Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

35 viewsMEC601 Metrology and Quality Engineering 3+1: Objectives

MEC601 Metrology and Quality Engineering 3+1: Objectives

Uploaded by

navneetkpatil8409This document outlines a course on Metrology and Quality Engineering that is 3 credits plus 1 lab credit. The course objectives are to study quality concepts, inspection methods, and precision measurement tools. The outcomes are that learners will be able to apply inspection gauges, understand critical dimensions, and analyze parts for accuracy. The course consists of 6 modules covering topics like measurement principles and standards, comparators, surface texture measurement, screw thread and gear measurement, quality control, statistical process control tools, and sampling techniques.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Amazon's Net Income/loss and Sales Figures For The Period 1995-2015Document2 pagesAmazon's Net Income/loss and Sales Figures For The Period 1995-2015Abiodun Ayo-bali0% (1)

- Learning English Through Research Methods TextbookDocument179 pagesLearning English Through Research Methods TextbookSerenaQiNo ratings yet

- Mechanical Measurement and Metrology PDFDocument2 pagesMechanical Measurement and Metrology PDFsuhas_SCEM0% (1)

- MEC601 Metrology and Quality Engineering 3+1: ObjectivesDocument1 pageMEC601 Metrology and Quality Engineering 3+1: ObjectivesHoney SinghNo ratings yet

- 9097 - Metrology & Quality ControlDocument7 pages9097 - Metrology & Quality ControlAhmed Abu-SinnaNo ratings yet

- Metrlogy CurriculumDocument3 pagesMetrlogy CurriculumDj GAMINGNo ratings yet

- University of Pune: T.E. (Mechanical) - 2012 Course Metrology and Quality Control (302044)Document3 pagesUniversity of Pune: T.E. (Mechanical) - 2012 Course Metrology and Quality Control (302044)Arvind BhosaleNo ratings yet

- MQC Teachers Manual PDFDocument5 pagesMQC Teachers Manual PDFnavneetkpatil8409No ratings yet

- MQCDocument8 pagesMQCnavneetkpatil8409No ratings yet

- Metrology Course Oulines.10batchDocument4 pagesMetrology Course Oulines.10batchTariq AslamNo ratings yet

- Gujarat Technological University - MeasurementDocument4 pagesGujarat Technological University - MeasurementA SNo ratings yet

- Limits, Fits and Tolerances PDFDocument22 pagesLimits, Fits and Tolerances PDFmirztrNo ratings yet

- MM SyllabusDocument2 pagesMM SyllabusS.Bharani KumarNo ratings yet

- MQC SyllDocument2 pagesMQC SyllAandy KhasdarNo ratings yet

- MEPR205C - El 1 Metrology & Computer Aided InspectionDocument3 pagesMEPR205C - El 1 Metrology & Computer Aided Inspectionዘረአዳም ዘመንቆረርNo ratings yet

- M&M 4TH Tecahnig PlanDocument4 pagesM&M 4TH Tecahnig PlansanjaymehtasupaulNo ratings yet

- Metrology & Quality ControlDocument127 pagesMetrology & Quality ControlArnav PandeyNo ratings yet

- 15hc04 Metrology and Computer Aided InspectionDocument1 page15hc04 Metrology and Computer Aided Inspectionarun2386No ratings yet

- Measurement of Form ErrorsDocument14 pagesMeasurement of Form Errorssanyam KanungaNo ratings yet

- Metrology and Instrumentation M 602 3Document1 pageMetrology and Instrumentation M 602 3AnilkumarGopinathanNairNo ratings yet

- MMC SyllabusDocument3 pagesMMC SyllabusTejas DesaiNo ratings yet

- M & IDocument12 pagesM & INenu Na RakshasiNo ratings yet

- State Board of Technical Education &training, Tamilnadu Diploma in Engineering / Technology Syllabus N - SchemeDocument15 pagesState Board of Technical Education &training, Tamilnadu Diploma in Engineering / Technology Syllabus N - SchemeIsrael Dharmaraj100% (1)

- Mechanical Engineering VI Sem SyllabusDocument25 pagesMechanical Engineering VI Sem Syllabussaurabh1116No ratings yet

- Metrology and Computer Aided InspectionDocument2 pagesMetrology and Computer Aided InspectionROOSSVELT PRABHU K A VNo ratings yet

- Syllabus M.tech MechanicalDocument23 pagesSyllabus M.tech Mechanicalडॉ. कनिष्क शर्माNo ratings yet

- Mechanical Measurement and MetrologyDocument2 pagesMechanical Measurement and MetrologyNarayanarao PalagaraNo ratings yet

- Me Syllabus PDFDocument26 pagesMe Syllabus PDFAaryansh PandeyNo ratings yet

- Applied Mathematics, Applied Physics, Engineering Graphics, Manufacturing Technology-IIDocument5 pagesApplied Mathematics, Applied Physics, Engineering Graphics, Manufacturing Technology-IIPRASENJIT MUKHERJEENo ratings yet

- 2.6 30256 MetrologyDocument2 pages2.6 30256 Metrologyanju konwarNo ratings yet

- TE Mechanical and TE Automobile (2015 Course)Document7 pagesTE Mechanical and TE Automobile (2015 Course)A SNo ratings yet

- Nptel: Metrology - Video CourseDocument3 pagesNptel: Metrology - Video CourseLakshya MaletiNo ratings yet

- MetrologyDocument87 pagesMetrologyParabellum GamingNo ratings yet

- Industrial Engineering PDFDocument3 pagesIndustrial Engineering PDFviswabali1596No ratings yet

- Bit Sindri, Dhanbad: NAMEOFDEPTT. /CENTRE: Department of Production EngineeringDocument1 pageBit Sindri, Dhanbad: NAMEOFDEPTT. /CENTRE: Department of Production Engineeringtalk2sumantaNo ratings yet

- 070 - ME8501 Metrology and Measurements - Anna University 2017 Regulation Syllabus PDFDocument2 pages070 - ME8501 Metrology and Measurements - Anna University 2017 Regulation Syllabus PDFSidhu Vev Sidhu0% (1)

- Measurement of Force, Torque and Shaft PowerDocument12 pagesMeasurement of Force, Torque and Shaft PowermirztrNo ratings yet

- Toaz - Info Engineering Metrology PRDocument129 pagesToaz - Info Engineering Metrology PRB05Vedant BarpandeNo ratings yet

- 18ME7F2-Metrology and Quality ControlDocument2 pages18ME7F2-Metrology and Quality ControlXaf FarNo ratings yet

- Me8501 SyllabusDocument1 pageMe8501 Syllabusk.l yuvarajNo ratings yet

- Subject: Metrology: Academic Year:2017-2018 Branch: Mechanical Engineering Subject: Metrology Year / Sem: Iii / IDocument2 pagesSubject: Metrology: Academic Year:2017-2018 Branch: Mechanical Engineering Subject: Metrology Year / Sem: Iii / IMech DeptNo ratings yet

- SyllabusDocument1 pageSyllabusShankar NarayananNo ratings yet

- ME334 Manufacturing Technology Laboratory - IIDocument5 pagesME334 Manufacturing Technology Laboratory - IInandan144No ratings yet

- Syllabus Sem 8 - MMMDocument4 pagesSyllabus Sem 8 - MMMAkash PatilNo ratings yet

- Mechanical Measurement & Metrology ME211: Nishith ParikhDocument18 pagesMechanical Measurement & Metrology ME211: Nishith ParikhDrMohamed MansourNo ratings yet

- MetrologyDocument3 pagesMetrologySachi DhanandamNo ratings yet

- ME312 Metrology and instrumentationKTUNOTES - IN PDFDocument4 pagesME312 Metrology and instrumentationKTUNOTES - IN PDFpraphultmenonNo ratings yet

- CH 1 - Metrology and MeasurementDocument51 pagesCH 1 - Metrology and MeasurementRahul PathakNo ratings yet

- SurveyorDocument18 pagesSurveyorAnup ShrivastvaNo ratings yet

- Detailed Content SEM 6Document16 pagesDetailed Content SEM 6HIMANSHU KUMARNo ratings yet

- Metrology Lesson PlanDocument4 pagesMetrology Lesson PlanvenkyNo ratings yet

- Mechanical Engg RM PET SyllabusDocument5 pagesMechanical Engg RM PET SyllabusAnil MagareNo ratings yet

- SyllubusDocument1 pageSyllubuskssudhagarNo ratings yet

- Apem2 3 - 127 134Document8 pagesApem2 3 - 127 134Egemet SatisNo ratings yet

- Metrology and Computer Aided InspectionDocument1 pageMetrology and Computer Aided Inspectionprincessaadhya29No ratings yet

- Syllabus: Department of Mechanical EngineeringDocument2 pagesSyllabus: Department of Mechanical EngineeringChhagan kharolNo ratings yet

- II. Metrology (26 Questions) : A. Common Gauges and Measurement Instruments C. Gauge Selection, Handling, and UseDocument1 pageII. Metrology (26 Questions) : A. Common Gauges and Measurement Instruments C. Gauge Selection, Handling, and UseRiaz AhmadNo ratings yet

- Engineering Metrology and MeasurementsDocument128 pagesEngineering Metrology and MeasurementsArvind Bhosale100% (7)

- Engineering Metrology and Measurements Unit 1 2Document82 pagesEngineering Metrology and Measurements Unit 1 2scorpionarnold100% (1)

- IP5SEMSYLLABUSDocument6 pagesIP5SEMSYLLABUSAditya RaoNo ratings yet

- Nmu at ExaminerDocument6 pagesNmu at Examinernavneetkpatil8409No ratings yet

- 2018-19 F.E. To B.E. Mechanical Engineering StructureDocument11 pages2018-19 F.E. To B.E. Mechanical Engineering Structurenavneetkpatil8409No ratings yet

- NAAC Criteria IV ChecklistDocument1 pageNAAC Criteria IV Checklistnavneetkpatil8409100% (1)

- Registration Sheet MechDocument1 pageRegistration Sheet Mechnavneetkpatil8409No ratings yet

- Report On Sports and Cultural ActivitiesDocument2 pagesReport On Sports and Cultural Activitiesnavneetkpatil8409No ratings yet

- Applied Thermodynamics LabDocument3 pagesApplied Thermodynamics Labnavneetkpatil8409No ratings yet

- EXP-6-Measurement of Screw ParametersDocument2 pagesEXP-6-Measurement of Screw Parametersnavneetkpatil8409No ratings yet

- Nmu at PDFDocument4 pagesNmu at PDFnavneetkpatil8409No ratings yet

- Statement of Grades: (100007) SSBT College of Engineering & Technology, Bambhori, JalgaonDocument1,898 pagesStatement of Grades: (100007) SSBT College of Engineering & Technology, Bambhori, Jalgaonnavneetkpatil8409No ratings yet

- Safe Elevators + (91) - 9130865244 Shop No.17, Eidgah Market, Ajanta Road, MIDC, Jalgaon - 425003, Near Ajanta ChowffulliDocument1 pageSafe Elevators + (91) - 9130865244 Shop No.17, Eidgah Market, Ajanta Road, MIDC, Jalgaon - 425003, Near Ajanta Chowffullinavneetkpatil8409No ratings yet

- Summer 2014 Model Answer PaperDocument42 pagesSummer 2014 Model Answer Papernavneetkpatil8409No ratings yet

- 4 Hours / 100 Marks: Seat NoDocument5 pages4 Hours / 100 Marks: Seat Nonavneetkpatil8409No ratings yet

- Seat No.: Instructions: (1) All Questions Are CompulsoryDocument4 pagesSeat No.: Instructions: (1) All Questions Are Compulsorynavneetkpatil8409No ratings yet

- Ode and NameDocument670 pagesOde and Namenavneetkpatil8409No ratings yet

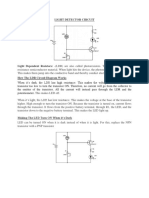

- Light Detector CircuitDocument1 pageLight Detector Circuitnavneetkpatil8409No ratings yet

- List of Exercises: Computer Integrated Manufacturing & Technology Driven PracticesDocument1 pageList of Exercises: Computer Integrated Manufacturing & Technology Driven Practicesnavneetkpatil8409No ratings yet

- Sample of A Hypothesis in A Research PaperDocument8 pagesSample of A Hypothesis in A Research PaperEssayHelpEugene100% (2)

- Difference Between Qualitative and QuantDocument7 pagesDifference Between Qualitative and QuantSharifah suuNo ratings yet

- 1st Quarter Summative Test in ReligionDocument2 pages1st Quarter Summative Test in ReligionElmer Oblino AbainzaNo ratings yet

- Germany17 JannDocument84 pagesGermany17 JannJuan Alonso Leon-AbarcaNo ratings yet

- CH 4 - Estimation & Hypothesis One SampleDocument139 pagesCH 4 - Estimation & Hypothesis One SampleDrake AdamNo ratings yet

- Science and Technology Throughout HistoryDocument11 pagesScience and Technology Throughout HistoryChristian Ivan CarmonaNo ratings yet

- 8.chi Sqaure Family IncomeDocument10 pages8.chi Sqaure Family IncomeShikarin KitaNo ratings yet

- POSTMODERNISM AND ITS RELEVANCE TO AFRICAN DEVELOPMENT - Timbee AkuulDocument5 pagesPOSTMODERNISM AND ITS RELEVANCE TO AFRICAN DEVELOPMENT - Timbee AkuulFrancis Abulude100% (1)

- Readiness For Pr1 QuestionnaireDocument2 pagesReadiness For Pr1 QuestionnaireMiyu VianaNo ratings yet

- QraDocument10 pagesQrauserscribd2011No ratings yet

- Newbold Sbe8 ch09 GeDocument62 pagesNewbold Sbe8 ch09 GeCamilo sextoNo ratings yet

- Probation Period ReportDocument17 pagesProbation Period ReportMiranti Puspitasari0% (1)

- Orth ArraysDocument8 pagesOrth ArraysSnehalphirkeNo ratings yet

- Fitri Anjaini Sinaga - 1906113279 - Laporan EVSONDocument7 pagesFitri Anjaini Sinaga - 1906113279 - Laporan EVSONFitri Anjaini SinagaNo ratings yet

- Uji Hartley Uji KolmogorovDocument5 pagesUji Hartley Uji KolmogorovHam HamNo ratings yet

- II IDocument74 pagesII IJM pajenagoNo ratings yet

- Guidelines For Dissertation and Applied Research - Latest 12102020Document21 pagesGuidelines For Dissertation and Applied Research - Latest 12102020apik4684No ratings yet

- VC-dimension For Characterizing ClassifiersDocument40 pagesVC-dimension For Characterizing ClassifiersRatheesh P MNo ratings yet

- Environmental Science Week No.1 2Document18 pagesEnvironmental Science Week No.1 2Mayla G. BalayonNo ratings yet

- How To Write An IB Lab ReportDocument5 pagesHow To Write An IB Lab ReportHashaDashaNo ratings yet

- Problem Statement HandoutDocument2 pagesProblem Statement HandoutAalok KarnaNo ratings yet

- Econometric Modeling: Model Specification and Diagnostic TestingDocument52 pagesEconometric Modeling: Model Specification and Diagnostic TestingYeasar Ahmed UshanNo ratings yet

- Submodule1 - Overview or Research ProcecssDocument10 pagesSubmodule1 - Overview or Research ProcecssYrrehc CawisNo ratings yet

- How Write A Lab ReportDocument2 pagesHow Write A Lab Reportapi-344568500No ratings yet

- Fear of Physics, and How To Help Students Overcome It (2023) - Jeffry V MallowDocument133 pagesFear of Physics, and How To Help Students Overcome It (2023) - Jeffry V MallowGardener AyuNo ratings yet

- Lab2 CEE 11Document3 pagesLab2 CEE 11Cristen AlvarezNo ratings yet

- A Study To Assess The Effectiveness of Aerobic Exercise On Depression Among Senior Citizens in Selected SMCHDocument6 pagesA Study To Assess The Effectiveness of Aerobic Exercise On Depression Among Senior Citizens in Selected SMCHEditor IJTSRDNo ratings yet

- Good RRLDocument2 pagesGood RRLDonna Mariano FilomenaNo ratings yet

MEC601 Metrology and Quality Engineering 3+1: Objectives

MEC601 Metrology and Quality Engineering 3+1: Objectives

Uploaded by

navneetkpatil84090 ratings0% found this document useful (0 votes)

35 views1 pageThis document outlines a course on Metrology and Quality Engineering that is 3 credits plus 1 lab credit. The course objectives are to study quality concepts, inspection methods, and precision measurement tools. The outcomes are that learners will be able to apply inspection gauges, understand critical dimensions, and analyze parts for accuracy. The course consists of 6 modules covering topics like measurement principles and standards, comparators, surface texture measurement, screw thread and gear measurement, quality control, statistical process control tools, and sampling techniques.

Original Description:

kj

Original Title

m23

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines a course on Metrology and Quality Engineering that is 3 credits plus 1 lab credit. The course objectives are to study quality concepts, inspection methods, and precision measurement tools. The outcomes are that learners will be able to apply inspection gauges, understand critical dimensions, and analyze parts for accuracy. The course consists of 6 modules covering topics like measurement principles and standards, comparators, surface texture measurement, screw thread and gear measurement, quality control, statistical process control tools, and sampling techniques.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

35 views1 pageMEC601 Metrology and Quality Engineering 3+1: Objectives

MEC601 Metrology and Quality Engineering 3+1: Objectives

Uploaded by

navneetkpatil8409This document outlines a course on Metrology and Quality Engineering that is 3 credits plus 1 lab credit. The course objectives are to study quality concepts, inspection methods, and precision measurement tools. The outcomes are that learners will be able to apply inspection gauges, understand critical dimensions, and analyze parts for accuracy. The course consists of 6 modules covering topics like measurement principles and standards, comparators, surface texture measurement, screw thread and gear measurement, quality control, statistical process control tools, and sampling techniques.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Course Code Course/Subject Name Credits

MEC601 Metrology and Quality Engineering 3+1

Objectives

1. To study the fundamentals of modem quality concepts and statistical techniques.

2. To study fundamentals of inspection methods and systems.

3. To acquaint with operation of precision measurement tools and equipment’s.

Outcomes: Learner will be able to…

1. Apply inspection gauge and checking systems.

2. Demonstrate the understanding of purpose of critical dimensions in manufacturing.

3. Analyse simple parts for dimensional accuracy and functionality.

Module Details Hrs.

01 1.1 Introduction to Metrology, Fundamental principles and definitions, 04

measurement standards / primary and tertiary standards, distinction

between precision and accuracy.

1.2 Limits, fits and tolerances, Tolerance grades, Types of fits, IS919,

GO and NO GO gauges- Taylor’s principle, design of GO and NO

GO gauges, filler gauges, plug gauges and snap gauges.

02 2.1 Comparators: Constructional features and operation of mechanical, 09

optical, electrical/electronics and pneumatic comparators,

advantages, limitations and field of applications.

2.2 Principles of interference, concept of flatness, flatness testing, optical

flats, optical interferometer and laser interferometer.

2.3 Surface texture measurement: importance of surface conditions,

roughness and waviness, surface roughness standards specifying

surface roughness parameters- Ra, Ry, Rz, RMS value etc., surface

roughness measuring instruments – Tomlinson and Taylor Hobson

versions, surface roughness symbols.

03 3.1 Screw Thread measurement: Two wire and three wire methods, 09

floating carriage micrometer.

3.2 Gear measurement: Gear tooth comparator, Master gears,

measurement using rollers and Parkinson’s Tester.

3.3 Special measuring Equipments: Principles of measurement using

Tool Maker’s microscope, profile projector & 3D coordinate

measuring machine.

04 Quality Control 05

Introduction, definition and concept of quality & quality control, set up

policy and objectives of quality control, quality of design and quality of

conformance, compromise between quality & cost, quality cost and

planning for quality.

05 SQC and SQC tools 06

Importance statistical methods in QC, measurement of statistical control

variables and attributes, pie charts, bar charts/ histograms, scatter

diagrams, pareto chart, GANT charts, control charts, X chart, X bar

charts, R charts, P charts, np charts their preparation, analysis and

applications. Elementary treatment on modern SQC tools.

06 Sampling Techniques 03

Sampling inspection and basic concepts, OC curves, consumer &

producer risk, single & double sampling plans and use of sampling tables.

23/113

University of Mumbai, Mechanical Engineering (Third and Final Year) Revised Course (Rev-2012)

You might also like

- Amazon's Net Income/loss and Sales Figures For The Period 1995-2015Document2 pagesAmazon's Net Income/loss and Sales Figures For The Period 1995-2015Abiodun Ayo-bali0% (1)

- Learning English Through Research Methods TextbookDocument179 pagesLearning English Through Research Methods TextbookSerenaQiNo ratings yet

- Mechanical Measurement and Metrology PDFDocument2 pagesMechanical Measurement and Metrology PDFsuhas_SCEM0% (1)

- MEC601 Metrology and Quality Engineering 3+1: ObjectivesDocument1 pageMEC601 Metrology and Quality Engineering 3+1: ObjectivesHoney SinghNo ratings yet

- 9097 - Metrology & Quality ControlDocument7 pages9097 - Metrology & Quality ControlAhmed Abu-SinnaNo ratings yet

- Metrlogy CurriculumDocument3 pagesMetrlogy CurriculumDj GAMINGNo ratings yet

- University of Pune: T.E. (Mechanical) - 2012 Course Metrology and Quality Control (302044)Document3 pagesUniversity of Pune: T.E. (Mechanical) - 2012 Course Metrology and Quality Control (302044)Arvind BhosaleNo ratings yet

- MQC Teachers Manual PDFDocument5 pagesMQC Teachers Manual PDFnavneetkpatil8409No ratings yet

- MQCDocument8 pagesMQCnavneetkpatil8409No ratings yet

- Metrology Course Oulines.10batchDocument4 pagesMetrology Course Oulines.10batchTariq AslamNo ratings yet

- Gujarat Technological University - MeasurementDocument4 pagesGujarat Technological University - MeasurementA SNo ratings yet

- Limits, Fits and Tolerances PDFDocument22 pagesLimits, Fits and Tolerances PDFmirztrNo ratings yet

- MM SyllabusDocument2 pagesMM SyllabusS.Bharani KumarNo ratings yet

- MQC SyllDocument2 pagesMQC SyllAandy KhasdarNo ratings yet

- MEPR205C - El 1 Metrology & Computer Aided InspectionDocument3 pagesMEPR205C - El 1 Metrology & Computer Aided Inspectionዘረአዳም ዘመንቆረርNo ratings yet

- M&M 4TH Tecahnig PlanDocument4 pagesM&M 4TH Tecahnig PlansanjaymehtasupaulNo ratings yet

- Metrology & Quality ControlDocument127 pagesMetrology & Quality ControlArnav PandeyNo ratings yet

- 15hc04 Metrology and Computer Aided InspectionDocument1 page15hc04 Metrology and Computer Aided Inspectionarun2386No ratings yet

- Measurement of Form ErrorsDocument14 pagesMeasurement of Form Errorssanyam KanungaNo ratings yet

- Metrology and Instrumentation M 602 3Document1 pageMetrology and Instrumentation M 602 3AnilkumarGopinathanNairNo ratings yet

- MMC SyllabusDocument3 pagesMMC SyllabusTejas DesaiNo ratings yet

- M & IDocument12 pagesM & INenu Na RakshasiNo ratings yet

- State Board of Technical Education &training, Tamilnadu Diploma in Engineering / Technology Syllabus N - SchemeDocument15 pagesState Board of Technical Education &training, Tamilnadu Diploma in Engineering / Technology Syllabus N - SchemeIsrael Dharmaraj100% (1)

- Mechanical Engineering VI Sem SyllabusDocument25 pagesMechanical Engineering VI Sem Syllabussaurabh1116No ratings yet

- Metrology and Computer Aided InspectionDocument2 pagesMetrology and Computer Aided InspectionROOSSVELT PRABHU K A VNo ratings yet

- Syllabus M.tech MechanicalDocument23 pagesSyllabus M.tech Mechanicalडॉ. कनिष्क शर्माNo ratings yet

- Mechanical Measurement and MetrologyDocument2 pagesMechanical Measurement and MetrologyNarayanarao PalagaraNo ratings yet

- Me Syllabus PDFDocument26 pagesMe Syllabus PDFAaryansh PandeyNo ratings yet

- Applied Mathematics, Applied Physics, Engineering Graphics, Manufacturing Technology-IIDocument5 pagesApplied Mathematics, Applied Physics, Engineering Graphics, Manufacturing Technology-IIPRASENJIT MUKHERJEENo ratings yet

- 2.6 30256 MetrologyDocument2 pages2.6 30256 Metrologyanju konwarNo ratings yet

- TE Mechanical and TE Automobile (2015 Course)Document7 pagesTE Mechanical and TE Automobile (2015 Course)A SNo ratings yet

- Nptel: Metrology - Video CourseDocument3 pagesNptel: Metrology - Video CourseLakshya MaletiNo ratings yet

- MetrologyDocument87 pagesMetrologyParabellum GamingNo ratings yet

- Industrial Engineering PDFDocument3 pagesIndustrial Engineering PDFviswabali1596No ratings yet

- Bit Sindri, Dhanbad: NAMEOFDEPTT. /CENTRE: Department of Production EngineeringDocument1 pageBit Sindri, Dhanbad: NAMEOFDEPTT. /CENTRE: Department of Production Engineeringtalk2sumantaNo ratings yet

- 070 - ME8501 Metrology and Measurements - Anna University 2017 Regulation Syllabus PDFDocument2 pages070 - ME8501 Metrology and Measurements - Anna University 2017 Regulation Syllabus PDFSidhu Vev Sidhu0% (1)

- Measurement of Force, Torque and Shaft PowerDocument12 pagesMeasurement of Force, Torque and Shaft PowermirztrNo ratings yet

- Toaz - Info Engineering Metrology PRDocument129 pagesToaz - Info Engineering Metrology PRB05Vedant BarpandeNo ratings yet

- 18ME7F2-Metrology and Quality ControlDocument2 pages18ME7F2-Metrology and Quality ControlXaf FarNo ratings yet

- Me8501 SyllabusDocument1 pageMe8501 Syllabusk.l yuvarajNo ratings yet

- Subject: Metrology: Academic Year:2017-2018 Branch: Mechanical Engineering Subject: Metrology Year / Sem: Iii / IDocument2 pagesSubject: Metrology: Academic Year:2017-2018 Branch: Mechanical Engineering Subject: Metrology Year / Sem: Iii / IMech DeptNo ratings yet

- SyllabusDocument1 pageSyllabusShankar NarayananNo ratings yet

- ME334 Manufacturing Technology Laboratory - IIDocument5 pagesME334 Manufacturing Technology Laboratory - IInandan144No ratings yet

- Syllabus Sem 8 - MMMDocument4 pagesSyllabus Sem 8 - MMMAkash PatilNo ratings yet

- Mechanical Measurement & Metrology ME211: Nishith ParikhDocument18 pagesMechanical Measurement & Metrology ME211: Nishith ParikhDrMohamed MansourNo ratings yet

- MetrologyDocument3 pagesMetrologySachi DhanandamNo ratings yet

- ME312 Metrology and instrumentationKTUNOTES - IN PDFDocument4 pagesME312 Metrology and instrumentationKTUNOTES - IN PDFpraphultmenonNo ratings yet

- CH 1 - Metrology and MeasurementDocument51 pagesCH 1 - Metrology and MeasurementRahul PathakNo ratings yet

- SurveyorDocument18 pagesSurveyorAnup ShrivastvaNo ratings yet

- Detailed Content SEM 6Document16 pagesDetailed Content SEM 6HIMANSHU KUMARNo ratings yet

- Metrology Lesson PlanDocument4 pagesMetrology Lesson PlanvenkyNo ratings yet

- Mechanical Engg RM PET SyllabusDocument5 pagesMechanical Engg RM PET SyllabusAnil MagareNo ratings yet

- SyllubusDocument1 pageSyllubuskssudhagarNo ratings yet

- Apem2 3 - 127 134Document8 pagesApem2 3 - 127 134Egemet SatisNo ratings yet

- Metrology and Computer Aided InspectionDocument1 pageMetrology and Computer Aided Inspectionprincessaadhya29No ratings yet

- Syllabus: Department of Mechanical EngineeringDocument2 pagesSyllabus: Department of Mechanical EngineeringChhagan kharolNo ratings yet

- II. Metrology (26 Questions) : A. Common Gauges and Measurement Instruments C. Gauge Selection, Handling, and UseDocument1 pageII. Metrology (26 Questions) : A. Common Gauges and Measurement Instruments C. Gauge Selection, Handling, and UseRiaz AhmadNo ratings yet

- Engineering Metrology and MeasurementsDocument128 pagesEngineering Metrology and MeasurementsArvind Bhosale100% (7)

- Engineering Metrology and Measurements Unit 1 2Document82 pagesEngineering Metrology and Measurements Unit 1 2scorpionarnold100% (1)

- IP5SEMSYLLABUSDocument6 pagesIP5SEMSYLLABUSAditya RaoNo ratings yet

- Nmu at ExaminerDocument6 pagesNmu at Examinernavneetkpatil8409No ratings yet

- 2018-19 F.E. To B.E. Mechanical Engineering StructureDocument11 pages2018-19 F.E. To B.E. Mechanical Engineering Structurenavneetkpatil8409No ratings yet

- NAAC Criteria IV ChecklistDocument1 pageNAAC Criteria IV Checklistnavneetkpatil8409100% (1)

- Registration Sheet MechDocument1 pageRegistration Sheet Mechnavneetkpatil8409No ratings yet

- Report On Sports and Cultural ActivitiesDocument2 pagesReport On Sports and Cultural Activitiesnavneetkpatil8409No ratings yet

- Applied Thermodynamics LabDocument3 pagesApplied Thermodynamics Labnavneetkpatil8409No ratings yet

- EXP-6-Measurement of Screw ParametersDocument2 pagesEXP-6-Measurement of Screw Parametersnavneetkpatil8409No ratings yet

- Nmu at PDFDocument4 pagesNmu at PDFnavneetkpatil8409No ratings yet

- Statement of Grades: (100007) SSBT College of Engineering & Technology, Bambhori, JalgaonDocument1,898 pagesStatement of Grades: (100007) SSBT College of Engineering & Technology, Bambhori, Jalgaonnavneetkpatil8409No ratings yet

- Safe Elevators + (91) - 9130865244 Shop No.17, Eidgah Market, Ajanta Road, MIDC, Jalgaon - 425003, Near Ajanta ChowffulliDocument1 pageSafe Elevators + (91) - 9130865244 Shop No.17, Eidgah Market, Ajanta Road, MIDC, Jalgaon - 425003, Near Ajanta Chowffullinavneetkpatil8409No ratings yet

- Summer 2014 Model Answer PaperDocument42 pagesSummer 2014 Model Answer Papernavneetkpatil8409No ratings yet

- 4 Hours / 100 Marks: Seat NoDocument5 pages4 Hours / 100 Marks: Seat Nonavneetkpatil8409No ratings yet

- Seat No.: Instructions: (1) All Questions Are CompulsoryDocument4 pagesSeat No.: Instructions: (1) All Questions Are Compulsorynavneetkpatil8409No ratings yet

- Ode and NameDocument670 pagesOde and Namenavneetkpatil8409No ratings yet

- Light Detector CircuitDocument1 pageLight Detector Circuitnavneetkpatil8409No ratings yet

- List of Exercises: Computer Integrated Manufacturing & Technology Driven PracticesDocument1 pageList of Exercises: Computer Integrated Manufacturing & Technology Driven Practicesnavneetkpatil8409No ratings yet

- Sample of A Hypothesis in A Research PaperDocument8 pagesSample of A Hypothesis in A Research PaperEssayHelpEugene100% (2)

- Difference Between Qualitative and QuantDocument7 pagesDifference Between Qualitative and QuantSharifah suuNo ratings yet

- 1st Quarter Summative Test in ReligionDocument2 pages1st Quarter Summative Test in ReligionElmer Oblino AbainzaNo ratings yet

- Germany17 JannDocument84 pagesGermany17 JannJuan Alonso Leon-AbarcaNo ratings yet

- CH 4 - Estimation & Hypothesis One SampleDocument139 pagesCH 4 - Estimation & Hypothesis One SampleDrake AdamNo ratings yet

- Science and Technology Throughout HistoryDocument11 pagesScience and Technology Throughout HistoryChristian Ivan CarmonaNo ratings yet

- 8.chi Sqaure Family IncomeDocument10 pages8.chi Sqaure Family IncomeShikarin KitaNo ratings yet

- POSTMODERNISM AND ITS RELEVANCE TO AFRICAN DEVELOPMENT - Timbee AkuulDocument5 pagesPOSTMODERNISM AND ITS RELEVANCE TO AFRICAN DEVELOPMENT - Timbee AkuulFrancis Abulude100% (1)

- Readiness For Pr1 QuestionnaireDocument2 pagesReadiness For Pr1 QuestionnaireMiyu VianaNo ratings yet

- QraDocument10 pagesQrauserscribd2011No ratings yet

- Newbold Sbe8 ch09 GeDocument62 pagesNewbold Sbe8 ch09 GeCamilo sextoNo ratings yet

- Probation Period ReportDocument17 pagesProbation Period ReportMiranti Puspitasari0% (1)

- Orth ArraysDocument8 pagesOrth ArraysSnehalphirkeNo ratings yet

- Fitri Anjaini Sinaga - 1906113279 - Laporan EVSONDocument7 pagesFitri Anjaini Sinaga - 1906113279 - Laporan EVSONFitri Anjaini SinagaNo ratings yet

- Uji Hartley Uji KolmogorovDocument5 pagesUji Hartley Uji KolmogorovHam HamNo ratings yet

- II IDocument74 pagesII IJM pajenagoNo ratings yet

- Guidelines For Dissertation and Applied Research - Latest 12102020Document21 pagesGuidelines For Dissertation and Applied Research - Latest 12102020apik4684No ratings yet

- VC-dimension For Characterizing ClassifiersDocument40 pagesVC-dimension For Characterizing ClassifiersRatheesh P MNo ratings yet

- Environmental Science Week No.1 2Document18 pagesEnvironmental Science Week No.1 2Mayla G. BalayonNo ratings yet

- How To Write An IB Lab ReportDocument5 pagesHow To Write An IB Lab ReportHashaDashaNo ratings yet

- Problem Statement HandoutDocument2 pagesProblem Statement HandoutAalok KarnaNo ratings yet

- Econometric Modeling: Model Specification and Diagnostic TestingDocument52 pagesEconometric Modeling: Model Specification and Diagnostic TestingYeasar Ahmed UshanNo ratings yet

- Submodule1 - Overview or Research ProcecssDocument10 pagesSubmodule1 - Overview or Research ProcecssYrrehc CawisNo ratings yet

- How Write A Lab ReportDocument2 pagesHow Write A Lab Reportapi-344568500No ratings yet

- Fear of Physics, and How To Help Students Overcome It (2023) - Jeffry V MallowDocument133 pagesFear of Physics, and How To Help Students Overcome It (2023) - Jeffry V MallowGardener AyuNo ratings yet

- Lab2 CEE 11Document3 pagesLab2 CEE 11Cristen AlvarezNo ratings yet

- A Study To Assess The Effectiveness of Aerobic Exercise On Depression Among Senior Citizens in Selected SMCHDocument6 pagesA Study To Assess The Effectiveness of Aerobic Exercise On Depression Among Senior Citizens in Selected SMCHEditor IJTSRDNo ratings yet

- Good RRLDocument2 pagesGood RRLDonna Mariano FilomenaNo ratings yet