TransmissionDocument10 pagesPower Shift TransmissionEpure GabrielNo ratings yet

- Genuine Delphi "Cva Kits": (Nozzle+ D/Valve)Document2 pagesGenuine Delphi "Cva Kits": (Nozzle+ D/Valve)smail bl100% (2)

- Manual Misia2Document64 pagesManual Misia2Epure GabrielNo ratings yet

- Design and Analysis of Column Mounted JIDocument21 pagesDesign and Analysis of Column Mounted JIEpure GabrielNo ratings yet

- Manuale Misia Chain HoistDocument40 pagesManuale Misia Chain HoistEpure GabrielNo ratings yet

- R05001D, Injector CR, Common Rail System DELPHI 320-06623Document1 pageR05001D, Injector CR, Common Rail System DELPHI 320-06623Epure GabrielNo ratings yet

- Ciocan Omp JCB PDFDocument2 pagesCiocan Omp JCB PDFEpure GabrielNo ratings yet

- 28317158,320-06881 Injector CR, Common Rail System DELPHIDocument1 page28317158,320-06881 Injector CR, Common Rail System DELPHIEpure GabrielNo ratings yet

- Echivalenti Filtre CatDocument5 pagesEchivalenti Filtre CatEpure GabrielNo ratings yet

- Echivalenti Clarcor JCBDocument18 pagesEchivalenti Clarcor JCBEpure GabrielNo ratings yet

- Technical Information: ! Safety Notice Page 1 of 5Document5 pagesTechnical Information: ! Safety Notice Page 1 of 5Epure Gabriel100% (2)

- Cmsis End User Licence AgreementDocument3 pagesCmsis End User Licence AgreementSindhuja VsNo ratings yet

- MydealsDocument23 pagesMydealsShagun BkumarNo ratings yet

- FILE TÓM TẮT SÁCH QTCCU - TIẾNG ANHDocument132 pagesFILE TÓM TẮT SÁCH QTCCU - TIẾNG ANHVit BeNo ratings yet

- Writing The Project Report 2Document3 pagesWriting The Project Report 2api-222015490No ratings yet

- 4.B Students Profile and Progress Report Fillable PDF Prof. Sam Bernales Jr. 2Document1 page4.B Students Profile and Progress Report Fillable PDF Prof. Sam Bernales Jr. 2Edgar Vergara CamoroNo ratings yet

- SOPRA Banking Tool PDFDocument27 pagesSOPRA Banking Tool PDFavNo ratings yet

- 1-Legal Tech and The Future of Civil JusticeDocument4 pages1-Legal Tech and The Future of Civil JusticejoaocoelhoNo ratings yet

- 7 OrderReshop 18.1 Implementation GuideDocument295 pages7 OrderReshop 18.1 Implementation Guidesubhayan.nittNo ratings yet

- PM 120A Fork Lift - May 2009 - Bhequipment - Co.zaDocument137 pagesPM 120A Fork Lift - May 2009 - Bhequipment - Co.zaMark Ferries-ScottNo ratings yet

- Case Study Slum RehabilitationDocument5 pagesCase Study Slum RehabilitationBerisha PearlNo ratings yet

- Weld Information Collection SystemDocument46 pagesWeld Information Collection Systemaabhimittal0% (1)

- dhc6 400 Relavop Original VersionDocument30 pagesdhc6 400 Relavop Original VersionJose Francisco Colina100% (1)

- Zvldor - Quot 20211013073547Document2 pagesZvldor - Quot 20211013073547ULLAS KRISHNAN J NNo ratings yet

- Datasheet LA1805 (AM-FM-IF-MPX Tuner System)Document13 pagesDatasheet LA1805 (AM-FM-IF-MPX Tuner System)vanmarteNo ratings yet

- SEO Tools: 7:google: Webmaster Tool, Google Analytics (Total Website InformationDocument8 pagesSEO Tools: 7:google: Webmaster Tool, Google Analytics (Total Website InformationTOP RSNo ratings yet

- Anticipated Failure DeterminationDocument19 pagesAnticipated Failure Determinationangelesmtz69927No ratings yet

- HCM15R Manual - 2002 - Issue 1Document4 pagesHCM15R Manual - 2002 - Issue 1hamidon3No ratings yet

- Mmmmmetro Electrical VariationDocument80 pagesMmmmmetro Electrical VariationchristianNo ratings yet

- Timetable HogwartsDocument36 pagesTimetable Hogwartsharshit.royNo ratings yet

- Creating UI Elements Dynamically in Abap Webdynpro ApplicationDocument5 pagesCreating UI Elements Dynamically in Abap Webdynpro ApplicationHarkesh Kumar YadavNo ratings yet

- Circulation in A LaundryDocument4 pagesCirculation in A LaundryDyna Wylene GardoniaNo ratings yet

- Journal of Cleaner ProductionDocument7 pagesJournal of Cleaner ProductionmarilauraNo ratings yet

- Nissan hr16 Taller PDFDocument237 pagesNissan hr16 Taller PDFJhon Sanchez Lopez100% (2)

- DNV OS D301 Fire ProtectionDocument46 pagesDNV OS D301 Fire ProtectionRicardo Gavilan Bendezu100% (1)