Professional Documents

Culture Documents

Formulation and Invitro Evaluation of Hydrocodone Oral Sustained Release Tablets

Formulation and Invitro Evaluation of Hydrocodone Oral Sustained Release Tablets

Uploaded by

Baru Chandrasekhar RaoCopyright:

Available Formats

You might also like

- Teaching Plan For Patient With ArthritisDocument1 pageTeaching Plan For Patient With ArthritisLouel VicitacionNo ratings yet

- Lercanidipine Hydrochloride 10mg and 20mg Film-Coated TabletsDocument65 pagesLercanidipine Hydrochloride 10mg and 20mg Film-Coated TabletsPai GampaengkamNo ratings yet

- 10 Rights of Drug Administration With Nursing ImplicationsDocument3 pages10 Rights of Drug Administration With Nursing ImplicationsJet Bautista100% (6)

- Opleidingen Voor Personal Trainers - Deel 1 OVERLOAD WORLDWIDEDocument27 pagesOpleidingen Voor Personal Trainers - Deel 1 OVERLOAD WORLDWIDEOverload WorldwideNo ratings yet

- Perspective in PharmacyDocument3 pagesPerspective in PharmacyAgniez Hannah Permites100% (4)

- 4.nag NifedipinebuccalRamreddy Dec 2012Document16 pages4.nag NifedipinebuccalRamreddy Dec 2012Siddhesh KharmateNo ratings yet

- Attachment PDFDocument10 pagesAttachment PDFHEPHZIBAH CHILAKANo ratings yet

- IJISRT21 MAY192 KuldeepDocument11 pagesIJISRT21 MAY192 KuldeepKuldeep VinchurkarNo ratings yet

- Design and Characterisation of Glimepiride and Pioglitazone Bilayered TabletsDocument61 pagesDesign and Characterisation of Glimepiride and Pioglitazone Bilayered TabletsUthej ReddyNo ratings yet

- Review Article Sep 2018Document11 pagesReview Article Sep 2018Vitor JacóNo ratings yet

- Design and Characterization of Nizatidine Effervescent Floating Matrix Tablets Employing Semisynthetic Rate-Retarding PolymersDocument11 pagesDesign and Characterization of Nizatidine Effervescent Floating Matrix Tablets Employing Semisynthetic Rate-Retarding PolymersSriram NagarajanNo ratings yet

- Available Online at ISSN 2278 - 0033: WWW - Novelsciencepharmacy.infoDocument7 pagesAvailable Online at ISSN 2278 - 0033: WWW - Novelsciencepharmacy.infoDoinitaNo ratings yet

- Ijpdt 8 (2) 2018 12-36Document25 pagesIjpdt 8 (2) 2018 12-36wlNo ratings yet

- Experimental Work: KCT'S R.G. Sapkal College of Pharmacy, Anjaneri, NashikDocument14 pagesExperimental Work: KCT'S R.G. Sapkal College of Pharmacy, Anjaneri, NashikPrasad ShiroleNo ratings yet

- Formulation and Evaluation of Gliclazide Immediate Release and Metformin Sustain Release Bilayer TabletDocument13 pagesFormulation and Evaluation of Gliclazide Immediate Release and Metformin Sustain Release Bilayer TabletEditor IJTSRDNo ratings yet

- Formulation and In-Vitro Characterisation of Sustained Releasemetronidazole Cocoa Butter SuppositoriesDocument7 pagesFormulation and In-Vitro Characterisation of Sustained Releasemetronidazole Cocoa Butter SuppositoriesRowaidaNo ratings yet

- Tablet Characteristics and Pharmacokinetics of Orally Disintegrating Tablets Containing Coenzyme Q10 Granules Prepared by Different MethodsDocument13 pagesTablet Characteristics and Pharmacokinetics of Orally Disintegrating Tablets Containing Coenzyme Q10 Granules Prepared by Different MethodsMyPSA PHCNo ratings yet

- Article WJPR 1483163718Document17 pagesArticle WJPR 1483163718Fahim FahimNo ratings yet

- IJPCR, Vol 4, Issue 4, Article 3Document4 pagesIJPCR, Vol 4, Issue 4, Article 3clementinaelvira200023No ratings yet

- 4.dileep Clopidogrel Oct 2012Document11 pages4.dileep Clopidogrel Oct 2012Suman kamuruNo ratings yet

- 7Document5 pages7Giselda FarmasiNo ratings yet

- Development and Evaluation of Enteric Coated Omeprazole Pellets 22.5% W/WDocument8 pagesDevelopment and Evaluation of Enteric Coated Omeprazole Pellets 22.5% W/Wvanvu buiNo ratings yet

- Formulation and Evaluation of Voglibose Mouth Dissolving TabletDocument30 pagesFormulation and Evaluation of Voglibose Mouth Dissolving Tabletbhagwan das vaishnavNo ratings yet

- Formulation and Characterization of Clarithromycin Floating Tablets by Using Various PolymersDocument11 pagesFormulation and Characterization of Clarithromycin Floating Tablets by Using Various PolymersIJAR JOURNALNo ratings yet

- 2 Vinay (2012)Document15 pages2 Vinay (2012)Abdullah ZenNo ratings yet

- Degradation Study of Different Brands of Rosuvastatin Calcium Tablet in Bangladesh Using UV SpectrophotometerDocument4 pagesDegradation Study of Different Brands of Rosuvastatin Calcium Tablet in Bangladesh Using UV SpectrophotometerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- PDF MPJ 640Document12 pagesPDF MPJ 640Risnawa Puji AstutiNo ratings yet

- Formulation and In-Vitro Dissolution of Clopidogrel Tablet by Using Sodium Starch Glycolate and Natural Xanthan GumDocument4 pagesFormulation and In-Vitro Dissolution of Clopidogrel Tablet by Using Sodium Starch Glycolate and Natural Xanthan GumPRASANTA KUMAR MOHAPATRANo ratings yet

- Formulation and Evaluation of Sustained Release Matrix Tablets of GliclazideDocument3 pagesFormulation and Evaluation of Sustained Release Matrix Tablets of Gliclazidequangoanh12042001No ratings yet

- 868-Article Text-2464-1-10-20140515Document6 pages868-Article Text-2464-1-10-20140515nisa nurhidayatiNo ratings yet

- Jurnal 4Document11 pagesJurnal 4saprifarmasiNo ratings yet

- Formulation and Evaluation of Sustained Release Metoprolol Succinate Tablet Using Hydrophilic Gums As Release ModifiersDocument5 pagesFormulation and Evaluation of Sustained Release Metoprolol Succinate Tablet Using Hydrophilic Gums As Release ModifiersAryanto DedyNo ratings yet

- Akhilesh Front PagesDocument11 pagesAkhilesh Front Pagescity cyberNo ratings yet

- Evaluate ODTDocument5 pagesEvaluate ODTcinthiasetiaNo ratings yet

- Jurnal Loperamide HCL BARUDocument3 pagesJurnal Loperamide HCL BARUcinthiasetiaNo ratings yet

- FDA QbD实例 速释片 Example QbD for IR Tablet (中英文对照)Document145 pagesFDA QbD实例 速释片 Example QbD for IR Tablet (中英文对照)dengboff96No ratings yet

- Optimization and Formulation of Orodispersible Tablets ofDocument7 pagesOptimization and Formulation of Orodispersible Tablets ofUmar AliNo ratings yet

- Chapter-4 Materials and MethodsDocument15 pagesChapter-4 Materials and MethodsSunil ChaudharyNo ratings yet

- 20.Md Musharraf Ali and V.saikishoreDocument9 pages20.Md Musharraf Ali and V.saikishoreBaru Chandrasekhar RaoNo ratings yet

- Analytical Method Development and Validation For The Estimation of The Azilsartan Medoxamil by RP HPLC Method in Bulk and Pharmaceutical Dosage FormDocument5 pagesAnalytical Method Development and Validation For The Estimation of The Azilsartan Medoxamil by RP HPLC Method in Bulk and Pharmaceutical Dosage FormEditor IJTSRDNo ratings yet

- Studies On Formulation and In-Vitro Evaluation of Mucoadhesive Microbeads of Rosuvastatin Calcium by Using Central Composite DesignDocument11 pagesStudies On Formulation and In-Vitro Evaluation of Mucoadhesive Microbeads of Rosuvastatin Calcium by Using Central Composite DesignInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Presentation by Chirag Kukreja M.pharm 2nd YearDocument28 pagesPresentation by Chirag Kukreja M.pharm 2nd YearChirag KukrejaNo ratings yet

- Formulation and Evaluation of Antifungal Micro Emulsion-Based Gel For Topical Drug Delivery Using MilletiapinnataDocument15 pagesFormulation and Evaluation of Antifungal Micro Emulsion-Based Gel For Topical Drug Delivery Using MilletiapinnataIJAR JOURNALNo ratings yet

- BCS Losartan PDFDocument8 pagesBCS Losartan PDFHesti HariantiNo ratings yet

- Formulation and Optimization of Solid DispersionDocument10 pagesFormulation and Optimization of Solid DispersionAdriana CastellanosNo ratings yet

- Abdul ResearchDocument13 pagesAbdul ResearchNutan Desai RaoNo ratings yet

- Formulation and In-Vitro Evaluation of Controlled Release Transdermal Drug Delivery System of Simvastatin A Model Hypocholesterolemia DrugDocument6 pagesFormulation and In-Vitro Evaluation of Controlled Release Transdermal Drug Delivery System of Simvastatin A Model Hypocholesterolemia DrugPRASANTA KUMAR MOHAPATRANo ratings yet

- 01piroxicamemulgel PDFDocument14 pages01piroxicamemulgel PDFNymas PutriNo ratings yet

- Proceedings 78 00035Document8 pagesProceedings 78 00035elang revyNo ratings yet

- Formulation Development and In-Vitro Evaluation of Bucoadhesive Tablet of Chlorpheniramine Maleate and Phenylephrine Hydrochloride in Combined Dosage FormDocument11 pagesFormulation Development and In-Vitro Evaluation of Bucoadhesive Tablet of Chlorpheniramine Maleate and Phenylephrine Hydrochloride in Combined Dosage FormNeerajNo ratings yet

- 30 Vol. 9 Issue 5 May 2018 IJPSR RA 8960Document6 pages30 Vol. 9 Issue 5 May 2018 IJPSR RA 8960rohan satwaraNo ratings yet

- Investigation of Different Lipid Based Materials As Matrices Designed To Control The Release of A Hydrophobic DrugDocument6 pagesInvestigation of Different Lipid Based Materials As Matrices Designed To Control The Release of A Hydrophobic DrugswabrijNo ratings yet

- Ftir FelodipineDocument6 pagesFtir FelodipineMelisa AprilianiNo ratings yet

- Formulation Development and Invitro Evaluation of Ranolazine Extended Release TabletsDocument6 pagesFormulation Development and Invitro Evaluation of Ranolazine Extended Release TabletsBaru Chandrasekhar RaoNo ratings yet

- Efecto de La Humedad de Los Excipientes en Formas Farmacéuticas Sólidas (Comprimidos)Document8 pagesEfecto de La Humedad de Los Excipientes en Formas Farmacéuticas Sólidas (Comprimidos)Héctor Fabio Leyton ArcosNo ratings yet

- Design and Evaluation of Transdermal Delivery System Containing Losartan PotassiumDocument6 pagesDesign and Evaluation of Transdermal Delivery System Containing Losartan PotassiumYvd SinghNo ratings yet

- Studies On Formulation and Evaluation of Bilayered Tablets of CurcuminDocument7 pagesStudies On Formulation and Evaluation of Bilayered Tablets of CurcuminMasayu Dinahya DiswantiNo ratings yet

- Advanced Pharmaceutics: International Journal ofDocument8 pagesAdvanced Pharmaceutics: International Journal ofdini hanifaNo ratings yet

- AB - Addition Cure HCR Impact of Inhibitors On The Elastomer Cure Profile PDFDocument7 pagesAB - Addition Cure HCR Impact of Inhibitors On The Elastomer Cure Profile PDFLin NiuNo ratings yet

- Design, Optimization and Pharmacodynamic Comparison of Dorzolamide Hydrochloride Soluble Ocular Drug Insert Prepared by Using 32 Factorial DesignDocument10 pagesDesign, Optimization and Pharmacodynamic Comparison of Dorzolamide Hydrochloride Soluble Ocular Drug Insert Prepared by Using 32 Factorial DesignANo ratings yet

- Formulation Design and Evaluation of Mucoadhesive Buccal Patch of Ketorolac For The Treatment of PeriodontitisDocument10 pagesFormulation Design and Evaluation of Mucoadhesive Buccal Patch of Ketorolac For The Treatment of PeriodontitisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Full TextDocument7 pagesFull TexttuayuNo ratings yet

- Drug Metabolism in Drug Design and Development: Basic Concepts and PracticeFrom EverandDrug Metabolism in Drug Design and Development: Basic Concepts and PracticeDonglu ZhangNo ratings yet

- Knowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyDocument8 pagesKnowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyBaru Chandrasekhar RaoNo ratings yet

- Development and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormDocument11 pagesDevelopment and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormBaru Chandrasekhar RaoNo ratings yet

- Analytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationDocument8 pagesAnalytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationBaru Chandrasekhar RaoNo ratings yet

- Gastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsDocument7 pagesGastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsBaru Chandrasekhar RaoNo ratings yet

- Pharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoDocument7 pagesPharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoBaru Chandrasekhar RaoNo ratings yet

- Review On: Inventory ManagementDocument8 pagesReview On: Inventory ManagementBaru Chandrasekhar RaoNo ratings yet

- A Brief Review On YawsDocument7 pagesA Brief Review On YawsBaru Chandrasekhar RaoNo ratings yet

- Relationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityDocument4 pagesRelationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityBaru Chandrasekhar RaoNo ratings yet

- Assessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaDocument7 pagesAssessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaBaru Chandrasekhar RaoNo ratings yet

- The Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalDocument11 pagesThe Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalBaru Chandrasekhar RaoNo ratings yet

- Descriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreDocument4 pagesDescriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreBaru Chandrasekhar RaoNo ratings yet

- Determination of Bioactive Compounds From Piper Nigrum L by Using Ft-Ir Spectroscopic AnalysisDocument3 pagesDetermination of Bioactive Compounds From Piper Nigrum L by Using Ft-Ir Spectroscopic AnalysisBaru Chandrasekhar RaoNo ratings yet

- Pharmacological and Phytochemical Evidence of Scutia Genus Plants - A ReviewDocument7 pagesPharmacological and Phytochemical Evidence of Scutia Genus Plants - A ReviewBaru Chandrasekhar RaoNo ratings yet

- DISTINCTIVE PHARMACOLOGICAL ACTIVITIES OF Eclipta Alba AND IT'S COUMESTAN WEDELOLACTONEDocument7 pagesDISTINCTIVE PHARMACOLOGICAL ACTIVITIES OF Eclipta Alba AND IT'S COUMESTAN WEDELOLACTONEBaru Chandrasekhar RaoNo ratings yet

- DETERMINATION OF BIOACTIVE COMPOUNDS FROM Piper Nigrum. L BY USING HPLC ANALYSISDocument3 pagesDETERMINATION OF BIOACTIVE COMPOUNDS FROM Piper Nigrum. L BY USING HPLC ANALYSISBaru Chandrasekhar RaoNo ratings yet

- RP-HPLC Method Development and Validation of Alogliptin Bulk and Tablet Dosage FormDocument8 pagesRP-HPLC Method Development and Validation of Alogliptin Bulk and Tablet Dosage FormBaru Chandrasekhar RaoNo ratings yet

- STUDIES ON QUALITATIVE PHYTOCHEMICAL ANALYSIS AND ANTIBACTERIAL ACTIVITY OF Piper NigrumDocument7 pagesSTUDIES ON QUALITATIVE PHYTOCHEMICAL ANALYSIS AND ANTIBACTERIAL ACTIVITY OF Piper NigrumBaru Chandrasekhar RaoNo ratings yet

- Determination of Bioactive Compounds From Piper Longum L. by Using HP-LC AnalysisDocument4 pagesDetermination of Bioactive Compounds From Piper Longum L. by Using HP-LC AnalysisBaru Chandrasekhar RaoNo ratings yet

- To Prepare gliclazide-SR PDFDocument11 pagesTo Prepare gliclazide-SR PDFNirav SoniNo ratings yet

- Pharmacy: Pharmacist Intervention Program at Different Rent Levels of Geriatric HealthcareDocument8 pagesPharmacy: Pharmacist Intervention Program at Different Rent Levels of Geriatric HealthcareAstiNo ratings yet

- Drug Study TramadolDocument2 pagesDrug Study TramadolJemina Rafanan Racadio100% (1)

- Plant HormonesDocument2 pagesPlant HormonesMuhammad Noman BhattiNo ratings yet

- 03 ON 2020 Prostate WBDocument43 pages03 ON 2020 Prostate WBabdullahNo ratings yet

- 7 Electrical Therapies Defib and PacingDocument16 pages7 Electrical Therapies Defib and PacingEricson LenovNo ratings yet

- Drug StudyDocument27 pagesDrug StudyMariefer EsplagoNo ratings yet

- Marijuana THC PresentationDocument21 pagesMarijuana THC PresentationJomariexOrtizNo ratings yet

- TGP Bamban Inventory FormDocument78 pagesTGP Bamban Inventory FormMichael LayugNo ratings yet

- Sedative Hypnotic DrugsDocument21 pagesSedative Hypnotic DrugstamaNo ratings yet

- Definitive Guide To Red Light Therapy PhotobiomodulationDocument10 pagesDefinitive Guide To Red Light Therapy PhotobiomodulationDavid Jenkins0% (2)

- Complementary and Alternative TherapiesDocument16 pagesComplementary and Alternative TherapiesHannah Jean Lapenid LemorenasNo ratings yet

- Migraine - National StudyDocument2 pagesMigraine - National StudyMagdallinaNo ratings yet

- Stock PPG Tangerang Mahakam, Kalbe & Hexpharm 07 Nov 23Document22 pagesStock PPG Tangerang Mahakam, Kalbe & Hexpharm 07 Nov 23rian agustianNo ratings yet

- Medication Formulary CBPDocument3 pagesMedication Formulary CBPZotac JascksonNo ratings yet

- The Treatment of Migraine Headaches in Children and AdolescentsDocument11 pagesThe Treatment of Migraine Headaches in Children and Adolescentsdo leeNo ratings yet

- Interstitial Lung Disease 2021 3Document11 pagesInterstitial Lung Disease 2021 3Khanh Ha NguyenNo ratings yet

- FAMCICLOVIRDocument23 pagesFAMCICLOVIRsujataNo ratings yet

- Maheshwari2009, Protocolo RanawatDocument6 pagesMaheshwari2009, Protocolo RanawatAdolfo La RocheNo ratings yet

- Pharm NotesDocument198 pagesPharm NotesNancy Danielz80% (5)

- Growth Hormone (Simatotropin, GH)Document7 pagesGrowth Hormone (Simatotropin, GH)nurliah armandNo ratings yet

- ACLS Skills ChecklistDocument2 pagesACLS Skills ChecklistabdullahNo ratings yet

- Clinical TRail Check List by KishanDocument1 pageClinical TRail Check List by Kishan23mphrga011No ratings yet

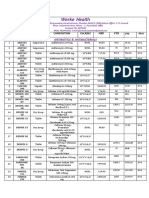

- Werke HealthDocument23 pagesWerke Healthganga ippltdNo ratings yet

- 1 XXX 4Document120 pages1 XXX 4joelrequenaNo ratings yet

- Antipsychotic: Antipsychotics, Also Known As NeurolepticsDocument28 pagesAntipsychotic: Antipsychotics, Also Known As NeurolepticsJussel Vazquez MarquezNo ratings yet

Formulation and Invitro Evaluation of Hydrocodone Oral Sustained Release Tablets

Formulation and Invitro Evaluation of Hydrocodone Oral Sustained Release Tablets

Uploaded by

Baru Chandrasekhar RaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Formulation and Invitro Evaluation of Hydrocodone Oral Sustained Release Tablets

Formulation and Invitro Evaluation of Hydrocodone Oral Sustained Release Tablets

Uploaded by

Baru Chandrasekhar RaoCopyright:

Available Formats

IAJPS 2017, 4 (12), 4236-4242 Gampa Vijaya Kumar et al ISSN 2349-7750

CODEN [USA]: IAJPBB ISSN: 2349-7750

INDO AMERICAN JOURNAL OF

PHARMACEUTICAL SCIENCES

http://doi.org/10.5281/zenodo.1095112

Available online at: http://www.iajps.com Research Article

FORMULATION AND INVITRO EVALUATION OF

HYDROCODONE ORAL SUSTAINED RELEASE TABLETS

Bhupathi Ashish Rahul1, Dr. V. Anjaneyulu2, Dr. G. Vijaya Kumar3

1,2

KGR Institute of Technology and Management, Rampally, Kesara, Rangareddy,

Telangana, India

2

Professor and Head, Dept. of Pharmacy, KGR Institute of Technology and Management,

Rampally, Kesara, Rangareddy, Telangana, India

Abstract:

The aim of the present study was to develop an sustained release formulation of Hydrocodone to maintain constant

therapeutic levels of the drug for over 8 hrs. Various grades of eudragit and HPMC were employed as polymers.

Hydrocodone dose was fixed as 4 mg. Total weight of the tablet was considered as 100 mg. Polymers were used in

the concentration of 10mg and 20mg concentration. All the formulations were passed various physicochemical

evaluation parameters and they were found to be within limits. Whereas from the dissolution studies it was evident

that the formulation (F3) showed better and desired drug release pattern i.e.,98.43 % in 12 hours. It followed zero

order release kinetics mechanism.

Keywords: Hydocodone, Eudragit, HPMC, Sustained release tablets.

Corresponding author:

Dr.Gampa Vijaya Kumar, QR code

Professor and Head, Dept. of Pharmacy,

KGR Institute of Technology and Management,

Rampally, Kesara, Rangareddy,

Telangana, India

Email ID: vijaytanu71@gmail.com

Please cite this article in press as Gampa Vijaya Kumar et al., Formulation and Invitro Evaluation of

Hydrocodone Oral Sustained Release Tablets, Indo Am. J. P. Sci, 2017; 4(12).

www.iajps.com Page 4236

IAJPS 2017, 4 (12), 4236-4242 Gampa Vijaya Kumar et al ISSN 2349-7750

INTRODUCTION:

Sustained release dosage forms are designed to RSPO, MCC pH 102, Magnesium stearate, PVP

release a drug at a predetermined rate in order to K30Cellulose chemicals were Laboratory grade made

maintain a constant drug concentration for a specific of SD Fine chemicals Pvt Ltd

period of time with minimum side effects [1-3].

Formulation of Hydrocodone Dispersible Tablet

Hydrocodone is a narcotic analgesic related to by Direct- Compression:

codeine, but more potent and more addicting by Composition of preliminary trials for Hydrocodone

weight. It is used also as cough suppressant.To Dispersible Tablet by direct compression is shown in

reduce the number of doses and to increase patient table 3.5. All the ingredients were weighed. Required

compliance it was formulated as sustained release quantity of drug and excipient mixed thoroughly in a

tablets. polybag. The blend is compressed using rotary tablet

machine-8 station with 6mm flat punch, B tooling.

MATERIALS AND METHODS: Each tablet contains 2.5 mg Hydrocodone and other

Hydrocodone, HPMC K4M, HPMC K15M, HPMC pharmaceutical ingredients.

K100M, Eudragit L 100, Eudragit S 100, Eudragit

Table 1: Formulation of Hydrocodone sutained release matrix tablets

INGREDIENT F1 F2 F3 F4 F5 F6 F7 F8 F9 F10 F11 F12

Hydrocodone 10 10 10 10 10 10 10 10 10 10 10 10

HPMC K4M 10 20 - - - - - - - - - -

HPMC K15M - - 10 20 - - - - - - - -

HPMC K100M - - - - 10 20 - - - - - -

Eudragit L-100 - - - - - - 10 20 - - - -

Eudragit S 100 - - - - - - - - 10 20 - -

Eudragit RSPO - - - - - - - - - - 10 20

PVP K30 5 5 5 5 5 5 5 5 5 5 5 5

Magnesium 2 2 2 2 2 2 2 2 2 2 2 2

Stearate

MCC 73 63 73 63 73 63 73 63 73 63 73 63

NOTE: All ingredients are expressed in mg only for a total weight of 100mg

Evaluation of prepared tablets

The designed formulation tablets were studied for their physicochemical properties like weight variation, hardness,

thickness, friability, In-vitro release and drug content.

RESULTS AND DISCUSSION:

Standard Calibration curve of Hydrocodone:

Table 2: Concentration and absorbance obtained for calibration curve of Hydrocodone in 0.1 N

hydrochloric acid buffer (pH 1.2)

S. No. Concentration Absorbance*

(g/ml) (at 230 nm)

0 0 0

1 5 0.227

2 10 0.406

3 15 0.621

4 20 0.824

5 25 0.957

Correlation Coefficient = 0.998

Absorbance y = 0.04x +0.012

www.iajps.com Page 4237

IAJPS 2017, 4 (12), 4236-4242 Gampa Vijaya Kumar et al ISSN 2349-7750

It was found that the estimation of Hydrocodone by Table 3: Observations for graph of Hydrocodone

UV spectrophotometric method at max 230.0 nm in in pH 6.8 phosphate buffer (234nm)

0.1N Hydrochloric acid had good reproducibility and

this method was used in the study. The correlation Conc [g/l] Abs

coefficient for the standard curve was found to be

closer to 1, at the concentration range, 5- 25g/ml. 0 0

The regression equation generated was y = 0.04x 2 0.125

+0.012. 4 0.267

6 0.367

8 0.456

10 0.571

12 0.701

It was found that the estimation of Hydrocodone by

UV spectrophotometric method at max 234.0 nm in

0.1N Hydrochloric acid had good reproducibility and

this method was used in the study. The correlation

coefficient for the standard curve was found to be

closer to 1, at the concentration range, 0- 12g/ml.

The regression equation generated was y = 0.056x

Fig 1: standard graph of Hydrocodone in 0.1 N +0.014.

HCl

Fig 2: Standard graph of Hydrocodone pH 6.8 phosphate buffer (234nm)

Evaluation Parameters for Sustained release Tablets of Hydrocodone:

Pre-compression parameters:

Table 4 Pre-compression parameters

Formulations Bulk Density Tap Density Carrs Index Hausner ratio Angle Of

(gm/cm3) (gm/cm3) (%) Repose()

F1 0.45 0.55 18.18 1.22 27.91

F2 0.47 0.55 14.54 1.17 28.23

F3 0.5 0.58 13.79 1.16 29.34

F4 0.46 0.55 16.36 1.19 26.71

F5 0.5 0.58 13.79 1.16 29.34

F6 0.47 0.55 14.54 1.17 28.23

F7 0.5 0.58 13.79 1.16 29.34

F8 0.41 0.5 18 1.21 26.78

F9 0.41 0.5 18 1.21 26.78

F10 0.42 0.51 18.24 1.2 26.68

F11 0.48 0.56 18.12 1.21 26.7

F12 0.41 0.54 18.11 1.22 26.71

www.iajps.com Page 4238

IAJPS 2017, 4 (12), 4236-4242 Gampa Vijaya Kumar et al ISSN 2349-7750

Post-compression parameters:

Table 5: Post-compression parameters

Formulations Weight variation Hardness Thickness Friability Assay

(mg) (kg/cm2) (mm) (%) (%)

F1 105 4.5 3.59 0.43 97.23

F2 104 4.6 3.64 0.34 98.55

F3 110 4.5 3.59 0.49 98.16

F4 109 4.6 3.58 0.47 99.34

F5 99.4 4.3 3.59 0.49 98.16

F6 102 4.7 3.64 0.34 98.55

F7 101 4.5 3.59 0.49 98.16

F8 107 4.6 3.56 0.34 99.25

F9 102 4.5 3.56 0.34 99.25

F10 103 4.4 3.55 0.43 98.6

F11 102.4 4.8 3.45 0.54 98.7

F12 98.5 4.5 3.54 0.43 98.5

Both the pre and post compression parameters were found to be with in the limits

Invitro Dissolution studies[6]:

Invitro dissolution studies were carried out by using paddle method. The dissolution studies were carried

900ml of 0.1 N HCl in USP dissolution apparatuss 2 out for about 12hr.

hrs after that using 6.8ph phosphate buffer by using

Table 6: Invitro dissolution data

Time( F1 F2 F3 F4 F5 F6 F7 F8 F9 F10 F11 F12

hrs)

0 0 0 0 0 0 0 0 0 0 0 0 0

0.5 10.46 7.46 6.77 8.54 5.46 9.66 10.79 11.77 8.73 9.75 11.46 13.87

1 20.22 14.26 15.02 17.21 14.66 16.22 21.1 19.5 23.54 16.44 20.74 22.46

2 32.65 20.65 22.55 35.53 28.44 25.45 32.86 31.88 38.33 27.87 31.57 34.78

3 49.68 39.29 40.89 50.12 43.85 46.89 43.24 49.28 44.25 32.44 42.76 46.18

4 55.24 59.55 48.22 68.84 65.88 62.83 66.49 61.11 51.01 39.78 62.15 55.41

6 74.24 80.65 59.77 79.63 96.12 72.7 84.25 82.58 78.98 58.74 85.46 76.15

8 97.55 98.34 74.35 87.46 97.56 89.26 99.96 100.25 96.99 70.84 92.82 82.16

10 97.45 98.24 91.49 98.89 97.34 98.98 99.09 100.76 96.56 81.87 97.46 87.46

12 97.35 97.67 98.43 98.67 97.95 98.33 98.45 99.67 96.18 90.47 97.13 91.16

Fig 3 : Cumulative drug release of formuations(F1-F3)

www.iajps.com Page 4239

IAJPS 2017, 4 (12), 4236-4242 Gampa Vijaya Kumar et al ISSN 2349-7750

Fig 6: Cumulative drug release of

Fig 4: Cumulative drug release of

formuations(F10-F12)

formuations(F4-F6)

From this dissolution studies it was found

that F3 formulation was the best formulation

compared to other formulations because f3

formulation shows 98.43% at 12 hrs. This

formulation was formulated by using HPMC K15M

in the concentration of 10mg. other formulations also

shown maximum drug release in 10 hrs like f1, f2, f5,

f7, and f9. And f8 formulation 100 % drug release at

10 hrs.

These formulations (f1, f2, f5, f7, f8, f9) had shown

maximum drug release in 10hrs only except F3 which

has shown desired drug release in 12hrs. So it is

considered as the optimised formula

Application of Release Rate Kinetics to Dissolution

Data:

Fig 5: Cumulative drug release of Various models were tested for explaining the kinetics

formuations(F7-F9) of drug release. To analyze the mechanism of the drug

release rate kinetics of the dosage form, the obtained

data were fitted into zero-order, first order, Higuchi,

and Korsmeyer-Peppas release model.

Table 7: Release kinetics data for optimised formulation (F3)

CUMULATIVE (%) TIME ( T ) ROOT ( T) LOG( %) LOG ( T ) LOG (%)

RELEASE Q RELEASE REMAIN

0 0 0 2.000

6.77 30 5.477 0.831 1.477 1.970

15.02 60 7.746 1.177 1.778 1.929

22.55 120 10.954 1.353 2.079 1.889

40.89 180 13.416 1.612 2.255 1.772

48.22 240 15.492 1.683 2.380 1.714

59.77 360 18.974 1.776 2.556 1.605

74.35 480 21.909 1.871 2.681 1.409

91.49 600 24.495 1.961 2.778 0.930

98.43 720 26.833 1.993 2.857 0.196

www.iajps.com Page 4240

IAJPS 2017, 4 (12), 4236-4242 Gampa Vijaya Kumar et al ISSN 2349-7750

Fig 7 : Zero order release kinetics graph Fig 10: First order release kinetics graph

From the above graphs it was evident that the

formulation F3 was followed peppas order release

kinetics.

CONCLUSION:

In the present work, an attempt has been made to

develop sustained release matrix tablets of

Hydrocodone. Different gradess of hydroxy propyle

methyl cellulose and different grades of eudragit

polymers used. All the formulations were prepared

by direct compression method using 6mm punch on 8

station rotary tablet punching machine. The blend of

all the formulations showed good flow properties

such as angle of repose, bulk density, tapped density.

The prepared tablets were shown good post

compression parameters and they passed all the

Fig 8 : Higuchi release kinetics graph quality control evaluation parameters as per I.P

limits.Among all the formulations F3 formulation

showed maximum % drug release i.e., 98.43 % in 12

hrs hence it is considered as optimized formulation.

The f3 formulation contains HPMC K15M in the

concentration of 10 mg.

REFERENCES:

1.Sarika Pundir Et.Al., Sustained Release Matrix

Technology And Recent Advance In Matrix Drug

Delivery System: A Review Int. J. Drug Res. Tech.

2013; Vol. 3 (1): 12-20.

2.Ashish Et Al. World Journal Of Pharmacy And

Pharmaceutical Sciences Sustained Release Matrix

Type Drug Delivery System: A Review,2015;4(02).

3. Querfurth Hw, Laferla Fm (28 January 2010).

"Alzheimer's Disease". The New England Journal Of

Fig 9: Kars Mayer peppas graph Medicine 362 (4): 329

44. Doi:10.1056/Nejmra0909142.Pmid 20107219.

4.Dr. Patel Bhavik N., Patel Devyani B., Dr. Patel

Chhagan N. Formulation And Evaluation Of

Modified Release Tablet Of Donepezil

www.iajps.com Page 4241

IAJPS 2017, 4 (12), 4236-4242 Gampa Vijaya Kumar et al ISSN 2349-7750

Hydrochloride World Journal Of Pharmaceutical 8.Roohullah, Zafar Iqbal, Fazli Nasir, Muhammad

Research ,2015;4( 05). Akhlaq, Sajid Khan Sadozai, Ibrahim Khadra and

5.Leon Shargel, Susanna Pong, Andrew B.C., Shahida Zakir Preparation and In-vitro Evaluation of

Applied Biopharmaceutics And Pharmacokinetics, Sustained Release Phenytoin Sodium Matrix Tablets

Modified-Release Drug Products, Pg 515 Fifth Prepared by Co-Evaporation Method Using Different

Edition, 2004 Polymers Middle-East Journal of Scientific

6.P. Ramya Deepthi1 *, Vure Prasad2 , Prakash V Research;2012; 11 (2): 246-252.

Diwan Preparation And In-Vitro Evaluation Of 9.Rohini Diwedi , S Alexandar And M J N

Donepezil Hydrochloride Sustained Release Matrix Chandrasekar Preparation And In Vitro Evaluation

Tablets Using Non-Gelling Polymer Iosr Journal Of Of Sustained Release Tablet Formulations Of

Pharmacy And Biological Sciences (Iosr-Jpbs) E- Metformin Hcl Asian Journal of Pharmaceutical and

Issn: 2278-3008, P-Issn:2319-7676. Volume 9, Issue Clinical Research,2012;5(1).

5 Ver. Iv (Sep -Oct. 2014);83-91 10.Mohd Abdul Hadi, V. Lokeswara Babu and

7.P. Bharghava Bhushan Rao, KEV. Nagoji and K. Narottam Pal Formulation and Evaluation of

Jayaveera Formulation, In Vitro Evaluation and Sustained Release Matrix Tablets of Glimepiride

Comparison of Sustained Release Matrix Tablets of Based on Combination of Hydrophilic and

Diclofenac Sodium using Okra Gum as Release Hydrophobic Polymers Journal of Applied

Modifier IJAPBC,2012;1(3). www.ijapbc.com Pharmaceutical Science,2012; 02 (06): 101-107

www.iajps.com Page 4242

You might also like

- Teaching Plan For Patient With ArthritisDocument1 pageTeaching Plan For Patient With ArthritisLouel VicitacionNo ratings yet

- Lercanidipine Hydrochloride 10mg and 20mg Film-Coated TabletsDocument65 pagesLercanidipine Hydrochloride 10mg and 20mg Film-Coated TabletsPai GampaengkamNo ratings yet

- 10 Rights of Drug Administration With Nursing ImplicationsDocument3 pages10 Rights of Drug Administration With Nursing ImplicationsJet Bautista100% (6)

- Opleidingen Voor Personal Trainers - Deel 1 OVERLOAD WORLDWIDEDocument27 pagesOpleidingen Voor Personal Trainers - Deel 1 OVERLOAD WORLDWIDEOverload WorldwideNo ratings yet

- Perspective in PharmacyDocument3 pagesPerspective in PharmacyAgniez Hannah Permites100% (4)

- 4.nag NifedipinebuccalRamreddy Dec 2012Document16 pages4.nag NifedipinebuccalRamreddy Dec 2012Siddhesh KharmateNo ratings yet

- Attachment PDFDocument10 pagesAttachment PDFHEPHZIBAH CHILAKANo ratings yet

- IJISRT21 MAY192 KuldeepDocument11 pagesIJISRT21 MAY192 KuldeepKuldeep VinchurkarNo ratings yet

- Design and Characterisation of Glimepiride and Pioglitazone Bilayered TabletsDocument61 pagesDesign and Characterisation of Glimepiride and Pioglitazone Bilayered TabletsUthej ReddyNo ratings yet

- Review Article Sep 2018Document11 pagesReview Article Sep 2018Vitor JacóNo ratings yet

- Design and Characterization of Nizatidine Effervescent Floating Matrix Tablets Employing Semisynthetic Rate-Retarding PolymersDocument11 pagesDesign and Characterization of Nizatidine Effervescent Floating Matrix Tablets Employing Semisynthetic Rate-Retarding PolymersSriram NagarajanNo ratings yet

- Available Online at ISSN 2278 - 0033: WWW - Novelsciencepharmacy.infoDocument7 pagesAvailable Online at ISSN 2278 - 0033: WWW - Novelsciencepharmacy.infoDoinitaNo ratings yet

- Ijpdt 8 (2) 2018 12-36Document25 pagesIjpdt 8 (2) 2018 12-36wlNo ratings yet

- Experimental Work: KCT'S R.G. Sapkal College of Pharmacy, Anjaneri, NashikDocument14 pagesExperimental Work: KCT'S R.G. Sapkal College of Pharmacy, Anjaneri, NashikPrasad ShiroleNo ratings yet

- Formulation and Evaluation of Gliclazide Immediate Release and Metformin Sustain Release Bilayer TabletDocument13 pagesFormulation and Evaluation of Gliclazide Immediate Release and Metformin Sustain Release Bilayer TabletEditor IJTSRDNo ratings yet

- Formulation and In-Vitro Characterisation of Sustained Releasemetronidazole Cocoa Butter SuppositoriesDocument7 pagesFormulation and In-Vitro Characterisation of Sustained Releasemetronidazole Cocoa Butter SuppositoriesRowaidaNo ratings yet

- Tablet Characteristics and Pharmacokinetics of Orally Disintegrating Tablets Containing Coenzyme Q10 Granules Prepared by Different MethodsDocument13 pagesTablet Characteristics and Pharmacokinetics of Orally Disintegrating Tablets Containing Coenzyme Q10 Granules Prepared by Different MethodsMyPSA PHCNo ratings yet

- Article WJPR 1483163718Document17 pagesArticle WJPR 1483163718Fahim FahimNo ratings yet

- IJPCR, Vol 4, Issue 4, Article 3Document4 pagesIJPCR, Vol 4, Issue 4, Article 3clementinaelvira200023No ratings yet

- 4.dileep Clopidogrel Oct 2012Document11 pages4.dileep Clopidogrel Oct 2012Suman kamuruNo ratings yet

- 7Document5 pages7Giselda FarmasiNo ratings yet

- Development and Evaluation of Enteric Coated Omeprazole Pellets 22.5% W/WDocument8 pagesDevelopment and Evaluation of Enteric Coated Omeprazole Pellets 22.5% W/Wvanvu buiNo ratings yet

- Formulation and Evaluation of Voglibose Mouth Dissolving TabletDocument30 pagesFormulation and Evaluation of Voglibose Mouth Dissolving Tabletbhagwan das vaishnavNo ratings yet

- Formulation and Characterization of Clarithromycin Floating Tablets by Using Various PolymersDocument11 pagesFormulation and Characterization of Clarithromycin Floating Tablets by Using Various PolymersIJAR JOURNALNo ratings yet

- 2 Vinay (2012)Document15 pages2 Vinay (2012)Abdullah ZenNo ratings yet

- Degradation Study of Different Brands of Rosuvastatin Calcium Tablet in Bangladesh Using UV SpectrophotometerDocument4 pagesDegradation Study of Different Brands of Rosuvastatin Calcium Tablet in Bangladesh Using UV SpectrophotometerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- PDF MPJ 640Document12 pagesPDF MPJ 640Risnawa Puji AstutiNo ratings yet

- Formulation and In-Vitro Dissolution of Clopidogrel Tablet by Using Sodium Starch Glycolate and Natural Xanthan GumDocument4 pagesFormulation and In-Vitro Dissolution of Clopidogrel Tablet by Using Sodium Starch Glycolate and Natural Xanthan GumPRASANTA KUMAR MOHAPATRANo ratings yet

- Formulation and Evaluation of Sustained Release Matrix Tablets of GliclazideDocument3 pagesFormulation and Evaluation of Sustained Release Matrix Tablets of Gliclazidequangoanh12042001No ratings yet

- 868-Article Text-2464-1-10-20140515Document6 pages868-Article Text-2464-1-10-20140515nisa nurhidayatiNo ratings yet

- Jurnal 4Document11 pagesJurnal 4saprifarmasiNo ratings yet

- Formulation and Evaluation of Sustained Release Metoprolol Succinate Tablet Using Hydrophilic Gums As Release ModifiersDocument5 pagesFormulation and Evaluation of Sustained Release Metoprolol Succinate Tablet Using Hydrophilic Gums As Release ModifiersAryanto DedyNo ratings yet

- Akhilesh Front PagesDocument11 pagesAkhilesh Front Pagescity cyberNo ratings yet

- Evaluate ODTDocument5 pagesEvaluate ODTcinthiasetiaNo ratings yet

- Jurnal Loperamide HCL BARUDocument3 pagesJurnal Loperamide HCL BARUcinthiasetiaNo ratings yet

- FDA QbD实例 速释片 Example QbD for IR Tablet (中英文对照)Document145 pagesFDA QbD实例 速释片 Example QbD for IR Tablet (中英文对照)dengboff96No ratings yet

- Optimization and Formulation of Orodispersible Tablets ofDocument7 pagesOptimization and Formulation of Orodispersible Tablets ofUmar AliNo ratings yet

- Chapter-4 Materials and MethodsDocument15 pagesChapter-4 Materials and MethodsSunil ChaudharyNo ratings yet

- 20.Md Musharraf Ali and V.saikishoreDocument9 pages20.Md Musharraf Ali and V.saikishoreBaru Chandrasekhar RaoNo ratings yet

- Analytical Method Development and Validation For The Estimation of The Azilsartan Medoxamil by RP HPLC Method in Bulk and Pharmaceutical Dosage FormDocument5 pagesAnalytical Method Development and Validation For The Estimation of The Azilsartan Medoxamil by RP HPLC Method in Bulk and Pharmaceutical Dosage FormEditor IJTSRDNo ratings yet

- Studies On Formulation and In-Vitro Evaluation of Mucoadhesive Microbeads of Rosuvastatin Calcium by Using Central Composite DesignDocument11 pagesStudies On Formulation and In-Vitro Evaluation of Mucoadhesive Microbeads of Rosuvastatin Calcium by Using Central Composite DesignInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Presentation by Chirag Kukreja M.pharm 2nd YearDocument28 pagesPresentation by Chirag Kukreja M.pharm 2nd YearChirag KukrejaNo ratings yet

- Formulation and Evaluation of Antifungal Micro Emulsion-Based Gel For Topical Drug Delivery Using MilletiapinnataDocument15 pagesFormulation and Evaluation of Antifungal Micro Emulsion-Based Gel For Topical Drug Delivery Using MilletiapinnataIJAR JOURNALNo ratings yet

- BCS Losartan PDFDocument8 pagesBCS Losartan PDFHesti HariantiNo ratings yet

- Formulation and Optimization of Solid DispersionDocument10 pagesFormulation and Optimization of Solid DispersionAdriana CastellanosNo ratings yet

- Abdul ResearchDocument13 pagesAbdul ResearchNutan Desai RaoNo ratings yet

- Formulation and In-Vitro Evaluation of Controlled Release Transdermal Drug Delivery System of Simvastatin A Model Hypocholesterolemia DrugDocument6 pagesFormulation and In-Vitro Evaluation of Controlled Release Transdermal Drug Delivery System of Simvastatin A Model Hypocholesterolemia DrugPRASANTA KUMAR MOHAPATRANo ratings yet

- 01piroxicamemulgel PDFDocument14 pages01piroxicamemulgel PDFNymas PutriNo ratings yet

- Proceedings 78 00035Document8 pagesProceedings 78 00035elang revyNo ratings yet

- Formulation Development and In-Vitro Evaluation of Bucoadhesive Tablet of Chlorpheniramine Maleate and Phenylephrine Hydrochloride in Combined Dosage FormDocument11 pagesFormulation Development and In-Vitro Evaluation of Bucoadhesive Tablet of Chlorpheniramine Maleate and Phenylephrine Hydrochloride in Combined Dosage FormNeerajNo ratings yet

- 30 Vol. 9 Issue 5 May 2018 IJPSR RA 8960Document6 pages30 Vol. 9 Issue 5 May 2018 IJPSR RA 8960rohan satwaraNo ratings yet

- Investigation of Different Lipid Based Materials As Matrices Designed To Control The Release of A Hydrophobic DrugDocument6 pagesInvestigation of Different Lipid Based Materials As Matrices Designed To Control The Release of A Hydrophobic DrugswabrijNo ratings yet

- Ftir FelodipineDocument6 pagesFtir FelodipineMelisa AprilianiNo ratings yet

- Formulation Development and Invitro Evaluation of Ranolazine Extended Release TabletsDocument6 pagesFormulation Development and Invitro Evaluation of Ranolazine Extended Release TabletsBaru Chandrasekhar RaoNo ratings yet

- Efecto de La Humedad de Los Excipientes en Formas Farmacéuticas Sólidas (Comprimidos)Document8 pagesEfecto de La Humedad de Los Excipientes en Formas Farmacéuticas Sólidas (Comprimidos)Héctor Fabio Leyton ArcosNo ratings yet

- Design and Evaluation of Transdermal Delivery System Containing Losartan PotassiumDocument6 pagesDesign and Evaluation of Transdermal Delivery System Containing Losartan PotassiumYvd SinghNo ratings yet

- Studies On Formulation and Evaluation of Bilayered Tablets of CurcuminDocument7 pagesStudies On Formulation and Evaluation of Bilayered Tablets of CurcuminMasayu Dinahya DiswantiNo ratings yet

- Advanced Pharmaceutics: International Journal ofDocument8 pagesAdvanced Pharmaceutics: International Journal ofdini hanifaNo ratings yet

- AB - Addition Cure HCR Impact of Inhibitors On The Elastomer Cure Profile PDFDocument7 pagesAB - Addition Cure HCR Impact of Inhibitors On The Elastomer Cure Profile PDFLin NiuNo ratings yet

- Design, Optimization and Pharmacodynamic Comparison of Dorzolamide Hydrochloride Soluble Ocular Drug Insert Prepared by Using 32 Factorial DesignDocument10 pagesDesign, Optimization and Pharmacodynamic Comparison of Dorzolamide Hydrochloride Soluble Ocular Drug Insert Prepared by Using 32 Factorial DesignANo ratings yet

- Formulation Design and Evaluation of Mucoadhesive Buccal Patch of Ketorolac For The Treatment of PeriodontitisDocument10 pagesFormulation Design and Evaluation of Mucoadhesive Buccal Patch of Ketorolac For The Treatment of PeriodontitisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Full TextDocument7 pagesFull TexttuayuNo ratings yet

- Drug Metabolism in Drug Design and Development: Basic Concepts and PracticeFrom EverandDrug Metabolism in Drug Design and Development: Basic Concepts and PracticeDonglu ZhangNo ratings yet

- Knowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyDocument8 pagesKnowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyBaru Chandrasekhar RaoNo ratings yet

- Development and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormDocument11 pagesDevelopment and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormBaru Chandrasekhar RaoNo ratings yet

- Analytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationDocument8 pagesAnalytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationBaru Chandrasekhar RaoNo ratings yet

- Gastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsDocument7 pagesGastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsBaru Chandrasekhar RaoNo ratings yet

- Pharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoDocument7 pagesPharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoBaru Chandrasekhar RaoNo ratings yet

- Review On: Inventory ManagementDocument8 pagesReview On: Inventory ManagementBaru Chandrasekhar RaoNo ratings yet

- A Brief Review On YawsDocument7 pagesA Brief Review On YawsBaru Chandrasekhar RaoNo ratings yet

- Relationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityDocument4 pagesRelationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityBaru Chandrasekhar RaoNo ratings yet

- Assessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaDocument7 pagesAssessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaBaru Chandrasekhar RaoNo ratings yet

- The Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalDocument11 pagesThe Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalBaru Chandrasekhar RaoNo ratings yet

- Descriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreDocument4 pagesDescriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreBaru Chandrasekhar RaoNo ratings yet

- Determination of Bioactive Compounds From Piper Nigrum L by Using Ft-Ir Spectroscopic AnalysisDocument3 pagesDetermination of Bioactive Compounds From Piper Nigrum L by Using Ft-Ir Spectroscopic AnalysisBaru Chandrasekhar RaoNo ratings yet

- Pharmacological and Phytochemical Evidence of Scutia Genus Plants - A ReviewDocument7 pagesPharmacological and Phytochemical Evidence of Scutia Genus Plants - A ReviewBaru Chandrasekhar RaoNo ratings yet

- DISTINCTIVE PHARMACOLOGICAL ACTIVITIES OF Eclipta Alba AND IT'S COUMESTAN WEDELOLACTONEDocument7 pagesDISTINCTIVE PHARMACOLOGICAL ACTIVITIES OF Eclipta Alba AND IT'S COUMESTAN WEDELOLACTONEBaru Chandrasekhar RaoNo ratings yet

- DETERMINATION OF BIOACTIVE COMPOUNDS FROM Piper Nigrum. L BY USING HPLC ANALYSISDocument3 pagesDETERMINATION OF BIOACTIVE COMPOUNDS FROM Piper Nigrum. L BY USING HPLC ANALYSISBaru Chandrasekhar RaoNo ratings yet

- RP-HPLC Method Development and Validation of Alogliptin Bulk and Tablet Dosage FormDocument8 pagesRP-HPLC Method Development and Validation of Alogliptin Bulk and Tablet Dosage FormBaru Chandrasekhar RaoNo ratings yet

- STUDIES ON QUALITATIVE PHYTOCHEMICAL ANALYSIS AND ANTIBACTERIAL ACTIVITY OF Piper NigrumDocument7 pagesSTUDIES ON QUALITATIVE PHYTOCHEMICAL ANALYSIS AND ANTIBACTERIAL ACTIVITY OF Piper NigrumBaru Chandrasekhar RaoNo ratings yet

- Determination of Bioactive Compounds From Piper Longum L. by Using HP-LC AnalysisDocument4 pagesDetermination of Bioactive Compounds From Piper Longum L. by Using HP-LC AnalysisBaru Chandrasekhar RaoNo ratings yet

- To Prepare gliclazide-SR PDFDocument11 pagesTo Prepare gliclazide-SR PDFNirav SoniNo ratings yet

- Pharmacy: Pharmacist Intervention Program at Different Rent Levels of Geriatric HealthcareDocument8 pagesPharmacy: Pharmacist Intervention Program at Different Rent Levels of Geriatric HealthcareAstiNo ratings yet

- Drug Study TramadolDocument2 pagesDrug Study TramadolJemina Rafanan Racadio100% (1)

- Plant HormonesDocument2 pagesPlant HormonesMuhammad Noman BhattiNo ratings yet

- 03 ON 2020 Prostate WBDocument43 pages03 ON 2020 Prostate WBabdullahNo ratings yet

- 7 Electrical Therapies Defib and PacingDocument16 pages7 Electrical Therapies Defib and PacingEricson LenovNo ratings yet

- Drug StudyDocument27 pagesDrug StudyMariefer EsplagoNo ratings yet

- Marijuana THC PresentationDocument21 pagesMarijuana THC PresentationJomariexOrtizNo ratings yet

- TGP Bamban Inventory FormDocument78 pagesTGP Bamban Inventory FormMichael LayugNo ratings yet

- Sedative Hypnotic DrugsDocument21 pagesSedative Hypnotic DrugstamaNo ratings yet

- Definitive Guide To Red Light Therapy PhotobiomodulationDocument10 pagesDefinitive Guide To Red Light Therapy PhotobiomodulationDavid Jenkins0% (2)

- Complementary and Alternative TherapiesDocument16 pagesComplementary and Alternative TherapiesHannah Jean Lapenid LemorenasNo ratings yet

- Migraine - National StudyDocument2 pagesMigraine - National StudyMagdallinaNo ratings yet

- Stock PPG Tangerang Mahakam, Kalbe & Hexpharm 07 Nov 23Document22 pagesStock PPG Tangerang Mahakam, Kalbe & Hexpharm 07 Nov 23rian agustianNo ratings yet

- Medication Formulary CBPDocument3 pagesMedication Formulary CBPZotac JascksonNo ratings yet

- The Treatment of Migraine Headaches in Children and AdolescentsDocument11 pagesThe Treatment of Migraine Headaches in Children and Adolescentsdo leeNo ratings yet

- Interstitial Lung Disease 2021 3Document11 pagesInterstitial Lung Disease 2021 3Khanh Ha NguyenNo ratings yet

- FAMCICLOVIRDocument23 pagesFAMCICLOVIRsujataNo ratings yet

- Maheshwari2009, Protocolo RanawatDocument6 pagesMaheshwari2009, Protocolo RanawatAdolfo La RocheNo ratings yet

- Pharm NotesDocument198 pagesPharm NotesNancy Danielz80% (5)

- Growth Hormone (Simatotropin, GH)Document7 pagesGrowth Hormone (Simatotropin, GH)nurliah armandNo ratings yet

- ACLS Skills ChecklistDocument2 pagesACLS Skills ChecklistabdullahNo ratings yet

- Clinical TRail Check List by KishanDocument1 pageClinical TRail Check List by Kishan23mphrga011No ratings yet

- Werke HealthDocument23 pagesWerke Healthganga ippltdNo ratings yet

- 1 XXX 4Document120 pages1 XXX 4joelrequenaNo ratings yet

- Antipsychotic: Antipsychotics, Also Known As NeurolepticsDocument28 pagesAntipsychotic: Antipsychotics, Also Known As NeurolepticsJussel Vazquez MarquezNo ratings yet