Professional Documents

Culture Documents

Observation

Observation

Uploaded by

kathrineOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Observation

Observation

Uploaded by

kathrineCopyright:

Available Formats

V.

Observation

The group has deduced that it is not very difficult to make your own logic trainer. But,

extreme caution is required in order to carry out the experiment properly. Since almost all the

components used are heat or temperature sensitive, it is a must to properly time the soldering

process. Taking too long during the soldering process may cause the component to overheat and

totally cut off the completion of the circuit.

Since the group used the manual method in placing the print on the board, it is quite

difficult since the lines in the lay-out are so close together therefore, it is advisable to use an

extremely sharp and precise knife to cut the lay-out. After cutting the lay-out is the etching

process which we didnt find that difficult and problematic.

After the etching process, the group used sand paper for the finishing touches which

made the copper plating shine. After which, the continuity of the circuit lay-out is checked. Some

of the parts which are so close together may be missed out during the etching process thus, it is a

must to check each one.

After checking, the drilling process now begins. The drilling process is very crucial since

the components legs have very specific spacing and sizes. Each one must be noted before drilling

holes in the printed circuit board. As soon as everything is good, the components may now be

placed. After checking, soldering and finalizing, the circuit of a magnitude comparator can now

be implemented.

As seen in the results portion, the circuit was properly implemented since the

characteristics of the magnitude comparator were correct. Thus, the group has concluded that the

logic trainer created is one that is reliable.

You might also like

- Anchor Bolt MSDocument7 pagesAnchor Bolt MSGaneshNo ratings yet

- Report FittingDocument33 pagesReport FittingNaqiuddin MuhamadNo ratings yet

- Report of Milling Project Lab 2Document12 pagesReport of Milling Project Lab 2Mohd Danial H100% (2)

- ME2257 Computer Aided Machine Drawing ManualDocument60 pagesME2257 Computer Aided Machine Drawing ManualRanjit Rajendran100% (1)

- FittingDocument7 pagesFittingAniz Farznor SariffuddinNo ratings yet

- Fakulti Teknologi Kejuruteraan Universiti Teknikal Malaysia MelakaDocument11 pagesFakulti Teknologi Kejuruteraan Universiti Teknikal Malaysia MelakaAbdul AzimNo ratings yet

- Engineering Workshp Report HDocument9 pagesEngineering Workshp Report HVivek RaoNo ratings yet

- Welding ProjectDocument21 pagesWelding ProjectOmachar JohnwalterNo ratings yet

- FhszhsazfhnfDocument20 pagesFhszhsazfhnfMahes WarNo ratings yet

- Chung Cheang Ping (20dkm18f2032)Document16 pagesChung Cheang Ping (20dkm18f2032)Syfull musicNo ratings yet

- Stub Setting ReportDocument7 pagesStub Setting ReportUanaid Van RooyenNo ratings yet

- Introduction To Soldering and Desoldering Techniques.Document6 pagesIntroduction To Soldering and Desoldering Techniques.Arsalan Ahmed100% (1)

- Plate 7.2 COPPER TUBE OPERATIONDocument10 pagesPlate 7.2 COPPER TUBE OPERATIONtornomarialynNo ratings yet

- Plate 7.3 BASIC WELDING ANGADocument11 pagesPlate 7.3 BASIC WELDING ANGAjason.angaNo ratings yet

- Group 1 WorkshopDocument5 pagesGroup 1 Workshop2000809546No ratings yet

- Chapter Four Project Carried Out During Siwes: 4.0 Machining A Cylindrical Bar 4.1 ObjectivesDocument5 pagesChapter Four Project Carried Out During Siwes: 4.0 Machining A Cylindrical Bar 4.1 ObjectivesDesmond NwadikeNo ratings yet

- Faculty of Mechanical and Manufacturing Engineering Department of Mechanical EngineeringDocument10 pagesFaculty of Mechanical and Manufacturing Engineering Department of Mechanical EngineeringEzzuan RaesNo ratings yet

- Mig ReportDocument14 pagesMig ReportDhana KumaranNo ratings yet

- Study Case Report 3Document2 pagesStudy Case Report 3Erick RiveraNo ratings yet

- Worksop Artefact Report - 231123 - 120644Document23 pagesWorksop Artefact Report - 231123 - 120644aaronmking.r35No ratings yet

- Lab Report Lathe (Sem 2)Document9 pagesLab Report Lathe (Sem 2)venosyah devanNo ratings yet

- Familiarization With Sheet-Metal Forming Il: Module Name: ME2024 Semester: 3Document9 pagesFamiliarization With Sheet-Metal Forming Il: Module Name: ME2024 Semester: 3Awishka EashanNo ratings yet

- RAMS Generic StatementsDocument25 pagesRAMS Generic Statementsdbrocklehurst13No ratings yet

- Assingment 1 Welding TechnologyDocument14 pagesAssingment 1 Welding TechnologyMuhammad Sufi MustafaNo ratings yet

- Report Pipe GiDocument11 pagesReport Pipe GiMai SarahNo ratings yet

- Laboratory Manual: MEC 317 Manufacturing Technology LaboratoryDocument27 pagesLaboratory Manual: MEC 317 Manufacturing Technology LaboratorySunil SharmaNo ratings yet

- Tugas Bahasa Inggris Teknik Untuk Observasi Ke Bengkel 2014 Bahasa InggrisDocument9 pagesTugas Bahasa Inggris Teknik Untuk Observasi Ke Bengkel 2014 Bahasa InggrisMuhammad BarilNo ratings yet

- First: (Intro) (Lalai) : "Removal and Replacement of Discrete Components" #Script For The Video !!! Lezz Do ThisssDocument5 pagesFirst: (Intro) (Lalai) : "Removal and Replacement of Discrete Components" #Script For The Video !!! Lezz Do ThissshillaryNo ratings yet

- ObjectDocument77 pagesObjectامير بشير جوادNo ratings yet

- Arc ReportDocument6 pagesArc ReportAmmr ZmbrNo ratings yet

- In Plant Training Report - Sanjay SureshDocument13 pagesIn Plant Training Report - Sanjay SureshAshutosh Prakash Mishra0% (2)

- Chess Piece: Nandha Engineering College (Autonomous)Document9 pagesChess Piece: Nandha Engineering College (Autonomous)Sowmiya MahendranNo ratings yet

- Work Shop Practice-Ii: Diploma in Mechanical EngineeringDocument36 pagesWork Shop Practice-Ii: Diploma in Mechanical EngineeringLEAGUE OF WARLORDSNo ratings yet

- Laboratory Manual: II Year B. Tech II-Semester Mechanical EngineeringDocument48 pagesLaboratory Manual: II Year B. Tech II-Semester Mechanical EngineeringNaga KiranNo ratings yet

- Exp.3 Specimen PreparationDocument9 pagesExp.3 Specimen PreparationG. Dancer GhNo ratings yet

- Plant LayoutDocument47 pagesPlant LayoutAnupam RanaNo ratings yet

- How To Pass The AWS D1Document11 pagesHow To Pass The AWS D1Lazaro CoutinhoNo ratings yet

- Design For Assenbly-1Document33 pagesDesign For Assenbly-1Mohamed FaragNo ratings yet

- TA-201 Lab MannualDocument19 pagesTA-201 Lab MannualAnujNagpalNo ratings yet

- 360 Degree Flexible Drilling Machine ReportDocument26 pages360 Degree Flexible Drilling Machine ReportSapna KumariNo ratings yet

- PM 1Document225 pagesPM 1danielrita570No ratings yet

- Practical 15,16,17,21Document11 pagesPractical 15,16,17,21Muhammad AwaisNo ratings yet

- Manufacture of Welding StandsDocument4 pagesManufacture of Welding Stands6dqqt6zjmjNo ratings yet

- Electrofusion WeldingDocument4 pagesElectrofusion WeldingRajesh RadeNo ratings yet

- European University of LefkeDocument13 pagesEuropean University of Lefkeصمتي شموخيNo ratings yet

- Lab File - Work RestDocument5 pagesLab File - Work RestSiddharthNo ratings yet

- Welding ProjectDocument10 pagesWelding ProjectSean LimNo ratings yet

- EPAS 11 - Q1 - W7 - Mod5Document40 pagesEPAS 11 - Q1 - W7 - Mod5Alberto A. FugenNo ratings yet

- Project ProposalDocument6 pagesProject ProposalRehan AmjadNo ratings yet

- Chapter 3&4: Jig and FixturesDocument55 pagesChapter 3&4: Jig and FixturesSenay HaftuNo ratings yet

- Valve SpringDocument6 pagesValve SpringSaddam LemuNo ratings yet

- Lab Report FittingDocument10 pagesLab Report FittingThiruvarasan M RavindranNo ratings yet

- Ta 201 A Laboratory ManualDocument22 pagesTa 201 A Laboratory ManualSunitNo ratings yet

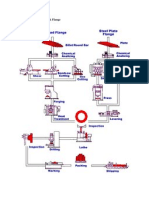

- Process Flow of Weld Neck FlangeDocument7 pagesProcess Flow of Weld Neck FlangeAmin KhairiNo ratings yet

- Manufacturing Processes LabDocument53 pagesManufacturing Processes LabUjjwal kecNo ratings yet

- PT SSA Sinar Surya ALumindo - Lampiran Methode LRT - Approval Louvre InteriorDocument13 pagesPT SSA Sinar Surya ALumindo - Lampiran Methode LRT - Approval Louvre InteriorfalahaskarNo ratings yet

- Laboratory Manual: College of Engineering, OsmanabadDocument47 pagesLaboratory Manual: College of Engineering, OsmanabadEngr Ali RazaNo ratings yet

- Workshop ManualDocument60 pagesWorkshop ManualSadasiva Rao T83% (6)

- Welding ReportDocument11 pagesWelding ReportJia Yee Ten100% (1)

- Thanks To Layla Mick For Adding These Lyrics. Writer(s) : Jillian BanksDocument2 pagesThanks To Layla Mick For Adding These Lyrics. Writer(s) : Jillian BankskathrineNo ratings yet

- Newton Raphson MethodDocument2 pagesNewton Raphson MethodkathrineNo ratings yet

- Digital Logic Circuit and Switching TheoryDocument20 pagesDigital Logic Circuit and Switching TheorykathrineNo ratings yet

- Pinoy Bix Radio Wave Propagation Answer KeyDocument14 pagesPinoy Bix Radio Wave Propagation Answer KeykathrineNo ratings yet

- Transmission MCQ Pinoy Bix 400Document23 pagesTransmission MCQ Pinoy Bix 400kathrineNo ratings yet

- Transmission MCQ Pinoy Bix 400Document23 pagesTransmission MCQ Pinoy Bix 400kathrineNo ratings yet