Professional Documents

Culture Documents

Jsa

Jsa

Uploaded by

Mohd AzrinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jsa

Jsa

Uploaded by

Mohd AzrinCopyright:

Available Formats

Prepared By :

JOB

SAFETY Reviewed By :

ANALYSIS

Approved By :

FPP-3 PROJECT JOB DESCRIPTION : PNEUMATIC TEST ACTIVITIES

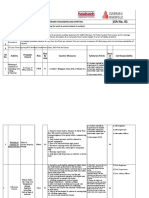

No. SEQUENCE OF JOBS HAZARD CONSEQUENCES

1 Working / tools and equipments Natural of working condition

condition, pre meeting and Work Permit

Equipments / tools failures

Failed communication

2 Install blind/spade, pressure gauge & etc.for line to Finger / hand injury Personal injury

test

Misuse of tools

3 Remove equipment that is not involved for the Finger / hand injury Personal injury

testing(pressure trasmitter & etc) and install

temporary spool.

Fall of equipment

4 Connection of hose ,Pressurize Striking object - Uncontrolled

through compressor machine / nitrogen gas (N2) release of stored air from

and pressure raised gradually. compressor

Failure of connection/ pipe line

Electrical shock due to electrical tools

use

5 Holding pressure time (1 hour) Failure of connection/ pipe line

Failure of communication

6 Depressurizing air gradually Failure of connection/ pipe line

7 Flushing and white cloth test Surging from pressurizing water

Exposed to dust from pipe line.

8 Remove blind/spade, pressure gauge & temporary Finger / hand injury Personal injury

spool and install back equipment (pressure trasmitter

& etc).

Equipments / tools failures

Failure of connection/ pipe line

9 Housekeeping Slip and tripping hazard.

10 Reinstatement Tool damage/ tool slippage

Name Company Sign Date

Dahali Ibrahim (HSE Supervisor) DYNACIATE

ROEL ALMEDA (DCM) SCEM

MOHD SABRIE B. EMBONG (HSE Manager) SCEM

ACTION BY

CONTROL MEASURE Work Leader Supervisor REMARKS

Yes No Sign Yes No Sign

a)If working for height / elevated area, permit shall be obtained / /

b) Indentify the weather condition before start work. / /

c) Stop if heavy rain or lightning / /

a)Equipment and tools shall be inspected prior to use, if found defects, to be

replaced / repaired accordingly.(Calibration certificate for compressor machine

/ /

shall be inspected on it validity.)

a)All job task and method must be plan by supervisor. / /

b)Toolbox briefing must be conduct by supervisor to arrange the job task.

/ /

c)Ensure work permit obtained / /

d) All personnel shall clear the test procedure and safety measures and

emergency routes / emergency response. / /

e) Barricade and warning sign/signals will be installed clear understanding of / /

entry restricted area.

a) Supervisor must be availbe during the work / /

b) Use proper tools/materials for the work. / /

c) Use suitable hand glove (semi leather/ cotton glove)when carried out the

work / /

a)To use suitable tools to operate/ tightening the equipment / bolt & nut. / /

b)Person In charge must ensure work be carried out with safe work practice. / /

a) Supervisor must be availabe during the work / /

b) Use proper tools/materials for the work. / /

c) Use suitable hand glove (semi leather/ cotton glove)when carried out the

work. / /

a)Proper handling of the equipments. / /

b)Work must be carried out by group/team. / /

c)Supervisor must be availabe during the work / /

a)Check list to be prepare to ensure the function of compressor machine is in

accordance with test package. / /

b)Use gate valves for charging and discharging the testing media. / /

a)Before pressurizing, air pressurizing inside the system shall be properly checked.

/ /

b)Use calibrated pressure gauges & ensure pressure does not exceed specified

/ /

value

c)Increase the pressure in steps and check for leaks. Ensure that pressure increase

/ /

is gradually.

d)Each pressurizing hose connection should provide with anti-whip. / /

a)Electrical extension wire must placed far distance from pipeline. / /

b)Electrical tools/equipment shall be inspected. / /

a)Pressurizing water inside the system shall be properly checked / /

b)Use calibrated pressure gauges & ensure pressure does not exceed specified

/ /

value

c)Increase the pressure in steps and check for leaks. Ensure that pressure increase

is gradually. / /

a)All job task and method must be clear instruction by supervisor. / /

b)Perform by testing team to relay information or instruction,by using (Hand

/ /

signal, 2 way radio/walkie talkie & etc.)

a)Pressurizing water inside the system shall be properly checked / /

b)Use calibrated pressure gauges & ensure pressure does not exceed specified

value / /

c)Increase the pressure in steps and check for leaks. Ensure that pressure increase

/ /

is gradually.

a)All job task and method must be clear instruction by supervisor. / /

b)Perform by hydro testing team to relay information or instruction,by using

(Hand signal, 2 way radio/walkie talkie & etc.) / /

a) Use proper hand glove. / /

b) Use proper dust must during carried out the work. / /

c)Work must be carried out according test package / /

a) Supervisor must be availabe during the work / /

b) Use proper tools/materials for the work. / /

c) Use suitable hand glove (semi leather/ cotton glove)when carried out the

work. / /

a)Equipment and tools shall be inspected prior to use, if found defects, to be

replaced / repaired accordingly. / /

a)Pressurizing water inside the system shall be properly checked / /

b)Use calibrated pressure gauges & ensure pressure does not exceed specified

value / /

c)Increase the pressure in steps and check for leaks. Ensure that pressure increase

is gradually. / /

a) Ensure all tools and equipment kept properly after finish work. / /

b) Ensure all debris clearly after work finish. / /

a)Only inspected and conditioned tools will be use / /

b)Proper PPE to be worn while tightening and loosing of bolts where ever

/ /

required

You might also like

- AZ-500 Book PDFDocument253 pagesAZ-500 Book PDFAldo SENo ratings yet

- flgx213 (2) Pkjun2015Document6 pagesflgx213 (2) Pkjun2015Jason Van Den HeeverNo ratings yet

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- JSA Tubing Leak TestDocument1 pageJSA Tubing Leak TestMuhammad Reza Gadran67% (3)

- A.C Motor ReplacementDocument1 pageA.C Motor ReplacementReda BoualiNo ratings yet

- JSA E&I 10.electrical Instrument Panels RemovalDocument3 pagesJSA E&I 10.electrical Instrument Panels RemovalAmyNo ratings yet

- 01 JSA CLEANING COMPRESSOR Rev 05 015 BIDocument8 pages01 JSA CLEANING COMPRESSOR Rev 05 015 BIMohd Khaidir100% (1)

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- ITP Temporary HoardingDocument1 pageITP Temporary HoardingMohd Azrin100% (1)

- JMSDocument10 pagesJMSMohd AzrinNo ratings yet

- OutlookDocument53 pagesOutlookAvi Kense100% (1)

- Rock Breaker Self ChecklistDocument1 pageRock Breaker Self ChecklistNair R RakeshNo ratings yet

- Pole Unit Install JhaDocument2 pagesPole Unit Install JhafatimahNo ratings yet

- Job Safety Analysis - RIG-UP OF GDS, CASCADE & SAFETY EQUIPMENTDocument3 pagesJob Safety Analysis - RIG-UP OF GDS, CASCADE & SAFETY EQUIPMENTJun DandoNo ratings yet

- JHA For Work PermitDocument1 pageJHA For Work PermitShahid RazaNo ratings yet

- Job Safety Analysis - Overhead Power LinesDocument2 pagesJob Safety Analysis - Overhead Power Linesrenee100% (2)

- Jsa n2 Purging PDF FreeDocument1 pageJsa n2 Purging PDF FreeSKH CultureNo ratings yet

- Jsa - Cable TerminationDocument4 pagesJsa - Cable TerminationD FiransyahNo ratings yet

- EHS Risk Assessment - 5. DTR ErectionDocument2 pagesEHS Risk Assessment - 5. DTR Erectionshamshu123No ratings yet

- Panipat Refinery & Petrochemical Complex Job Safety AnalysisDocument6 pagesPanipat Refinery & Petrochemical Complex Job Safety AnalysisSaiyad RiyazaliNo ratings yet

- Petrofac: Job Safety AnalysisDocument2 pagesPetrofac: Job Safety AnalysisMon Trang Nguyễn100% (1)

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- Jsa For Radiography WorkDocument2 pagesJsa For Radiography WorkVipul ShankarNo ratings yet

- Operating A Telescoping Aerial Boom LiftDocument1 pageOperating A Telescoping Aerial Boom LiftTFattahNo ratings yet

- Jha New - PWHTDocument6 pagesJha New - PWHTSalam AlkataluniNo ratings yet

- Job Safety Analysis: 1. Removing Spool From Existing Pipe LinesDocument5 pagesJob Safety Analysis: 1. Removing Spool From Existing Pipe Lineskaremkoko100% (2)

- 30 JHA On Calibration and Testing of Electrical RelaysDocument3 pages30 JHA On Calibration and Testing of Electrical RelaysUMA AKANDU UCHE100% (2)

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- JSA For Flue Gas Duct Height WorkDocument4 pagesJSA For Flue Gas Duct Height Worksubhadipmanna8No ratings yet

- 02-070302 JSA For Relocation of Monkey Ladder For Construction of Phase-I Tranformer Bay in Brown Zone.Document4 pages02-070302 JSA For Relocation of Monkey Ladder For Construction of Phase-I Tranformer Bay in Brown Zone.Mohammed MinhajNo ratings yet

- Jha Miura Z-Steam Boilers Intallation2Document8 pagesJha Miura Z-Steam Boilers Intallation2perquino oasanNo ratings yet

- AB8-ELE-73-HMO - Troubleshooting VFDDocument2 pagesAB8-ELE-73-HMO - Troubleshooting VFDvikrant911100% (1)

- Job Safety & Environment Analysis: Revision NoDocument3 pagesJob Safety & Environment Analysis: Revision NonishanthNo ratings yet

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- 2020 06 17 JSA For Installation of The AC Unit in The Server RoomDocument11 pages2020 06 17 JSA For Installation of The AC Unit in The Server RoomDarren OscarNo ratings yet

- Suspended From Man-Rider (Vertical Rescue Plan)Document1 pageSuspended From Man-Rider (Vertical Rescue Plan)Paul100% (1)

- Jsa For Ut TestDocument2 pagesJsa For Ut Testnasar_mahsood50% (2)

- Job Safety Analysis (Jsa) : Title of Activity / Work: DG OperationDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: DG Operationba ratnaparkheNo ratings yet

- Safety Check (Please Put Tick ( ) Mark in The Appropriate BoxDocument8 pagesSafety Check (Please Put Tick ( ) Mark in The Appropriate BoxAntony JebarajNo ratings yet

- Job Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Document5 pagesJob Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Madhan KannanNo ratings yet

- JSA For Blower Cyclone and Duct Installation - Revision 004Document8 pagesJSA For Blower Cyclone and Duct Installation - Revision 004WilsonNo ratings yet

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- 142 Jsa Modify To 2 Inch MPW-2 To Reactor 2 Piping LineDocument6 pages142 Jsa Modify To 2 Inch MPW-2 To Reactor 2 Piping LineMohd KhaidirNo ratings yet

- Heavy Lift Activity Checklist: Lifting & Erection of Fin Fan CoolerDocument3 pagesHeavy Lift Activity Checklist: Lifting & Erection of Fin Fan Coolerbrecht1980100% (1)

- Permit To Work Hseprof Com 1691465620Document36 pagesPermit To Work Hseprof Com 1691465620ajidwiyuniarsoNo ratings yet

- Chain Pulley Block JsaDocument2 pagesChain Pulley Block JsaAKBAR ALINo ratings yet

- JHA For Pipe Work-01.09Document3 pagesJHA For Pipe Work-01.09Anonymous Xb3zHio100% (1)

- JSA Electrical WiringDocument10 pagesJSA Electrical WiringWeru Morris100% (1)

- (SWMS) Shaft Work Duct ErectionDocument4 pages(SWMS) Shaft Work Duct Erectionsyed khaja misbhuddinNo ratings yet

- Jsa Installing BracketDocument3 pagesJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- JSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Document2 pagesJSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Koneti Janardhanarao100% (1)

- Jsa No-01 Container UnloadingDocument4 pagesJsa No-01 Container Unloadingsumith s100% (1)

- 19.DQ Working at Height Rescue PlanDocument3 pages19.DQ Working at Height Rescue Plankhurram0% (1)

- SOP For Pole Erection With All Hard WireDocument7 pagesSOP For Pole Erection With All Hard WireVIKAS SINGH BAGHELNo ratings yet

- 02 Heavy Vehicle Movement, Loading Unloading & Shifting SOPDocument8 pages02 Heavy Vehicle Movement, Loading Unloading & Shifting SOPB&R HSE BALCO SEP SiteNo ratings yet

- 10 - Cherry Picker Inspection ChecklistDocument1 page10 - Cherry Picker Inspection Checklistsanjeev kumarNo ratings yet

- Job Safety Analysis (JSA) : Description Hazard ControlDocument3 pagesJob Safety Analysis (JSA) : Description Hazard ControlRidha BennasrNo ratings yet

- PU-300 (PU Grouting)Document2 pagesPU-300 (PU Grouting)S EfendiNo ratings yet

- Spray Booth Risk AssessmentDocument3 pagesSpray Booth Risk AssessmentJohn Geddes100% (1)

- Safety Data Sheet: ARDROX 907PB AerosolDocument11 pagesSafety Data Sheet: ARDROX 907PB Aerosolabdulbaset alselwi100% (1)

- Asian Paints - Prem Gloss EnamelDocument1 pageAsian Paints - Prem Gloss EnamelwilliumstNo ratings yet

- Hadeed JSA Shearing Machine InstallationDocument11 pagesHadeed JSA Shearing Machine InstallationDhanu NikkuNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- JSA Safety Valve CertivicationDocument12 pagesJSA Safety Valve CertivicationelvandiNo ratings yet

- SDS Gyproc FireLineDocument3 pagesSDS Gyproc FireLineMohd AzrinNo ratings yet

- RFQ - Fire Rated Door For Offshore & Onshore - Petronas MalaysiaDocument1 pageRFQ - Fire Rated Door For Offshore & Onshore - Petronas MalaysiaMohd AzrinNo ratings yet

- Hdyw DPR Cpoc QB 21 001Document2 pagesHdyw DPR Cpoc QB 21 001Mohd AzrinNo ratings yet

- Proposed Schedule ArkemaDocument1 pageProposed Schedule ArkemaMohd AzrinNo ratings yet

- Hoarding Construction at Arkema Kerteh 2 ProjectDocument1 pageHoarding Construction at Arkema Kerteh 2 ProjectMohd AzrinNo ratings yet

- Method Statement For Mg1 Piping Rectification Works: Dynaciate (Kuantan) SDN BHDDocument2 pagesMethod Statement For Mg1 Piping Rectification Works: Dynaciate (Kuantan) SDN BHDMohd AzrinNo ratings yet

- Title: Flow Progress of Pavement Road Installation Date: 14 Nov 2016Document2 pagesTitle: Flow Progress of Pavement Road Installation Date: 14 Nov 2016Mohd AzrinNo ratings yet

- Please Flush at Welding Portion Before Buff #300Document1 pagePlease Flush at Welding Portion Before Buff #300Mohd AzrinNo ratings yet

- API Process PumpsDocument40 pagesAPI Process Pumpsmahi_mNo ratings yet

- Using RFT Probes With Magnifi 4 v.01Document68 pagesUsing RFT Probes With Magnifi 4 v.01shahid khan100% (1)

- Poetic DictionDocument25 pagesPoetic DictionTalha100% (1)

- Bismuth in Organometal Halide PerovskitesDocument34 pagesBismuth in Organometal Halide PerovskitesFernando HeelerNo ratings yet

- 8.tugas Laporan Bahasa InggrisDocument13 pages8.tugas Laporan Bahasa InggrisSanjaya JrNo ratings yet

- Lec 9Document19 pagesLec 9Aqsa gulNo ratings yet

- Treasure IslandDocument266 pagesTreasure IslandNader HaddadNo ratings yet

- Human Resources For Health in India: Need To Go Beyond NumbersDocument4 pagesHuman Resources For Health in India: Need To Go Beyond NumbersMohammed ArshadNo ratings yet

- Carboxymethyl Cellulose Synthesis From Durian Seed Flour: The Effect of Sodium Chloroacetate VariationDocument13 pagesCarboxymethyl Cellulose Synthesis From Durian Seed Flour: The Effect of Sodium Chloroacetate VariationHabbyyu MuhammadNo ratings yet

- G.R. No. 200233 JULY 15, 2015 LEONILA G. SANTIAGO, Petitioner, People of The Philippines, RespondentDocument7 pagesG.R. No. 200233 JULY 15, 2015 LEONILA G. SANTIAGO, Petitioner, People of The Philippines, RespondentMaria AndresNo ratings yet

- Case 1 - SuperMart Case StudyDocument26 pagesCase 1 - SuperMart Case Studyfadzilah hananiNo ratings yet

- Chapter 7Document15 pagesChapter 7Lowella May Tan ChengNo ratings yet

- Emad 21522379 Type A KWH PDFDocument8 pagesEmad 21522379 Type A KWH PDFEMAD ABDULRAHMAN ABDULLAH HASAN MASHRAH -No ratings yet

- Group 2 - The Basic Verb PhraseDocument12 pagesGroup 2 - The Basic Verb PhraseMuhammad FirnasNo ratings yet

- Weight-Volume Relationships, Plasticity, and Structure of SoilDocument30 pagesWeight-Volume Relationships, Plasticity, and Structure of SoilHanafiahHamzahNo ratings yet

- Prinsip-Prinsip EkonomiDocument11 pagesPrinsip-Prinsip EkonomiRev AwNo ratings yet

- Reading 15 Analysis of Dividends and Share Repurchases - AnswersDocument31 pagesReading 15 Analysis of Dividends and Share Repurchases - AnswersNeerajNo ratings yet

- Nilesh Kumar (Progress Report)Document2 pagesNilesh Kumar (Progress Report)nkdhanani2No ratings yet

- ACP1withsolution 16303 16301873391Document23 pagesACP1withsolution 16303 16301873391Arman DehuriNo ratings yet

- Secret CodesDocument6 pagesSecret CodesUMANo ratings yet

- EPM Model5014i ManualDocument352 pagesEPM Model5014i ManualJorgeLuisUriarteNo ratings yet

- Ignou Assignment Wala Ehi 1 Solved Assignment 2018-19Document7 pagesIgnou Assignment Wala Ehi 1 Solved Assignment 2018-19NEW THINK CLASSES100% (1)

- ABB - Motor-StartersDocument10 pagesABB - Motor-StartersMac WaseemNo ratings yet

- TW 05 ZhangDocument9 pagesTW 05 ZhangAhmed ELhefnawyNo ratings yet

- Price and Output Determination Under Monopolistic OnDocument13 pagesPrice and Output Determination Under Monopolistic OnShoaib Ahmed KhosoNo ratings yet

- Module 1 Study Notebook ABRIOL JOEY O.Document5 pagesModule 1 Study Notebook ABRIOL JOEY O.RhoseNo ratings yet

- Freedom of The Human PersonDocument7 pagesFreedom of The Human PersonThreedotsNo ratings yet